Professional Documents

Culture Documents

Levafix CA

Uploaded by

José Augusto MarquesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Levafix CA

Uploaded by

José Augusto MarquesCopyright:

Available Formats

Levafix® CA

Add value to your

business with

DyStar's reactive

diamonds

Levafix CA - New high performance dyes to meet retailer demands

Contents

1 Overview of product range

2 Requirements of the textile supply chain and retailers

3 Color Confidence with Levafix CA

4 Controlled Coloration in exhaust processes

5 Controlled Coloration in pad processes

6 Levafix Olive CA / Olive CA 100

7 Summary

M&I TM Cell Levafix CA - May, 2006

close

Overview of product range

Levafix CA range

b 100

Brilliant Yellow CA

80 Yellow CA

60

Amber CA Orange CA

40

Scarlet CA

20

Olive CA 100

Red CA

Rubine CA

0

-20 0 20 40 60 70 a

FastRed CA

Navy CA -20

-40 Blue CA

M&I TM Cell Levafix CA - May, 2006

close

Overview of product range

Product overview

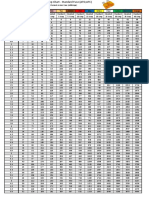

0.35% 1.50% 3.50%

Levafix Brill. Yellow CA

Brilliant, greenish yellow. Non photochromic. Can be combined with

Remazol turquoise dyes. Easy to wash off. Good wet fastness properties.

Levafix Yellow CA

Light fast trichromatic yellow with very good build-up. Easy to wash off.

Good wet fastness.

Levafix Amber CA

Non-photochromic yellow for trichromatic shades.

It is excellent suitable for pale to medium shades. High fastness profile.

Levafix Orange CA

Brilliant orange. Basis for orange/red shades and trichromatic shades. High

solubility, good light fastness and good perspiration wet light fastness

compared to other orange dyes. Excellent wash-off properties.

M&I TM Cell Levafix CA - May, 2006

close

Overview of product range

Product overview

0.35% 1.50% 3.50%

Levafix Scarlet CA

Brilliant scarlet. Good light fastness and perspiration wet light fastness compared with

other scarlets. Excellent wash-off properties. Basis for brilliant scarlet/red shades.

Levafix Red CA

Very bright red dye. Basis for brilliant shades and trichromatic combinations.

Good wash-off properties. Good wet fastness.

Levafix Rubine CA

Bluish red dye with high light fastness. For trichromatic shades.

Good fastness to chlorine. Very good build-up.

Levafix FastRed CA 0.125% 0.50% 2.0%

High light fast copper-free red for ternary shades. Stable also for M&S C7

perspiration fastness. Recommended in combination with Amber CA,

Blue CA and Olive CA 100

M&I TM Cell Levafix CA - May, 2006

close

Overview of product range

Product overview

0.35% 1.50% 3.50%

Levafix Blue CA

Clear, neutral dye with high light fastness for dyeing trichromatic shades.

Good build-up. Good wash-off properties. Blue dye with very good levelling

properties, even in pale shades.

Levafix Navy CA

Clear navy blue for medium to deep combination and trichromatic shades.

Good wash-off properties. Good wet fastness.

Levafix Olive CA

Homogeneous olive for khaki and earth shades. Very high light fastness,

wet light fastness and fastness to oxidising agents. Very good reproducibility.

M&I TM Cell Levafix CA - May, 2006

close

Dye recommendations

Trichromatic combinations

Pale shades Medium shades Dark shades

Levafix Amber CA Levafix Yellow CA Levafix Yellow CA

Levafix FastRed CA Levafix Amber CA Levafix Amber CA

Levafix Blue CA (non-photochromism) (non-photochromism)

Levafix FastRed CA Levafix Red CA

Levafix Red CA Levafix Rubine CA

Levafix Blue CA Levafix Blue CA

Levafix Navy CA

M&I TM Cell Levafix CA - May, 2006

close

Dye recommendations

Specific shades

Brilliant Red/Coral Brill. Green/Turquoise Olive/Khaki

Levafix Orange CA Levafix Brilliant Yellow CA Levafix Olive CA 100

Levafix Scarlet CA Remazol Brilliant Green 6B shading dyes

Levafix Red CA Levafix Blue CA

Levafix Amber CA

Levafix Blue CA Levafix FastRed CA

Levafix Blue CA

M&I TM Cell Levafix CA - May, 2006

close

Colour triangle of Levafix Amber CA, FastRed CA, Blue CA

0.20% Levafix Amber CA

0.16%/ - /0.04% 0.16%/0.04%/ -

0.12%/ - /0.08% 0.12%/0.04%/0.04% 0.12%/0.08%/ -

0.08%/ - /0.12% 0.08%/0.04%/0.08% 0.08%/0.08%/0.04% 0.08%/0.12%/ -

0.04%/ - /0.16% 0.04%/0.04%/0.12% 0.04%/0.08%/0.08% 0.04%/0.12%/0.04% 0.04%/0.16%/ -

0.20% Levafix Blue CA - / 0.04%/0.16% - /0.08%/0.12% - /0.12%/0.08% - /0.16%/0.04% 0.20% LevafixFastRedCA

M&I TM Cell Levafix CA - May, 2006

close

Color triangle of Levafix Amber CA, Rubine CA, Blue CA

0.2 % Levafix Amber CA

0.04%/ - /0.16% - /0.04%/0.16%

0.08%/ - /0.12% 0.04%/0.04%/0.12% - /0.08%/0.12%

0.12%/ - /0.08% 0.08%/0.04%/0.08% 0.04%/0.08%/0.08% - /0.12%/0.08%

0.16%/ - /0.04% 0.12%/0.04%/0.04% 0.08%/0.08%/0.04% 0.04%/0.12%/0.04% - /0.16%/0.04%

0.2 % Levafix Blue CA 0.16%/0.04%/ - 0.12%/0.08%/ - 0.08%/0.12%/ - 0.04%/0.16%/ - 0.2 % Levafix Rubine CA

M&I TM Cell Levafix CA - May, 2006

close

Color triangle of Levafix Yellow CA, Red CA, Blue CA

0.2 % Levafix Yellow CA

0.04%/ - /0.16% - /0.04%/0.16%

0.08%/ - /0.12% 0.04%/0.04%/0.12% - /0.08%/0.12%

0.12%/ - /0.08% 0.08%/0.04%/0.08% 0.04%/0.08%/0.08% - /0.12%/0.08%

0.16%/ - /0.04% 0.12%/0.04%/0.04% 0.08%/0.08%/0.04% 0.04%/0.12%/0.04% - /0.16%/0.04%

0.2 % Levafix Blue CA 0.16%/0.04%/ - 0.12%/0.08%/ - 0.08%/0.12%/ - 0.04%/0.16%/ - 0.2 % Levafix Red CA

M&I TM Cell Levafix CA - May, 2006

close

Color triangle of Levafix Amber CA, Rubine CA, Blue CA

2.0 % Levafix Amber CA

0.40%/ - /1.60% - /0.40%/1.60%

0.80%/ - /1.20% 0.40%/0.40%/1.20% - /0.80%/1.20%

1.20%/ - /0.80% 0.80%/0.40%/0.80% 0.40%/0.80%/0.80% - /1.20%/0.80%

1.60%/ - /0.40% 1.20%/0.40%/0.40% 0.80%/0.80%/0.40% 0.40%/1.20%/0.40% - /1.60%/0.40%

2.0 % Levafix Blue CA 1.60%/0.40%/ - 1.20%/0.80%/ - 0.80%/1.20%/ - 0.40%/1.60%/ - 2.0 % Levafix Rubine CA

