Professional Documents

Culture Documents

Ur S6rev9corr2

Ur S6rev9corr2

Uploaded by

Maan MrabetOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ur S6rev9corr2

Ur S6rev9corr2

Uploaded by

Maan MrabetCopyright:

Available Formats

S6

S6

S6 Use of Steel Grades for Various Hull Members -

(1978)

(cont)

(Rev.1 Ships of 90 m in Length and Above

1980)

(Rev.2 S6.0 Application

1996)

(Rev.3 This UR does not apply to CSR Bulk Carriers and Oil Tankers.

May 2002)

Rev.4 S6.1 Ships in normal worldwide service

July 2003)

(Rev.5 Materials in the various strength members are not to be of lower grade than those

Sept 2007) corresponding to the material classes and grades specified in Table 1 to Table 7. General

(Rev.6 requirements are given in Table 1, while additional minimum requirements are given in the

May 2010) following:

(Rev.7

Apr 2013) Table 2: for ships, excluding liquefied gas carriers covered in Table 3, with length

(Rev.8 exceeding 150 m and single strength deck,

Dec 2015)

(Rev.9 Table 3: for membrane type liquefied gas carriers with length exceeding 150 m,

July 2018)

(Corr.1 Table 4: for ships with length exceeding 250 m,

Mar 2021)

(Corr.2 Table 5: for single side bulk carriers subjected to SOLAS regulation XII/6.4,

Nov 2021)

Table 6: for ships with ice strengthening.

The material grade requirements for hull members of each class depending on the thickness

are defined in Table 7.

For strength members not mentioned in Tables 1 to 6, Grade A/AH may generally be used.

The steel grade is to correspond to the as-built plate thickness and material class.

Plating materials for sternframes supporting the rudder and propeller boss, rudders, rudder

horns and shaft brackets are in general not to be of lower grades than corresponding to Class

II. For rudder and rudder body plates subjected to stress concentrations (e.g. in way of lower

support of semi-spade rudders or at upper part of spade rudders) Class III is to be applied.

Notes:

1. Changes introduced in Rev.5 are to be uniformly implemented by IACS Members and

Associates from 1 July 2008.

2. Changes introduced in Rev.7 are to be uniformly implemented by IACS Members from

1 July 2014.

3. Changes introduced in Rev.8 are to be uniformly implemented by IACS Members from

1 January 2017.

4. Changes introduced in Rev.9 are to be uniformly implemented by IACS Members from

1 July 2019.

Page 1 of 10 IACS Req. 1978/Rev.9 Corr.2 2021

S6

Table 1 - Material Classes and Grades for ships in general

S6

(cont) Structural member category Material class/grade

SECONDARY: - Class I within 0.4L amidships

- Grade A/AH outside 0.4L amidships

A1. Longitudinal bulkhead strakes, other than that

belonging to the Primary category

A2. Deck plating exposed to weather, other than

that belonging to the Primary or Special

category

A3. Side plating

PRIMARY: - Class II within 0.4L amidships

- Grade A/AH outside 0.4L amidships

B1. Bottom plating, including keel plate

B2. Strength deck plating, excluding that belonging

to the Special category

B3. Continuous longitudinal plating of strength

members above strength deck, excluding hatch

coamings

B4. Uppermost strake in longitudinal bulkhead

B5. Vertical strake (hatch side girder) and

uppermost sloped strake in top wing tank

SPECIAL: - Class III within 0.4L amidships

- Class II outside 0.4L amidships

C1. Sheer strake at strength deck (*) - Class I outside 0.6L amidships

C2. Stringer plate in strength deck (*)

C3. Deck strake at longitudinal bulkhead, excluding

deck plating in way of inner-skin bulkhead of

double-hull ships (*)

