Professional Documents

Culture Documents

316 Mix Design For Boared Cast in Situ Pile Concrete Grade M-35

316 Mix Design For Boared Cast in Situ Pile Concrete Grade M-35

Uploaded by

Anup Pandey0 ratings0% found this document useful (0 votes)

21 views30 pagesOriginal Title

316 Mix Design for Boared Cast in Situ Pile Concrete Grade M-35

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views30 pages316 Mix Design For Boared Cast in Situ Pile Concrete Grade M-35

316 Mix Design For Boared Cast in Situ Pile Concrete Grade M-35

Uploaded by

Anup PandeyCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 30

°° eq farasra Prov feats

‘o VW Rail Vikas Nigam Limited /

CIN : L74999DL.2003G01118633 (A Government of india Enterprise)

1742, eiferreraRaTeraTy Rea Serer TTT4G 2024,

‘the: +91(755) 4295368, 3if: 4289909

No: RVNUMPMRCL/Indore/INO2/ 0% i Date: 07/03/2022

The Engineer

DB-Geodata-Louis Berger,

General Consultant

Indore Metro Rail Project

Indore

Name of work: Design and Construction of Seven (7) Elevated Metro Rail Stations including

Viaduct portion within the stations and Transition spans on either side of the

stations, Entry-Exit Structures, Architectural Finishes, E&M Works etc.

(ISBT/MR10 Flyover, Chandragupta Square, Hira Nagar, Bapat Square,

Meghdoot Garden, Vijay Nagar Square & Radisson Square)" of Indore Metro

Rail Project.

Reference: 1. LOA No:- 1022/MPMRCL/2021 dated 18.09.2021

2. RVNLIMPMRCL/Indore/INO2/0299, Dated 01.03.2022

‘Subject: ‘Mix Design for Bored Cast in situ Pile Concrete Grade-M3:

MIx-WM135-00001, R2- Reg,

Dear Sir,

With reference to above cited subject, hereby submitting the Mix Design for Bored

Cast in situ Pile Concrete Grade-M35, (Document No: IN-02-CIC-MIX-M35-00001, R2)

with updated DRS sheet for your kind review and approval.

Hereby enclosed the Durability Test Reports, 7 Days Compressive strength observation

sheet of Trial Mix confirmative.

‘Thanking you and assuring you of our best services at all times

DA: As stated above

For & on behalf of

Rail Vikas Nigam Limited

a

(s.t-Kaltkarn

Addl. General Manager (P)

Indore

Copy to: CPM/RVNLIBhopal _- for kind information please.

Regd. Off. : Plot No. 25, (1st Floon, August Kranti Bhavan, Bhikaji Gama Place, New Delhi-110066

Tel: +91! 11 26738289 Fax: +91 11 26182957, Web : www.rvnl.org,

= Dy a A conf A sor weaemapnse| oe a

[ea aPNT al DVGONGIN OO | == mean = = — = =

Fa SHC. 5 wl yowmanvs's| cron anal ~ vs mame

“Faron =e oo = SS rare i

2ateg ner @VIVG03I0m (GG) waw

STAEAM «| DB) mczo0w Qos] | J asta

Goreme of rsa Eee)

INDORE METRO RAIL PROJECT YELLOW LINE PACKAGE - 1NO2

MIX DESIGN FOR PILE CONCRETE ~ M35 GRADE

CLIENT: :MADHYAPRADESHMETRORAILCO.LTD.

EPCCONTRACTOR: :RAIL VIKAS NIGAM LIMITED

GENERAL CONSULTANT — :DB-GEODATA-LOUISBERGER-GC

DOCUMENTNO: IN-02-CIC-MIX-M35-00001, R2

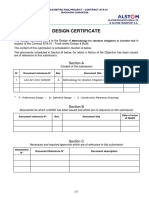

Preparer P. Mths Kearny ge MANPWER.

‘Checker S copy akumnere— Jigonsee— GA Manaus

Approver

Vitmsnmeee. | Aesth | Contractr-te.

Review Status — a

oti ‘Notice of No - Others

NoObjection, with

" me Objection | |

‘Comments ¢ » |

Revision History

RO 09-Feb-2022

RI 28-Feb-2022

R2 (07-Mar-2022

Page Tori0—

inangam (Demon o=- =]

INDORE METRO RAIL PROJECT YELLOW LINE PACKAGE - INO2

Contents

1) Purpose of M35 Grade Concrete:

2) Design Stipulation:......

3) Test Data For Material

4) Source of Material

5) Target Mean Strength: : . enn “ .

6) Selection of Free Water- Cementitious Ratio) 7 sv

7) Selection of Water content...

8) Selection of Cementit

pus Content. . a .

9) Proportion of Volume of Coarse Aggregate and Fine aggregate.

10) Reduction in Coarse Aggregate

11) Mix Caleulations..

12) Trials Observations (Trial Mix No TM 05)........

13) Cube strength Results: (Trial Mix No TM 05)...

14) Confirmative Trial mix TM-0S Compressive strength M35.

15) Review of trial Mix TM-05 with Confirmative test grade of Concrete M35.

Page Zor 10

(DB)

GEODATA

1) Purpose of M35 Grade Conerete:

As per Contract Document Volume

Conereting.

2) Design Stipulation:

>

>

vvvvy

vVvVVVY¥YVVY v

v

Type of Mix

Gradedesignation

Clause 4.3.1)

Characteristic Compressive strength at 28 days

Target Mean strength of Concrete

‘Type of Cement

Clause 4.2)

‘Type of Mineral Admixture

Maximum Nominal size of aggregate

Type of exposure

Minimum Cement Content

Maximum Cement Content

Revision, Section 1700, Clause 1703.3)

Maximum Water- Cement Ratio

‘Table 1700-2)

‘Adopt Free Water-Cement Ratio as on Trials

‘Type of Chemical Admixture

Specifications & Volume V, Clause 12.5)

Maximum Temperature at Batching Plant

Maximum Temperature after Placement

Workability Slump

Method of Conerete placing

Degree of Supervision

‘TypeofAggregate(20mm)

‘HofFineAggregate

% of Coarse Aggregate

Ratio of 20mm & 10

% of Volume entrapped air in wetConerete

for20mmNominalsizeAgeregate)

Transportation Time of Concrete

Type of Chemical Admixture

IV, Clause 4.3.1M3S Grade of Concrete is for Bored cast in situ Pile

louis 3eraer|

: Design Mix

‘M3S(As per Contract Document Volume —TV,,

:35N/mm’(As per IS456-2000, Table 2)

+: 43.25N/mm2(As per 1456-2000, Table-8)

