Professional Documents

Culture Documents

Bard - Technicoat

Uploaded by

Gabriel Ortiz MOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bard - Technicoat

Uploaded by

Gabriel Ortiz MCopyright:

Available Formats

TechniCoat Coating Information

TechniCoat

Coil Coating System

TechniCoat coils will function in most corrosive environments 5 to 10

times longer than uncoated coils. TechniCoat is the ultimate in

corrosive protection for HVAC/R coils in coastal and other corrosive

environments. Total Immersion ensures complete coverage with no

significant loss of thermal efficiency.

The 4-step coating system consist of (1) etch prime, (2) epoxy

polyamide, (3) epoxy-modified phenolic, and (4) phenolic sealer.

The result is a hi-density thin-film coating, which is applied to the louvered fins without bridging even at

26 fins per inch spacing. The finished TechniCoat surface is so smooth and free of micro-porosity,

provides exceptional sheeting action, which means less fouling, easier cleaning, and prevention of

microbiological contaminants.

Thermal efficiency loss consistently tests out at a negligible "under 1%." The longest ASTMB-117 salt

spray test conducted so far was terminated at 3100 hours with "no fin corrosion or degradation."

Uncoated aluminum finned coils are severely corroded after only 500 hours of testing, while copper-to-

copper coils were corroded and restricted air flow after 775 hours.

TechniCoat Is A Cost Effective Alternative For Coils In Coastal & Corrosive Environments

TechniCoat Coils Versus Copper-to-Copper Style Coils:

* A TechniCoat coil is generally 2.25 times less expensive.

* A Technicoat coil is nearly 3 times lighter than a copper finned coil.

* A Technicoat coil withstands more hours of exposure/operation that other coil options

Applications To Consider The Use Of TechniCoat Coated Coil Option

* Wastewater Treatment Plants * Wineries

* Gas and Oil Refinery Operations * Chemical Plants

* Battery Manufacturers * Pulp and Paper Mills

* Areas with Sulfur Water * Seacoast Installations

Bard Manufacturing Company – Bryan, Ohio 1 of 2 12/15/2003

TechniCoat Coating Information

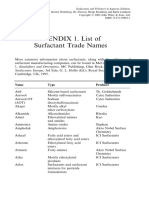

TechniCoat 10-1TM Is Resistant To Fumes Of The Following:

acetates - all citric acid nitric acid (dilute)

acetic acid coke oven gas nitrides - all

acetone esters-all nitrobenzene

acetylene ethers - all nitrogen fertilizers

acrylonitrile ethylene oxide oils - minerals / vegetable - all

alcohols - all fatty acids oxalic acid

aldehyders - all fluosilicic oxygen

alum formaldehyde perchloric acid (dilute)

amines - all formic acid phenol

ammonia Freon phosphoric acid

ammonium hydroxide fuels - all picric acid

ammonium nitrate gases - inert propane

aniline gases - manufactured salicylic acid

benzoic acid gases - natural silicic acid

benzol glycerine steam vapor

boric acid glycols - all stearic acid

brine hydrocarbons - all sulfate liquors

butane hydrochloric - acid sulfonic acid

carbolic acid hydrogen sulfur dioxide

carbonates - all iodides - all sulfuric acid

carbon dioxide ketones - all sulfurous acid

carbonic acid lacquers surfactants

carbon monoxide lactic acid tannic acid

carbon tetracholoride maleic acid tetraethyl lead

chlorides - all malic acid toluene

chlorinated solvents methanol trisodium phosphate

chlorine - less than 100 ppm methylene chloride urea

chloroform napthalene water

chromic acid nitrates - all xylene

The information presented about is based on both research and experience and are believeed to be entirely accurate. However, no guarantee of their accuracy can be

made for obvious reasons and no responsibility can be assumed by TechniCoat, Inc., and/or Bard Manufacturing Company.

