Professional Documents

Culture Documents

JIB Repair

Uploaded by

Ertan KoseOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JIB Repair

Uploaded by

Ertan KoseCopyright:

Available Formats

SERVICE INFORMATION

625/1586 E rev.: a 2003-07-02

How to Handle Damaged Jibs

General Recommendation about the repair

So called dubblers, meaning that the damaged steel

This instruction is a guidance in how to handle plate will be hidden underneath a new plate, are not

damaged jibs. It does not cover all types of damages accepted as a permanent repair. It might be accepted

but gives only a general guidance. as a temporary repair, if approved by a surveyor from

the Society of Classification. MacGREGOR Cranes'

Note: If there is any doubt in how the damage shall recommendation is, that the damaged parts should

be repaired, contact shall be done with Service be changed. This can either be done by changing a

Department at MacGREGOR Cranes who can help part of a steel plate, or changing a part of a profile.

in this matter. New weld cannot be performed closer than 200 mm

from the existing weld.

This Service Information describes

1. Repair of damage. Choice of steel material for repair

2. Repair of cracks. See page 4.

3. Limits of corrosion. Steel from approved steel mill and certificate

4. Interchangeability of steel materials. according to DIN 50049-3.1C.

5. Welding Procedure Specification (WPS).

Repair company

The company shall have at its disposal appropriate

1. Repair of damage

welding coordination personnel according to EN 719

(European Norms) or similar. This means that welding

In order to judge if the crane jib has got such a small

personnel can be supplied with the necessary welding

damage that it might be allowed for duty, compare

procedure specifications or work instructions and that

the actual figure on the damaged jib with the allowed

the work can be properly performed and controlled.

tolerances in accordance with the Quality Instruction.

If the figures of the actual crane jib are within the

tolerances, the crane jib might be allowed for duty. Welding consumables

The condition is, that the distorsion etc. is smooth The consumables shall be according to requirement

and not sharp, because a sharp flopper is dangerous in the drawing.

also if it has a reasonable depth. If the figures are not

within the tolerances, the jib has to be repaired. Performance of the joint

The joints shall be fully penetrated, if possible by

Society of Classification welding on both sides. If this is not possible, the

All repair should be done with approval by a welding shall be performed from one side with steel

classification surveyor. If the surveyor so requires backing of permanent type.

an overload test must be done after the repair.

Welding class B quality levels according to EN 25817.

The Original Manufacturer of HÄGGLUNDS Cranes 1 (6)

SERVICE INFORMATION

625/1586 E rev.: a 2003-07-02

Non-destructive testing and quality inspection,

dimension check

After welding a NDT (Non-Destructive Testing) has Magnaflux. If no failure is observed during the

to be performed by certified personnel and according penetrant or the Magnaflux tests, only 20% of the

to EN 473 or similar. length of the jib has to be either ultrasonic or X-ray

tested. If failure is observed either during the crack

The company responsible for the rapair has to make

penetration, the ultrasonic or the X-ray tests, 100%

the welding procedure WPS (Welding Procedure

of the welds have to be X-ray or ultrasonic tested.

Specification) according to EN 288-3 and record the

dimension of the crane jib. The dimension has to be

within the tolerances specified in MacGREGOR WPS guidelines

Cranes' Quality Instruction. If the tolerance cannot The company responsible for the repair shall make

be fulfilled the misalignment has to be approved by the welding procedure (WPS).

MacGREGOR Cranes in Sweden. The WPS enclosed is for guidance only.

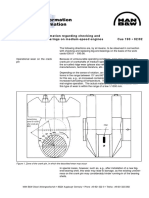

Quality inspection of the welds Example of how the repair should be done

All welds, that are new, repaired or are located close a) If a jib section has a dent on a corner a U-profile

to the damaged area, have to be visually inspected. must be replaced. See Fig. 1.

The quality class of the weld is specified in ISO 5817.

The repair has to be checked after tacking, where b) If a jib section has a damage on the complete profile

the joint preparation is inspected. After welding all a complete box must be replaced. See Fig. 2.

new and repaired welds or welds close to the

damaged zone have to be tested with penetrant or c) If a longer section is to be replaced the section shall

be made so it fits into the existing welds.