C4. Strength deck plating at outboard corners of - Class III within 0.4L amidships

cargo hatch openings in container carriers and - Class II outside 0.4L amidships

other ships with similar hatch opening - Class I outside 0.6L amidships

configurations - Min. Class III within cargo region

C5. Strength deck plating at corners of cargo hatch - Class III within 0.6L amidships

openings in bulk carriers, ore carriers - Class II within rest of cargo region

combination carriers and other ships with

similar hatch opening configurations

C5.1 Trunk deck and inner deck plating at corners of

openings for liquid and gas domes in

membrane type liquefied gas carriers

C6. Bilge strake in ships with double bottom over - Class II within 0.6L amidships

the full breadth and length less than 150 m - Class I outside 0.6L amidships

C7. Bilge strake in other ships (*) - Class III within 0.4L amidships

- Class II outside 0.4L amidships

- Class I outside 0.6L amidships

C8. Longitudinal hatch coamings of length greater - Class III within 0.4L amidships

than 0.15L including coaming top plate and - Class II outside 0.4L amidships

flange - Class I outside 0.6L amidships

C9. End brackets and deck house transition of - Not to be less than Grade D/DH

longitudinal cargo hatch coamings

(*) Single strakes required to be of Class III within 0.4L amidships are to have breadths not

less than 800+5L (mm), need not be greater than 1800 (mm), unless limited by the

geometry of the ship’s design.

Page 2 of 10 IACS Req. 1978/Rev.9 Corr.2 2021

S6

Table 2 - Minimum Material Grades for ships, excluding liquefied gas carriers

S6 covered in Table 3, with length exceeding 150 m and single strength deck

(cont)

Structural member category Material grade

• Longitudinal plating of strength deck where Grade B/AH within 0.4L amidships

contributing to the longitudinal strength

• Continuous longitudinal plating of strength

members above strength deck

Single side strakes for ships without inner Grade B/AH within cargo region

continuous longitudinal bulkhead(s) between

bottom and the strength deck

Table 3 - Minimum Material Grades for membrane type liquefied gas carriers with

length exceeding 150 m *

Structural member category Material grade

Longitudinal plating of strength deck where Grade B/AH within 0.4L amidships

contributing to the longitudinal strength

Trunk deck plating Class II within 0.4L amidships

Continuous longitudinal • Inner deck plating Grade B/AH within 0.4L amidships

plating of strength

members above the • Longitudinal strength

strength deck member plating

between the trunk

deck and inner deck

(*) Table 3 is applicable to membrane type liquefied gas carriers with deck arrangements

as shown in Fig. 1. Table 3 may apply to similar ship types with a “double deck”

arrangement above the strength deck.

Page 3 of 10 IACS Req. 1978/Rev.9 Corr.2 2021

S6

S6 Trunk Deck

(cont)

Stringer Plate

Sheer Strake Inner Deck

Strength Deck

Bilge Strake

Fig. 1 Typical deck arrangement for membrane type Liquefied Natural Gas Carriers

Table 4 - Minimum Material Grades for ships with length exceeding 250 m

Structural member category Material grade

Sheer strake at strength deck (*) Grade E/EH within 0.4L amidships

Stringer plate in strength deck (*) Grade E/EH within 0.4L amidships

Bilge strake (*) Grade D/DH within 0.4L amidships

(*) Single strakes required to be of Grade D/DH or Grade E/EH as shown in the above table

and within 0.4L amidships are to have breadths not less than 800+5L (mm), need not be

greater than 1800 (mm), unless limited by the geometry of the ship’s design.

Page 4 of 10 IACS Req. 1978/Rev.9 Corr.2 2021

S6

Table 5 - Minimum Material Grades for single-side skin bulk carriers subjected to

S6 SOLAS regulation XII/6.4

(cont)

Structural member category Material grade

Lower bracket of ordinary side frame (*), (**) Grade D/DH

Side shell strakes included totally or partially Grade D/DH

between the two points located to 0.125 above

and below the intersection of side shell and bilge

hopper sloping plate or inner bottom plate (**)

(*) The term "lower bracket" means webs of lower brackets and webs of the lower part of

side frames up to the point of 0.125 above the intersection of side shell and bilge

hopper sloping plate or inner bottom plate.

(**) The span of the side frame, , is defined as the distance between the supporting

structures.