M&I TM Cell Levafix CA - May, 2006

close

Color triangle of Levafix Yellow CA, Red CA, Blue CA

2.0 % Levafix Yellow CA

0.40%/ - /1.60% - /0.40%/1.60%

0.80%/ - /1.20% 0.40%/0.40%/1.20% - /0.80%/1.20%

1.20%/ - /0.80% 0.80%/0.40%/0.80% 0.40%/0.80%/0.80% - /1.20%/0.80%

1.60%/ - /0.40% 1.20%/0.40%/0.40% 0.80%/0.80%/0.40% 0.40%/1.20%/0.40% - /1.60%/0.40%

2.0 % Levafix Blue CA 1.60%/0.40%/ - 1.20%/0.80%/ - 0.80%/1.20%/ - 0.40%/1.60%/ - 2.0 % Levafix Red CA

M&I TM Cell Levafix CA - May, 2006

close

Market Communication Network

Textile Market Communication Network

Garment

Dyer Converter Retailer

Maker

Machine Fibre

Maker Maker

M&I TM Cell Levafix CA - May, 2006

close

Requirements of the retailer / brands and their supply chain

High quality performance requirements to differentiate textile articles

Wet fastness

Multiple wash in activated bleach detergents (ISO 105 CO9)

Single wash in activated bleach detergents (ISO 105 CO8)

Oxidative hydrolysis

Light fastness

To blue standard fade (ISO)

To set hours 20/40 (AATCC)

Wet light fastness

Detergent (M&S C9A)

Perspiration alkali/acid (Nike)

Minimal photochromism

Shade achievability with no metamerism

M&I TM Cell Levafix CA - May, 2006

close

Requirements of the dyer

High application requirements to drive down the unit production costs

Compatibility

For homogeneous exhaustion / fixation

Reproducibility

For right-first-time production

Homogeneous migration/diffusion

For level dyeings and no two sidedness of emerised fabrics

High fixation value with similar fixation behaviour

For generally good wash-off properties and controlled colour build-up in cpb

No tailing

To reduce the seconds quality of every unit

Suitability for all processes

To minimise metamerism if production is dyed by different application methods

M&I TM Cell Levafix CA - May, 2006

close

DyStar - Working for your benefit

Color Confidence and Controlled Coloration

For performance - driven segment (meeting retailer/brand needs)

Color Confidence

For application benefits (meeting dyer's needs)

Controlled Coloration

M&I TM Cell Levafix CA - May, 2006

close

Color Confidence with Levafix CA

Requirements of the supply chain and retailers

Color Confidence

High fastness levels

Minimal photochromism

Insensitive to copper ions in

domestic water supply

Meeting market demands

M&I TM Cell Levafix CA - May, 2006

close

High fastness levels

Levafix FastRed CA for Color Confidence

Material: bleached CO tricot * Evaluation: change of shade/staining of CTA/CO/PA6.6/PES/PAN/CV

M&I TM Cell Levafix CA - May, 2006

close

High fastness levels

Levafix CA dyes have very good fastness properties

compared with competing dyes in deep trichromatic shades

60°C- Chlo rinate d Perspiratio n w et

Lig ht fastne ss NIKE pe rspiratio n

De e p trichromatic C2 do me stic w ate r, 60°C-w ashing lig ht fastne ss

ISO 105-B02 w e t lig ht fastness

shade launde ring 20 mg /l (ISO 105- C09) (in-ho use te st)

(Xe no n) te st acid/ alkaline

(ISO 105-C06) act. chlo rine dry/ acid/ alk.

Le vafix *4/5/5/ 3R 4 4-5 4-5 / 4 / 4-5 4 / 3-4

1,37% Yellow CA 5/5/5/5

1,62% Re d CA

1,18% Blue CA

Le vafix *4/5/5/ 3-4 4 6 5/5/5 4 / 3-4

1,05% Ambe r CA 5/5/5/5

1,80% Rubine CA

1,30% Blue CA

Cibacro n *4/5/3/ 3 4 4-5 4-5 / 4-5 / 4-5 3Y / 1

1,07% Yellow FN-2R 5/5/5/4

2,00% Re d C-2G

1,60% Blue FN-R

Sumifix Supra *3/5/2/ 3R 3-4R 4 4-5 / 3-4 / 4 3-4 / 2Y

2,00% Yellow 3RF 4/4/4/4

2,25% Brilliant Re d 3BF

2,18% Blue BRF

Co lo r Inde x Re active * 2-3R / 5 / 4 / 2-3R 2-3R 3Y 3-4 / 2 / 3-4 2-3 / 1

1,55% Yellow 176 5/5/5/5

1,92% Re d 239

0,69% Black 5

Material: bleached CO-tricot *Evaluation: change of shade/staining of: CTA/CO/PA6.6/PES/PAN/CV

M&I TM Cell Levafix CA - May, 2006

close

High fastness levels

Levafix CA dyes are far more stable to repeated washing than Cibacron C dyes

Washing fastness test 60 °C, ISO 105-C09

Levafix CA dyes Cibacron C dyes

dE Grey dE Grey

Dyeing ISO 105-C09 CIELAB scale Dyeing ISO 105-C09 CIELAB scale

Yellow CA Yellow C-2R

Red CA

2.7 4 Red C-2G

4.9 2-3

Yellow CA Yellow C-2R

Red CA 2.3 4 Red C-2G 5.0 2-3

Blue CA Navy C-B

Yellow CA Yellow C-2R

Red CA 0.56 4-5 Red C-2G 7.3 2

Navy CA Navy C-B

Material: bleached CO-tricot Wash fastness 60 °C ISO 105-C09 simulates a multiple washing

M&I TM Cell Levafix CA - May, 2006

close

Minimal photochromism

Unlike many reactive yellow dyes, Levafix Amber CA has minimal photochromism

Photochromism of different yellow reactive dyestuffs

2,50

2,00

1,50

dE The lower the dE,

1,00 the less photochromic

the dyes

0,50

0,00

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 41 43 45 47 49

n u m b e r o f fla sh e s

Cibacron Yellow C-R01 Cibacron Yellow C-2R

Levafix Yellow CA Levafix Yellow E-3RL

Levafix Golden Yellow E-G 150% Remazol Golden Yellow RNL 150%

Remazol Yellow 3 RS 133% Levafix Amber CA

Cibacron Yellow NP

M&I TM Cell Levafix CA - May, 2006

close

Insensitive to copper ions in domestic water supply

Levafix Rubine CA is stable against copper ions, whereas

Cibacron Red FN/C-2BL and Cibacron C-2G are very sensitive to copper ions

0.25% Levafix Rubine CA 0.25% Cibacron Red C-2G

Household washing

Simulated effect if Cu++ ions

present in domestic wash

cycle using activated bleach

detergents

0.25% Levafix Rubine CA 0.25% Cibacron Red FN/C-2BL

Original Original Original + Original + Original Original

+ H2O2 H2O2 +

Cu++ soda ash soda ash Cu++

Dyebath

Simulated effect if Cu++ ions

and rest of peroxide from pre-

treatment are present in the

dyebath and no sequesterent is

used

Original + H2O2 Original + H2O2

soda ash and Cu++ Material: bleached CO-tricot soda ash and Cu++

M&I TM Cell Levafix CA - May, 2006

close

Controlled Coloration in exhaust processes

Requirements of exhaust dyers

Compatibility

Controlled Coloration

Reproducibility

Levelness / Migration

Fixation value

Driving down

Right-First-Time philosophy the unit costs of production

M&I TM Cell Levafix CA - May, 2006

close

Compatibility

Levafix FastRed CA: homogenous dyeing behaviour every time

0.125% Levafix Amber CA

0.360% Levafix FastRed CA

0.105% Levafix Blue CA

Alkali dosing 5.00 g/l soda ash

20 g/l NaCl

50% progression 0.75 ml/l caustic soda 50%

1 g/l Erkantol AS

10' 5' 5' 10' 10' 15' 15' 15' 30'