:OPC 53 Grade(Contract Document Volume ~ IV,

Fly Ash(IS3812,P-1:2013)

220mm

‘Moderate

:360Kg/m’(as per IS 456-2000)

: not in excess of 450 kg/m3 (as per MORTH 5"

:0.45(as per MORTH 5" Revision, Section 1700,

04

:FosrocAuramix 350 (as per Clause 1012 of MORTH,

: Shallnotexceed 30°CnotbelowS*C

(As Per Tender Vol.5 Clause no.12.11.11)

40°C(As Per Tender Vol.5 Clause no.12.11.11)

:150MM TO 180MM (As per IS2911, P-1/See-2:2010)

: By Chute with Tremie Pipe

Good

‘Crushed Angular aggregate

:38.9%

261.1%

65% & 35%

21% (AsperlS10262:2019 clause 5.2Table-3,

2120 min Approximately

: PCE based Superplasticizer

Pages or10—

mim

MPME

HIGEODATA Q ise

INDORE METRO RAIL PROJECT YELLOW LINE PACKAGE - INO2

> Type of Structure

3) Test Data For Materials:

> TypeofCementandGrade

> Specific gravity of Cement

> Specific gravity of Fly ash

> Chemicaladmixture

> SpecificgravityofAdmixture

> Specificgravityofwater

>

>

Specificgravityof20mm

Specificgravityofl0mm.

> Specific gravity of M- Sand

> WaterAbsorptionof20mm

> WaterAbsorptionofl 0mm

> Water absorption of M- Sand

4) Source of Material

: 1 (TP Report No: TC783221000005756F)

:2.92 (TP Report No: TC783222000000308F)

: RCC (Bored Cast in-situ Pile)

Ultratech OPC 53 Grade

15(TP Report No: TC783220000000530F)

2.10(TP Report No: TC783220000000526F)

FOSROCAURAMIX350

1 (TP Report No: TC783220000000528F)

2.90 (TP Report No: TC783222000000307F)

71(TP Report No: TC783222000000301F)

0.64% (IP Report No: TC783222000000308F)

0.83% (TP Report No: TC783222000000307F)

:2.47% (TP Report No: TC783222000000301F)

Material T - Source _—

1 | Cement Ultratech (As per Contract Document Volume- V, Appendix-A)

| | oo

2 | Fly Ash ‘ShriSinghali, ThermalPower Plant (As per Contract Document Volume- V,

Appendix-A)

3 ‘Aggregate 20mm, Pithampur, Supplier: BR stones (As per INO2-CIC-MAR-00002)

4 ‘Aggregate 10mm Pithampur, Supplier: BR stones (As per INO2-CIC-MAR-00002)

3 Fine Aggregate Betma, Supplier: MAA Narmatha (As per INO2-CIC-MAR-O0001)

6 ‘Admixture Fosroc (As per Contract Document Volume- V, Appendix-A)

7 Water URC Casting Yard Well point (As per IN02-CIC-MAR-00003)

5) Target Mean Strength:

Pap = fet 1.65 x S (As per IS 456:

where,

2000, Table 8)

f'q= target mean compressive strength at 28 days

fa= characteristic compressive strength at 28 days, herefa= 35

S = standard deviation, N/mm’

‘Therefore, target mean strength usi

Pye het LO8xS

SAS + 1655.0

=5.0 (from table 8 of IS Code 456 : 2000)

ing equations, that is,

(NAEAM | DB accoo1, Qos mo Id iii

MP ome Eee

INDORE METRO RAIL PROJECT YELLOW LINE PACKAGE - INO2

43.25 N/mm?

‘Therefore, target mean strength will be 43.25 N/mm?

6) Selection of Free Water- Cementitious Ratio)

From as per IS 456 Table no. 5,

Maximum water cement ratio moderate condition = 0.45

Based on trials, adopt water cement ratio = 0.4

0.4<0.45(as per MORTH 5" Revision, Section 1700, Table 1700-2, maximum W/Cis 0.45), Hence O.K

7) Selection of Water content

From IS 10262:2019 Table 4, Maximum water content for 20mm aggregate =186 lit (for 25mm

to 50mm Slump Range)

Estimated water content for 25-50mm slump = 186.0 Liters

From IS 10262:2019 Clause 5.3 increase about 3% water for every 25mm slump

For 170 mm Slump water required — 186 + 14.4/100* 186 =212.784Kg

From IS 10262:2019 Clause 5.3 Water reducing admixtures or super plasticizing admixture

usually decrease water content 20 Percent above respectively at appropriate dosages.

Based on trials with Super Plasticizer; Water Content reduction of 12.3 Percent has been

achieved for the admixture volume of 0.3% by volume of total cementitious content. Hence

the arrived water content = 212.784-(12.34212.784)/100= 186.6 Liters, say 187Kg.

8) Selection of Cementitious Content

Water Cement Ratio achieved = 0.4

Hence Cementitious Content: W/C = 0.4 => 187/0.4 = 467.16 Kg/ m3

say 467kg/m*>360Kg/Cum(as per MORTH 5"Revision, Table 1700-2), minimum 360Kg of

cement content is required.

Fly ash @ 18% (IS 10262:2019 Table-9) of total cementitious material content Total

Cementitious Content — 467 kg /m3.

Hence fly ash content = 467 x18 % — 84.06 kg/ m3, Say 84 kg/m?

Cement (OPC-53) — 467-84 = 383 kg/m?

383>360 (Minimum cement content is 360 Kg/m’(As Per IS; 456: 2000), The maximum cement

content in concrete in normal course is also limited to 450 kg. per cum of concrete (as per MORTH 5"

Revision, Section 1700, Clause 1703.3). Hence cement content isOK.

Pages or10—

INDORE METRO RAIL PROJECT YELLOW LINE PACKAGE - INO2

9) Proportion of Volume of Coarse Aggregate and Fine aggregate

From Table -5 of IS: 10262-2019,

Volume of coarse aggregate corresponding to 20 mm size aggregate and fine aggregate Zone-1, water

cement ratio 0.5 is 0.60.

For WIC 0.4, every decrease of 0.05 in water cement ratio, there is a increase of 0.01 volume

inaggregate.