With over 30 years experience and more than 750,000 coils in which TechniCoat has been applied,

TechniCoat 10-1TM stands are the state of the art in coil corrosion control.

For TechniCoat coil option availability and pricing information please contact the Bard Distributor for

your area.

Bard Manufacturing Company – Bryan, Ohio 2 of 2 12/15/2003

You might also like

- Chemical Resistances MaterialDocument4 pagesChemical Resistances MaterialCecep AtmegaNo ratings yet

- Verbund is intelligence in chemistryDocument1 pageVerbund is intelligence in chemistrytotpityiNo ratings yet

- Krytox Chemical StabilityDocument2 pagesKrytox Chemical StabilityMichael PimentelNo ratings yet

- Flow Basf Ludwigshafen 2014Document1 pageFlow Basf Ludwigshafen 2014totpityiNo ratings yet

- Appendix 2 Chemical Compatibility of Materials With Homogeneous GRAFOIL SheetDocument11 pagesAppendix 2 Chemical Compatibility of Materials With Homogeneous GRAFOIL SheetHolayilNo ratings yet

- Applications of Spray Drying: Product ListDocument4 pagesApplications of Spray Drying: Product ListGeorgina SalvatoreNo ratings yet

- Global Importer Metallic Salts ChemicalsDocument2 pagesGlobal Importer Metallic Salts ChemicalsChun HuangNo ratings yet

- Gasket Material Technical Data SheetDocument2 pagesGasket Material Technical Data SheetOnur ÇınarNo ratings yet

- Kalrez: Table K.1Document4 pagesKalrez: Table K.1reddyNo ratings yet

- Cargo Carried SheetDocument2 pagesCargo Carried SheetRubayatur Rahman NionNo ratings yet

- Basic LubricantDocument15 pagesBasic LubricantYanuar ArbasyahNo ratings yet

- Balluff Chemical ResistanceDocument17 pagesBalluff Chemical ResistanceHéctor Eduardo Hernández LópezNo ratings yet

- Chemical Products Guide: A Condensed Catalog of ProductsDocument3 pagesChemical Products Guide: A Condensed Catalog of Productslino fornollesNo ratings yet

- Ficha Tecnica Ácido Láctico - Galacid Heat-Stable 88Document1 pageFicha Tecnica Ácido Láctico - Galacid Heat-Stable 88Jorge Alejandro0% (1)

- Oilfield Services: Anti-Foams Antioxidants / Iron Control EthyleneaminesDocument2 pagesOilfield Services: Anti-Foams Antioxidants / Iron Control EthyleneaminesDarmawanSaputraNo ratings yet

- Paint TechnologyDocument5 pagesPaint TechnologyHesham MostafaNo ratings yet

- An ISO 9001:2015, ISO 14001:2015 & BS ISO 45001:2018 CompanyDocument6 pagesAn ISO 9001:2015, ISO 14001:2015 & BS ISO 45001:2018 Companysrikanth_krishnamu_3No ratings yet

- Resistance of Wefapress Plastics To Chemicals and Other Media!Document20 pagesResistance of Wefapress Plastics To Chemicals and Other Media!Pedro Henriques RamosNo ratings yet

- Tanker Cargo SheetDocument1 pageTanker Cargo SheetpardeepNo ratings yet

- uPVC & PVC Pipes Catalogue uPVC & PVC Pipes Catalogue: High Standard PipeDocument35 pagesuPVC & PVC Pipes Catalogue uPVC & PVC Pipes Catalogue: High Standard PipeFerryTimothyNo ratings yet

- Nor Syafi'Ah Diana Binti Mohd Nor Masitah Binti MD - YusofDocument27 pagesNor Syafi'Ah Diana Binti Mohd Nor Masitah Binti MD - Yusofctah2605No ratings yet

- 134 Data SheetDocument4 pages134 Data SheetcarlosNo ratings yet

- 1 TRADING PRODUCT LIST - Rev-01Document3 pages1 TRADING PRODUCT LIST - Rev-01aeryvishal4No ratings yet