60° C

M1 M2 M3 M4 M5 M6 M7 M8 M9

soaped

unsoaped

Dyeing conditions:

60 °C constant

100% bleached CO tricot

liquor ratio 10:1 M1 M2 M3 M4 M5 M6 M7 M8 M9

M&I TM Cell Levafix CA - May, 2006

close

Compatibility

Levafix CA level dyeing every time

1.05 % Levafix Amber CA

1.80 % Levafix Rubine CA

1.80 % Levafix Blue CA 5 g/l soda ash

70 g/l NaCl Alkali dosing

50% progression 1.6 ml/l NaOH 50%

1 g/l Erkantol AS

10' 5' 5' 10' 10' 15' 15' 15' 30'

60° C

M1 M2 M3 M4 M5 M6 M7 M8 M9

soaped

unsoaped

Dyeing conditions:

60°C constant

bleached CO tricot

liquor ratio 10:1

M&I TM Cell Levafix CA - May, 2006

close

Compatibility

Levafix CA level dyeing every time

1.37 % Levafix Yellow CA

1.62 % Levafix Red CA

1.18 % Levafix Blue CA 5 g/l soda ash

70 g/l NaCl Alkali dosing

50% progression 1.6 ml/l NaOH 50%

1 g/l Erkantol AS

10' 5' 5' 10' 10' 15' 15' 15' 30'

60° C

M1 M2 M3 M4 M5 M6 M7 M8 M9

soaped

unsoaped

Dyeing conditions:

60°C constant

bleached CO tricot

liquor ratio 10:1

M&I TM Cell Levafix CA - May, 2006

close

Compatibility

Risk of unlevel dyeing resulting from neutral fixation of Cibacron Blue FN-R

0.1 % Levafix Blue CA 0.1 % Cibacron Blue FN-R

Amount of

Na-bicarbonate

in process water Final shade after 30 min after 30 min Final shade

(100 %) (before adding soda ash) (before adding soda ash) (100 %)

0 ppm 8.0 % 22.2 %

100 ppm 8.4 % 23.6 %

300 ppm 11.1 % 25.2 %

600 ppm 13.41 % 25.0 %

Material: bleached CO tricot Dye Soda ash

Recipe: LR 10:1, 60 °C constant Salt

x % dye (bicarbonate)

15 g/l NaCl

60 °C 30 min 60 min

5 g/l soda ash

M&I TM Cell Levafix CA - May, 2006

close

Reproducibility

Levafix FastRed CA: Right-First-Time performance for critical ternaries

Le vafix Ambe r CA % 0.125 1,5

Le vafix FastRe d CA % 0.360

Le vafix Blue CA % 0.105

1

NaCl g/l 20.000

delta H greener

So da ash g/l 7.000

Liquo r ratio 1 : 10 0,5

96

Fixatio n time min 60 8 2 10

Pro ce ss 60 °C co nst. 30 5 4117

141 13

12

-1,5 -1 -0,5 0 0,5 1 1,5

Sample Sample -0,5

redder

1 Standard 9 Alkali + 10%

2 Overfill + 10 % 10 Time - 15 min -1

3 Underfill - 10 % 11 Time + 15 min

4 Overfill + 20 % 12 Temperature - 5 °C -1,5

5 Underfill - 20 % 13 Temperature + 5 °C

6 Salt - 10 % 14 Liquor ratio - 30% d u ller d elta C b rig h ter

7 Salt + 10 % 15 Liquor ratio + 30%

8 Alkali - 10 % standard

2 3 4 5 6 7 8 9 10 11 12 13 14 15

M&I TM Cell Levafix CA - May, 2006

close

Reproducibility

Levafix CA hit the target whenever you dye

Le vafix Ambe r CA % 0,120 1,5

Le vafix Rubine CA % 0,180

Le vafix Blue CA % 0,120

1

NaCl g/l 20,000

So da ash g/l 5,000

delta H greener

NaOH 50% ml/l 0,750 0,5

Liquo r ratio 1 : 10 8

12 116 5

Fixatio n time min 60 140 2 3915

Pro ce ss 60°C co nst. 10

-1,5 -1 -0,5 04 1 0,5 1 1,5

7

Sample Sample 13

redder

-0,5

1 Standard 9 Alkali + 10%

2 Overfill + 10 % 10 Time - 15 min

3 Underfill - 10 % 11 Time + 15 min -1

4 Overfill + 20 % 12 Temperature - 5 °C

5 Underfill - 20 % 13 Temperature + 5 °C

6 Salt - 10 % 14 Liquor ratio - 30% -1,5

duller delta C brighter

7 Salt + 10 % 15 Liquor ratio + 30%

8 Alkali - 10 % standard

2 3 4 5 6 7 8 9 10 11 12 13 14 15

M&I TM Cell Levafix CA - May, 2006

close

Reproducibility

Levafix CA dyes have better reproducibility than Cibacron FN dyes

Cibacro n Ye llo w NP % 0,153 1,5

Cibacro n Re d FN-2BL % 0,374

Cibacro n Blue FN-R % 0,120

4 1

NaCl g/l 30,000

So da ash g/l 5,000 12

6

delta H greener

NaOH 50% ml/l 0,270 20,5

8 15

Liquo r ratio 1 : 10 13

10

Fixatio n time min 60 911

0

Pro ce ss 60°C co nst. -1,5 -1 -0,5 01

3 7

140,5

5 1 1,5

Sample Sample

redder

-0,5

1 Standard 9 Alkali + 10%

2 Overfill + 10 % 10 Time - 15 min

3 Underfill - 10 % 11 Time + 15 min -1

4 Overfill + 20 % 12 Temperature - 5 °C

5 Underfill - 20 % 13 Temperature + 5 °C

6 Salt - 10 % 14 Liquor ratio - 30% -1,5

7 Salt + 10 % 15 Liquor ratio + 30%

8 Alkali - 10 % standard

2 3 4 5 6 7 8 9 10 11 12 13 14 15

M&I TM Cell Levafix CA - May, 2006

close

Reproducibility

Levafix CA dyes have better reproducibility than Drimaren HF dyes

Drimare n Orang e HF-2GL % 0,120 1,5

Drimare n Re d HF-2B % 0,200

Drimare n Blue HF-RL % 0,170 1

NaCl g/l 50,000

So da g/l 5,000

delta H greener

0,5 13 9

Liquo r ratio 1 : 10

Fixiatio n time min 60 28 35

6 11 7

12 10

Pro ce ss 60°C co nst. 0 4 14

´15

-1,5 -1 -0,5 0 1 0,5 1 1,5

Sample Sample

redder

-0,5

1 Standard 9 Soda ash + 10%

2 Overfill + 10 % 10 Time - 15 min

3 Underfill - 10 % 11 Time + 15 min -1

4 Overfill + 20 % 12 Temperature - 5 °C

5 Underfill - 20 % 13 Temperature + 5 °C

6 Salt - 10 % 14 Liquor ratio - 30% -1,5

duller delta C brighter

7 Salt + 10 % 15 Liquor ratio + 30%

8 Soda ash - 10 % standard

2 3 4 5 6 7 8 9 10 11 12 13 14 15

M&I TM Cell Levafix CA - May, 2006

close

Levelness / Migration

Levafix CA dyes migrate on tone in the exhaust phase

A B + D Final shade

Substantive dyeing Substantive Migration onto

dyeing after undyed material 60 °C const.