Therefore,

‘The volume of Coarse Aggregate = 0.62 X 100 = 62%

Volume of Coarse aggregate 10mm — 35 .00%

Volume of Coarse aggregate 20mm — 65.00%

Volume of fine Aggregate = 100-62 = 38.0%

10) Reduction in Coarse Aggregate

From Clause 5.52 of IS 10262: 2019, Desirable to reduce the estimate coarse aggregate content up to

10%, As per trial coarse aggregate content reduce up to 1.5% Coarse aggregate and fine aggregate after

correction for pumping

Coarse aggregate = 62% x(100-1.5)=61.1%

Fine aggregate = (100-61.1)% =38.90%

11) Mix Calculations

a) Volume of Conerete =1m'

b) Volume of Air Content in Concrete = 0.01

©) Volume of Cement = Mass of Cement/Specific gravity * (1/1000)

= 383/3.15 * (1/1000)

=0.122m°

4) Volume of Fly Ash Mass of Fly Ash/Specific gravity * (1/1000)

84/2.1 * (1/1000)

= 0.040m*

©) Volume of Water Mass of Water/Specific gravity* (1/1000)

= 187/1 *(1/1000)

0.187 m’

f) Volume of Admixture @ 0.3%

by mass of cement = Mass of Admixture/Specific gravity* (1/1000)

Page 6 of 10

imnneAm

MP

HICEODATA @ visser id. eae?

INDORE METRO RAIL PROJECT YELLOW LINE PACKAGE - INO

4/11 * (1/1000)

= 0.0013m°

g) Volume of All in Aggregate =ab(ctdteHl)

= 1-0.01-(0.1224+0.04040.18740.0013)

6397

1h) Mass of Coarse Aggregate 20mm. ‘Volume of all in aggregate * 0.611*0.65*specitic gravity*1000

=0.6397*0.611*.65"2.92*1000

4L.85Kg, say 742K g

i) Mass of Coarse Aggregate 10mm = Volume of all in aggregate * 0.611*0.35*specific gravity*1000

= 0.6397*0.611*0.35%2,9*1000

= 396.72Kg, say 397Kg

i) Mass of Fine Aggregate = Volume of Fine aggregate*specific gravity *1000

0.6397*0.389*2.71* 1000

= 674.36Kg, say 674Kg,

MixProportions(SSDCondition)perCum.(TestReportAttached)

Content Quantity/m*

‘Cement 383kg

FlyAsh. 84kg

CoarseAggregate20mm Ta2kg

CoarseAggregate!0mm 397kg,

‘CrushedSand 674kg.

Water 187Kg,

meee heal 1.40kg

‘Total 2468Kg

MixProportions(DryCondition)perCum,

Content

Cement 383 kg

C FlyAsh 84 kg

‘Coarse Aggregate 20 mm 73 7ke

Coarse Aggregate 10 min 304kg

CrushedSand OT kg

Water Dake

‘Admixture (0.3 % by weight 140 kg

of cementitious)

Page Toro

int Am (DB) HICEODATA @ ss ta Ve f=

INDORE METRO RAIL PROJECT YELLOW LINE PACKAGE - INO2

‘Total 2468 Kg

12) Trials Observations (Trial Mix No TM 08)

The slump shall be measured, and the water content and dosage of admixture shall be adjusted

for achieving the required slump based on trial, if required, the mix proportions shall be

reworked for the actual water content and checked for durability requirements.

12.00PM | 01.00PM 1.30PM 2.00PM Remarks

Duration Initial 60min 90min 120min Cohesive

Slump Collapse 200mm 190mm. 175mm. (Attached

testreport)

13) Cube strength Results: (Trial Mix No TM 05)

‘AgeinDays Dateoftesting Strength (Nimm’) | Remarks

Date of casting 11-01-2022

7-day Compressive strength | 18-01-2022 341

28-day Compressive 08-02-2022 45.7

strength

14) Confirmative Trial mix TM-05ACompressive strength M35

Dateofeasting:21-02-2022

a ‘Average

SINo| Cubel | Dateof Weight Falta) eet | Compressiv

D Testing |Ageof| (Gms) | Load inen?) estrength

Cube ier (Vinm')

1 22-02-2022 350.1 482

1 2 2-02-2022) act 525.1 464 468

3__b2-02-2022 5168 458

4 28-02-2022 7 Days] 8990 | 82650] 36.70

2 5 b8.02-2022 see | 764.00] 34.00 3430

6 __bs.02-2022 3904 _| 72690| 32.30

3

Page 8 oF 10—

mirem

MP

‘ts fewer oor fits

ECEODATA @ toss sere Id. ‘vrei /

INDORE METRO RAIL PROJECT YELLOW LINE PACKAGE - INO2

15) Review of trial Mix TM-05 with Confirmative test grade of Concrete M35

Content ‘TrialMixnodS | TriaIMixNo0SA. | TriaiMixN | TrialMixNo 05C

005B

Cement 383kg 383k;

FlyAsh B4kg 84kg

CoarseAggregate20nun 742kg 7A2kg

CoarseAggregatel0mm 397g 397g

Crushed Sand 6T4kg 674kg

‘Water 187Ke 187Ke

ofeenenttn) | 4k 140k

Total 2468Kg 2468Kg

Mix Proportions (SSD Condition) per Cum

Content TrinlMixno 05 | TrialMixNo | TrialMIxNo OSB) pyigintinNo 05C

054

383kg 383kg

Cement

FlyAsh Bake Bake

CoarseAggregateOmm Tadkg 742k;

CoarseA geregatelOmm 397kg 397g

‘CrushedSand 675kg 675kg

Water 187Ke 187Ke

‘Admixtare(O Swat Ga 140g

Total 2468Kg 468K

Mix Proportions (DRY Condition) per Cum

Content ‘TrialMixno0S | Trial Mix No| Trial Mix | Trial Mix No SC

= No SB

Cement 383 ke 383

FyAsh 84 kg 84

CoarseAggregate20 mm T37kg 742

CoarseA ggregate10 mm 394kg 397

‘CrushedSand 658ke-|——«6T6

Water 212kg 187

‘Admixture(0. Sees oF 140 kg 140

Total 2468 Kg 2468

Pages oF 10

mninem

HECEODATA @ saison

MP.

