Professional Documents

Culture Documents

Daimler MBN 10324 10-09 Eng

Uploaded by

gültekin gökOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Daimler MBN 10324 10-09 Eng

Uploaded by

gültekin gökCopyright:

Available Formats

October 2009

Mercedes-Benz

MBN

Rivet nuts 10 324

Supersedes

Observe list of approved suppliers edition: 2009-06

Date of translation: 2009-10

Dimensions in mm

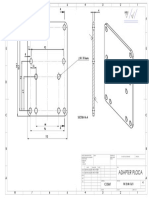

1. Dimensions, designation

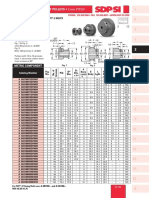

1.1 Rivet nuts type RSN

Schnitt

Section A - B

B

66 bis

to 88ribs, spread

Rippen evenly ig

gleichmäß l1

A around the circumference

am Umfang verteilt l3 l2

d4

d2

d1

d3

B

h min.

Fig. 1

Table 1

7/16-20

M12x1,5

UNF-2B 2)

Thread (d1)

M5 M6 M8 M10 M12

P 1) 0,8 1,0 1,25 1,5 1,75

d2 – 0,5 13,0 13,0 16,0 19,3 23,0

d3 ± 0,15 6,8 6,8 8,8 12,0 13,6

d4 ± 0,2 9,0 9,0 11,5 14,8 16,1

l1 ± 0,4 8,3 9,0 11,5 14,1 16,0

(l2) 3,5 3,5 4,0 4,5 4,5

l3 ± 0,2 4,8 5,5 7,5 9,6 11,5

hmin. 4,3 4,8 6,44 8,04 10,37

Weight kg 0,005 0,005 0,010 0,017 0,030

1)

P = pitch of the coarse thread

2)

After ANSI B1.1; only for the attachment of seat belts.

Designation: according to type, thread d1, material and surface protection, e.g.

Rivet nut MBN 10324 – RSN M6 – 8 DBL8451.76

Continued on pages 2 to 13

Issued by: Daimler AG Technical responsibility (name): Varga

70546 Stuttgart Department: GR/PQS Plant: 019

Standard (GR/PQS) Telephone: +49(0)711 17-3 35 80 HPC: D652

Confidential! All rights reserved. Distribution or reproduction without written agreement by Daimler AG prohibited.

Unkontrollierte Kopie bei AusdruckContractors may only receive

(: Christin Poleska,standards2009-11-30)

through the responsible purchasing department.

Page 2

MBN 10 324 : October 2009

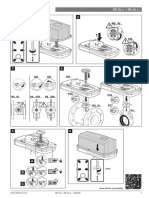

1.2 Rivet nuts type RND

Schnitt A -AB- B

Section

6 to 8 ribs, spread evenly

6around

bis 8 Rippen gleichmäßig

the circumference l2

A am Umfang verteilt

l3

h min.

d5

d2

d1

d4

d3

Gewindeprüfun

Thread test g

B

l1

Fig. 2

Table 2

7/16-20

M12x1,5

UNF-2B 2)

Thread (d1)

M5 M6 M8 M10 M12

P 1) 0,8 1,0 1,25 1,5 1,75

d2 ± 0,2 9,7 9,7 12,8 15,0 16,1

d3 ± 0,15 7,6 7,6 9,6 11,6 13,6

d4 ± 0,2 9,7 9,7 12,8 15,0 16,1

d5 – 0,5 16,0 16,0 21,0 26,0 28,0

l1 ± 0,4 10,5 10,5 12,5 15,0 17,0

l2 ± 0,4 7,5 7,5 9,0 11,2 13,0

l3 ± 0,2 3,5 3,5 4,6 5,7 7,2

hmin. 4,9 4,9 6,44 8,04 10,37

N ribs 6 6 6 8 8

Weight kg 0,006 0,006 0,014 0,024 0,032

1)

pitch of the coarse thread

2)

After ANSI B1.1; only for the attachment of seat belts.

Designation: according to type, thread d1, material and surface protection, e.g.

