Professional Documents

Culture Documents

Coopers etc... homebrewing instructions

Uploaded by

Eric SteenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coopers etc... homebrewing instructions

Uploaded by

Eric SteenCopyright:

Available Formats

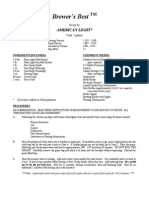

Coopers etc…

a) First of all, gather your equipment.

b) Before starting, read through all of these instructions.

c) All your equipment should be cleaned with a chlorinated soap, rinsed with hot water, sterilized with aseptox (without

rinsing) or sulphite (rinsed with sterile water).

d) Note the type of beer and the starting date. ______________________________

Step 1 PRIMARY FERMENTATION

1) Soak the unopened can of malt in hot water for about 20 minutes, it helps soften the contents. (Remove the label and the packet of yeast

before.)

2) Boil 3 to 4 liters of water.

3) When your malt and water are ready, pour the malt extract in the fermentation pail and rinse the can with a little of the boiled hot water.

Add the remaining boiling water and stir well to dissolve the malt.

Add dextrose (corn sugar): 6-7 cups of sugar for 23 liters.

4) Add pure water to a total volume equal to 23 liters, stir well.

5) Make sure that the liquid temperature is between 21 and 25 C before proceeding to the next step.

Check with your gravity, you should get a reading between 1.035 and 1.045 in most cases.

Add your yeast (sprinkle and stir slightly). Caution: Do not rehydrate your yeast in warm water.

6) Cover your pail with your lid and let ferment in a room where the temperature is between 21 and 23 C.

N.B. Take a gravity test using the hydrometer every day and record results on a fermentation log.

Step 2 SECONDARY FERMENTATION

The time required to get to this stage can vary depending on the fermentation temperature. (Approximately 3 to 5 days).

Gravity at the time of racking should be between 1.018 and 1.015.

7) Siphon your beer into the carboy, taking care not to disturb the sediment in the bottom of the fermenter. Fill to about 8 to 10

centimeters of the bung.

8) Install the rubber bung and airlock assembly into the top of the carboy to close it off. Aseptox is not recommended for the airlock, a

sulphite and water solution is recommended.

9) Allow your beer to finish fermenting at a normal temperature of 21 to 23 C. It will take approximately 8 days.

10) After 8 days have passed, check the gravity using a hydrometer, you should get a reading between 1.006 and 1.008.

11) Two days later, check again the gravity of the beer, if you get the same reading, your beer can be bottled. Otherwise, wait two more

days and retest gravity.

Step 3 BOTTLING

Prepare + / - 66 bottles (341 ml standard beer bottles) by cleaning thoroughly with chlorinated soap, rinse well with warm water.

Subsequently, sterilize your bottles with aseptox (without rinsing) or sulphite (rinse with sterile water).

12) Siphon your beer from carboy to your primary fermenter, being careful not to transfer the sediment in the carboy.

13) Add dextrose (corn sugar) in the bowl and stir well. Approximately 1and a 1 / 3 cup sugar (220 grams) for a volume of 23

liters.

14) You must immediately bottle your beer, racking the beer into each bottle. Fill them up to about 4 centimeters below the rim and use

the capper to close off the caps (the use of a bottle filler is recommended).

15) Let your beer referment at room temperature for another 2 weeks. You will notice an improvement in the overall quality of your beer

if you let it age another month or two.

You might also like

- Morebeer! Beer Making Instructions: Morebeer! Personal Brewery Starter SystemDocument2 pagesMorebeer! Beer Making Instructions: Morebeer! Personal Brewery Starter SystemTeddy Riaño AlarconNo ratings yet

- How To Brew - by John PalmerDocument4 pagesHow To Brew - by John Palmerzaratustra210% (1)

- Beer Instruction ManualDocument4 pagesBeer Instruction ManualShaheer MuhammadNo ratings yet

- Extract Brewing Instructions: Necessary Equipment and SuppliesDocument2 pagesExtract Brewing Instructions: Necessary Equipment and SuppliesHenry Clark TravagliniNo ratings yet