Soda ash

migration

Levafix Amber CA / Levafix Rubine CA / Levafix Blue CA Levafix Yellow CA / Levafix Red CA / Levafix Blue CA

A B D Final shade A B D Final shade

Cibacron Yellow NP/ Red FN-2BL / Blue FN-R Cibacron Yellow FN-2R / Red FN-2BL / Blue FN-R

A B D Final shade A B D Final shade

Test conditions: liquor ratio 10:1, 60°C, bleached CO knitgoods

M&I TM Cell Levafix CA - May, 2006

close

Levelness / Migration

Levafix CA dyes migrate on tone in the exhaust phase

A B + D Final shade

Substantive dyeing Substantive Migration onto

dyeing after undyed material 60 °C const.

Soda ash

migration

Levafix Amber CA / Levafix Rubine CA / Levafix Blue CA Levafix Yellow CA / Levafix Red CA / Levafix Blue CA

A B D Final shade A B D Final shade

Sumifix Supra Yellow 3RF/ Brilliant Red 3BF / Blue BRF Color Index Reactive Yellow 176 / Red 239 / Black 5

A B D Final shade A B D Final shade

Test conditions: liquor ratio 10:1, 60°C, bleached CO knitgoods

M&I TM Cell Levafix CA - May, 2006

close

Fixation value

Levafix CA dyes have high fixation values

Fixation (%)

Fixation behaviour in exhaust dyeing at 60 °C on bleached, mercerised CO, 2% dyeing, liquor ratio 10:1

M&I TM Cell Levafix CA - May, 2006

close

Right-First-Time philosophy

Effect of "Wrong-First-Time" on process costs

= 217%

Cost of corrections

= 166%

= 134%

= 117%

= 105%

= 100%

Dye ing + sampling + 1 additio n + 1 additio n + drying , + drying ,

w itho ut in the in a shading o ve rdye ing

sampling same bath fre sh bath co rre ctio n in black

CO-tricot - reactive dyes (jet, 300 kg, LR 8:1, 3 shifts)

M&I TM Cell Levafix CA - May, 2006

close

Controlled Coloration in pad processes

Requirements of pad dyers

Reproducibility

Homogeneous migration / Controlled Coloration

diffusion

No two sidedness

No tailing

Compatible fixation behaviour in

cpb

Pad liquor stability in cpb

Driving down

Easy wash-off

the unit costs of production

Suitability for all processes

M&I TM Cell Levafix CA - May, 2006

close

Reproducibility

Lab-to-bulk reproducibility in the Econtrol process

Grey

CMC DE

0.93

Levafix Yellow CA gran 3.8 g/l Lab

Levafix Red CA gran 1.8 g/l

Levafix Blue CA gran 6.5 g/l

M&I TM Cell Levafix CA - May, 2006

close

Reproducibility

Levafix FastRed CA: insensitivity to continuous dyeing variables

Robustness in pad-dry pad-steam process

Standard: 150 g/l salt 300 g/l salt

Levafix Amber CA g/l 5.1 95% 103%

Levafix FastRed CA g/l 2.8 101%

Levafix Blue CA g/l 2.8 Standard

Common salt g/l 250 102%

103% 103%

Soda ash g/l 20

NaOH 50% ml/l 4

Drying: 60 seconds at 120 °C 2 ml/l NaOH, 20 g/l soda 12 ml/l NaOH

Steaming: 60 seconds at 102 °C 30" steaming time 120" steaming time

M&I TM Cell Levafix CA - May, 2006

close

Reproducibility

Levafix CA: insensitive to continuous dyeing variables

As for standard, As for standard, As for standard,

but with 150 g/l salt but with 200 g/l salt but for 300 g/l salt

100% 100% 103%

dE 0,07 dE 0,06 dE 0,22

Standard

100%

97% 103% 97% 101%

dE 0,11 dE 0,24 dE 0,53 dE 0,09

As for standard,

As for standard, As for standard, As for standard,

but with 1 ml/l NaOH but with 4 ml/l NaOH

No soda ash but steam for 30 s but steam for 90 s

Standard: 6.8 g/l Levafix Yellow CA 20 g/l soda ash

2.1 g/l Levafix Rubine CA 3 ml/l NaOH 50%

2.5 g/l Levafix Blue CA Drying 60 seconds at 120 °C

250 g/l salt Steaming 60 seconds at 102 °C

Material: bleached, merc. CO

M&I TM Cell Levafix CA - May, 2006

close

Reproducibility

Levafix FastRed CA: balanced migration behaviour in pad-dry pad-steam

- big advantage versus competition -

Sandwich test

Levafix Amber CA g/l 5.1 Cibacron Yellow NP g/l 7.0

Levafix FastRed CA g/l 2.8 Cibacron Red C-2BL g/l 2.8

Levafix Blue CA g/l 2.8 Cibacron Blue C-R g/l 2.8

On-tone Off-tone

Original 100% 100%

Top 119% 143%

Bottom 69% 78%

M&I TM Cell Levafix CA - May, 2006

close

Homogeneous migration / diffusion

Levafix CA dyes migrate on tone.

Cibacron C dyes indicate migration problems during drying

2,7 g/l Levafix Amber CA 4.0 g/l Cibacron Yellow NP

0,8 g/l Levafix Rubine CA 1,6 g/l Cibacron Red C-2BL

0,8 g/l Levafix Blue CA 1.0 g/l Cibacron Blue C-R

100% 1. Standard 100%

dE 1,5 2. Front dE 2,1

dE 0,67 3. Back dE 1,4

Sandwich test (to test migration)

1.) Standard: dyed as usual in the pad-dry-pad-steam process

2.) and 3.) are padded with dye solution placed on top of each other and dried together

the dyeings are then completed separately (chemical pad steaming)

The smaller the difference in shade between the three dyeings, the more evenly the dyes

migrate and the lower the difference in shade between the front and back of the fabric.

Material: bleached, merc. CO; liquor pick-up 65%

M&I TM Cell Levafix CA - May, 2006

close

Migration behaviour

Levafix FastRed CA: perfect tailing behaviour in pad-steam application

Bulk trial results No difference in depth

on corduroy

Levafix Amber CA g/l 3.5

Levafix FastRed CA g/l 4.6

No difference in hue

Levafix Olive CA 100 g/l 13.0

Soda ash g/l 20.0

Padding temperature: 25 °C

Pick up: 70%

No difference in chroma

Steaming time: 90''

Steaming temperature: 102 °C

M&I TM Cell Levafix CA - May, 2006

close

Emerised fabric

Levafix CA: homogenous migration/fixation in CPB for minimised

two sidedness on emerised fabric and corduroy

Levafix CA Silicate 50 method

Face Back

Levafix Amber CA g/l 0.35 Emerised

fabric

Levafix FastRed CA g/l 0.22

Corduroy

Levafix Olive CA 100 g/l 2.00

Levafix Amber CA g/l 5.50

Levafix FastRed CA g/l 7.10 Corduroy

Levafix Blue CA g/l 16.10

M&I TM Cell Levafix CA - May, 2006

close

No two-sidedness

Levafix Amber CA, Remazol Red FLM and

Levafix Blue CA does not cause two sidedness

20.97 g/l Levafix Amber CA 32.74 g/l Levafix Amber CA

7.74 g/l Remazol Red FLM 14.8 g/l Levafix Blue CA

15.06 g/l Levafix Blue CA

Front Back Front Back

A A

B B

Comparison: A: Nip

B: Trough

Dyeing conditions: silicate 50 method, liquor pick-up 65%, emerised CO

M&I TM Cell Levafix CA - May, 2006

close

No tailing

Increase your profit by reduced tailing

1.5 g/l Lev. Amber CA 0.45 g/l Lev. Amber CA 1.6 g/l Lev. Amber CA 1.5 g/l Lev. Amber CA 1.1 g/l Lev. Amber CA 0.62 g/l Lev. Amber CA

0.8 g/l Rem. Red FLM 0.2 g/l Rem. Red FLM 0.5 g/l Rem. Red FLM 0.1 g/l Rem. Red FLM 0.3 g/l Rem. Red FLM 0.5 g/l Rem. Red FLM

0.27 g/l Lev. Blue CA 0.27 g/l Lev. Blue CA 0.96 g/l Lev. Blue CA 1.0 g/l Lev. Blue CA 1.4 g/l Lev. Blue CA 1.7 g/l Lev. Blue CA

Rem azo l m et h o d (silicat e 50), liq u o r p ick-u p 60% , Test conditions :

100% m erc.CO ren fo rce

0 1 2 3 4 5 6 7

A freshly formulated liquor is padded onto A and

the dyeing is carried out. Then a 5 m length of

2 2 fabric is then padded with a fresh liquor. The

dE in a ccorda nce w it h

1,62 residual liquor is padded onto B and the dyeing is

1,5 1,48 1,5

1,33

completed.