Rivet nut MBN 10324 – RND M6 – 8 DBL8451.76

Unkontrollierte Kopie bei Ausdruck (: Christin Poleska, 2009-11-30)

Page 3

MBN 10 324 : October 2009

2. Technical Delivery Conditions

Table 3

Material Steel

General International

DIN ISO 8992

requirements standard

Tolerance 6G for bright nuts/6H for nuts with surface protection

Thread

International

standards DIN ISO 724, DIN ISO 965-2

Property class 8 or 10

Mechanical

properties

Style decisive for

Coarse pitch thread Style 1

mechanical properties

Limit deviations Product grade A

and geometrical

tolerances International

DIN ISO 4759-1

standards

Requirements for surface protection in accordance with DBL.

Finish

Limits for surface discontinuities are covered in DIN EN ISO 6157-2.

Acceptability For acceptance testing, DIN ISO 3269 and MBN 10365 shall apply.

3. Application note

The installation geometry and the preparation and layout of the sheet metal part are independent of the

material.

Agreement with the Fastener Representative (VTB) must be sought.

4. Feature list

For nuts in accordance with this Standard, Feature List MBN 4000-161-5 applies.

5. Change

- In table 1 and table 2 footnote 2) added.

Unkontrollierte Kopie bei Ausdruck (: Christin Poleska, 2009-11-30)

Page 4

MBN 10 324 : October 2009

Annex A (informative)

Information provided by company PROFIL

A.1 Minimum edge and spacing dimensions

Rivet nut RND

Limits of sizes, edge dimensions and nut spacing

H max.

H max.

H max.

ØD ØD ØD

Ymin. Ymin. Ymin. Ymin.

100°

Application example

The metal sheet quality shall conform at least to the

technical delivery conditions and quality standards

for Fe P04 (cold-rolled) in accordance with EN 10

130.

The spacing dimensions apply to all metal sheet

thicknesses. The minimum dimensions can only

be achieved in conjunction with special pierce

heads.

If the spacing limits are not reached, please

contact PROFIL.

06 08 10 12

Nut RND

Y min. 10 12,5 15 16

H max.

H max. 60 58 53 55

ØD 16 21 26 28

Ymin.

Unkontrollierte Kopie bei Ausdruck (: Christin Poleska, 2009-11-30)

Page 5

MBN 10 324 : October 2009

Rivet nut RND

Limits of sizes, edge dimensions and nut spacing

ØD

Nut RND 06 08 10 12

X1 min.

38 45 55 60

(Double pierce head)

X2 min.

58,5 65,5

(Single pierce head)

X min. 1, 2, 3

X3 min.

17 22 27 29

(Nut in two stages)

ØD 16 21 26 28

The spacing limits apply to pierce heads for the

processing of the pierce and rivet nut RND with thread

sizes M5 – M12. The spacing dimensions apply to all

metal sheet thicknesses. The minimum dimensions can

only be achieved in conjunction with special pierce

heads and possibly only by introducing the nuts in two

separate working processes.

If the spacing limits are not reached, please contact

PROFIL.

Riveting in one tool stage Riveting in two tool stages

with double pierce head

Feed ≥ X2

X1 min.

X3 min.

2nd tool stage

with single pierce

X2 min.

1st tool stage

Unkontrollierte Kopie bei Ausdruck (: Christin Poleska, 2009-11-30)

Page 6

MBN 10 324 : October 2009

Rivet nut RND

Limits of sizes, edge dimensions and nut spacing

H max.

The spacing dimensions apply to all metal sheet

thicknesses.

ØD If a further reduction of the dimensional limits is

required, please contact PROFIL.

Ymin.

Only for feed direction

perpendicular to sheet wall

Application example

The spacing limits apply to pierce heads for the

processing of the pierce and rivet nut RND with

thread sizes M5 – M12.

If the spacing limits are not reached, please

contact PROFIL.

Also refer to PN-RS 03.1

06 08 10 12

Nut RND

Y min. 22 25 27,5 28,5

H max. 140 145 150 152

ØD 16 21 26 28

Unkontrollierte Kopie bei Ausdruck (: Christin Poleska, 2009-11-30)

Page 7

MBN 10 324 : October 2009

Rivet nut RSN

Limits of sizes, edge dimensions and nut

spacing

H max.

H max.

ØD ØD

H max.

ØD

Ymin. Ymin. Ymin. Ymin.

Application example

The metal sheet quality shall conform at least to the

technical delivery conditions and quality standards in

accordance with EN 10 130.