Ve] Ba fe fe

Id: alas Newt

Rewaneeetias SH

INDORE METRO RAIL PROJECT YELLOW LINE PACKAGE - INO2

SlumpDetails

Content Trial MixnoS | Trial MixNo | Trial Mix | Trial Mix No

SA NosB sc

‘Slump (min) Initial Collapse Collapse

Slump (mm) 60 MIN 200mm 200mm

Siump (mm) 90 MIN 190mm 190mm

Slump (mm) 120 MIN 175mm 170mm

js aeinsNwt

CompressivestrengthdetailsinN/mm’

Content TriatMixnoS | Trial Mix | DrigiMiix | TrialMixNo SC

Nosa | No

‘argetmeanstrength Required 28days a ot Bas 4a36

CT = 46.80

ctualachievedstrength7days 34.10 34.30

[Actualachievedstrength28days 45.70

S.NO Parameter Unit Results Third party Report

Ref. Number

1 Water Permeability at $ bar mm Fr KTRC/2201003201

pressure for 72Hours, depth of a)

penetration

2 Chloride, Cl % 0.014 KTRC/2201003201

| (8)

3 Sulphate, SO; % 032 KTRC/2201003201

(8)

Page 10 of 10

Test & Research Centre Pvt. Ltd

KrRciario708"1

Page No. 1/1

TEST REPORT

BRN & LRN

Name and Address of Customer Date of Receipt

MPMRCL Satisfactory

Coens ae ped Pred Condition, when received Satistoc

Yellow Line Package IN 02 & IN 03 Packing, when received Packe

Quantity Received (Approx.) Sufficient

Contact Person Name : ‘Date of Start of Test | 0601.2022

Date of Casting | __sx01.2022

}—

Sample Identification: Mix Design (M35) Date of Completion Of Test _98.02.202

(roniPRe} Date of Reporting 08.02 2022

Customer Reference : Letter Dated 29.12.2021

Sample Particular: Mix Design (M-36) (For Pile)

Test Results:

) Compressive Strength of the Concrete mi:

S.No. | Description I

| ESE -

> | 28-days compressive strength,

(Nimm’) { —

466

: } =

Average, (Nimm*) 45.7

Note: This report is in continuation of our earlier BR No. KTRCI2201000105 issued on Dated 01.02.2022.

This is Final Report

“End of Report™*

Er. Ashish Pawar

Manager (BM) & Authorized Signatory

Test & Research Centre Pvt. Ltd.

Quality first & forever

BR No.: KTRC/2201000105 & LR No.: 22011121705. Pave.6/7

H) PROPOSED DESIGN MIX PROPORTION FOR 4 CU. MTR VOLUME OF CONCRETE BY

WEIGHT IS AS FOLLOWS:

Trial-t,

() Cement © Flyash : Sand Coarse Aggregate wic Admixture

0.82 018 1.45 2.44 0.40 0.0030

(ii) Water Cement Ratio WIC = 0.40 by Weight on SSD basis

Cement (82%) 383 kgim’

1 | Cementitious Content -—

| Flyash (18%) 84 kgim?

2 Fine Aggregate (Crushed Sand)

10 mm (35%)

3. | Coarse Aggregate a

20 mm (65%)

4 | Water 187 kgim?

(after 60 Minutes) 200 mm

5 | Slump (After 90 Minutes) 190 mm

(After 120 Minutes) 175mm

6 [ Admixture (0.3% of Cement Content) 1.40 kg

|) Compressive Strength of the Concrete mix

S.No. Description Trial-t,

| | 348

| T-days Compressive - 32.0

\ Strength, (Nimm’) OS

| 34.6

Average, (Nimm?) 34.4

28-days Compressive

5 Strength, (Nimm?) “Results Awaited

| Average, (Nim) | :

( T

Chee hue yee ye

1 Wot: wane floc « CIN -U7>GaHb2<06PTCOTD

eohaig esi

Test & Research Centre Pvt. Ltd.

Quatity first & forever

LR No: KTRC/2201003201 (A), Page: 1 of 1

KTRCIFIO708/0%

TEST REPORT

Taboratary Reference Number ]

Name and Address of Customer Ore

MPMRCL pect Reet

Indore-Metro Rail Project Conaltion, When Reseived

Yellow Line Package IN 03 lasting When tcaivon

Quantity Received (Approx.)

Contact Person Name ;

Date of Start of Test

Sample Identification: Water Permeability of Bate ofCompletion of Test |

(M-38) Grade Concrete | Date of Reporting

14.02.2022

Customer Reference: Letter Dated: 29.12.2021

Sample Particulars : Water Permeebilily Test of (M-38) Grade Concrete

TEST RESULTS.

] Requirement as

TEST per MORTH 5!

| METHOD | — Revision,

|

T

S.No. | PARAMETER UNIT RESULTS

| casse irs

| Water Permeabiity at § bar pressure for 72 |

4 hous, mm "

Determination of depth of water penetration |

tls Ct Pes

Ercastiish Pawar 7

Manuger (BI) & Authorized Signatory

Quatity first & forever

Test & Research Centre Pvt. Ltd.

LR No.: KTRC/2201003201 (8), Page: 1 of 1

KTRCIQF/0708/01

TEST REPORT

Name and Address of Customer

MPMRCL

Indore-Metro Rail Project

Yellow Line Package IN 02

Contact Person Name :

Sample Identification: Chjoride & S

Content of (M-35) Grade Concrete

Customer Reference: Letter Dated: 29.12.2021

Sample Particulars : Chloride & Sulphate Content Test of (M-35) Grade Concrete |

Laboratory Reference Number

oo

Date of Receipt

Condition, When Received

Packing, When Received

Quantity Received (Approx.)

Date of Start of Test

Date of Completion of Test

Date of Reporting

TEST RESULTS:

] REQUIREMENT

T T

eres | o} oom | | vouoe

rd (Part =124)- 2018 | Peed

2 | sulphate, Sos % 032 | ome

“*End of Report **

re gs

si tg

Manager (Chemical)

Authorized Signatory

2100 Wim -¥1 fo.ub!s

sien

[pve poesy =

ahs DATE hs. z

LIS. ZBI T |

v

se-v9s90 =593 | 2989 «529 =s0

(,wo/34) ww) |

‘dulo) aan

wajennba | peize109 jo 11s duos i

3105 aiai5uoD WaLIED Sqn aT (n.3e07 on's

WeW)=A Tw

ae tua na = aunen [OS IES

= saamoney | wo emgey usin | ung

: SS=H peo

2Z)-a0/ $e Sunset jo area ‘ea/eel] 16 ‘Bunse9 jo ayeq

Ze peo ge 0 sobLiai ONY

“S| ows PR

wo | Agpanss) pa. 6S6T-9TS'SI

wazioro aaa 4a¥OD 8 3GND FL3YINOD LNIW3D

4O HLONYLS 3AISSNdINOD

08-90/W9/41/¥L¥ "ON W054

2100 Yum 31 fo ubis

sueway

aaeraAy

Lo €

T

THOT a

s2"t4599 =503 | s2°t*59 -s92

A (wuss) {,w9/By) as

dorm= | wopeqny | wo qn

0 | wojeanba | ruajenndy

310) 838/9U05 waa) 290) 318903 UIT | 17) peor | ( ONS

(Hx) =A v

wo no c pwpsy | OxO*DTE=¥

- = auinjon fw BEETS eayy cay

: =.afHoney | w: 135 wis (p} wig KO)