CMC 2:1

1 1,04 1

0,78 0,84 The lower the difference in shade between

0,5 0,5 A and B, the more equal the substantivity of the

0 0 dyes in respect of tailing

1 2 3 4 5 6

M&I TM Cell Levafix CA - May, 2006

close

No tailing

Competition dye selections can decrease your profit.

Reduce the seconds quality by using Levafix CA

Cibacron Cibacron Cibacron Cibacron Cibacron Cibacron

1.97 g/l Yellow NP 0.64 g/l Yellow NP 2.04 g/l Yellow NP 1.94g/l Yellow NP 1.48 g/l Yellow NP 0.81 g/l Yellow NP

1.31 g/l Red C2BL 0.33 g/l Red C2BL 0.68 g/l Red C2BL 0.09 g/l Red C2BL 0.38 g/l Red C2BL 0.66 g/l Red C2BL

0.29 g/l Blue R-R 0.30 g/l Blue C-R 0.96 g/l Blue C-R 1.01 g/l Blue C-R 1.45g/l Blue R-R 1.77g/l Blue C-R

Silicate 70 m eth o d , Ciba Var. C3, liq u o r p ick-u p 60% , Test conditions :

100% m erc. CO ren force

0 1 2 3 4 5 6 7

A freshly formulated liquor is padded onto A and

the dyeing is carried out. Then a 5 m length of

2 2,35 2,5 fabric is then padded with a fresh liquor. The

dE in a ccorda nce w it h

1,5 1,86 1,9 2 residual liquor is padded onto B and the dyeing is

1,7 1,8

1,55 completed.

CMC 2:1

1,5

1

1 The lower the difference in shade between

0,5 0,5 A and B, the more equal the substantivity of the

0 0 dyes in respect of tailing

1 2 3 4 5 6

M&I TM Cell Levafix CA - May, 2006

close

No tailing

The suitable selections for medium to deep shades

in the cold pad batch process

Levafix Amber CA / Levafix Rubine CA / Levafix Blue CA

Levafix Yellow CA / Levafix Red CA / Levafix Blue CA

Test conditions: A freshly formulated liquor is padded onto A and the dyeing is completed. A 5 m length of fabric is then padded with a fresh liquor.

The residual liquor is padded onto B and the dyeing is completed.

The lower the difference in shade between A and B, the more equal the substantivity of the dyes in respect of tailing

M&I TM Cell Levafix CA - May, 2006

close

Compatible fixation behaviour in cpb

What a dyer needs: Controlled color build-up

19,0 g/l Levafix Amber CA 21,0 g/l Sumifix Supra Yellow EXP

5,0 g/l Levafix Rubine CA 7,6 g/l Sumifix Supra Red EXF

28,0 g/l Levafix Blue CA 22,5 g/l Sumifix Supra Blue EXF

16 h at 25 °C 16 h at 25 °C

standard standard

97% 99% 108% 113%

dE 0,25 dE 0,16 dE 0,72 dE 1,14

24 h 48 h 24 h 48 h

at 25 °C at 25° C at 25 °C at 25° C

M&I TM Cell Levafix CA - May, 2006

close

Pad liquor stability in cpb

Stable pad liquors prevent tailing

5 min 10 min 20 min 30 min

8,5 g/l Levafix Amber CA

5,9 g/l Levafix Rubine CA

99% 95% 87% 83%

20,0 g/l Levafix Blue CA standard

dE 0,24 dE 0,70 dE 1,42 dE 1,81

Pad liquor temperature 30°C

7,5 g/l Cibacron Yellow C-2R

8,5 g/l Cibacron Red C-R

99% 95% 85% 74%

20,5 g/l Cibacron Blue C-R standard

dE 0,85 dE 1,53 dE 3,29 dE 5,10

Pad liquor temperature 30°C

M&I TM Cell Levafix CA - May, 2006

close

Easy wash-off

Easy wash-off properties provide excellent

fastnesses and short processes

19,0 g/l Levafix Amber CA 21,0 g/l Sumifix Supra Yellow EXP

5,0 g/l Levafix Rubine CA 7,6 g/l Sumifix Supra Red EXF

28,0 g/l Levafix Blue CA 22,5 g/l Sumifix Supra Blue EXF

16 h at 25 °C 16 h at 25 °C

Wash-off behaviour

40 °C 95 °C 95 °C) 95 °C 60 °C 40 °C 60 °C 80 °C 95 °C 95 °C 95 °C 60 °C

60 °C 80 °C

M&I TM Cell Levafix CA - May, 2006

close

Suitability for all processes

Suitability for all application processes can prevent metamerism.

Levafix CA dyes can be applied by all processes

Cold pad-batch Pad-dry- Pad-dry- Pad-dry- Exhaust

Pad-steam

Levafix Soda ash/NaOH pad-steam steam thermofix process

37.0 g/l Scarlet CA

54.0 g/l Red CA

4.0 % Scarlet CA

5.0 % Red CA

1.0 g/l Amber CA

1.0 g/l Brown E-RN

10.0g/lOlive CA

0.1 % Amber CA

0.1 % Brown E-RN

1.0 % Olive CA

2.0 g/l Amber CA

0.48 g/l Rubine CA

0.019 g/l Blue CA

0.2 % Amber CA

0.040 % Rubine CA

0.002 % Blue CA

Cold pad-batch and continuous processes: bleached, merc. CO, liquor pick-up 60%;