The spacing dimensions apply to all metal sheet

thicknesses. The minimum dimensions can only be

achieved in conjunction with special pierce heads.

If the spacing limits are not reached, please contact

PROFIL.

Also refer to PN-RS 03.1

06 08 10 12 14

Nut RSN

H max.

Y min. 8,5 10 13,5 15 18

H max. 59 57 55

ØD 13 16 19,3 23 26

Ymin.

Unkontrollierte Kopie bei Ausdruck (: Christin Poleska, 2009-11-30)

Page 8

MBN 10 324 : October 2009

Rivet nut RSN

Limits of sizes, edge dimensions and nut

spacing

ØD

Nut RSN 06 08 10 12 14

X1 min.

40 45 50

(Double pierce head)

X2 min.

58,5 63

X min. 1, 2, 3

(Single pierce head)

X3 min.

14 17 20,3 24 30

(Nut in two stages)

ØD 13 16 19,3 23 26

The spacing limits apply to pierce heads for the

processing of the rivet nut RSN with thread sizes M5 –

M14. The spacing dimensions apply to all metal sheet

thicknesses. The minimum dimensions can only be

achieved in conjunction with special pierce heads and

possibly only by introducing the nuts in two separate

working processes.

If the spacing limits are not reached, please contact

PROFIL.

Riveting in one tool stage Riveting in two tool stages

with double pierce

Feed ≥ X2

X1 min.

X3 min.

2nd tool stage

with single pierce

X2 min.

1st tool stage

Unkontrollierte Kopie bei Ausdruck (: Christin Poleska, 2009-11-30)

Page 9

MBN 10 324 : October 2009

Rivet nut RSN

Limits of sizes, edge dimensions and nut

spacing

H max.

The spacing dimensions apply to all metal sheet

ØD thicknesses.

If a further reduction of the dimensional limits is

required, please contact PROFIL.

Ymin.

Only for feed direction

perpendicular to sheet wall

Application example

The spacing limits apply to pierce heads for the

processing of the rivet nut RSN with thread

sizes M5 – M14.

If the spacing limits are not reached, please

contact PROFIL.

06 08 10 12 14

H max.

Nut RSN

Y min. 21 25 26 29

H max. 146 148 150 152 158

ØD 13 16 19,3 23 26

Ymin.

Unkontrollierte Kopie bei Ausdruck (: Christin Poleska, 2009-11-30)

Page 10

MBN 10 324 : October 2009

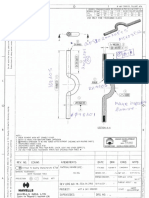

A 2 processing type

Rivet nut RND

1st piercing and 2nd

beading

Expansion of hole

edge permissible Type B

Type A

ØK

ØK

+0,2 +0,2

rounded

Øn Øn

rounded

s

s

Z

(30°)

(45°)

t

t

1st stage piercing

2nd stage

Y

0.1

Y

0.20 ±

Mh *

Table: sheet thicknesses, bead dimensions and pierce hole diameter

(1st stage piercing and 2nd stage positioning)

Sheet

Type Type ∅K Mh ∅n t

thickness s

0.80 – 1.25 4.3

A 15.0 1.5

1.30 – 1.50 3.8

RND06 10.0

1.55 – 1.95 3.8

B 13.5 1.5

2.00 – 3.00 3.5

0.80 – 1.25 5.3

A 18.2 1.5

1.30 – 1.95 4.9

RND08 13.3

2.00 – 3.00 B 17.0 4.5 1.5

1.00 – 1.25 6.3

A 22.0 1.5

RND10 1.30 – 1.95 6.0 15.3

2.00 – 3.50 B 19.5 5.5 2.0

1.00 – 1.95 A 24.8 8.0 1.8

RND12 16.7

2.00 – 3.50 B 21.0 7.0 2.4

The use of the RND nut for thicknesses outside the sheet thickness range specified above may be possible.

Please contact PROFIL to clarify the possible application.

• The Mh dimension is only intended as a guideline value. The fit of the nut shall be checked by measuring the torque or tear-out

moment.

• Please observe the relevant tables in this context.

The hole preparation specified here applies to metal sheets in accordance with the technical delivery conditions and quality standards of

EN 10 130. In the event of any deviating metal sheet properties, such as strength (e.g high-strength metal sheet grades) or material (e.g.

aluminum, sandwich sheets), an adjustment of the hole shape or diameter may be necessary to achieve optimum properties for the

nut/sheet combination. Please contact PROFIL for a discussion in this case.