- Λίστα Με Εμπορικές Ονομασίες ΕπιφανειοδραστικώνDocument7 pagesΛίστα Με Εμπορικές Ονομασίες ΕπιφανειοδραστικώνVassia TsoukalaNo ratings yet

- Osh Oiics 2010 2 3 2Document161 pagesOsh Oiics 2010 2 3 2Idris AdeniranNo ratings yet

- Chemical Compatibility Guide: PolypropyleneDocument5 pagesChemical Compatibility Guide: PolypropyleneNishaNo ratings yet

- Bryan KumferDocument28 pagesBryan KumferNam Vu TranNo ratings yet

- Mud Chemicals Cross Ref ChartDocument18 pagesMud Chemicals Cross Ref ChartMari WellNo ratings yet

- Surfactant CHEMISTRYDocument64 pagesSurfactant CHEMISTRYOzgur Selvi100% (3)

- Urea Plant Inspection (Sec 2)Document77 pagesUrea Plant Inspection (Sec 2)Mo LyNo ratings yet

- Supporting Information For:: I. Hita, S. Ghoreishi, J.I. Santos, T. Barth, H.J. HeeresDocument10 pagesSupporting Information For:: I. Hita, S. Ghoreishi, J.I. Santos, T. Barth, H.J. HeeresinnshiNo ratings yet

- Producerea RasinilorDocument115 pagesProducerea RasinilorPaul Chende100% (2)

- TR 301 Temperature Range For ElastomersDocument1 pageTR 301 Temperature Range For ElastomerscochcorpNo ratings yet

- ChemDocument3 pagesChemAlquino Heart RubioNo ratings yet

- Hydraulic Fracturing in HPHT WellsDocument36 pagesHydraulic Fracturing in HPHT WellsarispriyatmonoNo ratings yet

- Chemical Resistance ChartDocument1 pageChemical Resistance ChartushafireinfoNo ratings yet

- Lecture 7 Formic AcidDocument5 pagesLecture 7 Formic Acidhamzamaher.boy123No ratings yet

- Improvised Explosive Quick Guide: Chemical PrecursorsDocument4 pagesImprovised Explosive Quick Guide: Chemical Precursorsraman kumarNo ratings yet

- Greatcell Solar Material ListDocument2 pagesGreatcell Solar Material Listluciano_gularteNo ratings yet

- Chemical Compatibility Guide For Polyethylene ItemsDocument5 pagesChemical Compatibility Guide For Polyethylene Itemsredpole12No ratings yet

- FGS Line Pipe-OverviewDocument45 pagesFGS Line Pipe-OverviewTaras ByloNo ratings yet

- Scheduled of Lab Routine AnalysisDocument3 pagesScheduled of Lab Routine Analysisdilip matalNo ratings yet

- Sightglass For Flanges DatasheetDocument3 pagesSightglass For Flanges DatasheetKiky YulianaNo ratings yet

- Chemical Resistance Table Provides InsightsDocument5 pagesChemical Resistance Table Provides Insightsnoto.sugiartoNo ratings yet

- Arnite Chemical Resistance v1 1Document13 pagesArnite Chemical Resistance v1 1tomasykNo ratings yet

- Petronas Methanol Labuan Process OverviewDocument18 pagesPetronas Methanol Labuan Process OverviewSheena DovenantNo ratings yet

- Acid Base and Redox Titration CalculationsDocument33 pagesAcid Base and Redox Titration CalculationsoscarbecNo ratings yet

- Linde WAO TechnologyDocument30 pagesLinde WAO Technologyrzlisk01No ratings yet

- Industrial effluent discharge standards water qualityDocument8 pagesIndustrial effluent discharge standards water qualityFauzan HardiNo ratings yet