sopn oney | wa mmngry sullen 6 “

. a —

v5 STW ape19 PPO Gries,

1 92)79/77 © Buna jomea a7 a3[r0fiz Buyse3.jo a1eq UD by: 28e sano duy

‘sea, SQLILTI ony SELLE: (sheq) ay

We ons bal dy

wo | abana 6S6T°9TS's|

vozouto | seq ans] 28028 38ND aLaYONOD INIWID

4O HLONAYLS FAISSIUdWOD

ov-s0/wa/si/o4in | “on yeuoy

Quatity first & forever

LRNO. KTRCI2112001430, Page 1 of 2

KTRCIQF/O708/01

TEST REPORT

LR:TC783222000000530F ee

Name and Aatdrase of Customor [Laboratory Reforonce Number (RN). | :| KTRCTT20048

| MPNIRCL | Date of Receipt [30122021

| Indore-Metro Rail Project [ Condition, When Re Satisfactory

Yellow Line Package IN 02 & IN 03 [Pac ecei

Packing, When Packed

Contact Person Name : “Quantity Received (Approx): 50 -

Eb _ Date of Start of Test [p[si.12.3007

| Sample Tdentification : Cement OPC §3 [Date of Com plotion of Test | 28.01.2028

“Date of Reporting = [02.02.2022

Customer Reference : Lelier Dated 29 12'2021

| Sample Particulars : Ordinary Portland Cement 53 Grade, Source : UNvaiech

TEST RESULTS:-

()) PHYSICAL TESTS

S.NO. | PARAMETER” [UNIT RESULTS | TEST | SPECIFICATION

| METHOD AS PER

1 1s 269: 2015

1 | Consstaney = 270 | 18 4031 (Bari4 yee :

2] Specte gravy [F815 is aot grant 11) 1086) ———

3 l Fineness FG 302 TS 4031 (Peri 2): 1999 Min. 225

| Permeability Method) jo a

8yLe Chatetier Method — 1s 4031 (Part 3) Wax

By Auciove j [ec 08

‘Setting Time

| 184031 (Parts): 1988 [Win 30 —]

| Max. 606,

, Compressive Strengih ] i i

[Zein 5 4081 (Port a 7

Be |) [468229 ——— Mpa [492 | $4031 (Part 6): 1988 -—— 77 |

(2) erase i MPa | ~eat i Min. 33 ——}

vi Ruby S.tahotra

Quality Manager 8 Authorized Signatory \

Sm) ol a yo sees poi, 2 Te cea ae ied prams is Rept asunder ero

coerce etenené cen, 4 Sone iii tobe sonzenegandis do ntesaunng tea 3. Sangm atte saves ais vethhine theater een one

Cinvnte esos ene co ca be roses a noe sen a oa

Test & Research Centre Pvt. Ltd.

Quality tirst & forever

LRNO. KTRCI2112001430, Page 2 of 2

(ll) CHEMICAL TESTS:

[S.No PARAMETER | UNIT RESULTS TEST T ‘SPECIFICATION }

ie

Saree

_|eeage 7 _|

er

om |

5 ‘Total Sulphur Content Calculated % by 304 IS 4032 : 1985,

Hea — aah

7 a

| mass 0.05 (For Prestressed

- | a

|b) Potassium Oxide (KeO} % —_ 1

Ae Ruby S.Mathotra

Quali} tipager & Authorized Signatory

y

a

8

Plot No, 141 C, Electronic Complex, Pardoshipuse, at LT3bdTET3 ooh, usd, a0

Email; contacte@ailtech.net, electronics @kailtach.net g Web : wirw-halloch.nat ¢ CIN - Ts tuulaPZanceTCO: 9008

Torms of Service

rer stores

2: Semple nat re by sped 2 The esa ts ihe et Report forthe stmtag trp on tsps 3 The pat eon

tccentnae ofourtemsonscnciens& Sample sip tobe consumed andor destcted dng sing 5 Sop be dione ofr one mre dat ate

race pce ond cated az 6. Tha Repo comet be proc ear canat bx edn ofan ny nb, verse nw? of 0 ako

Quality first & forever

LRNO.KTRC/2112001030, Page 1 of 2

KTRCIQE/0708/01

TEST REPORT

___ULR: 7¢783222000000526F - - _

Name and Address of Customer Laboratory Reference Number (LRN) | = | KTRGI2112001030

MPMRCL Date of Receipt 30.12.2027 |

Indore-Metro Rail Project, Condition, When Received [= [Satisfactory

Yellow Line Package IN 02 & IN 03 Packing, When Received [Packed

Contact Person Name : [Quantity Received (Approx) 72 kg. -

- Date of Start of Test 31.12.2021

| Sample identification : Fly Ash Date of Completion OF Test 29.01.2022

Date of Reporting [02.02.2022

| customer Reference Coir Dated 29.12 2021

‘Sample Particulars : Fly Ash, Source : Shri Singhaji, Thermal Power Plant -

TEST RESULTS:-

(I) PHYSICALTESTS

SNO. | PARAMETER | unit) RESULTS TEST

| METHOD

“i Speaite araviy NisraT 967

rp wriess-Specife Surace By mi ister 967 7 —

[2 | tines Petmeanaty ethos |

| 3 Particle Retained on 45 Micron [a

IS Sieve (Wet Sioving)

| ine Reaciviy Nw?

| | Average Compressive Strength \

S| Compressive Strength at 28 days —[-F — —

| 2) | Compressive Stengin of Cement | Ninn | aa | 1S 47a 367 | —

b) 1S 1727 7967 | Not lass than 60 percent |

| ofthe sirenath of

corresponding pain

| | Zee

6 | Soundness By Autoclave Test | % 0.05 18 1727 1967 ‘Wax. 0.8

* Fly ash of fineness 250 m#lkg Min, is elso permitied to be used in manulaciure of Portland Pozzolana cement by

a

Ae

( :

My Ruby Malhotra :

ual Marager& Authorised Signatory

3

Test & Research Centre Pvt. Ltd.