The processing company shall be responsible for the monitoring and qualitative assessment of the riveting process.

1)

Water-tightness shall be ascertained by the user by means of a performance test, whereby the forming behavior of the metal sheet

material and the fastener as well as the processing stages for the end product and the operating conditions in practical application shall be

observed.

Unkontrollierte Kopie bei Ausdruck (: Christin Poleska, 2009-11-30)

Page 11

MBN 10 324 : October 2009

Rivet nut RND

1st Beading and 2nd piercing

Ra ØB

s

Z

t

+0,2

Øn Z

Rb

ØA

Mh *

0.20 ±

01

Y

Table: sheet thicknesses, bead dimensions and pierce hole diameter

(1st stage beading and 2nd stage piercing)

Sheet

Type ∅A ∅B ∅n Mh t Ra Rb

thickness s

0.75 - 0.85 13.1 4.5 0.8

0.90 - 1.15 13.3 4.4

11.5

1.20 - 1.40 13.6 4.3 1.0

RND06 1.45 - 1.65 13.9

10.25

4.2

1.3

1.70 - 1.90 14.2 4.3

12.0 1.2

1.95 - 2.15 14.5 4.2

0.3

0.75 - 0.85 17.0 5.8 0.8

0.90 - 1.15 17.2 5.7

15.1

1.20 - 1.40 17.5 5.6 1.0

RND08 13.6 1.6

1.45 - 1.65 17.7

1.70 - 1.90 5.5

15.6 18.2 1.2

1.95 - 2.15

0.75 - 0.85 19.3 6.6 0.8

0.90 - 1.15 19.5 6.5

17.2 0.5

1.20 - 1.40 19.6 1.0

1.45 - 1.65 19.8

RND10 15.5 1.7

1.70 - 1.90 20.2

6.4

1.95 - 2.15 20.4

17.7 1.2 0.3

2.20 - 2.40 20.5

2.45 - 2.65 20.7

The use of the RND nut for thicknesses outside the sheet thickness range specified above may be possible.

Please contact PROFIL to clarify the possible application.

• The Mh dimension is only intended as a guideline value. The fit of the nut shall be checked by measuring the torque or tear-out

moment.

• Please observe the relevant tables in this context.

The hole preparation specified here applies to metal sheets in accordance with the technical delivery conditions and quality standards of

EN 10 130. In the event of any deviating metal sheet properties, such as strength (e.g high-strength metal sheet grades) or material (e.g.

aluminum, sandwich sheets), an adjustment of the hole shape or diameter may be necessary to achieve optimum properties for the

nut/sheet combination. Please contact PROFIL for a discussion in this case.

The processing company shall be responsible for the monitoring and qualitative assessment of the riveting process.

1)

Water-tightness shall be ascertained by the user by means of a performance test, whereby the forming behavior of the metal sheet

material and the fastener as well as the processing stages for the end product and the operating conditions in practical application shall be

observed.

Unkontrollierte Kopie bei Ausdruck (: Christin Poleska, 2009-11-30)

Page 12

MBN 10 324 : October 2009

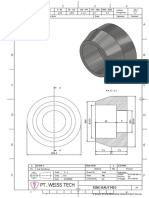

Rivet nut RSN

Piercing and beading

Type A Type B

Sheet thickness 0.80 – Expansion of hole edge Sheet thickness >

2.00mm permissible

R

R

Table: sheet thicknesses, bead dimensions and pierce hole diameter

Type s Type ∅K Mh1 Mh2 ∅n R t

0.80 – 1.25 6.7 0.7

A 14.0 1.5

1.30 – 2.00 6.4 1.2

RSN06 9.2

2.05 – 2.50 6.4 1.6

B 13.0 1.3

2.55 – 3.00 6.0 1.9

0.80 – 2.00 A 17.5 8.8 1.0 1.5

RSN08 11.8

2.05 – 2.50 8.5 1.6

B 16.0 1.3

2.55 – 3.50 8.0 2.1

1.00 – 2.00 A 21.0 11.2 1.1 2.0

RSN10 2.05 – 2.50 11.2 15.3 1.6

2.55 – 3.50 B 18.0 10.6 2.1 1.5

3.55 – 4.00 9.7 2.6

The use of the RSN nut for thicknesses outside the sheet thickness range specified above may be possible. Please

contact PROFIL to clarify the possible application.