Table 6 - Minimum Material Grades for ships with ice strengthening

Structural member category Material grade

Shell strakes in way of ice strengthening area for Grade B/AH

plates

Page 5 of 10 IACS Req. 1978/Rev.9 Corr.2 2021

S6

Table 7 - Material Grade Requirements for Classes I, II and III

S6

(cont) Class I II III

Thickness, in mm MS HT MS HT MS HT

t ≤ 15 A AH A AH A AH

15 < t ≤ 20 A AH A AH B AH

20 < t ≤ 25 A AH B AH D DH

25 < t ≤ 30 A AH D DH D DH

30 < t ≤ 35 B AH D DH E EH

35 < t ≤ 40 B AH D DH E EH

40 < t ≤ 50 D DH E EH E EH

S6.2 Ships exposed to low air temperatures

For ships intended to operate in areas with low air temperatures (below -10ºC), e.g. regular

service during winter seasons to Arctic or Antarctic waters, the materials in exposed

structures are to be selected based on the design temperature tD, to be taken as defined in

S6.3.

Materials in the various strength members above the lowest ballast water line (BWL) exposed

to air (including the structural members covered by the Note [5] of Table 8) and materials of

cargo tank boundary plating for which S6.4 is applicable are not to be of lower grades than

those corresponding to Classes I, II and III, as given in Table 8, depending on the categories

of structural members (SECONDARY, PRIMARY and SPECIAL). For non-exposed structures

(except as indicated in Note [5] of Table 8) and structures below the lowest ballast water line,

S6.1 applies.

Page 6 of 10 IACS Req. 1978/Rev.9 Corr.2 2021

S6

Table 8 - Application of Material Classes and Grades – Structures Exposed at Low

S6 Temperatures

(cont)

Material class

Structural member category Within Outside

0.4L 0.4L

amidships amidships

SECONDARY:

Deck plating exposed to weather, in general

Side plating above BWL I I

Transverse bulkheads above BWL[5]

Cargo tank boundary plating exposed to cold cargo [6]

PRIMARY:

Strength deck plating [1]

Continuous longitudinal members above strength deck, excluding

longitudinal hatch coamings II I

Longitudinal bulkhead above BWL[5]

Top wing tank bulkhead above BWL[5]

SPECIAL:

Sheer strake at strength deck [2]

Stringer plate in strength deck [2] III II

Deck strake at longitudinal bulkhead [3]

Continuous longitudinal hatch coamings [4]

Notes:

[1] Plating at corners of large hatch openings to be specially considered. Class III or Grade

E/EH to be applied in positions where high local stresses may occur.

[2] Not to be less than Grade E/EH within 0.4L amidships in ships with length exceeding

250 metres.

[3] In ships with breadth exceeding 70 metres at least three deck strakes to be Class III.

[4] Not to be less than Grade D/DH.

[5] Applicable to plating attached to hull envelope plating exposed to low air temperature.

At least one strake is to be considered in the same way as exposed plating and the

strake width is to be at least 600 mm.

[6] For cargo tank boundary plating exposed to cold cargo for ships other than liquefied

gas carriers, see S6.4.

The material grade requirements for hull members of each class depending on thickness and

design temperature are defined in Table 9. For design temperatures tD < -55ºC, materials are

to be specially considered by each Classification Society.

Page 7 of 10 IACS Req. 1978/Rev.9 Corr.2 2021

S6

Table 9 - Material Grade Requirements for Classes I, II and III at Low Temperatures