Quality first & forever

LRNO.KTRCI2112001030, Page 2 of 2

(il) CHEMICAL TESTS

:NO. | PARAMETER UNIT RESULTS [TEST WETHOD SPECIFICATION |

| | AS PER !

| neers

| "SICEOUS "CALCAREOUS |

1 Seon Bisse (SIOm Pus By Mass | SLB — 1s 77B7N05 wn. 70 Min 85 — |

| ‘Aluminium Oxide (A205)

Pius Fon Oxide (F205) | |

Sieon Dixkle (S103) By Mase | BOSE) 18-1727 ee — we in

Rasaweats ——| wejnas| —2rar—|-—aace |e |e —|

[Mevesion ie USOT | 6 BYNaE REE | is TAT” 80 | aso

Tam Suber Spi By Maes" | —aR 15 rar i867 | — Nak 30] Wax 30 |

|_| rroxite (805) -

© | Avaliable Alvalios As % By Mass | ——¥ “Annet Max tS) Wax TS |

| Equivalent Sodium Oxide

{ (Nax0) I _ _

7 ¥ Total Chiorides | %8y Mass ‘0.038 1S 40827 1985 Max.0.05 Max. 0.08 |

8 [Toss on ignition ‘%By Mass | O26" I 1S 173777067 | ‘Max. 5.0, | Max. 5.0, i

"Tes under proces, report shai be submited separately a -

“End of Report™

Se a po

ve

Ee Ruby S.stathotra

Quality Mancber & Authorized Signatory

sn|s0 901; 201s cared Laboreoy

Lines), oasis, 4948008

sch get @ CIN -UYS1@0MPZUDEPTCO19006

Plot No, 141 6. Electronic Complex, Pardeshipura, Indore -452010 iNDsA} Ps

Email: contact@kailech net, sleetronicsiDkar 9 Wee wy it

Farms of Senview,

4: Some ot rn ya is eli 2 te rests ted nthe Tet Mapa rf Ne bite amps ese prt. 2. Abts ined later eure

“uence of tr ondcoins 4 Samp sti abt canard estate tig tao 3, ldo one wth ome ofaosed Catekon ec

hare sc ancy ux Tas eer enn be erence ror cab ssn a al hy re, wes peony nivening obaof ce acon

Mitebttieimecd ovat nl poenetohswihLR art andor ou NAL 8 AV ape et standf iscsi tndeheny

Quality first & torever

URN. KTRC/2112001428/1, Page 1 of 2

KTRCIQFIO708/04

TEST REPORT

___ULR: To783222000000308F _ — _ — -

“Name and Address of Customer Taborstory Reference Number (LRN) |: | KTRC/21 12000426"

MPMRCL Date of Receipt [25.12.2021

Indore-Metro Rail Project [Condition, When Recewed | | Saiisfactory —

Yeliow Line Package IN 02 & IN 03 | Packed

Contact Person Name tty Received (Approx) Ths a0 i _

___ [Bato of Startof Test | | 27.12.2021 -

_ Sample Identification ; Coarse Aggregate | Date of Completion of Test 20.01.2022

20mm Date of Reporting — =) 31.01.2022

Customer Reference =

TEST RESULTS:

(I) PHYSICAL TESTS

“Size nd Grading ot

Aagregotes™

Faas nor

{Banga ne

‘Conrad Fakoade ad

4 Bengation index

5 Spree Ge c=

$i Abeer Va —|

uk Darl

7 | Rood

tose f

3 | egesse Costing Vabe® |)

| Aerts cl Vater %

|

| 2

a

Agree Abrasion Valle —%

| (Coe Angeles macrino)

[:

Ls

“Foie Conant

Cualy Mane & Authored Signatory (

‘otter Date 22.12.2021 & Email Dated 31.01 2022

‘Sample Particulars : Coarse Aggregate - 20 mmn, Source : BR Slone Quarry at Pithampur

| see 7 —%

Designation

| TEST WETHOD

RESULTS

Possing

(ano) 1s zasae 1) 1983

S205 3) 1963 a

18 208518 3): 1963)

ey arwce

EERSTE ATES]

SHPO]

TSAR 4) 186 |

| 18 2386 ay: F069

KTRGISOPIO8

a0

‘Te test was wieéced by hr Fraz Khan, Ganeral Consul MPAICL. Indore

Test & Research Centre Pvt, itd,

Test & Research Centre Pvt, Ltd.

Quality first & forever

LRN. KTRC/2112001425/1, Page 2 of 2

(l)) CHEMICAL TESTS

i aay PARAMETER UNIT) RESULTS “| TesT wETHOS 7

a 082) ae 2.00

O_o zane 2) t968 | 40

a % 90 18 Zant 2) 1969 =

alenal Fear Than 75: % 9215 23004 1): 1989 Max. 1.00

L IB Sieve .

_Atcl Aggreaate Reacion ——

‘eset War

Barmeitos

p47 S787): 0558

15.383" 2048 hese than 0109 = nnoscus

‘More than 0.20 = Poeriisayaeetrious

“etwgon0 10 end 020% = Innocieus &

Ai Govtetcas fod peccmarce

‘Sodium Supine — 132386(° 5): 1962 | (lars Oye) M2

L Nnnesiu Sulphate 85, L ‘ater § Gye = Max.18

Note -This supersedes our earlier report no. KTRC 72112001405 issued on 22.07.2022. Amendment ie

done in customer Name. No change in previous reported results.

“End of Roport™™

i

|) be Ruby s.ttahotra (

ual iepager 8 Autorzed Signatory

hn |s0003: 20 cartes taro

Plot No. 141 C, Blactronic Gomplex, Perdeshipura, iviore - 452040 INDIA} Ph 481-791-4787565 jt Lines), ADAGOSS. anesnss

Email: cantact@kaiitech 92, leetronics@akalterin nek g Webs wen ular nat g id 0s 2908

Terms of Service

4. Soi at on Ba espe 2. Te rat tine es: Roi ret ibe so ony er eniomare

eran fo termsond cad 4, Some tbe ceased andr dated tesg 5 sone wilde oped rane mab em ted fsa ots ores

sree speed and eepted wT Report be eos an cant te ed mp finan mia, ees permed sung 7 Leen ofou ooking

‘iedcotieinicedonounton: 3 Repost grenthMRarenotndercurfABL opt 3 Alpe sero] he course nese sok

Test & Research Centre Pvt. Ltd.

Quality tirst & forever

LRN. KTRC/211201328/1, Page 1 of 2

KTRC/QFIO708/01,

TEST REPORT

ULR: 1¢783222000000307F

[Name and Address of Customer Laboratory Reforonse Number || KTRCTRVT200TS257

| MPMIRCL Len) z| |

Indore-Metro Rail Project ‘Date of Receipt 2 | 512-2001

| Yellow Line Package IN 02 & IN 03 |

Contact Person Name : |

Quantity Received (Approx) SI

_ [Date of Start of Test - [2at2 2027

Sample Identification : Coarse Aggregate Date of Completion of Test [-# [20.01.2022

10mm Date of Reporting |: [3torz02

Customer Reference : Leller Date 22.12.2021 & Email Oated 31 012022 _

[Sample Particulars : Coarse Aggregate - 10 mm, Source : BR Stone Quarry at Bihampar J

TEST RESULT:

(I) PHYSICAL TESTS

“SH PARAMETER oar RESULTS —] Tes METHOD SPECICATION

AS PER

- - wae |

1) Saad craig or >see 7% -

Fagegats Designaen | Passing

| [125 1a] 1s ance 1: 1063

io] ae

as Ti

_ | 238 [35

7 Rawese wae i 7 SR aes

3 [Eongston no % 165 | 18 zane 1) 4983,

Combined kines wd |e uz TS 2388" 1) 135

+ | Ehogaton exe | | |

sl = - 20 SOUP I as ~

5 bens Vos az aes TS 236603) ot -

7 — 1s 238613): 1969,

7 - sa

[3 | Aanrepate wana vane | —% Teepe Ra

| Ssnbeageit ewig eras

TO | Rearegala Aoason Value | —% ar 1

{las Angeles machine)

(ieee % om ~ RTRC ISPD |

“The test was winessed By Wr, Faz Khan, General Caneultanl MPMCL. Indore

a we

Wigs. ruby smatnona

Quality Manager & kutnorzed Signatory

Test & Research Centre Put. Ltd.

