Professional Documents

Culture Documents

Profound PDA DLT Leaflet Uk

Uploaded by

Probal ProsoilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Profound PDA DLT Leaflet Uk

Uploaded by

Probal ProsoilCopyright:

Available Formats

PDA/DLT-series

Pile Driving Analysis/Dynamic Load Testing

Dynamic Load Testing (DLT) is a frequently used worldwide

technique to evaluate the bearing capacity of piles. The Profound

PDA/DLT-system is used for both DLT and for Pile Driving Analysis

(PDA) as a powerful tool to control the pile driving process and

reduce risks involved. During testing the instrumented pile is

monitored, whereby the Profound PDA/DLT-system directly displays

and saves the measurement data. The PDA/DLT-system meets

national and international standards, such as ASTM D4945-12.

Dynamic Load Testing

The Dynamic Load Test (DLT) is a considerably faster and

cost-effective alternative for a Static Load Test (SLT). With the The PDA-USB conditioner allows for optimum flexibility

Profound PDA/DLT-system the bearing capacity of several piles in the choice of a rugged notebook.

can be assessed in a single day. DLT is used for cast-in-place,

prefabricated concrete piles and all types of steel piles.

Flexible and efficient in the field

The load is applied by an impact hammer or a suitable drop An experienced qualified engineer can set up a pile test within 15

weight onto the prepared pile head. The generated compression minutes, whereby the pile is instrumented with sets of combined

wave travels down the pile and reflects upwards. This reflected strain and acceleration sensors. The robust and compact PDA-

wave contains information about the shaft friction, toe resistance USB conditioner is connected to a Windows® notebook

and possible pile defects. The measured signals are processed and directly checks and shows correct connection as

and automatically stored by the PDA/DLT-system. The data can well as status of the sensors.

easily be retrieved for further review, graphical presentations or

reporting in full accordance with ASTM D4945-12. DLT has been in The complete PDA/DLT-system is used

use worldwide for decades and extensive correlations between both for PDA and DLT. The accompanying

simulated and actual static load tests have proven the reliability PDA/DLT software for monitoring and

of this method. reporting includes many features to

further facilitate signal processing

and interpretation.

Pile Driving Analysis

During pile driving the performance of the hammer, the

condition of the cushion, the behaviour of the pile and the driving Analysis Software

resistance of the soil are accurately monitored and analysed. Pile Driving Prediction software

(PDPWAVE) is delivered within the

The Profound PDA-USB conditioner directly processes standard PDA/DLT package and is used

the signals from the sensors and immediately for pre-analysis. Signal matching software

shows a variety of results from the velocity DLTWAVE is essential to provide an estimate of the

and force signals obtained for each ultimate bearing capacity from a DLT. It provides the

hammer blow on the screen of soil resistance distribution along the pile shaft and a static load

the notebook. A selection of the displacement graph.

available graphs, all presented as

a function of time and scaled

in SI units, include: force and Key advantages of the PDA/DLT-system

velocity x impedance, downward • Fully digital signal processing

and upward travelling waves, • Optimum flexibility and reliability

transferred energy, driving • Integrated sensor condition testing

resistance and the estimated • Immediate presentation of acquired data on screen

static resistance. In addition other • Flexible USB based conditioner

important parameters such as • Easy mounting and handling of sensors and cables

maximum compression and tension • Proven technique in full compliance with ASTM D4945-12

stresses in the pile, shaft friction and toe • Backed by 40 years of pile testing experience

resistance can be shown as a function of • Efficient addition to Static Load Testing according to Eurocode 7

blow number or penetration.

PDA/DLT-series

Specifications PDA/DLT-system

PDA-USB conditioner

Dimensions : 165 x 171 x 52 mm

Weight : 0.9 kg

Housing : Hard anodized aluminum case

Operating temperature : -20 °C to + 60 °C

I/O : 2x USB for power and data transmission

1x connector for cable to junction box

Compatibility : Windows XP/Vista/WIN 7.0

Sensor status control : 4x Multicolor LED, 1 per channel

Strain transducer

Range : > (-2000…+2000) µε

Shock : 5000 g

Natural frequency when attached to foundation,

greater than 2000 Hz

Accelerometer

Type : Piezoresistive accelerometer

Frequency range : DC to 8000 Hz

Damping ratio : 0.7

Range : > (-5000…+5000) g

Training and support

High strain dynamic tests require special knowledge and experience. Only qualified

engineers should directly run the tests and do further interpretation. New users are

strongly advised to follow a training course at the Profound Academy where operation

of the system, the theory of PDA/DLT and interpretation of the measurement signals

are discussed.