S6

(cont) Class I

Plate thickness, -11/-150C -16/-250C -26/-350C -36/-450C -46/-550C

in mm MS HT MS HT MS HT MS HT MS HT

t ≤ 10 A AH A AH B AH D DH D DH

10 < t ≤ 15 A AH B AH D DH D DH D DH

15 < t ≤ 20 A AH B AH D DH D DH E EH

20 < t ≤ 25 B AH D DH D DH D DH E EH

25 < t ≤ 30 B AH D DH D DH E EH E EH

30 < t ≤ 35 D DH D DH D DH E EH E EH

35 < t ≤ 45 D DH D DH E EH E EH ∅ FH

45 < t ≤ 50 D DH E EH E EH ∅ FH ∅ FH

∅ = Not applicable

Class II

Plate thickness, -11/-150C -16/-250C -26/-350C -36/-450C -46/-550C

in mm MS HT MS HT MS HT MS HT MS HT

t ≤ 10 A AH B AH D DH D DH E EH

10 < t ≤ 20 B AH D DH D DH E EH E EH

20 < t ≤ 30 D DH D DH E EH E EH ∅ FH

30 < t ≤ 40 D DH E EH E EH ∅ FH ∅ FH

40 < t ≤ 45 E EH E EH ∅ FH ∅ FH ∅ ∅

45 < t ≤ 50 E EH E EH ∅ FH ∅ FH ∅ ∅

∅ = Not applicable

Class III

Plate thickness, -11/-150C -16/-250C -26/-350C -36/-450C -46/-550C

in mm MS HT MS HT MS HT MS HT MS HT

t ≤ 10 B AH D DH D DH E EH E EH

10 < t ≤ 20 D DH D DH E EH E EH ∅ FH

20 < t ≤ 25 D DH E EH E EH E FH ∅ FH

25 < t ≤ 30 D DH E EH E EH ∅ FH ∅ FH

30 < t ≤ 35 E EH E EH ∅ FH ∅ FH ∅ ∅

35 < t ≤ 40 E EH E EH ∅ FH ∅ FH ∅ ∅

40 < t ≤ 50 E EH ∅ FH ∅ FH ∅ ∅ ∅ ∅

∅ = Not applicable

Single strakes required to be of Class III or of Grade E/EH or FH are to have breadths not

less than 800+ 5L mm, maximum 1800 mm.

Plating materials for sternframes, rudder horns, rudders and shaft brackets are not to be of

lower grades than those corresponding to the material classes given in 6.1.

Page 8 of 10 IACS Req. 1978/Rev.9 Corr.2 2021

S6

S6.3 Design temperature tD

S6

(cont) The design temperature tD is to be taken as the lowest mean daily average air temperature in

the area of operation.

Mean: Statistical mean over observation period

Average: Average during one day and night

Lowest: Lowest during year

For seasonally restricted service the lowest value within the period of operation applies.

For the purpose of issuing a Polar Ship Certificate in accordance with the Polar Code, the

design temperature tD shall be no more than 13oC higher than the Polar Service Temperature

(PST) of the ship.

In the Polar Regions, the statistical mean over observation period is to be determined for a

period of at least 10 years.

Fig. 2 illustrates the temperature definition.

Fig. 2 Commonly used definitions of temperatures

MDHT = Mean Daily High (or maximum) Temperature

MDAT = Mean Daily Average Temperature

MDLT = Mean Daily Low (or minimum) Temperature

Page 9 of 10 IACS Req. 1978/Rev.9 Corr.2 2021

S6

S6.4 Cold cargo for ships other than liquefied gas carriers

S6

(cont) For ships other than liquefied gas carriers, intended to be loaded with liquid cargo having a

temperature below -10o C, e.g. loading from cold onshore storage tanks during winter

conditions, the material grade of cargo tank boundary plating is defined in Table 9 based on

the following:

- tc design minimum cargo temperature in oC

- steel grade corresponding to Class I as given in Table 8

The design minimum cargo temperature, tc is to be specified in the loading manual.

End of

Document

Page 10 of 10 IACS Req. 1978/Rev.9 Corr.2 2021

You might also like

- Material Class & ApplicationDocument6 pagesMaterial Class & ApplicationYl WongNo ratings yet

- Requirements Concerning Gas Tankers: International Association of Classification SocietiesDocument36 pagesRequirements Concerning Gas Tankers: International Association of Classification SocietieschrisNo ratings yet

- Section 2 MaterialsDocument7 pagesSection 2 MaterialsButnariu CristianNo ratings yet

- Analysis and Design of A Box Culvert1Document7 pagesAnalysis and Design of A Box Culvert1Uwua DanielNo ratings yet

- Mukhopadhyay Question-Answer: 1. Latest Regulations For Bulk CarrierDocument88 pagesMukhopadhyay Question-Answer: 1. Latest Regulations For Bulk CarrierMariyath Muraleedharan KiranNo ratings yet