- 1 US Gallon Water PurifierDocument16 pages1 US Gallon Water Purifieremily turnerNo ratings yet

- Brew Buddy StarterDocument2 pagesBrew Buddy StarterJuk ArmstrongNo ratings yet

- 25 L SUPER Reflux Still Ins With Z FilterDocument16 pages25 L SUPER Reflux Still Ins With Z FiltertoffeloffeNo ratings yet

- 5L Super Reflux Still InstructionsDocument16 pages5L Super Reflux Still InstructionsAndréRochaNo ratings yet

- Homebrew Equipment and Step-by-Step Brewing ProcessDocument2 pagesHomebrew Equipment and Step-by-Step Brewing ProcessDavid SanzNo ratings yet

- Still Spirits 25L Super Reflux Still 55719 WEB June08Document4 pagesStill Spirits 25L Super Reflux Still 55719 WEB June08AndréRochaNo ratings yet

- Calibrating Volumetric GlasswareDocument5 pagesCalibrating Volumetric GlasswareJazz DescalzoNo ratings yet

- American Pale AleDocument2 pagesAmerican Pale AleJustin GarciaNo ratings yet

- How to Distill Sugar Wash into AlcoholDocument3 pagesHow to Distill Sugar Wash into AlcoholJefferson RobertoNo ratings yet

- 25L Pot Still: ManualDocument8 pages25L Pot Still: ManualrectechNo ratings yet

- Apple Cider InstructDocument2 pagesApple Cider InstructlegionsixNo ratings yet

- Brooklyn Brew Shop Punk IPA InstructionsDocument3 pagesBrooklyn Brew Shop Punk IPA InstructionsRamón Farré GómezNo ratings yet

- Mangrove Jack's Brewer's Series Kit InstructionsDocument2 pagesMangrove Jack's Brewer's Series Kit InstructionsEsteban Iturra CerónNo ratings yet

- The Synthesis of Ethyl Ethanoate: A2 Experiment 13.5 (3) Teachers' GuideDocument3 pagesThe Synthesis of Ethyl Ethanoate: A2 Experiment 13.5 (3) Teachers' GuideRudyNo ratings yet

- Basic Mead Making: University of Minnesota Instructional Poster #158, Gary S. Reuter, Department of EntomologyDocument1 pageBasic Mead Making: University of Minnesota Instructional Poster #158, Gary S. Reuter, Department of EntomologysanjosewhoreNo ratings yet

- Homebrew Oatmeal Stout Kit GuideDocument3 pagesHomebrew Oatmeal Stout Kit Guideriffs_ahoyNo ratings yet

- Bulldog Brews InstructionsDocument4 pagesBulldog Brews InstructionsrciobanasuNo ratings yet

- Mangrove Jack's Craft Series Beer Pouch InstructionsDocument2 pagesMangrove Jack's Craft Series Beer Pouch InstructionsJoao MoreiraNo ratings yet

- The Key IngredientsDocument4 pagesThe Key Ingredientsk_168911826No ratings yet

- Beer Brewing For BeginnersDocument5 pagesBeer Brewing For BeginnerspauloadrianoNo ratings yet

- Calibration of Glassware 2009Document5 pagesCalibration of Glassware 2009Imad AghilaNo ratings yet

- Still Spirits Turbo Air Still GuideDocument8 pagesStill Spirits Turbo Air Still Guidefrasers1No ratings yet

- A Short Overview of Distilling: - Plus 2 Bonus RecipesDocument4 pagesA Short Overview of Distilling: - Plus 2 Bonus RecipesMatheus Jeronimo MarianNo ratings yet

- Brooklyn Brew Shop - Everyday IPA InstructionsDocument3 pagesBrooklyn Brew Shop - Everyday IPA Instructionstecleador10% (1)

- Midwest Honeybee AleDocument2 pagesMidwest Honeybee AleJesso GeorgeNo ratings yet