- Chemicals For Substitution of Hazardous ChemicalsDocument6 pagesChemicals For Substitution of Hazardous ChemicalsFatima AnwarNo ratings yet

- India-Eu Environment Forum Hazardous Waste Management in India: An Overview 'Document42 pagesIndia-Eu Environment Forum Hazardous Waste Management in India: An Overview 'shree_soni92No ratings yet

- Info Chemical WasteDocument14 pagesInfo Chemical WasteHendra Andreas Noverman SinagaNo ratings yet

- Material SealDocument2 pagesMaterial SealDennis SetiawanNo ratings yet

- Sulfuric Acid Production Sulfuric Acid: By: Carl Cesar H. BibatDocument7 pagesSulfuric Acid Production Sulfuric Acid: By: Carl Cesar H. BibatSam Denielle TugaoenNo ratings yet

- KES Chemicals Product PresentationDocument26 pagesKES Chemicals Product Presentationrangudusumanth1No ratings yet

- Textile Processing InputsDocument18 pagesTextile Processing InputsUjjwal JhaNo ratings yet

- Introduction To Semiconductor Manufacturing Technology: T. S. Chao Dept. of ElectrophysicsDocument81 pagesIntroduction To Semiconductor Manufacturing Technology: T. S. Chao Dept. of ElectrophysicsMichael KaoNo ratings yet

- Petroleum Refining Processes OverviewDocument21 pagesPetroleum Refining Processes OverviewCNAltNo ratings yet

- Bard - Wall Mount W R410A 3.5@6 TR, PartsDocument15 pagesBard - Wall Mount W R410A 3.5@6 TR, PartsGabriel Ortiz MNo ratings yet

- Bard - Wall Mount W R410A 1.5@2 TR, PartsDocument8 pagesBard - Wall Mount W R410A 1.5@2 TR, PartsGabriel Ortiz MNo ratings yet

- Bard - Wall Mount W R410A, Catalogo InglesDocument12 pagesBard - Wall Mount W R410A, Catalogo InglesGabriel Ortiz MNo ratings yet

- Bard - Roof Top PA-13 Series R410A, CatalogoDocument8 pagesBard - Roof Top PA-13 Series R410A, CatalogoGabriel Ortiz MNo ratings yet

- Ashrae 09 2hr Rev7d Part 1Document42 pagesAshrae 09 2hr Rev7d Part 1Gabriel Ortiz MNo ratings yet

- ANSINSF37Document44 pagesANSINSF37Gabriel Ortiz MNo ratings yet

- LPN2 Unheated Sanitation SubmittalsDocument2 pagesLPN2 Unheated Sanitation SubmittalsGabriel Ortiz MNo ratings yet

- Iom LPN2Document7 pagesIom LPN2Gabriel Ortiz MNo ratings yet

- Grooved Catalogue 2011 MechDocument34 pagesGrooved Catalogue 2011 MechantonioNo ratings yet

- Greenheck - Fan Selection Guide 2015Document4 pagesGreenheck - Fan Selection Guide 2015Gabriel Ortiz MNo ratings yet

- Alcohols Past PapersDocument5 pagesAlcohols Past PapersDhairya KumarNo ratings yet

- Solved Example: 1. The Final Product Obtained in The ReactionDocument43 pagesSolved Example: 1. The Final Product Obtained in The ReactionHardik SharmaNo ratings yet

- Determination of Phenol With HachDocument6 pagesDetermination of Phenol With HachDiraf FaridNo ratings yet

- Wood PreservationsDocument239 pagesWood Preservationsdora_grebeNo ratings yet

- Phenol Water System-Libre PDFDocument7 pagesPhenol Water System-Libre PDFManuel Esteban Videla BustosNo ratings yet

- BP301T organic chemistry exam questionsDocument1 pageBP301T organic chemistry exam questionsrajdavv2007No ratings yet

- Propofol SynthesisDocument8 pagesPropofol SynthesisGiorgos Doukas Karanasios0% (1)