- Design of Pressure Vessel 1Document55 pagesDesign of Pressure Vessel 1Ezio3511No ratings yet

- Analysis and Design of Box Culvert: A Manual Approach: March 2019Document7 pagesAnalysis and Design of Box Culvert: A Manual Approach: March 2019Ibrahim KhanNo ratings yet

- Ur G1rev3corr1Document20 pagesUr G1rev3corr1Seong Ju KangNo ratings yet

- BKI 2009 Vol 2 Section 1Document8 pagesBKI 2009 Vol 2 Section 1Nida I. FarihahNo ratings yet

- Analysis and Design of Box Culvert: A Manual Approach: March 2019Document7 pagesAnalysis and Design of Box Culvert: A Manual Approach: March 2019Ashlesha DubeyNo ratings yet

- SECTION - 1 General DifinitionDocument7 pagesSECTION - 1 General DifinitionGig MacoNo ratings yet

- Rules For The Survey and Construction of Steel Ships: Part BDocument10 pagesRules For The Survey and Construction of Steel Ships: Part BThe MatrixNo ratings yet

- Analysis and Design of Box Culvert: A Manual Approach: March 2019Document7 pagesAnalysis and Design of Box Culvert: A Manual Approach: March 2019Gopu RNo ratings yet

- Rules For The Classification and Construction of Sea-Going Ships Part Ii HullDocument319 pagesRules For The Classification and Construction of Sea-Going Ships Part Ii Hull1059283523No ratings yet

- 06.. Control Trim, Stability and StressDocument13 pages06.. Control Trim, Stability and StressIkbal100% (2)

- Presentation Slides For Tank Construction and MaintenanceDocument71 pagesPresentation Slides For Tank Construction and Maintenancemujeebmehar86% (14)

- TB Rule Reference Original 1st January 2014 Issue Pdf2304Document385 pagesTB Rule Reference Original 1st January 2014 Issue Pdf2304Carmen IchimNo ratings yet

- Pressure Vessel DesignDocument3 pagesPressure Vessel DesignlatshareNo ratings yet

- Tank Arrangement WordsDocument2 pagesTank Arrangement WordsManpreet SinghNo ratings yet

- 380 Erstl A Egstl A 2017Document38 pages380 Erstl A Egstl A 2017Erwin GunawanNo ratings yet

- Mil S 901DDocument83 pagesMil S 901DParamaet TamNo ratings yet

- Requirements Concerning Gas Tankers: International Association of Classification SocietiesDocument36 pagesRequirements Concerning Gas Tankers: International Association of Classification Societiesantopaul2No ratings yet

- Tanks DetialsDocument11 pagesTanks DetialsHarshal ChimankarNo ratings yet

- Vessels 6-10-2012Document26 pagesVessels 6-10-2012Mohammed.abudi1996No ratings yet

- Notes 1Document20 pagesNotes 1Ruben ChirinosNo ratings yet

- 37 IJAERS MAR 2019 34 Analysisand1Document7 pages37 IJAERS MAR 2019 34 Analysisand1Mearg NgusseNo ratings yet

- Requirements Concerning Gas Tankers: International Association of Classification SocietiesDocument31 pagesRequirements Concerning Gas Tankers: International Association of Classification SocietiescklconNo ratings yet

- Requirements Concerning Mooring, Anchoring and Towing: International Association of Classification SocietiesDocument34 pagesRequirements Concerning Mooring, Anchoring and Towing: International Association of Classification SocietiesBorza DorinNo ratings yet

- Mil S 901DDocument83 pagesMil S 901Dadithegrea83No ratings yet

- Ur A2 Rev3 Cor1 pdf2425Document6 pagesUr A2 Rev3 Cor1 pdf2425Ahmed MagdyNo ratings yet

- SM TutorialDocument23 pagesSM TutorialSapna DasNo ratings yet

- Requirements Concerning Mooring, Anchoring and Towing: International Association of Classification SocietiesDocument28 pagesRequirements Concerning Mooring, Anchoring and Towing: International Association of Classification SocietiesmajdirossrossNo ratings yet

- The Design of Liquefied Gas CarriersDocument10 pagesThe Design of Liquefied Gas CarriersRijin ENo ratings yet