- (Lab Report Operation Unit) Experiment 4: INTRODUCTION TO A BATCH PROCESS: SIMPLE BATCH DISTILLATIONDocument10 pages(Lab Report Operation Unit) Experiment 4: INTRODUCTION TO A BATCH PROCESS: SIMPLE BATCH DISTILLATIONFazsroul86% (7)

- WaterKefir Instructions Updated 102219Document7 pagesWaterKefir Instructions Updated 102219Joshua AugustaNo ratings yet

- Serving Draught Beer: Glassware CleaningDocument4 pagesServing Draught Beer: Glassware CleaningDeven SolankiNo ratings yet

- ALCOHOL DISTILLATION StepsDocument8 pagesALCOHOL DISTILLATION StepsRaad AshkarNo ratings yet

- Rice BeerDocument8 pagesRice BeerPied7PiperNo ratings yet

- Clawhammer DistillingDocument11 pagesClawhammer Distillingbala murali n.No ratings yet

- Do-It-Yourself Yeast-Generated CO2 SystemDocument3 pagesDo-It-Yourself Yeast-Generated CO2 SystemPuscau SorinNo ratings yet

- Is 8897Document32 pagesIs 8897Ayan Naskar100% (1)

- Caution: Oil Will Be Hot, and May Splatter or Catch Fire. Wear Goggles at All TimesDocument4 pagesCaution: Oil Will Be Hot, and May Splatter or Catch Fire. Wear Goggles at All TimesRodil ChipanaNo ratings yet

- How To Make Your Own Red Dragon Fruit WineDocument8 pagesHow To Make Your Own Red Dragon Fruit WineShakura Ahseyia0% (1)

- BASIC STEPS TO MAKING ANY FRUIT WINEDocument3 pagesBASIC STEPS TO MAKING ANY FRUIT WINEQuenne Abonero BelocuraNo ratings yet

- Steam Distillation Cloves 2013Document2 pagesSteam Distillation Cloves 2013Rade NovakovicNo ratings yet

- Freeze-Banking YeastDocument2 pagesFreeze-Banking YeasttxgoatNo ratings yet

- Nickel Experiment XWDocument4 pagesNickel Experiment XWKhairul Anwar Abd HamidNo ratings yet

- Hand Book of Home DistillationDocument90 pagesHand Book of Home DistillationYuri AltieriNo ratings yet

- Brewers Friend Checklist ExtractDocument2 pagesBrewers Friend Checklist ExtractGanges LimNo ratings yet

- How To Brew Beer at HomeDocument5 pagesHow To Brew Beer at Homelucas.siqueiraNo ratings yet

- 1 Gallon Mead Recipe For Beginners - Easy Mead Recipe & KiDocument5 pages1 Gallon Mead Recipe For Beginners - Easy Mead Recipe & KiRyanNo ratings yet

- Beer Making ClassDocument5 pagesBeer Making ClassMichael BernierNo ratings yet

- MeadinstructionsftaDocument3 pagesMeadinstructionsftaapi-520147643No ratings yet

- 1018 American LightDocument2 pages1018 American LightAhmet MetinNo ratings yet

- Extracting Capsaicin From PeppersDocument3 pagesExtracting Capsaicin From PeppersSciNut100% (2)

- UntitledDocument5 pagesUntitledPetar HristovNo ratings yet

- Milk and Milk ProductsDocument8 pagesMilk and Milk ProductsUsman GhaniNo ratings yet

- Laboratory Manual 5Document3 pagesLaboratory Manual 5yamlehtemagallanes888No ratings yet

- Synthesis of Benzoic AcidDocument6 pagesSynthesis of Benzoic AcidHakdogNo ratings yet

- How To Brew Beer: April JohnsonDocument5 pagesHow To Brew Beer: April Johnsonapi-278329775No ratings yet

- Preoces de DezalcoolizareDocument18 pagesPreoces de DezalcoolizareMarina ButuceaNo ratings yet

- TABLA DE LupulosDocument2 pagesTABLA DE LupulosAna TorrealbaNo ratings yet

- Heineken CaseDocument18 pagesHeineken CaseSecond FloorNo ratings yet

- Measurement and Automation in Breweries: Customized Instrumentation As A Complete SolutionDocument44 pagesMeasurement and Automation in Breweries: Customized Instrumentation As A Complete SolutionPedro QueirozNo ratings yet