- Chemical Compatibility Data PVC, LDPE, PTFEDocument13 pagesChemical Compatibility Data PVC, LDPE, PTFEAnastasijaNo ratings yet

- Alcohol Phenol and EthersDocument25 pagesAlcohol Phenol and EthersAyaz100% (2)

- Producing Cumene from Benzene and PropyleneDocument4 pagesProducing Cumene from Benzene and Propylenemiza adlinNo ratings yet

- XII Zoom PPT Final NewDocument219 pagesXII Zoom PPT Final NewBhuwan JoshiNo ratings yet

- Kerala University of Health Sciences: Bachelor Degree Course in PHARMACY (B.Pharm)Document65 pagesKerala University of Health Sciences: Bachelor Degree Course in PHARMACY (B.Pharm)Mukesh TiwariNo ratings yet

- Proceeding Bromometric Phenol Assay Without Starch IndicatorDocument6 pagesProceeding Bromometric Phenol Assay Without Starch IndicatorAsiyahNo ratings yet

- Alcohol, Phenol and Ether FinalDocument21 pagesAlcohol, Phenol and Ether FinalBhavesh KNo ratings yet

- Qualitative Test For PhenolDocument6 pagesQualitative Test For PhenolRonak PandeyNo ratings yet

- NCERT Solutions For Class 12 Chemistry Chapter 11 Alcohols Phenols and EthersDocument32 pagesNCERT Solutions For Class 12 Chemistry Chapter 11 Alcohols Phenols and EthersVIJAYNo ratings yet

- Coursebook Answers Chapter 25 Asal ChemistryDocument4 pagesCoursebook Answers Chapter 25 Asal ChemistryAditiNo ratings yet

- USEPA Aminoantipryne Metoda HACHDocument6 pagesUSEPA Aminoantipryne Metoda HACHdark_knight007No ratings yet

- Systematic Qualitative Organic AnalysisDocument17 pagesSystematic Qualitative Organic Analysisravi@laviNo ratings yet

- Alcohols-Structure and Synthesis 2Document82 pagesAlcohols-Structure and Synthesis 2Diana Cárdenas MuñozNo ratings yet

- Amines, Aromatic, DiarylaminesDocument8 pagesAmines, Aromatic, DiarylaminesEmmanuel ChangNo ratings yet

- Versalis Proprietary Cumene Process TechnologyDocument4 pagesVersalis Proprietary Cumene Process TechnologyJohn DalkiaNo ratings yet

- Chemistry 2 For OCR - David Acaster PDFDocument247 pagesChemistry 2 For OCR - David Acaster PDFClint GreerNo ratings yet

- Class Test -1 Chapter 1 Alcohol Phenol & EthersDocument1 pageClass Test -1 Chapter 1 Alcohol Phenol & EthersSomu Yashawant ChaudhariNo ratings yet

- Hydroxy CompoundsDocument9 pagesHydroxy Compoundschong56No ratings yet

- The Kinetics and Thermodynamics of The Phenol From Cumene Process: A Physical Chemistry ExperimentDocument5 pagesThe Kinetics and Thermodynamics of The Phenol From Cumene Process: A Physical Chemistry Experimentkanokwan jaruekNo ratings yet

- Carboxylic Acids and Derivatives SolutionsDocument16 pagesCarboxylic Acids and Derivatives SolutionsAmbrieshKarthikNo ratings yet

- CBSE Class 12 Chemistry Question Paper 2019Document7 pagesCBSE Class 12 Chemistry Question Paper 2019BT De0pA PUBG MOBILENo ratings yet

- One-Pot Synthesis of Aromatic Hydroxyketones Under Microwave Irradiation and Solvent-Free ConditionsDocument6 pagesOne-Pot Synthesis of Aromatic Hydroxyketones Under Microwave Irradiation and Solvent-Free ConditionsAwad SaidNo ratings yet