- Requirements Concerning Gas Tankers: International Association of Classification SocietiesDocument31 pagesRequirements Concerning Gas Tankers: International Association of Classification Societiesharikrishnanpd3327No ratings yet

- Materials Selection Guideline For Mobile Offshore Drilling Units No. 11Document4 pagesMaterials Selection Guideline For Mobile Offshore Drilling Units No. 11Marlon Alejandro Arboleda TapiaNo ratings yet

- IACS Under 90 Steel SelectionDocument16 pagesIACS Under 90 Steel SelectionsreeNo ratings yet

- LNG MitsubishiDocument4 pagesLNG Mitsubishireade2011No ratings yet

- Understanding The Design of Liquefied Gas CarriersDocument20 pagesUnderstanding The Design of Liquefied Gas Carriersbahrul100% (1)

- Section 23 Bulk Carriers, Ore Carriers and Ships With Strengthenings For Bulk Cargo and Heavy CargoDocument24 pagesSection 23 Bulk Carriers, Ore Carriers and Ships With Strengthenings For Bulk Cargo and Heavy CargoSubodh PillaiNo ratings yet

- Vvol II 2017 Rules For Hull2017 32 209Document178 pagesVvol II 2017 Rules For Hull2017 32 209engineering jrNo ratings yet

- RR G 1602D PDFDocument9 pagesRR G 1602D PDFliuyx866No ratings yet

- 3.1 Load Line & Tonnage Conv - 1-11pgsDocument11 pages3.1 Load Line & Tonnage Conv - 1-11pgsoussama achouri100% (1)

- Freestanding Jib Crane: Spanco® Product Specifications 1Document10 pagesFreestanding Jib Crane: Spanco® Product Specifications 1behruzNo ratings yet

- ANCSYSENG004Document21 pagesANCSYSENG004Tom MoritzNo ratings yet

- CN Stab of Open CraftDocument19 pagesCN Stab of Open CraftVECTOR MARINE & OFFSHORE TECHNOLOGYNo ratings yet

- Imo Gas Code: 4.1 GeneralDocument11 pagesImo Gas Code: 4.1 GeneralŞansal DikmenerNo ratings yet

- IACS - Strength of ShipsDocument266 pagesIACS - Strength of ShipsMorgan100% (2)

- Gas Tanker ProjectDocument40 pagesGas Tanker ProjectJudson FarrayNo ratings yet

- ANSI RD1.0 - 2006 - Standard For Steel Roof DeckDocument5 pagesANSI RD1.0 - 2006 - Standard For Steel Roof DeckDaniel PereiraNo ratings yet

- Storage TanksDocument62 pagesStorage Tankstoychom2013No ratings yet

- Ur A1 Corr2 Mar 2017 CLNDocument15 pagesUr A1 Corr2 Mar 2017 CLNFawwaz MananNo ratings yet

- IACS Requirements For Mooring, Anchoring and TowingDocument34 pagesIACS Requirements For Mooring, Anchoring and TowingCapitan PetacaNo ratings yet

- C15 Recommendations Manifolds Refrigerated Liquefied Natural Gas Carriers - Ed. 1994Document12 pagesC15 Recommendations Manifolds Refrigerated Liquefied Natural Gas Carriers - Ed. 1994Hihachi Esconde Michima0% (1)

- Rules For Construction and Equipment of Ships Carrying Liquefied Gases in Bulk Amendments 2020Document58 pagesRules For Construction and Equipment of Ships Carrying Liquefied Gases in Bulk Amendments 2020Farrukh ZainNo ratings yet

- Parametric Study of RCC Staging (Support Structure) For Overhead Water Tanks As Per 1s-811682-1985 and Is-3370-Ijaerdv04i0159905Document5 pagesParametric Study of RCC Staging (Support Structure) For Overhead Water Tanks As Per 1s-811682-1985 and Is-3370-Ijaerdv04i0159905Editor IJAERDNo ratings yet

- ABS 2005 Steel Vessels Corrigenda March 2005Document14 pagesABS 2005 Steel Vessels Corrigenda March 2005Erick Cruz MontañezNo ratings yet