The hole preparation specified here applies to metal sheets in accordance with the technical delivery conditions and

quality standards of EN 10 130. In the event of any deviating metal sheet properties, such as strength (e.g high-strength

metal sheet grades) or material (e.g. aluminum, sandwich sheets), an adjustment of the hole shape or diameter may be

necessary to achieve optimum properties for the nut/sheet combination. Please contact PROFIL for a discussion in this

case.

Riveting process:

During the riveting process, the rivet section plunges through the prebeaded and pierced sheet metal part and, in

continuation of the closing movement of the pierce head, it is then formed into a rivet head which encloses the sheet

material water-tight on all sides.

The processing company shall be responsible for the monitoring and qualitative assessment of the riveting process.

1)

Water-tightness shall be ascertained by the user by means of a performance test, whereby the forming behavior of the

metal sheet material and the fastener as well as the processing stages for the end product and the operating conditions

in practical application shall be observed.

Unkontrollierte Kopie bei Ausdruck (: Christin Poleska, 2009-11-30)

Page 13

MBN 10 324 : October 2009

Annex C (informative)

Company PROFIL

A.3 Cracking of rivet nuts and studs

In the case of RND, RSN and RSF rivet nuts, material and surface cracks may occur in the area of the riveted

section following riveting; refer to Fig. 1. These material and surface cracks are created as a result of

deviating/not properly adjusted pressing forces or insufficient lubrication during the pressing process, but will be

accepted to a certain extent. Care shall be taken to ensure that the cracks do not affect the strength of the

component. Test pull-out forces and torques. If the values are ok, the connection is good. In case of doubt, the

fastener technology representative shall assess and approve the fastener to technically assure the intended

subsequent application.

Figure 1: Rivet nuts with cracking

Unkontrollierte Kopie bei Ausdruck (: Christin Poleska, 2009-11-30)

You might also like

- Motor Handle For Manual Rotating RBSDocument1 pageMotor Handle For Manual Rotating RBSIrfhan FebrianNo ratings yet

- Nota: Raze de Racordare R 5 MM Muchiile Se Tesesc La 1 X 45Document1 pageNota: Raze de Racordare R 5 MM Muchiile Se Tesesc La 1 X 45Vlad SuteuNo ratings yet

- The Production Solution For High-Precision Micro-Threads From Diameter M1.0Document5 pagesThe Production Solution For High-Precision Micro-Threads From Diameter M1.0Marcos PauloNo ratings yet

- SBD Plummer Block Housings For Bearings On An Adapter Sleeve and A Stepped Shaft - TCM - 12-231180Document3 pagesSBD Plummer Block Housings For Bearings On An Adapter Sleeve and A Stepped Shaft - TCM - 12-231180gopalNo ratings yet

- SBD Plummer Block Housings For Bearings On An Adapter Sleeve and A Stepped Shaft - TCM - 12-231180Document3 pagesSBD Plummer Block Housings For Bearings On An Adapter Sleeve and A Stepped Shaft - TCM - 12-231180gopalNo ratings yet

- Keyway Jis StandartDocument1 pageKeyway Jis StandartNeo Dinastian OnssalisNo ratings yet

- 10.4. Abacus+ Tubing SchematicsDocument1 page10.4. Abacus+ Tubing SchematicsLamer HassenNo ratings yet

- GT 2 / GT 3 Timing Belt Pulleys - 2 MM Pitch: Double or No Flange ProfileDocument1 pageGT 2 / GT 3 Timing Belt Pulleys - 2 MM Pitch: Double or No Flange ProfileJohandry MartínezNo ratings yet

- Belimo GRG DRG Installation-InstructionsDocument2 pagesBelimo GRG DRG Installation-Instructionsprashil.honeywellNo ratings yet

- AssemblyDocument1 pageAssemblyWaqasNo ratings yet

- DAYTON MatrixesDocument30 pagesDAYTON MatrixesSilvioNo ratings yet

- Sheet Metal FormingDocument1 pageSheet Metal FormingtadeleNo ratings yet

- Ukk Paket 4 - Spur GearDocument1 pageUkk Paket 4 - Spur GearM.samsul HudaNo ratings yet