Min. 1.5 m

Damage

Min. 200 mm Min. 1.5 m

Min. 200 mm

Welds Welds

Damage

Welds

Welds

Area to be replaced Area to be replaced

Fig. 1. Damaged jib. Fig. 2. Damaged jib.

2 (6) The Original Manufacturer of HÄGGLUNDS Cranes

SERVICE INFORMATION

625/1586 E rev.: a 2003-07-02

Preparation of the new jib part

It is important that the new jib part as well as the

existing part is prepared so its stiffeners are supported

by a support. See Fig. 3.

Also the weld joints must be prepared according to

original drawing.

50 50

Stiffener

Support

Fig. 3. Preparation of jib.

2. Repair of cracks

1. The crack has to be ground in its bottom. The 4. Check the welds made. Methods to be used are

beginning and the end of the crack has to be 100% MPI, 100% ultrasonic test or 100% X-ray.

rounded off. Paint shall be removed near the crack.

Rounded off by grinding or drilling at both ends. 5. Approval by classification socitey if required.

2. The crack has to be filled with a weld bead if the

joint is wide and deep. Weaving is not allowed. 3. Limits of corrosion

Recommended electrodes are ESAB OK 48.00 or

similar. Dimension 2.5 - 3.25 mm. See Service Information 625/1568 E.

3. In order to improve the area where cracks have

arisen, there should be a smooth connection

between weld and parent metal. The best method

to reach better strength is to use the TIG-method

for the connection between weld and parent metal.

If this is impossible, grinding can be used.

The Original Manufacturer of HÄGGLUNDS Cranes 3 (6)

SERVICE INFORMATION

625/1586 E rev.: a 2003-07-02

4. Interchangeability of steel materials

Steel plate

In order to achieve a correct level of quality when for some reason

the specified Swedish, DIN or other standard steel qualities have

to be substituted with steel of other standards, the following shall

apply:

Standard Steel grade

Swedish standard SS1312 SS1414 SS1415 SS2134 SS2135

ReL in Mpa 220 260 260 355 355

EN 10025 S235JRG2 S275 J2

DIN St44-3N* StE355** StE355**

JIS

EN 10113-2 S355N S355NL

Classification Societies

ABS B D27 E27 DH36 EH36

BV B D27 E27 DH36 EH36

DNV B D27 E27 D36 E36

GL B D32 E32 D36 E36

LRS B D27 E27 DH36 EH36

PRS B D27 E27 D36 E36

USSR B D27 E27 D36 E36

ZC B D27 E27 D36 E36

NKK KB HD32 KE32 KD36 KE36

o

* St44-3N is tested for impact value at -20 C, according to the

requirements of DIN 17100. When this steel is substituted for E27

or o

E36, it must be demonstrated by testing for impact value at -

40 C that the values as listed below have been obtained. Usage of

this steel must be approved by MacGREGOR Cranes.

**

According to DIN 17102 the requirements on impact value and

test temperature have to be specified by the buyer.

The carbon equivalent defined as Ce = C + Mn/6 + (Cr+Mo+V)/5 + (Cu+Ni)/

15 (ladle analysis) shall not exceed 0,41%. If the subcontractor not is able to

purchase steel plate with Ce ≤ 0,41%, MGC will accept acceptera Ce ≤ 0,44 provided

that:

The welding take place in room temperature

The combined plate thickness tcomb not exceed 40 mm (se next page)

The weld deposite hydrogen contents is ≤ 10 ml/100. H10

4 (6) The Original Manufacturer of HÄGGLUNDS Cranes

SERVICE INFORMATION

625/1586 E rev.: a 2003-07-02

The Original Manufacturer of HÄGGLUNDS Cranes 5 (6)

SERVICE INFORMATION

625/1586 E rev.: a 2003-07-02

6 (6) The Original Manufacturer of HÄGGLUNDS Cranes

You might also like

- CWB Study Guide - Weld Quality and Examination MethodsDocument56 pagesCWB Study Guide - Weld Quality and Examination MethodsPubcrawlNo ratings yet

- Repair and Buttering ProcedureDocument14 pagesRepair and Buttering Proceduremohd as shahiddin jafri100% (3)

- GMW14058Dec2005-ARC WELDING ACCEPTANCE CRITIRIADocument19 pagesGMW14058Dec2005-ARC WELDING ACCEPTANCE CRITIRIAMuhammad Ali100% (2)