exhaust process: bleached CO tricot, liquor ratio10:1, 60°C

M&I TM Cell Levafix CA - May, 2006

close

Levafix Olive CA 100: shades

All difficult earth tone shades can be dyed reliably with Levafix Olive CA 100

Levafix Olive CA 100

2.00 %

2.00% 2.00% 2.00%

0.10% 0.10% 0.10%

2.00% 2.00% 2.00%

0.33% 0.33% 0.33%

2.00% 2.00% 2.00%

0.60% 0.60% 0.60%

Levafix Olive CA 100 Levafix Olive CA 100 Levafix Olive CA 100

Levafix Amber CA Levafix FastRed CA Levafix Blue CA

M&I TM Cell Levafix CA - May, 2006

close

Levafix Olive CA 100: Controlled Coloration due to excellent reproducibility

Right-First-Time performance for difficult earth tone shades, beige and olive

1,5

d e lta H g reen er

0,5

6

8

2 3 0,10

11

0 1294 13 05

14

71 5

-1,5 -1 -0,5 0 0,5 1 1,5

-0,5

re d d er

Sample Sample

1 Standard 9 Alkali + 10% -1

2 Overfill + 10 % 10 Time - 15 min

3 Underfill - 10 % 11 Time + 15 min

4 Overfill + 20 % 12 Temperature - 5 °C -1,5

5 Underfill - 20 % 13 Temperature + 5 °C d u lle r d e lta C b rig h te r

6 Salt - 10 % 14 Liquor ratio - 30%

7 Salt + 10 % 15 Liquor ratio + 30%

8 Alkali - 10 % standard

2 3 4 5 6 7 8 9 10 11 12 13 14 15

M&I TM Cell Levafix CA - May, 2006

close

Levafix Olive CA: Controlled Coloration from excellent reproducibility

Increase the productivity by "right-first-time" performance

Le vafix Ambe r CA % 0,525 1,5

Le vafix Rubine CA % 0,200

Le vafix Olive CA % 2,000

1

NaCl g/l 60,000

So da ash g/l 5,000

delta H greener

NaOH 50 % ml/l 1,400 0,5

Liquo r ratio 1 : 10

13

Fixatio n time min 60

8 0 614 11

Pro ce ss 60°C co nst. 12 5´15

2 10

-1,5 -1 -0,5 4 0 91 7 0,5 1 1,5

3

Sample Sample

redder

-0,5

1 Standard 9 Soda ash + 10%

2 Overfill + 10 % 10 Time - 15 min

3 Underfill - 10 % 11 Time + 15 min -1

4 Overfill + 20 % 12 Temperature - 5 °C

5 Underfill - 20 % 13 Temperature + 5 °C

6 Salt - 10 % 14 Liquor ratio - 30% -1,5

7 Salt + 10 % 15 Liquor ratio + 30% duller delta C brighter

8 Soda ash - 10 % standard

2 3 4 5 6 7 8 9 10 11 12 13 14 15

M&I TM Cell Levafix CA - May, 2006

close

Levafix Olive CA: Controlled Coloration from excellent reproducibility

The Cibacron combination is much more sensitive to dyeing parameters

Cibacro n Ye llo w NP % 2,080 1,5

Cibacro n Re d FN-2BL % 0,720

Cibacro n Blue FN-R % 1,010

1

NaCl g/l 70,000 2

So da ash g/l 5,000

delta H greener

NaOH 50 % ml/l 0,540 0,5 15

Liquo r ratio 1 : 10 10

4

6

Fixatio n time min 60

0

Pro ce ss 60°C co nst. 8

-1,5 -1 -0,5 3 01 0,5 1 1,5

Sample Sample 14

redder

97

-0,5 11

1 Standard 9 Soda ash + 10%

2 Overfill + 10 % 10 Time - 15 min 5

12

3 Underfill - 10 % 11 Time + 15 min -1

4 Overfill + 20 % 12 Temperature - 5 °C

5 Underfill - 20 % 13 Temperature + 5 °C

13

6 Salt - 10 % 14 Liquor ratio - 30% -1,5

7 Salt + 10 % 15 Liquor ratio + 30% duller delta C brighter

8 Soda ash - 10 % standard

2 3 4 5 6 7 8 9 10 11 12 13 14 15

M&I TM Cell Levafix CA - May, 2006

close

Levafix Olive CA: Controlled Coloration from excellent reproducibility

The Sumifix Supra combination is much more sensitive to dyeing parameters

Sumifix Supra Ye llo w 3RF % 2,810

1,5

Sumifix Supra Brilliant Re d 3BF % 0,600

Sumifix Supra Blue BRF % 1,580

NaCl g/l 50,000 4 1

So da ash g/l 20,000

delta H greener

Liquo r ratio 1 : 10 2

0,5

Fixatio n time min 60 6

Pro ce ss 60°C co nst. 8 15

013

11

-1,5 -1 -0,5 0 1 10

0,5 1 1,5

9

Sample Sample

redder

-0,5 14 7

12

1 Standard 9 Soda ash + 10%

3

2 Overfill + 10 % 10 Time - 15 min

-1

3 Underfill - 10 % 11 Time + 15 min

4 Overfill + 20 % 12 Temperature - 5 °C 5

5 Underfill - 20 % 13 Temperature + 5 °C -1,5

6 Salt - 10 % 14 Liquor ratio - 30%

7 Salt + 10 % 15 Liquor ratio + 30% duller delta C brighter

8 Soda ash - 10 % standard

2 3 4 5 6 7 8 9 10 11 12 13 14 15

M&I TM Cell Levafix CA - May, 2006

close

Levafix Olive CA 100: fastness

Controlled Coloration and Color Confidence

- Levafix Olive CA 100 is the best option -

60 °C Chlorinated NIKE perspiration

JIS test, 60 °C Light fastness

Olive C2 domestic water wet light fastness

10 mg/l washing ISO 105 B02

shade laundering 20 mg/l test

act. chlorine (ISO 105- C09) (xenon)

(ISO 105-C06) act. chlorine acid/alkaline

Levafix

0.58% Amber CA * 4/5/4 - 5/5/5/

5-6 4-5/3-4R

0.47% FastRed CA 5/5 3G 3-4G 4

2.70% Olive CA 100

Cibacron

1.05% Yellow FN-2R * 4 /5/4 - 5/5/5/

2Y 2Y 3-4 4 4-5R/3R

1.05% Red FN-2BL 5/5

0.66% Blue FN-R

Cibacron

1.86% Yellow NP * 3 - 4 /5/3 G/4 - 5/

5Y 4 - 5/ 3 - 4 Y

0.86% Red FN-2BL 5/4 - 5/4 G 2Y 2Y 4

0.74% Blue FN-R

Sumifix Supra

1.69% Yellow 3RF 150% * 3 - 4 /5/3 - 4 B/5/

4-5 4G/1-2G

0.54% Brill. Red 3BF 150% 5/4 - 5/3 - 4 2R 2R 3

1.00% Blue BRF 150%

Material: bleached CO tricot

* Evaluation: change of shade/staining of CTA/CO/PA6.6/PES/PAN/CV

M&I TM Cell Levafix CA - May, 2006

close

Levafix Olive CA: Fastness

Controlled Coloration and Color Confidence

- Levafix Olive CA is the best option -

JIS-

60°C- Chlorinatedwat test, 60°C- Light fastness Perspiration wet light NIKE perspiration

Olive C2 domestic er, 10 mg/l washing ISO 105 B02 fastness wet

laundering 20 mg/l act. (ISO 105- (Xenon) (in-house test) light fastness test

shade chlorine

(ISO 105-C06) act. chlorine C09) dry/acid/alk. acid/alkaline

Levafix

0,53% Amber CA *4 /5 /4-5 /5 /5 /

0,20% Rubine CA

2,00% Olive CA 5 /4-5 4 4 4 6 4-5 /4-5 /4-5 4R /3-4R

Cibacron

2,08%.Yellow NP * 3-4 /5 / 3G/ 5

0,72% Red FN-2BL /5 / 4-5 /3-4G 2G 1-2G 4 4R 4 /4R /4R 4B /3-4B

1,01% Blue FN-R

Sumifix Supra

2,81% Yellow 3RF *3 /5 /2-3B /5 /

0,60% Brilliant Red 3BF 4 /3R /3R

1,58% Blue BRF 5 / 4-5 /3-4B 2R 2-3R 3-4 4G 3 /2G

Material: bleached CO-tricot

*Evaluation: change of shade/staining of: CTA/CO/PA6.6/PES/PAN/CV

M&I TM Cell Levafix CA - May, 2006

close

Levafix Olive CA: Fastness

Highest light fastness performance

Light fastness ISO 105 B02 (xenon)

0,53% Levafix Amber CA

0,20% Levafix Rubine CA 6

2,00% Levafix Olive CA

2,08% Cibacron Yellow NP

0,72% Cibacron Red FN-2BL 4Y

1,01% Cibacron Blue FN-R

2,81% Sumifix Supra Yellow 3RF

0,60% Sumifix Supra Brilliant Red 3BF 4R

1,58% Sumifix Supra Blue BRF

blue scale 2 - 8

Material: bleached CO-tricot

M&I TM Cell Levafix CA - May, 2006

close

Summary

Levafix CA The better solution for high retailer demands

Levafix CA

Flexibility with highest process security.