- Null 3Document1 pageNull 3Matthews Andrea MachilaNo ratings yet

- Service Manual: Wireless AmplifierDocument60 pagesService Manual: Wireless AmplifiergermieNo ratings yet

- Gates 2GT Pulley 20TDocument1 pageGates 2GT Pulley 20TSofien SellamiNo ratings yet

- Tehnicka Škola ''Rade Metalac'' Leskovac: Mašinski Tehnicar Za Kompjutersko KonstruisanjeDocument12 pagesTehnicka Škola ''Rade Metalac'' Leskovac: Mašinski Tehnicar Za Kompjutersko KonstruisanjeMaja i Aleksandar JovanovićNo ratings yet

- Flansa2 2D PDFDocument1 pageFlansa2 2D PDFVlad SuteuNo ratings yet

- Engrane2 Drawing 1Document1 pageEngrane2 Drawing 1José RiveraNo ratings yet

- Schematic - TX FM VALVULADO - 2024 03 14Document1 pageSchematic - TX FM VALVULADO - 2024 03 14Doni SouzaNo ratings yet

- HPC 19311 04 01 02Document1 pageHPC 19311 04 01 02phong viNo ratings yet

- Arbore Bun PDFDocument1 pageArbore Bun PDFMarius8No ratings yet

- Schemi Elettrici Vari MesDocument1,251 pagesSchemi Elettrici Vari MesE. S. MecchiNo ratings yet

- Dumy Rack RXP501 PDFDocument1 pageDumy Rack RXP501 PDFTuyenNo ratings yet

- Process Control Procedures: Fitting Up Section Inspection ReportDocument3 pagesProcess Control Procedures: Fitting Up Section Inspection ReportNguyễn Hoàng DũngNo ratings yet

- Hil-Sda-01-2950 Spindle Cover Rod Aisi304 HilDocument2 pagesHil-Sda-01-2950 Spindle Cover Rod Aisi304 HilKaran ChadhaNo ratings yet

- Sprockets: Iso Chain Sprockets Asa Chain Sprockets Stainless Steel Chain SprocketsDocument53 pagesSprockets: Iso Chain Sprockets Asa Chain Sprockets Stainless Steel Chain SprocketsAnonymous lswzqloNo ratings yet

- Train Assembly (Exploded View)Document1 pageTrain Assembly (Exploded View)NLNo ratings yet

- FCL 2Document2 pagesFCL 2Ahmad irsyalNo ratings yet

- Drylin T Rail Guide Systems - Product Range: Low-Profile Guide RailsDocument1 pageDrylin T Rail Guide Systems - Product Range: Low-Profile Guide RailsSajin RayNo ratings yet

- DWG No. A4 SQ 12/3/2018 Plate / Section: Next ProcessDocument1 pageDWG No. A4 SQ 12/3/2018 Plate / Section: Next ProcesshadeNo ratings yet

- Schematic Diagram of Hall Speed Measuring EncoderDocument1 pageSchematic Diagram of Hall Speed Measuring Encoderezio ghitarrariNo ratings yet

- LSP SMK Persatuan 2 Handel Pemutar: 3 Lathe CNC R3 R5 C1,5Document1 pageLSP SMK Persatuan 2 Handel Pemutar: 3 Lathe CNC R3 R5 C1,5M.samsul HudaNo ratings yet

- Segment of 200mm: 2 X N X 2 X M4x0.7 6Document1 pageSegment of 200mm: 2 X N X 2 X M4x0.7 6Santi Diaz MonteroNo ratings yet

- 1.2 Clutch - Hub - Basket - McedDocument1 page1.2 Clutch - Hub - Basket - Mcedaleksandar.omasystemsNo ratings yet

- Hes B117-03 Flange NutsDocument5 pagesHes B117-03 Flange NutsPreetam KumarNo ratings yet

- SBD Plummer Block Housings For Bearings On A Cylindrical Seat and A Stepped Shaft - TCM - 12-231177Document3 pagesSBD Plummer Block Housings For Bearings On A Cylindrical Seat and A Stepped Shaft - TCM - 12-231177Akash RockNo ratings yet

- Siw-Hex Bolt-A2-70 PDFDocument1 pageSiw-Hex Bolt-A2-70 PDFSagar GavaneNo ratings yet