Quality first & forever

LRN, KTRC/211201328/1, Page 2 of 2

(l)) CHEMICAL TESTS

‘S.No, | PARAMETER: uniT [RESULTS | TEST METHOD "SPECIFICATION

‘SPER

| L ws: 20%6 |

+ | ebinaas iors 1) Mex 200

si Goaratigne 5 _| i$ zaee 7: vas ox 00, =

ate — ‘3.0 [18 29002): 1963 Sox 1.00

a! es an TE Micon 052 (Sees | 1963 ‘Mex -00"

2 tage Raaaion _ - |

a cert Morar * 008 — | SERRA; 608 | iparcen /

Screed | A88he ane tess hone

| sure 90

utweur0ond020

- eae pay

3 | Seas = j

Solin Sham | 8 Js is 23055): 1989 aca owe Maz

_| eqns Saigrae 1 “37 (ater Shee M16

Note -This supersedes our eaier report no. KTRC 2112001328 issued on 22.01.2022. Amendinent Is

done in customer Name, No change in previous reported results

os oe “end of Repor™

per

Ruby S.Mathotra

(Quality ttanager & Authorized Signatory

Plot Ma, 141 G, Electronic Compl, Pardoshiurs,

Email; contact@kailtech net, slectronios katte

Torms of Service

4. Samples) ot ron ya ons specie, 2. Te ress ited nthe Ret part for the be amples and tested rots ny. 3. This Rapa sued otf cuter

ccetanc of cures an coins Samples ay to beconamedandfr cesta uring tetng 5 Sample be dose fe ne mart fred sure Test hepa ness

‘shen sat odd oT rp ct bert rr ote ei parvo a weary wring 7 bby fr kee

ior ABUT AMA PH <9°-791

waedsealont mat @ HAN = 3b ReP 2m

7596 130 Linus) 406655, 9989055

toils

et @

Test & Research Centre Pvt. Ltd.

Quality first & forever

To.7832

URN. KTRC/2112000725/1, Page 1 of 2

KTRCIQFIO708/04

TEST REPORT

ULR: TC783222000000301F a eet:

"Name and Address of Customer Laboratory Reference Number KTRCI2112000725/1

MPMRCL (LRN) |

Indore-Metro Rail Project Date of Receipt 25.12.2021

Yellow Line Package IN 02 & IN 03 Condition, When Rect — i

| Contact Person Name :

Packing, When Rec

| Quantity Received (Approx) o |

| Date of Start of Test : 27422001

‘Sample [dentifcation : Fine Aggregate Date of Completion of Test 49.03.2022

(i-Sang) [Date of Reporting : = [31.01 2022

Customer Reference

Letter Date = 23.12.2027 & Email Dated 31.01.2002

Sample Particulars :

ing Aggregate (M-Sand), Source : Maa Narmatna - a

TEST RESULTS:

(l) PHYSICAL TESTS

[SNe PARAMETER ONT RESULTS TEST METHOD ~ SPECIFICATION —

} AS PER

t 1s 383 2016

1 | Sa ana Gaara of S See % | erties Fine Aaregaie—— }

ageegates” Designation | Passing

10 ao} 208696 1): 1969

a7 103

239 380

118 438

ae00— | — so.

2.300 72

0180 35

Zone i _|

7 Saat Gam an SRE Teas 7

3. | Wiser Absorpion Vat « 27 15 2386(F3) 1969 ==

| Buirrmo fine aggregate® | ‘0s 1S 236613) 1985.

5

[Buk Densiy™ - — —

odds rai J} ts 2006 9-198 »

Leoee Te -

t tis Ca iE 27 IRCBUISORNS

“The test was wiinessed by Wr, Froz Khan, General Consultant MPMIRCL. Indore

we

ww qs

7 by S.Mathotra 7 Age

Quality Manager & Authorized Signatory f ie

er

er

ie Complex, Pardashipura, Indere 82010 (DIA) Ph +9

Test & Research Centre Pvt, Ltd.

LRN. KTRCI211200072511, Page 2 of 2

(ll) CHEMICAL TESTS

[ S.No. PARAMETER ‘UNIT | RESULTS TEST METHOD “SPECIFICATION |

AS PER

isan 7016

1 [Tait at paranages ofa Dateereus |] —<0aT Wer 200 |

Moterals (Excluding mica). } = =

[cesta tania =| ao eas Pes Tae 10O

[Tey Lams % [eos 2396 (Pa) 96 jax 100

«s) | Matera ner Than 7& Meron S Seve —% | 148] 182386 (4): 1003 vor so

| Tea organ porto | Agent [15 206 a-163 | “Sanat cone Paral ganic prion —|

“a ies Content % [oF IRGISOPTO. | vhetrateg Br werum cami, 157

} | pment ana soanon foment uterine

Thie wounjectto it assinaus mast eicg |

[2 kai Aggregate Reaction -

i) accleraed Morar [oe BET ETE eipanaton

Bermehod i909. 2018 bess nano "0% Innocuous

“Benean 010 3nd 0.20 % = Innacvous &

_| | sdeletetow nfo pefeonarce

[3 sears 7 — : — — =}

i) Soxum supa a0 (er SCyo Ma

Eee % Gag ——]_15 2888" 5): 1968 eS

‘Note -This supersedes ur earier report no. KTRC 21 12000725 issued on 23.01 2020 Amendment is

done in customer Name. No change in previous reported results.

“End of Report™

woe

er nun sans

Quality mhnager & Authorized Signatory

a

mall: coniaceBatiocn st allech.net g Wet mete ks

exms at Service

ceesance af one terms coodions A. Sanpete consumed ond est

citee Put, Led.