- MMD Nav Arch-II TheoryDocument69 pagesMMD Nav Arch-II TheoryYashwanth PanneerNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- A2 Tank Cleaning Openings F3Document1 pageA2 Tank Cleaning Openings F3Maan MrabetNo ratings yet

- F45 Installation of BWMS On-Board ShipsDocument9 pagesF45 Installation of BWMS On-Board ShipsMaan MrabetNo ratings yet

- Ur F15rev6corr1Document1 pageUr F15rev6corr1Maan MrabetNo ratings yet

- Amsa1627 STCW 59Document5 pagesAmsa1627 STCW 59Maan MrabetNo ratings yet

- GL NDA 0027ND Rev9 Guidelines For Marine Lifting Operations1Document42 pagesGL NDA 0027ND Rev9 Guidelines For Marine Lifting Operations1Maan MrabetNo ratings yet

- Ur E25rev1Document2 pagesUr E25rev1Maan MrabetNo ratings yet

- Ur F16rev1Document1 pageUr F16rev1Maan MrabetNo ratings yet

- Ur F13rev1Document1 pageUr F13rev1Maan MrabetNo ratings yet

- Ur F2rev2Document1 pageUr F2rev2Maan MrabetNo ratings yet

- Ur F5rev1Document1 pageUr F5rev1Maan MrabetNo ratings yet

- Ur F24rev2Document1 pageUr F24rev2Maan MrabetNo ratings yet

- Ur F8rev1Document1 pageUr F8rev1Maan MrabetNo ratings yet

- Deleted 1997Document1 pageDeleted 1997Maan MrabetNo ratings yet

- Ur F6rev1Document1 pageUr F6rev1Maan MrabetNo ratings yet

- Cargo Openings in The Bottoms of Topside Tanks of Ships Carrying Alternatively Oil and Grain F27Document1 pageCargo Openings in The Bottoms of Topside Tanks of Ships Carrying Alternatively Oil and Grain F27Maan MrabetNo ratings yet

- Fire Testing of Flexible Pipes: IACS Req. 1995Document1 pageFire Testing of Flexible Pipes: IACS Req. 1995Maan MrabetNo ratings yet

- Ur F29rev6Document1 pageUr F29rev6Maan MrabetNo ratings yet

- Fire Detecting System For Unattended Machinery Spaces F32: IACS Req. 1976Document1 pageFire Detecting System For Unattended Machinery Spaces F32: IACS Req. 1976Maan MrabetNo ratings yet

- Ur F20rev7Document3 pagesUr F20rev7Maan MrabetNo ratings yet

- Ur F26rev3Document1 pageUr F26rev3Maan MrabetNo ratings yet

- Ur E17rev1Document1 pageUr E17rev1Maan MrabetNo ratings yet

- Ur F35rev8Document2 pagesUr F35rev8Maan MrabetNo ratings yet

- Ur E10rev8corr1Document11 pagesUr E10rev8corr1Maan MrabetNo ratings yet

- Prohibition of Carriage in Fore Peak Tanks of Oil or Other Liquid Substances Which Are Flammable F33Document1 pageProhibition of Carriage in Fore Peak Tanks of Oil or Other Liquid Substances Which Are Flammable F33Maan MrabetNo ratings yet

- Ur F43rev2Document1 pageUr F43rev2Maan MrabetNo ratings yet

- Ur E11rev4Document8 pagesUr E11rev4Maan MrabetNo ratings yet

- Ur E7rev5Document1 pageUr E7rev5Maan MrabetNo ratings yet

- Ur F46newDocument1 pageUr F46newMaan MrabetNo ratings yet

- Requirements Concerning Electrical and Electronic InstallationsDocument113 pagesRequirements Concerning Electrical and Electronic InstallationsMaan MrabetNo ratings yet

- Ur E13rev3corr1Document6 pagesUr E13rev3corr1Maan MrabetNo ratings yet

- D000 Index of DECK Check Lists 01-06-13Document3 pagesD000 Index of DECK Check Lists 01-06-13jrjenniferrajNo ratings yet