Profound, pioneer in the field of professional pile testing both

in research and equipment, has over 50 years of worldwide

experience and continuously strives to make the best technology

available to clients. PDA/DLT is backed by over 40 years of pile

testing experience for clients all over the world, onshore and

offshore.

Screenshot from the PDA/DLT software.

For further information:

Profound BV

P.O. Box 469

2740 AL Waddinxveen

The Netherlands

Phone +31 (0) 182 640 964

PDA016/08/2013

Fax +31 (0) 182 649 664

E-mail info@profound.nl

Website www.profound.nl

Profound BV

You might also like

- Partial Discharge Monitor For GISDocument4 pagesPartial Discharge Monitor For GISAlauddin khanNo ratings yet

- Brochure Allnamics DLT en Rev11Document4 pagesBrochure Allnamics DLT en Rev11Anand JadoenathmisierNo ratings yet

- Datasheet Terminal IND 246Document2 pagesDatasheet Terminal IND 246SatriyaNo ratings yet

- Vepal Tx300E: Platform HighlightsDocument29 pagesVepal Tx300E: Platform HighlightsSatya PrakashNo ratings yet

- Dfa100 Gis Brochure 03-09 Us LRDocument2 pagesDfa100 Gis Brochure 03-09 Us LREngr Irfan AkhtarNo ratings yet

- TX 130Document13 pagesTX 130Richard ThainkhaNo ratings yet

- HDPQDataSheetJ12Rev 2ADocument27 pagesHDPQDataSheetJ12Rev 2AGladys QuinilloNo ratings yet

- Dynatest: 3032 Light Weight DeflectometerDocument8 pagesDynatest: 3032 Light Weight DeflectometerKarol MonteiroNo ratings yet

- Brochure Teledyne - Dms Motion SensorsDocument4 pagesBrochure Teledyne - Dms Motion Sensorswanderson1974No ratings yet

- Pile Dynamics Analyzer-DLT (PDA-DLT) : Accurate. Reliable. EfficientDocument2 pagesPile Dynamics Analyzer-DLT (PDA-DLT) : Accurate. Reliable. Efficients pradhanNo ratings yet

- Smart Device For Voltage RegulationDocument27 pagesSmart Device For Voltage RegulationErnani CrepliveNo ratings yet

- Next-Generation Optical Network Test Solution: A Step AheadDocument12 pagesNext-Generation Optical Network Test Solution: A Step AheadppalaiNo ratings yet

- Idp 782Document2 pagesIdp 782Doddy Taufiq AriefNo ratings yet

- JDSU MTS-2000 OverviewDocument4 pagesJDSU MTS-2000 OverviewIbnuNo ratings yet

- Universal Precision Cable and Pipe LocatorDocument8 pagesUniversal Precision Cable and Pipe LocatorBojan FarkasNo ratings yet

- GDU 8 Channel Data Acquisition Unit 100-120 V 60 HZDocument2 pagesGDU 8 Channel Data Acquisition Unit 100-120 V 60 HZgeotecnica modelNo ratings yet

- 63-Hdl64es2g Hdl-64e s2 CD Hdl-64e s2 Users Manual Low ResDocument43 pages63-Hdl64es2g Hdl-64e s2 CD Hdl-64e s2 Users Manual Low ResSajeesh ThambirajNo ratings yet

- Performance and Versatility Delivered: Ready To WorkDocument4 pagesPerformance and Versatility Delivered: Ready To WorkseabellNo ratings yet

- 6768 D12R D6R D3R Digital Winding TesterDocument4 pages6768 D12R D6R D3R Digital Winding Testermoises_romero_12100% (1)

- mts-4000 Otdr - SDocument8 pagesmts-4000 Otdr - SAbdalmoedAlaiashyNo ratings yet

- 402-2038-00-A1 Aurora AP8 SSDocument1 page402-2038-00-A1 Aurora AP8 SSY.EbadiNo ratings yet