- Miller FinalDocument20 pagesMiller FinalNikhil PalNo ratings yet

- The Brewdog Blueprint 2018Document13 pagesThe Brewdog Blueprint 2018Daniela Paz González EncinaNo ratings yet

- Production of WineDocument24 pagesProduction of Wineali purityNo ratings yet

- Heineken: Positioning in Changing Times: BackgroundDocument20 pagesHeineken: Positioning in Changing Times: BackgroundHai Nguyen Lam PhuocNo ratings yet

- Craft Beer & Brewing Winter 2023Document116 pagesCraft Beer & Brewing Winter 2023antonio alberto gutierrez suarezNo ratings yet

- Kapital CupsDocument2 pagesKapital CupsdabdabdabdabNo ratings yet

- Rice Wine Project: Mark Stephen C.Dayata 11-AquamarineDocument17 pagesRice Wine Project: Mark Stephen C.Dayata 11-AquamarineMark DayataNo ratings yet

- CiceroneDocument21 pagesCiceroneYerco UrquizaNo ratings yet

- Task 1 - Email Template v2Document2 pagesTask 1 - Email Template v2Stuti MathurNo ratings yet

- Diploma in Packaging Syllabus 2018Document16 pagesDiploma in Packaging Syllabus 2018Amy Leigh WilliamsNo ratings yet

- Brewing With Cannabis Sativa Vs Humulus Lupulus A ReviewDocument9 pagesBrewing With Cannabis Sativa Vs Humulus Lupulus A ReviewJusepe Hbk LópezNo ratings yet

- Millercoors' Sol Brews Up A Sunny RedesignDocument1 pageMillercoors' Sol Brews Up A Sunny RedesignFabian Dario Barrera RodriguezNo ratings yet

- Unit 2.01 - Measurement of Alpha-GlucanDocument9 pagesUnit 2.01 - Measurement of Alpha-GlucanRiyanNo ratings yet

- Cat's Meow Home Brewing 13 Historical RecipesDocument8 pagesCat's Meow Home Brewing 13 Historical RecipesnawickNo ratings yet

- Industrial MicrobiologyDocument77 pagesIndustrial MicrobiologyOPSNo ratings yet

- Beverages - The Good Cook SeriesDocument182 pagesBeverages - The Good Cook SeriesEddy Wibowo75% (4)

- Value-Added ProductsDocument7 pagesValue-Added ProductsTendai MutisiNo ratings yet

- Amarillo Red AleDocument2 pagesAmarillo Red AleFlávio MariniNo ratings yet

- CHAPTER 10 Conclusion and Recomm. FINALDocument5 pagesCHAPTER 10 Conclusion and Recomm. FINALPatrick Kyle AgraviadorNo ratings yet

- FST-Paper - II Food Beverages - IV-SemesterDocument80 pagesFST-Paper - II Food Beverages - IV-SemesterAnrey Magallanes VolanteNo ratings yet

- Brand NameDocument4 pagesBrand NameAnjnaKandariNo ratings yet

- Digbeu Armand OUREGA, Louis Ban KOFFI Kouadio Florent N'GUESSAN, Gnopo Jean NEMLIN, Kablan TANO, and Koffi Marcellin DJEDocument12 pagesDigbeu Armand OUREGA, Louis Ban KOFFI Kouadio Florent N'GUESSAN, Gnopo Jean NEMLIN, Kablan TANO, and Koffi Marcellin DJEFousseyni TRAORENo ratings yet

- Microbrewery Business PlanDocument28 pagesMicrobrewery Business PlanTom TronconeNo ratings yet

- All-Grain Brewing GuideDocument3 pagesAll-Grain Brewing GuideEidetikosNo ratings yet

- How To Read A HydrometerDocument2 pagesHow To Read A Hydrometerbartolomej7No ratings yet

- Hazop Study.xDocument17 pagesHazop Study.xNur AishaNo ratings yet