- GMW16215 PDFDocument7 pagesGMW16215 PDFJuanPeriquitanNo ratings yet

- Method Statement - Pipe WorksDocument14 pagesMethod Statement - Pipe WorksDarl Anthony Veloso100% (4)

- Weld Acceptance Criteria and Repair Procedures Drawn-Arc Welded Automotive Studs, Nuts and Brackets - SteelDocument8 pagesWeld Acceptance Criteria and Repair Procedures Drawn-Arc Welded Automotive Studs, Nuts and Brackets - SteelMuhammad AliNo ratings yet

- GMW16215Document7 pagesGMW16215JOECOOL67100% (1)

- What Is A Search and Rescue Transponder (SART)Document4 pagesWhat Is A Search and Rescue Transponder (SART)Ertan KoseNo ratings yet

- Low Power Out Mack mp10 mp8 mp7Document5 pagesLow Power Out Mack mp10 mp8 mp7hamilton mirandaNo ratings yet

- CLSM SpecDocument24 pagesCLSM SpecgullipalliNo ratings yet

- Switch Yard Aluminum Bus Bar Piping Construction (Welding Part)Document11 pagesSwitch Yard Aluminum Bus Bar Piping Construction (Welding Part)Ren SalazarNo ratings yet

- Destructive Testing of Stud Welds: The FactsDocument2 pagesDestructive Testing of Stud Welds: The FactsGerson Suarez CastellonNo ratings yet

- Weld Joint Repaire Procedure - 08.04.14Document6 pagesWeld Joint Repaire Procedure - 08.04.14Raj AryanNo ratings yet

- Section 09 Weld QualityDocument32 pagesSection 09 Weld Qualityforlan pinheiro100% (1)

- A - PG - 029 - Anlage - 12: General Rework Regulations For Welding SeamsDocument9 pagesA - PG - 029 - Anlage - 12: General Rework Regulations For Welding SeamspranayNo ratings yet

- UM - MVG - SO60976 - Modificaton BucketDocument4 pagesUM - MVG - SO60976 - Modificaton Bucket1989vasu.pNo ratings yet

- UNIT NO. 5.8 Welding of Structural Steel: © Lifting Equipment Engineers Association 2012 - Training/5-8uDocument13 pagesUNIT NO. 5.8 Welding of Structural Steel: © Lifting Equipment Engineers Association 2012 - Training/5-8uYAKUBU A. AROGENo ratings yet

- Vdocuments - MX Gmw16215pdfDocument7 pagesVdocuments - MX Gmw16215pdfluizNo ratings yet

- Astm G10 - 10Document3 pagesAstm G10 - 10Sofia YuliNo ratings yet

- Weandc 2019 3 198Document7 pagesWeandc 2019 3 198shahidrazzaqNo ratings yet

- Api 510 PTR 7Document3 pagesApi 510 PTR 7HemaNo ratings yet

- Base Plate and Anchor Rod DesignDocument2 pagesBase Plate and Anchor Rod DesignKannan MurugesanNo ratings yet

- Explosion Resistant EquipmentDocument3 pagesExplosion Resistant EquipmentAndrewrzeNo ratings yet

- Specific Bendability of Pipeline Coatings: Standard Test Method ForDocument3 pagesSpecific Bendability of Pipeline Coatings: Standard Test Method ForCamilo GuardadoNo ratings yet

- Instructions To Surveyors: Domestic Commercial VesselDocument7 pagesInstructions To Surveyors: Domestic Commercial VesselAnonymous wnCaPNIspNo ratings yet

- Ancon - Tapered Thread CouplersDocument12 pagesAncon - Tapered Thread CouplersAntonio BrasilNo ratings yet

- Repair Welding of A Rotating Electrical Machine's Broken ShaftDocument7 pagesRepair Welding of A Rotating Electrical Machine's Broken ShaftLargyla Torres MendesNo ratings yet

- 12 - Exhibit C Sp-Welding of Pipelines &facilitiesDocument13 pages12 - Exhibit C Sp-Welding of Pipelines &facilitiesMoaatazz Nouisri100% (1)

- GMW 14057Document10 pagesGMW 14057JOECOOL67No ratings yet

- Repair Welding of A Rotating Electrical Machine's Broken ShaftDocument7 pagesRepair Welding of A Rotating Electrical Machine's Broken ShaftkanosriNo ratings yet