- RPV311 DFR + TWFLDocument7 pagesRPV311 DFR + TWFLSathishNo ratings yet

- VDSL Tester User Manual - Comprehensive Guide to xDSL Installation and Maintenance TestingDocument50 pagesVDSL Tester User Manual - Comprehensive Guide to xDSL Installation and Maintenance TestingJuan Manuel Martinez AlbaceteNo ratings yet

- TRIO C8 Series CutsheetDocument2 pagesTRIO C8 Series Cutsheetcredondo1No ratings yet

- Performance and Versatility Delivered: Ready To WorkDocument4 pagesPerformance and Versatility Delivered: Ready To WorkVinoth KumarNo ratings yet

- LD 300 CeDocument29 pagesLD 300 Ceze das couvesNo ratings yet

- Fact Sheet: Bently Nevada Asset Condition Monitoring ADAPT 3701/46 Hydro MonitorDocument2 pagesFact Sheet: Bently Nevada Asset Condition Monitoring ADAPT 3701/46 Hydro MonitorViet DinhTrongNo ratings yet

- ZingDocument2 pagesZingLindgrenNo ratings yet

- DOC0535335316Jun23 SC4500Document4 pagesDOC0535335316Jun23 SC4500axel.spallekNo ratings yet

- Kindly Remind:The S/N and Password Asked Above Can Be Foundin An Encelop Rem Arked by "S/N:"charactersDocument2 pagesKindly Remind:The S/N and Password Asked Above Can Be Foundin An Encelop Rem Arked by "S/N:"charactersMartin AguilarNo ratings yet

- D3 Digital PositionerDocument12 pagesD3 Digital PositionerEdward ChanNo ratings yet

- Satellite Terminal: FeaturesDocument2 pagesSatellite Terminal: Featuresnama sayaNo ratings yet

- SvdrproDocument2 pagesSvdrproUFUKKKNo ratings yet

- 04 Catalogue ManHinhHienThi IND570Document4 pages04 Catalogue ManHinhHienThi IND570Tùng Hồ ThanhNo ratings yet

- DCT6088 Digital Correlation Transit Time FlowmeterDocument4 pagesDCT6088 Digital Correlation Transit Time FlowmeterGustavoSilvinoSilvinoNo ratings yet

- GT 1200Document2 pagesGT 1200Miguel AngelNo ratings yet

- Thermo Recorder: Easy USB ConnectionDocument4 pagesThermo Recorder: Easy USB ConnectionarukkNo ratings yet

- Sunset SDH: Sunrise TelecomDocument10 pagesSunset SDH: Sunrise TelecomMauroNo ratings yet

- 24-Port Gigabit Desktop/Rackmountable Switch: DGS-1024DDocument2 pages24-Port Gigabit Desktop/Rackmountable Switch: DGS-1024DLâm NguyễnNo ratings yet

- Compression Testing MachineDocument2 pagesCompression Testing MachineRabnawaz ImamNo ratings yet

- Toughsonic 12 30mm Data SheetDocument2 pagesToughsonic 12 30mm Data SheetCARLOS XNo ratings yet

- Texas - Instruments TPD4E1U06DBVR DatasheetDocument20 pagesTexas - Instruments TPD4E1U06DBVR DatasheetAldebaran SentauriNo ratings yet

- TPS54328 4.5-V To 18-V Input, 3-A Synchronous Step-Down Converter With Eco-Mode™Document31 pagesTPS54328 4.5-V To 18-V Input, 3-A Synchronous Step-Down Converter With Eco-Mode™Gus Khoir SrNo ratings yet

- DDR Memory Design and TestDocument13 pagesDDR Memory Design and TestKevin_INo ratings yet

- PHY Validation of Thunderbolt & DisplayPortDocument43 pagesPHY Validation of Thunderbolt & DisplayPortvelusnNo ratings yet

- Tan Delta & Capacitance Test SystemDocument12 pagesTan Delta & Capacitance Test SystemRanabir DebNo ratings yet

- DX-2100 Series Industrial 3G Cloud Router User ManualDocument6 pagesDX-2100 Series Industrial 3G Cloud Router User ManualkosicenetflixNo ratings yet

- Data Acquisition System: Sumeet Patel Enroll. No. - 110050111040Document25 pagesData Acquisition System: Sumeet Patel Enroll. No. - 110050111040Princy Merin JoseNo ratings yet

- Dataacquisitionsystem 141028142838 Conversion Gate01Document25 pagesDataacquisitionsystem 141028142838 Conversion Gate01priyaNo ratings yet