Quality first & forever

Page No. 1/4

ATRCIQF/O708I01

TEST REPORT

ULR: 7¢783222000000528F

| Name and Address of Custom Laboratory Reference Number KTRCI2112001230

MPMRCL (LRN)

Indore-Metro Rail Project, [Date of Receipt | = | 30182001

i

Yellow Line Package IN 02 & IN 03 in, When Received Selisfactory

| Contact Person Name : ——

‘Quantity Receives (Approx) |: | SLir

3

2022

‘Sample ldentieation : Admidure rc 27.01.2022 |

oe [Date of Reporting = | 02022022 |

Customer Reference Letter Dated 20122021, SSS

[‘Sampte Particulars : Admixture, Source : Fosros (Auraran 250) - |

TEST RESULTS:-

| SNO. | PARAMETER” [UNIT | RESULTS | "TEST METHOD -SPEciricarion

‘pH - 65 ‘Annex. €- 5

2] Ghiorde fon Content) | gota] 18 6925: 1973 | Witin 10 pereant of he value

| cor within 02 percent wichever

| 'S greater as stated by ne

manufacturer

| | | eetared = 1020

[Ran Content % By 228 Banax E-2 O.ssTeACet.05T

= Mass _| |

4 | By Watenal Content —|—% by | 2.58 ‘annex. €-1 0957 SDC <1.05T

| meen | Maat | | Desired 23 25

Ss Relative Density 110° ‘Annex. €-3 ‘Within 0.02 of the value stated

by te menutactrer

a _ Declared =1 083

Abbievaton

+ T-Manufacturer’s stated valve

+ AC Test Result

“End of Report™*

ii

Ye uy sainoea

uaity Manager 8: Authorize Signatory

Survica

2. Sarel ot row by est speed 2. Th et tothe Yet Report fre si

coors fortes and condor Sane Reta ecneredentor cere dag eng 8 oat ashe

erie eed on nf, Tn co ered in nbc nae. ieee

snp ond ested parameters ony 2. The apo eon afte eames

rant func ae

Test & Research Centre Pvt. Ltd.

Quality first & torever

To-7e02

Page No. tit

KTREIOFIO7OBIO1

TEST REPORT

ULR: 16783224000005757F

Laboratory Reference Number] > | KTRCBIY

Name and Address of Customer (LRN) mor emia

MPMRCL [Date of Recoist = [02 202% |

Indore-Meto Rail Project Condition, When Received Salisfaciony

Yellow Line Package IN 02 & IN 03 | Packing, When Received Packed

Contact Person Name | Quantity Received (Approx) 2u

Jate of Start Test _ 30.12.2021

Sample Identification : Water Date of Completion of Tost 31.12.2021

Date of Reporting F307 2022

| Customer Reference : Letier Date | 29.12.2021 & Email dated 31.01 2097 ~

Sample Particulars : Water. Source : URC Casing Yard Well Pont

TEST RESULT:

5. NO. PARAMETER UNIT] RESULTS | TEST METHOD SPECIFICATION

AS PER

1 486 2000

1 PH 77 1S 3025 (P 11) - 1983 More than6.0

2 | chonde (cy mgt 208m 1S 3025 (P 32) 1568 Max. 2000,

3] Supnate ($03) imgi [851] 18 3005 (P29): 1866 ‘ax 400 |

7 Pirorganie mgh_[ e740 | 15 3005 (P18) 1068 Bax, 3000

Ss ‘Organic - mgit 357.0 1S 3025 (P 18): 1984 ‘Max. 200

6 ‘Suspended matter moi | 630 1S 3025 (P17) 1964 ‘Max. 2000

7 —[o neutralize 100 mi Sample ot] — ml 30S 3025 PZ] 9B Max

water by 0.02 normal NaOH,

Using Phenolphthaiein as an

Indicator.

3] To neutaize 100m Semple of | a BO} 1S 3025 P23). 1088 Wan

wate 0.02 Normal HsS0u, Using

€ Moved ndeator

‘Note -This supersedes our earlier report no. KTRC /2112002130 issued on 31.12.2021. Amendment is

done in custorier Name & sample particulars. No change in previous reported results,

“End of Report”

Manager (Chemit

Plot No. 141 C, Electronic Complex, Pardeshipura, Indore - 452010 (INDIA) Ph, +91-731-4787555 (20 Lines), 4046055, 4048085

Email: contact@xaiitech.net,electronics@kailtech,net ¢ Wed : www.kalltech.net » CIN - U73100MP2006PTCO19006

Terms of Service

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Contractor Certificates VibrationDocument2 pagesContractor Certificates VibrationAnup PandeyNo ratings yet

- LAA 421 C0U 1400033 A - Methodology For Vibration Mitigation in Corridor 1&2Document26 pagesLAA 421 C0U 1400033 A - Methodology For Vibration Mitigation in Corridor 1&2Anup Pandey100% (1)

- 332 Submission of Geotechnical Report For Test Pile at Super Corridor Station-5 Package IN-03Document16 pages332 Submission of Geotechnical Report For Test Pile at Super Corridor Station-5 Package IN-03Anup PandeyNo ratings yet

- 342 Method Statement For Construction of OpenRaft FoundationDocument52 pages342 Method Statement For Construction of OpenRaft FoundationAnup PandeyNo ratings yet

- InteriorDocument18 pagesInteriorAnup PandeyNo ratings yet

- Pandro LDocument35 pagesPandro LAnup PandeyNo ratings yet

- Rail StckingDocument1 pageRail StckingAnup PandeyNo ratings yet

- Work AreasDocument1 pageWork AreasAnup PandeyNo ratings yet

- Inst Code Institute Name BR Code Branch Name Seat Pool VacancyDocument1 pageInst Code Institute Name BR Code Branch Name Seat Pool VacancyAnup PandeyNo ratings yet

- Inst Code Institute Name BR Code Branch Name Seat Pool VacancyDocument1 pageInst Code Institute Name BR Code Branch Name Seat Pool VacancyAnup PandeyNo ratings yet

- Inst Code Institute Name BR Code Branch Name Seat Pool VacancyDocument3 pagesInst Code Institute Name BR Code Branch Name Seat Pool VacancyAnup PandeyNo ratings yet

- 5Document1 page5Anup PandeyNo ratings yet

- Inst Code Institute Name BR Code Branch Name Seat Pool VacancyDocument1 pageInst Code Institute Name BR Code Branch Name Seat Pool VacancyAnup PandeyNo ratings yet

- M-AJT2-000000-CR00-MSS-000001 - 003 Method Statement For Plinth Work On ViaductDocument160 pagesM-AJT2-000000-CR00-MSS-000001 - 003 Method Statement For Plinth Work On ViaductAnup PandeyNo ratings yet