- DIN 906 - 1983hexagon Socket Pipe PlugsDocument4 pagesDIN 906 - 1983hexagon Socket Pipe PlugsChris StefanouNo ratings yet

- 1.clamp Arm: Clamp Mini Bench ViseDocument10 pages1.clamp Arm: Clamp Mini Bench VisexnumericallyNo ratings yet

- NHD-24064CZ-NSW-BBW: Graphic Liquid Crystal Display ModuleDocument11 pagesNHD-24064CZ-NSW-BBW: Graphic Liquid Crystal Display ModuleMitchell DanielsNo ratings yet

- 721 Lincoln 1K1C810Document1 page721 Lincoln 1K1C810Thành Vinh PhạmNo ratings yet

- Tutorial 3 DrawingDocument1 pageTutorial 3 DrawingAlexNo ratings yet

- CahuraDocument1 pageCahuraMarko KolaNo ratings yet

- PDA Data Analysis For Near Injection Region of 3-Hole Gasoline Direct InjectorDocument28 pagesPDA Data Analysis For Near Injection Region of 3-Hole Gasoline Direct InjectorAbdul Hadi ButtNo ratings yet

- Notes: - Break All Sharp Edges 0.3x45 - Unspecific Chamfer 1x45 - Medium ToleranceDocument1 pageNotes: - Break All Sharp Edges 0.3x45 - Unspecific Chamfer 1x45 - Medium ToleranceRAN GamingNo ratings yet

- Standaarddelen A3Document1 pageStandaarddelen A3Maxim WynantsNo ratings yet

- Pt. Weiss Tech: Ring Baut M10Document1 pagePt. Weiss Tech: Ring Baut M10Fuad EfendiNo ratings yet

- 8Q-IAI - A321 - Cabin and Emergency Equipment Layout - Rev 05 - SignedDocument1 page8Q-IAI - A321 - Cabin and Emergency Equipment Layout - Rev 05 - SignedMugilanNo ratings yet

- Din 1592Document1 pageDin 1592Sudarshan KaragudariNo ratings yet

- Schematic MOSFET 2 2023-06-09Document1 pageSchematic MOSFET 2 2023-06-09panchal vivekNo ratings yet

- 16 - Hexagon Socket Head Cap Screws JIS B 11762006Document1 page16 - Hexagon Socket Head Cap Screws JIS B 11762006Adhi candra irawanNo ratings yet

- Adapter - Sheet1Document1 pageAdapter - Sheet1Ady NugrohoNo ratings yet

- TURNING FIX (04-005) - Sheet - 1Document1 pageTURNING FIX (04-005) - Sheet - 1daryosh hassanyNo ratings yet

- Process Control Procedures: Final Inspection ReportDocument3 pagesProcess Control Procedures: Final Inspection ReportNguyễn Hoàng DũngNo ratings yet

- Adapter Ploca: Dipl - Mas.ing - Filic MICA 47384 Dipl - Mas.ing - Filic MICA 47384Document1 pageAdapter Ploca: Dipl - Mas.ing - Filic MICA 47384 Dipl - Mas.ing - Filic MICA 47384Mica FilicNo ratings yet

- Tutorial 4 DrawingDocument2 pagesTutorial 4 DrawingAlexNo ratings yet

- Sharpen (8X) : 1 1 Plate T 1.5Document1 pageSharpen (8X) : 1 1 Plate T 1.5andreas endrasNo ratings yet

- Let's Practise: Maths Workbook Coursebook 8From EverandLet's Practise: Maths Workbook Coursebook 8No ratings yet

- NOR 1453363 000 00 W-HTX EnglischDocument46 pagesNOR 1453363 000 00 W-HTX Englischgültekin gökNo ratings yet

- MBN10231 Eng+2008-09Document12 pagesMBN10231 Eng+2008-09gültekin gökNo ratings yet

- Daimler - MBN 11011 ENG - 12-07Document31 pagesDaimler - MBN 11011 ENG - 12-07gültekin gökNo ratings yet

- Daimler MBN 10317 Eng 09-09Document27 pagesDaimler MBN 10317 Eng 09-09gültekin gökNo ratings yet

- Daimler - MBN 11250 ENG - 07-09Document26 pagesDaimler - MBN 11250 ENG - 07-09gültekin gökNo ratings yet