- Compact Optical Test: T-BERD®/MTS-6000 PlatformDocument4 pagesCompact Optical Test: T-BERD®/MTS-6000 PlatformViet Chau DaoNo ratings yet

- Affordable TOFD and PA capability at your fingertipsDocument8 pagesAffordable TOFD and PA capability at your fingertipsJlaraneda SantiagoNo ratings yet

- AlfaDocument2 pagesAlfaDigvijay TiwariNo ratings yet

- FINAL 236146 Prisma Brochure - 8pp A4 V3 1Document8 pagesFINAL 236146 Prisma Brochure - 8pp A4 V3 1Ahmed SaadNo ratings yet

- Weighing Indicator Ind570Document4 pagesWeighing Indicator Ind570Erivelton AntonioNo ratings yet

- D3 Digital Positioner: Product InformationDocument12 pagesD3 Digital Positioner: Product Informationfcustódio_19No ratings yet

- Orbcomm ST 6100 DatasheetDocument2 pagesOrbcomm ST 6100 DatasheetThomas A KadiNo ratings yet

- Vepal Tx130M+: Platform Highlights Synce/Ieee 1588V2Document13 pagesVepal Tx130M+: Platform Highlights Synce/Ieee 1588V2cogentech appNo ratings yet

- TX130+ D05-00-40P D00 LoResDocument13 pagesTX130+ D05-00-40P D00 LoResGabriel SantosNo ratings yet

- Oan551 Sensors and Transducers: Sns College of EngineeringDocument18 pagesOan551 Sensors and Transducers: Sns College of EngineeringRavi JNo ratings yet

- Practical Data Acquisition for Instrumentation and Control SystemsFrom EverandPractical Data Acquisition for Instrumentation and Control SystemsNo ratings yet

- DRILL BITS BitsDocument1 pageDRILL BITS BitsProbal ProsoilNo ratings yet

- VBMicro Data Sheet - VCIDocument4 pagesVBMicro Data Sheet - VCIProbal ProsoilNo ratings yet

- PunditLab Remote 20111024 2Document18 pagesPunditLab Remote 20111024 2Probal ProsoilNo ratings yet

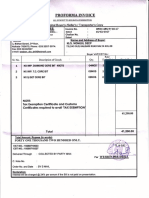

- Quotation For Prosoil - Bangladesh - 015-01-2016Document14 pagesQuotation For Prosoil - Bangladesh - 015-01-2016Probal ProsoilNo ratings yet

- Mail - MDDocument2 pagesMail - MDProbal ProsoilNo ratings yet

- Profound BATsystem Leaflet Uk 2Document2 pagesProfound BATsystem Leaflet Uk 2Probal ProsoilNo ratings yet

- 4.0 CPTu Report - GandharbpurDocument15 pages4.0 CPTu Report - GandharbpurProbal ProsoilNo ratings yet

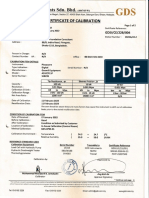

- 6.0 Appendix B - Calibration Certificate S18235)Document2 pages6.0 Appendix B - Calibration Certificate S18235)Probal ProsoilNo ratings yet

- Profound SIT Series Leaflet UkDocument2 pagesProfound SIT Series Leaflet UkProbal ProsoilNo ratings yet

- Esg98 BardDocument16 pagesEsg98 BardProbal ProsoilNo ratings yet

- 9.0 Appendix EDocument1 page9.0 Appendix EProbal ProsoilNo ratings yet

- 8.1 Liquefaction Calculation v2Document11 pages8.1 Liquefaction Calculation v2Probal ProsoilNo ratings yet

- 59lhsu (1) ..22Document1 page59lhsu (1) ..22Probal ProsoilNo ratings yet

- Astm d5778 12Document20 pagesAstm d5778 12farquinNo ratings yet

- 2.0 TopDocument1 page2.0 TopProbal ProsoilNo ratings yet

- 1.0 Cover Page A3Document1 page1.0 Cover Page A3Probal ProsoilNo ratings yet

- CPTU Report on Gandharbpur Water Treatment ProjectDocument2 pagesCPTU Report on Gandharbpur Water Treatment ProjectProbal ProsoilNo ratings yet