- UntitledDocument8 pagesUntitledaldairlopesNo ratings yet

- Weld Defects or Imperfections in Welds - Lack of Sidewall and Inter-Run FusionDocument4 pagesWeld Defects or Imperfections in Welds - Lack of Sidewall and Inter-Run FusionmanimaranNo ratings yet

- Afl Manual PDFDocument55 pagesAfl Manual PDFDeanna ChapmanNo ratings yet

- Weld RepairsDocument8 pagesWeld RepairsAhmedAleshiNo ratings yet

- PART 38 CSWIP 3.1 Noted Points - Part 2Document7 pagesPART 38 CSWIP 3.1 Noted Points - Part 2ravindra_jivaniNo ratings yet

- Inspection and Testing of WeldsDocument22 pagesInspection and Testing of WeldsKamarul NizamNo ratings yet

- Supplementary Information Regarding Checking and Replacing Big-End Bearings On Medium-Speed Engines Cus 190Document4 pagesSupplementary Information Regarding Checking and Replacing Big-End Bearings On Medium-Speed Engines Cus 190mariodalNo ratings yet

- EagleBurgmann - CB Clamshell Metal Expansion Joints - ENDocument4 pagesEagleBurgmann - CB Clamshell Metal Expansion Joints - ENYasmine HammamiNo ratings yet

- ARTICLE - Destructive Testing Basics (2012)Document4 pagesARTICLE - Destructive Testing Basics (2012)Sangameswaran RamarajNo ratings yet

- Hull FabricationDocument63 pagesHull Fabricationdeepak.vectormarineNo ratings yet

- Standard 2 5 5 7: Object IndexDocument8 pagesStandard 2 5 5 7: Object IndexSuresh ShindeNo ratings yet

- GMW14057Document19 pagesGMW14057Felipe De la cruzNo ratings yet

- In-Plane Stability of Portal Frames: Rainham SteelDocument3 pagesIn-Plane Stability of Portal Frames: Rainham SteelMonsieur PatateNo ratings yet

- Astm A775 A775m 01Document4 pagesAstm A775 A775m 01shahidmehmood346No ratings yet

- Casting Repairs and Rebuild Procedure Rev.02Document13 pagesCasting Repairs and Rebuild Procedure Rev.02sboergertNo ratings yet

- Api 107Document14 pagesApi 107Yersin Hernandez AldanNo ratings yet

- Visual SL APEXDocument3 pagesVisual SL APEXOscar Gomez Gonzalez100% (1)

- Port 5Document18 pagesPort 5gbsubbuNo ratings yet

- Enbridge Pipeline Repair Workplan WeldingDocument23 pagesEnbridge Pipeline Repair Workplan WeldingJesus MaestreNo ratings yet

- STUD WELDING REQUIREMENTS From AWS D1.1-D 1.1M-2015Document10 pagesSTUD WELDING REQUIREMENTS From AWS D1.1-D 1.1M-2015Mark Darrel AranasNo ratings yet

- Astm A775-A97Document7 pagesAstm A775-A97Артем ТитовNo ratings yet

- EN AuV Couplers Manual 2012Document17 pagesEN AuV Couplers Manual 2012ArdamitNo ratings yet

- Building Standards ActDocument2 pagesBuilding Standards ActLungisaniNo ratings yet

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 pagesSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!hector diazNo ratings yet

- MAN Bulletin Cus 190.02-02Document5 pagesMAN Bulletin Cus 190.02-02lhuichienNo ratings yet

- Ancon Tapered Thread Couplers International VersionDocument16 pagesAncon Tapered Thread Couplers International VersionRanjan SinghNo ratings yet

- Welding Repair Procedure OF Pressure Vessel: PT Gerbang Sarana Baja Standard ProcedureDocument4 pagesWelding Repair Procedure OF Pressure Vessel: PT Gerbang Sarana Baja Standard Proceduregst ajahNo ratings yet

- W32 Qualification Scheme For Welders of Hull Structural Steels W32Document15 pagesW32 Qualification Scheme For Welders of Hull Structural Steels W32Muhamad ShakyreenNo ratings yet

- Epoxy-Coated Steel Reinforcing Bars: Standard Specification ForDocument8 pagesEpoxy-Coated Steel Reinforcing Bars: Standard Specification ForMark DingalNo ratings yet