- Daimler - DBL 8451 ENG - 09-08Document14 pagesDaimler - DBL 8451 ENG - 09-08gültekin gökNo ratings yet

- DME - 1 One Mark Q's (KDR)Document13 pagesDME - 1 One Mark Q's (KDR)durgaraokamireddyNo ratings yet

- Chris Juarez ResumeDocument1 pageChris Juarez Resumeapi-487648580No ratings yet

- Striker ManualDocument51 pagesStriker ManualDani Garcia AlvarezNo ratings yet

- Mechanics of Deformable Bodies - Supplementary ProblemsDocument7 pagesMechanics of Deformable Bodies - Supplementary ProblemsDhenil ManubatNo ratings yet

- GuidesDocument7 pagesGuidesALCHY IGNNo ratings yet

- Sample Base Plate As Per Is800 20Document45 pagesSample Base Plate As Per Is800 20mtech structuresNo ratings yet

- Orca Share Media1596535415451 6696354879170259171Document2 pagesOrca Share Media1596535415451 6696354879170259171Raymart CubidNo ratings yet

- Design Analysis of Light StructuresDocument17 pagesDesign Analysis of Light StructuresgligamsnNo ratings yet

- Aircraft Structure Design PrinciplesDocument28 pagesAircraft Structure Design PrinciplesVenugopal Krishna0% (1)

- Catalog PrymDocument17 pagesCatalog Prymmirelamar100% (1)

- Engineering Plastics Design Guide - Joining TechniquesDocument38 pagesEngineering Plastics Design Guide - Joining TechniquesSakith Devadatta100% (8)

- 2013 TBX Tower Catalog Current Version (Rev 5.20.13)Document12 pages2013 TBX Tower Catalog Current Version (Rev 5.20.13)Rubic SantosNo ratings yet

- St. Aloysius Institute of Technology, JabalpurDocument2 pagesSt. Aloysius Institute of Technology, JabalpurBorad M. BarkacharyNo ratings yet

- Ships Const QuizDocument4 pagesShips Const Quizmario enriquezNo ratings yet

- Fighter Ultralight PlansDocument24 pagesFighter Ultralight PlansMaps98% (46)

- Bolted ConnectionsDocument135 pagesBolted ConnectionsDhruv patelNo ratings yet

- 805steel Gravity Water TanksDocument20 pages805steel Gravity Water TanksAMITaXWINo ratings yet

- Classification of DamageDocument3 pagesClassification of DamageTegar VirgaNo ratings yet

- Four Wheel Rear Drive Vipv Light Urban Electric Vehicle Prototype ProjectDocument14 pagesFour Wheel Rear Drive Vipv Light Urban Electric Vehicle Prototype ProjectUmeh HenryNo ratings yet

- Design Analysis Article in The October, 1944 Issue of Aviation Magazine FW190 DraftDocument36 pagesDesign Analysis Article in The October, 1944 Issue of Aviation Magazine FW190 DraftAaron ParkerNo ratings yet

- Wallaert J J, Fisher J W. Shear Strength of High-Strength Bolts - 1964Document61 pagesWallaert J J, Fisher J W. Shear Strength of High-Strength Bolts - 1964徐蒋张No ratings yet

- Tensionmembers With Staggered HolesDocument10 pagesTensionmembers With Staggered HolesJomarie AlcanoNo ratings yet

- Examination of AISC LRFD Shear Lag Design ProvisionsDocument16 pagesExamination of AISC LRFD Shear Lag Design ProvisionsSergioAlcantaraNo ratings yet

- Lecture 6 Riviting DesignDocument17 pagesLecture 6 Riviting DesignAbdelrahman yasser ZaghloulNo ratings yet

- Chinese Equivalent of International Steel StandardsDocument149 pagesChinese Equivalent of International Steel Standardslivnucas1972100% (1)

- Mustang Eleanor Body Kit Install GuideDocument14 pagesMustang Eleanor Body Kit Install Guidechrisb3100% (1)

- Food Processing 8Document3 pagesFood Processing 8Gladez Lucaya Galagaran100% (7)

- Hydraulic RevitingDocument29 pagesHydraulic RevitingDinesh KumarNo ratings yet

- Steel Bridge Code PDFDocument139 pagesSteel Bridge Code PDFmallikarjuna rao bodduNo ratings yet