Applicable in exhaust (50/60 °C)-, cpb- and all

continuous processes

Good reproducibility and reliable application

High fixation yield and excellent

wash-off properties

Problem solver for specific requirements e. g.

perspiration

wet light fastness, oxidative wash fastness

(multiple wash cycles), low staining on PA,

AOX-free dyeings.

M&I TM Cell Levafix CA - May, 2006

close

Summary

Levafix CA: Real Team players covering large shade and fastness areas

Trichromatic dyes Shade specialists

FastRed Amber Rubine

CA CA CA

Premium trichromatic dyes for Brilliant

highest light fastness, non Orange

Yellow

potochromic CA

CA

Blue

CA for brilliant for brilliant

green shades red and orange shades

High performance

trichromatic dyes

Yellow Red Scarlet Olive

CA CA CA CA

High performance trichromatic

dyes for dark shades for brilliant for earth and

red and coral shades khaki shades

Navy

CA

M&I TM Cell Levafix CA - May, 2006

close

Summary: Controlled Coloration and Color Confidence from DyStar

Levafix CA have many advantages compared with other dyes

Compe ting dye vs. Mig ratio n Fixatio n

Re pro ducibility Fastne ss pro pe rtie s

Le vafix CA pro pe rtie s pro file

Wash-o ff pro pe rtie s

Lig ht and w e tlig ht

Re pe ate d w ashing

Substantivity and

Rang e o f me tho ds

No t pho to chro mic

Fixatio n yie ld

We tfastne ss

Co ntinuo us

Co ntinuo us

be havio ur

re activity

Chlo rine

Exhaust

Exhaust

Cibacro n C/ FN - o - -/ o o -/ o - o -/ o - o o o

Sumifix Supra - o - -/ o o - - - - - -/ o -

Commo ditie s - - - - - - - o - - - -/ o -

- inferior to Levafix CA

o comparable to Levafix CA

M&I TM Cell Levafix CA - May, 2006

close

Summary: Five more reasons to choose DyStar

Five more reasons to choose DyStar

Reliable product quality

High safety and ecology

standards worldwide

Innovative products

Expert local service

Comprehensive internet services

M&I TM Cell Levafix CA - May, 2006

close

You might also like

- Fuse Voltage Drop Chart - Standard Fuse PDFDocument2 pagesFuse Voltage Drop Chart - Standard Fuse PDFJosue Rodrigo Cruz Caballero85% (13)

- SweetSugarBelle's Icing Color Chart (Printable Version)Document1 pageSweetSugarBelle's Icing Color Chart (Printable Version)sweetsugarbelleNo ratings yet

- R E S E P – R E S E P R A C I K A N Untuk di APOTIKDocument20 pagesR E S E P – R E S E P R A C I K A N Untuk di APOTIKMutiara Dita PutriNo ratings yet

- 5 2776 FolkArt Acrylic PaintDocument7 pages5 2776 FolkArt Acrylic PaintPatrícia LavosNo ratings yet

- Worksheet Circular Seating ArrangementsDocument5 pagesWorksheet Circular Seating ArrangementsPratim Majumder0% (1)

- Hexis hx20000 Colors PDFDocument2 pagesHexis hx20000 Colors PDFPoschina CiprianNo ratings yet

- Dyes Recommend For CPB - Silicate FreeDocument1 pageDyes Recommend For CPB - Silicate FreeNghia Phan TrungNo ratings yet

- Dyefix-CF - Dye Fixing Agent With Excellent Fastness To Chlorine.Document10 pagesDyefix-CF - Dye Fixing Agent With Excellent Fastness To Chlorine.L.N.CHEMICAL INDUSTRYNo ratings yet

- Pantone - Color Trend 2021 - Recipes by Fiber V2.0Document15 pagesPantone - Color Trend 2021 - Recipes by Fiber V2.0JUAN SEBASTIAN BUSTOS GARNICA100% (1)

- Io Io: Avolan UL 75Document2 pagesIo Io: Avolan UL 75P. PaarthNo ratings yet

- Concentrating On ConcentrationsDocument4 pagesConcentrating On ConcentrationsDrNareshSarafNo ratings yet

- Solusoft SE1 Liq - e TIDocument3 pagesSolusoft SE1 Liq - e TIekoyonatanNo ratings yet

- FactSheet Dyeing Finishing DyStar IngeoColorationPack PDFDocument53 pagesFactSheet Dyeing Finishing DyStar IngeoColorationPack PDFJose Iniesta PerezNo ratings yet

- Benninger Mercerizing SolutionsDocument16 pagesBenninger Mercerizing SolutionsWc ChanNo ratings yet

- Passion For Exterior Textiles: Best-In-Class Innovations, Applications and System SolutionsDocument8 pagesPassion For Exterior Textiles: Best-In-Class Innovations, Applications and System SolutionsMUHAMMAD UBAID ULLAHNo ratings yet

- Apeo - NpeoDocument13 pagesApeo - NpeosaqureshNo ratings yet

- MI 2008-30e Acid CellulasesDocument3 pagesMI 2008-30e Acid CellulasesCarlos Rodríguez GandarillasNo ratings yet

- IKEA - Huntsman Positive List - 27 May 2016 - EN - FINAL - v1Document30 pagesIKEA - Huntsman Positive List - 27 May 2016 - EN - FINAL - v1Flávia DutraNo ratings yet

- Z&S PesDocument8 pagesZ&S Pesguven44No ratings yet

- Definition of Pad-Batch DyeingDocument4 pagesDefinition of Pad-Batch DyeingJuan CubasNo ratings yet

- MPM Textile Enhancers - UpdateDocument17 pagesMPM Textile Enhancers - UpdateRomán M Martín del CNo ratings yet

- Cat IonizerDocument6 pagesCat IonizerAnonymous 5HRD46hNo ratings yet

- 01703Document3 pages01703Shaique SiddiqueNo ratings yet

- Novacron FN Pocket Card1Document24 pagesNovacron FN Pocket Card1textile1to35No ratings yet

- Indigo Water Resuse Looptec 6 Print NomarksDocument4 pagesIndigo Water Resuse Looptec 6 Print NomarksAwais ImranNo ratings yet

- Sapamine SPL New TDSDocument5 pagesSapamine SPL New TDSraju_hosssenNo ratings yet

- Alkali Dye FixingDocument5 pagesAlkali Dye Fixingdebmallya4037No ratings yet

- Archroma PassionDocument8 pagesArchroma PassionPalashNo ratings yet

- Synozol K HLDocument6 pagesSynozol K HLEclair RNo ratings yet

- Arc RomaDocument31 pagesArc RomaMohammed Atiqul Hoque ChowdhuryNo ratings yet

- Dyeing of Polyester/Cellulose BlendsDocument17 pagesDyeing of Polyester/Cellulose Blendsnagpal_aakashNo ratings yet

- Clay Based Bleaching AgentDocument3 pagesClay Based Bleaching AgentsekhonnsNo ratings yet

- Archroma Passion-For-Toweling 210630Document10 pagesArchroma Passion-For-Toweling 210630Nguyễn Huy CườngNo ratings yet

- Pad BatchDocument6 pagesPad BatchBabaNo ratings yet

- Ecodye: Ecodye - The Dyeing RevolutionDocument4 pagesEcodye: Ecodye - The Dyeing RevolutionRamzi HajjajiNo ratings yet

- Chemical Inventory ICCL 2019 Update For GRS EDITEDDocument9 pagesChemical Inventory ICCL 2019 Update For GRS EDITEDDyeing DyeingNo ratings yet

- Washoff Compatibility TestDocument3 pagesWashoff Compatibility TestDyeing DyeingNo ratings yet