- TEST-Use of SMCP For Routine Communication (13.01.2021) PDFDocument1 pageTEST-Use of SMCP For Routine Communication (13.01.2021) PDFMitea Gabriel-Cristian100% (2)

- Harding ProductDocument24 pagesHarding Productviperov50% (2)

- The Crew of The TitanicDocument2 pagesThe Crew of The TitanicАлена ХитрукNo ratings yet

- The Wreck of The TitanicDocument2 pagesThe Wreck of The TitanicVkkbNo ratings yet

- History of The American Bureau of Shipping (ABS) PDFDocument172 pagesHistory of The American Bureau of Shipping (ABS) PDFgnd100100% (1)

- Dokumen - Tips - Alamat Perusahaan Pelayaran 56a6ff8d8a868Document25 pagesDokumen - Tips - Alamat Perusahaan Pelayaran 56a6ff8d8a868jackNo ratings yet

- Ship ParticularsDocument1 pageShip ParticularsPerdanaNo ratings yet

- Fugro Searcher BrochureDocument2 pagesFugro Searcher BrochuretjsprangNo ratings yet

- Specification, DP2 Offshore Support Vessel SimaDocument5 pagesSpecification, DP2 Offshore Support Vessel Simathe.crystal.scorpionNo ratings yet

- Flag Hoist SignalingDocument36 pagesFlag Hoist SignalingKrista Joy PetalioNo ratings yet

- MV KairosDocument104 pagesMV KairosDominic VillamanteNo ratings yet

- Sea ProtestDocument10 pagesSea ProtestenglisgoNo ratings yet

- Port Cargo Transport EfficiencyDocument8 pagesPort Cargo Transport EfficiencyNataniel BaiaoNo ratings yet

- IncotermsDocument11 pagesIncotermsSky509No ratings yet

- Transpo CasesDocument173 pagesTranspo CasesArah Obias Cope100% (1)

- Personal Details: Rambutan RT 002 RW 001, Purwosari, Wonoasri, Madiun Jawa Timur - 63153Document1 pagePersonal Details: Rambutan RT 002 RW 001, Purwosari, Wonoasri, Madiun Jawa Timur - 63153Dimas Ageng KurniawanNo ratings yet

- Lot Data ComputationDocument6 pagesLot Data ComputationKuzan Aokiji0% (1)

- Floatability and Stability of Oating Dock-Docked Ship SystemDocument7 pagesFloatability and Stability of Oating Dock-Docked Ship SystemEnida MataNo ratings yet

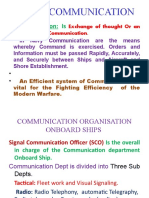

- Naval CommunicationDocument30 pagesNaval CommunicationMohan KhavnekarNo ratings yet

- Assignment For Seam 5Document6 pagesAssignment For Seam 5Jane CANo ratings yet

- Ship-Board Organizational Structure: Berdonar Agustin RosarioDocument28 pagesShip-Board Organizational Structure: Berdonar Agustin RosarioRonald C. Valdez Jr.No ratings yet

- Ship Particular Blue Marlin 02Document2 pagesShip Particular Blue Marlin 02Hermawan NathanaelNo ratings yet

- Standard Marine Communication PhrasesDocument152 pagesStandard Marine Communication PhrasesChristina PutriNo ratings yet

- OIL Record Book - Part II - Cargo&Ballast Operations SampleDocument3 pagesOIL Record Book - Part II - Cargo&Ballast Operations SampleSadik OzdamarNo ratings yet

- Msre - Anchoring Procedure Letter PDFDocument5 pagesMsre - Anchoring Procedure Letter PDFanhlh100% (1)

- Certificate of Bollard PullDocument2 pagesCertificate of Bollard PullAhmed SaadNo ratings yet

- Correcting An Angle of LollDocument6 pagesCorrecting An Angle of LollJames 123No ratings yet

- Singapore MagazineDocument36 pagesSingapore MagazinerobinxsunNo ratings yet

- St. Therese-Mtc Colleges Nav7Document34 pagesSt. Therese-Mtc Colleges Nav7Jeffrey SacramentoNo ratings yet