- Technical Inquiries To API 1104Document20 pagesTechnical Inquiries To API 1104Rey Fiedacan92% (12)

- 002 - Brochure 2055g LightDocument23 pages002 - Brochure 2055g Lightmunawar786No ratings yet

- 1000 LADDERS AROUND Version Sept 21Document18 pages1000 LADDERS AROUND Version Sept 21Ertan KoseNo ratings yet

- Pilot Ladder ChecklistDocument1 pagePilot Ladder ChecklistChrisNo ratings yet

- Despiece SUSP. DEL 930EDocument2 pagesDespiece SUSP. DEL 930EAndersson Campos VásquezNo ratings yet

- Method Statement For Miscellaneous Metal WorksDocument19 pagesMethod Statement For Miscellaneous Metal Worksmohsin.meizaNo ratings yet

- Hitachi Hiacs Multi3000Document10 pagesHitachi Hiacs Multi3000a_596No ratings yet

- Box Pushing Paper - 1Document5 pagesBox Pushing Paper - 1Naresh KumarNo ratings yet

- Flight Line MarshallerDocument24 pagesFlight Line MarshallerCap TainNo ratings yet

- 2001 ME Thesis PapersDocument53 pages2001 ME Thesis Papersazd1973No ratings yet

- Dayton Tech StampingDocument78 pagesDayton Tech StampingRaghu VenkatNo ratings yet

- Dti Oil and Gas Industry White PaperDocument36 pagesDti Oil and Gas Industry White PaperSoniya AgnihotriNo ratings yet

- Using Carsoft Cable For Dis With InpaDocument16 pagesUsing Carsoft Cable For Dis With InpaidarNo ratings yet

- Acp NotesDocument6 pagesAcp NotesAaronNo ratings yet

- In-Display Fingerprint SensorDocument20 pagesIn-Display Fingerprint SensorPrakhil SethiNo ratings yet

- 1 s2.0 S2352012423002503 MainDocument14 pages1 s2.0 S2352012423002503 MainQuangNguyenVanNo ratings yet

- Bhavin Desai ResumeDocument5 pagesBhavin Desai Resumegabbu_No ratings yet

- Barcelo - Computational Intelligence in ArchaeologyDocument437 pagesBarcelo - Computational Intelligence in Archaeologyhristijan_anch100% (1)

- CEH v8 Labs Module 02 Footprinting and ReconnaissanceDocument85 pagesCEH v8 Labs Module 02 Footprinting and ReconnaissancenazaNo ratings yet

- Abus Jib CranesDocument13 pagesAbus Jib CranesWibowo ArieNo ratings yet

- Erhard Butterfly ValveDocument23 pagesErhard Butterfly ValvetangouzeNo ratings yet

- The Autosweep RFID System Can Be Used in The Following ExpresswaysDocument2 pagesThe Autosweep RFID System Can Be Used in The Following ExpresswaysJhez EstuariaNo ratings yet

- Installation Guide: Connecting Workstations Problem SolvingDocument2 pagesInstallation Guide: Connecting Workstations Problem Solvingjuan_mxNo ratings yet

- NDT TrainingDocument8 pagesNDT TrainingdashNo ratings yet

- QC Hemato Mei 2014 NormalDocument29 pagesQC Hemato Mei 2014 Normalsri wahyuniafif2425No ratings yet

- Quick Start - WireGuardDocument5 pagesQuick Start - WireGuardΚαωεη ΣηαδNo ratings yet

- Unit ConversionDocument21 pagesUnit ConversioninsidereaderNo ratings yet

- Salesforce MVC Architecture Model View ControllerDocument3 pagesSalesforce MVC Architecture Model View ControllerRai Sanjay0% (1)

- SWP001 04 G1B - R01Document86 pagesSWP001 04 G1B - R01Roberto MontoyaNo ratings yet

- Volume 4, Issue 2 (2017) Tropical Plant ResearchDocument173 pagesVolume 4, Issue 2 (2017) Tropical Plant ResearchTropPlResNo ratings yet

- 5 KW OFF GRID & Grid Tie Quotation 31-03-2021Document3 pages5 KW OFF GRID & Grid Tie Quotation 31-03-2021ImranFazalNo ratings yet

- WholeDocument389 pagesWholeCarlos Enrique Sánchez CáceresNo ratings yet