- Colour and Textile Chemistry-A Lucky Career Choice: Aatcc Review April 2009Document32 pagesColour and Textile Chemistry-A Lucky Career Choice: Aatcc Review April 2009Neva BernadetteNo ratings yet

- Invatex Lta NewDocument5 pagesInvatex Lta NewruestchivaNo ratings yet

- Salt Alkali Free ReactiveDocument6 pagesSalt Alkali Free ReactiveSaif Rahman100% (1)

- 418002e - CTI - LANASET Coverage of Barriness PDFDocument5 pages418002e - CTI - LANASET Coverage of Barriness PDFMarti VincenzoNo ratings yet

- Adhesive Testing at The Canadian ConservationDocument27 pagesAdhesive Testing at The Canadian ConservationraniakrdNo ratings yet

- 2 Presentation Dr. Pankaj DesaiDocument37 pages2 Presentation Dr. Pankaj DesaiMitesh ShahNo ratings yet

- Textile Pre Treatment Right First TimeDocument53 pagesTextile Pre Treatment Right First Timewsarakarn100% (1)

- Project Final File 000Document102 pagesProject Final File 000usmanazeemNo ratings yet

- CHT Textile Auxiliaries for Efficient Dyeing and Finishing of 100% CottonDocument1 pageCHT Textile Auxiliaries for Efficient Dyeing and Finishing of 100% CottonTribhuvan Kumar SangerpalNo ratings yet

- Dorosperse CaDocument9 pagesDorosperse CaDarul Hijrah ArcheryNo ratings yet

- Washing: Since 1986Document16 pagesWashing: Since 1986孙兴峰No ratings yet

- Smart Prep Cibacron On SlavosDocument4 pagesSmart Prep Cibacron On SlavosagnberbcNo ratings yet

- Dyeing Cationic Dyeable Polyester with Cationic DyesDocument2 pagesDyeing Cationic Dyeable Polyester with Cationic DyesFathi Mustafa0% (2)

- Optavon Mex: Highly Effective Complexing Agent of Versatile Application During All Pretreatment ProcessesDocument2 pagesOptavon Mex: Highly Effective Complexing Agent of Versatile Application During All Pretreatment ProcessesRezoanul HaqueNo ratings yet

- Analyzing Electrolytes for Reactive Cotton DyeingDocument6 pagesAnalyzing Electrolytes for Reactive Cotton DyeingRajeev MehraNo ratings yet

- Catalog DyestufDocument60 pagesCatalog DyestufRohendi Hasan50% (2)

- Tubifast As 5087 Ff-EnDocument4 pagesTubifast As 5087 Ff-EnrajasajjadNo ratings yet

- f3c7a08543f11dc50c88dc7a76212879Document3 pagesf3c7a08543f11dc50c88dc7a76212879孙兴峰No ratings yet

- Everzol Dyes StructuresDocument9 pagesEverzol Dyes StructuresNestor Mauricio Florian RamirezNo ratings yet

- Clariant Blue MagicDocument9 pagesClariant Blue MagicHrishikesh DhawadshikarNo ratings yet

- Z&s Finishing CottonDocument12 pagesZ&s Finishing Cottonguven440% (1)

- Benninger Bleaching SolutionsDocument16 pagesBenninger Bleaching SolutionsWc ChanNo ratings yet

- Achieving New Heights: Textile EffectsDocument24 pagesAchieving New Heights: Textile EffectsRickgable100% (1)

- Lyoprint Atp 30Document5 pagesLyoprint Atp 30Lambo SunNo ratings yet

- Wash Solutions en PDFDocument6 pagesWash Solutions en PDFLambo SunNo ratings yet

- Invazyme SOFT Enzyme: Technical Data SheetDocument5 pagesInvazyme SOFT Enzyme: Technical Data SheetsaskoNo ratings yet

- Wine-yeast-chart-red-wine-style-2020Document1 pageWine-yeast-chart-red-wine-style-2020Anonymous ePcnZoBENo ratings yet

- Tabela de Cores HTMLDocument11 pagesTabela de Cores HTMLBiel Divulgações - O terror das ProduçõesNo ratings yet

- Linear structure wall and window area analysisDocument9 pagesLinear structure wall and window area analysisJohnNo ratings yet

- ARNETTE 2019 CatalogueDocument70 pagesARNETTE 2019 Cataloguegr75sNo ratings yet

- E - Katalog FullDocument11 pagesE - Katalog FullAdhitama Satya NegaraNo ratings yet

- Inventario AtuntaquiDocument4 pagesInventario AtuntaquiDavid CuatimpasNo ratings yet

- Bella Canvas Color CardDocument11 pagesBella Canvas Color CardHaley BrightNo ratings yet

- Colores JRDocument5 pagesColores JRCheleivan Nahui Tit KuishtyNo ratings yet

- Diamont FINAL ENGDocument5 pagesDiamont FINAL ENGDanijel DNo ratings yet

- Eco-Friendly Dyeing of Cotton and Polyester Fabrics With Natural Dyes Extracted From Different Varieties of Kola NutsDocument6 pagesEco-Friendly Dyeing of Cotton and Polyester Fabrics With Natural Dyes Extracted From Different Varieties of Kola Nutsm.asepmawardiNo ratings yet

- Pengaruh Waktu Pemaparan Sinar Terhadap Penyimpangan Warna Matahari (Lightfastness) Pada Cetakan Dengan Menggunakan Tinta Base Color (Indoor)Document10 pagesPengaruh Waktu Pemaparan Sinar Terhadap Penyimpangan Warna Matahari (Lightfastness) Pada Cetakan Dengan Menggunakan Tinta Base Color (Indoor)Chunaifi IstianaNo ratings yet

- For Sephiroth and Paths: (Based On The Servants of The Light A Tree of Life' atDocument9 pagesFor Sephiroth and Paths: (Based On The Servants of The Light A Tree of Life' atjossbrown3784No ratings yet

- COLOR CODING OF NSN BTS Alarm and E1 CableDocument2 pagesCOLOR CODING OF NSN BTS Alarm and E1 CableMD Sahid100% (2)

- Crayola 120 Crayons Swatch Chart: CeruleanDocument1 pageCrayola 120 Crayons Swatch Chart: Ceruleankey jeyNo ratings yet

- Excel PricelistDocument19 pagesExcel Pricelistaogp93No ratings yet

- Lamp. No. 058 - PRICELIST RETAIL 26 AGS 2021 ZONA A1Document28 pagesLamp. No. 058 - PRICELIST RETAIL 26 AGS 2021 ZONA A1Metta Libia100% (1)

- Data Base-Packing List BuyerDocument465 pagesData Base-Packing List BuyerPuLung SambadhaNo ratings yet

- List Pre-58 ColorantsDocument3 pagesList Pre-58 ColorantsRamirez Luis0% (1)

- PEDRO Men ESS VOL 3Document15 pagesPEDRO Men ESS VOL 3Matheus Dharma PrathamaNo ratings yet

- PRICESDocument5 pagesPRICESSekretaris Warna Tanjung JayaNo ratings yet

- Lista de precios mayorista bicicletas y componentesDocument48 pagesLista de precios mayorista bicicletas y componentesYahir AbadNo ratings yet

- Raw materials and dyes reportDocument4 pagesRaw materials and dyes reportMizanur RiponNo ratings yet

- Hasil Uji Kemasan Fitkom Vs YouvitDocument14 pagesHasil Uji Kemasan Fitkom Vs YouvitBilly ChandraNo ratings yet

- 99 Color Combinations by RHR PDFDocument138 pages99 Color Combinations by RHR PDFRH Rumy67% (3)

- Bahasa Inggris SLBDocument7 pagesBahasa Inggris SLBsmplbn sabang100% (1)