- Spec. - CSL - As Per Contract - 2021Document3 pagesSpec. - CSL - As Per Contract - 2021Probal ProsoilNo ratings yet

- HWD5SL (1)Document1 pageHWD5SL (1)Probal ProsoilNo ratings yet

- Cross Hole Sonic Integrity Tests - Khulna - 15.11.2014Document6 pagesCross Hole Sonic Integrity Tests - Khulna - 15.11.2014Probal ProsoilNo ratings yet

- Estimation of Shallow S-Wave Velocity Structure and Site Response Characteristics by Microtremor Array Measurements in Tekirdag Region, NW TurkeyDocument17 pagesEstimation of Shallow S-Wave Velocity Structure and Site Response Characteristics by Microtremor Array Measurements in Tekirdag Region, NW TurkeyProbal ProsoilNo ratings yet

- Group Pile Subgrade Reaction-Meyerhof 1976Document12 pagesGroup Pile Subgrade Reaction-Meyerhof 1976Probal ProsoilNo ratings yet

- BH 1Document28 pagesBH 1Probal ProsoilNo ratings yet

- ) 4sructurai FrameworkDocument1 page) 4sructurai FrameworkProbal ProsoilNo ratings yet

- Single Pile Subgrade Reaction-Meyerhof 1976Document12 pagesSingle Pile Subgrade Reaction-Meyerhof 1976Probal ProsoilNo ratings yet

- Group Pile Subgrade Reaction-Meyerhof 1976Document12 pagesGroup Pile Subgrade Reaction-Meyerhof 1976Probal ProsoilNo ratings yet

- Bangladesh's Energy Resources and Formation of the Ganges-Brahmaputra DeltaDocument1 pageBangladesh's Energy Resources and Formation of the Ganges-Brahmaputra DeltaProbal ProsoilNo ratings yet

- Group Pile Subgrade Reaction-Meyerhof 1976Document12 pagesGroup Pile Subgrade Reaction-Meyerhof 1976Probal ProsoilNo ratings yet

- Equation For Geotechnical AnalysisDocument9 pagesEquation For Geotechnical AnalysisProbal ProsoilNo ratings yet

- Radc TR 85 194Document578 pagesRadc TR 85 194Fadli RamdhaniNo ratings yet

- Question Bank 4th SemesterDocument16 pagesQuestion Bank 4th SemesterJeevanandam ShanmugasundaramNo ratings yet

- Performance-Based Design - RMSP PDFDocument16 pagesPerformance-Based Design - RMSP PDFdiegoNo ratings yet

- Reliability Control Program: Engineering & Technical Support & ServicesDocument141 pagesReliability Control Program: Engineering & Technical Support & ServicespeterNo ratings yet

- RCM Introduction - Process and Requirements Management AspectsDocument15 pagesRCM Introduction - Process and Requirements Management AspectsflavianosamelNo ratings yet

- ESD ValvesDocument19 pagesESD Valvesrkubal100% (1)

- Failure Mode and Effect Analysis Applied To Power TransformersDocument6 pagesFailure Mode and Effect Analysis Applied To Power Transformerscarlos patrickNo ratings yet

- Testing GeneralDocument84 pagesTesting GeneralAcadeauadilieNo ratings yet

- Di1 0005 Eng QP v1 Paper 2Document9 pagesDi1 0005 Eng QP v1 Paper 2Nathalie Derrell-SaundersNo ratings yet

- Stock Maintenance System EditedDocument20 pagesStock Maintenance System EditedRosalyn AgananNo ratings yet

- TQM in HealthcareDocument4 pagesTQM in HealthcareALtit66No ratings yet

- Drive Down Operating Costs,: With The Leader in HVAC EfficiencyDocument52 pagesDrive Down Operating Costs,: With The Leader in HVAC EfficiencydesignselvaNo ratings yet

- Masterpact NT and NW: Maintenance GuideDocument32 pagesMasterpact NT and NW: Maintenance GuideRoshin99No ratings yet

- ITIL For Dummies v1Document22 pagesITIL For Dummies v1api-384967888% (17)

- AboutGRC 100620Document51 pagesAboutGRC 100620Nadeson Ganesan100% (1)

- Principles and Practices of Maintenance PlanningDocument6 pagesPrinciples and Practices of Maintenance PlanningGopi KrishnanNo ratings yet

- Gea Westfalia Separator Group Company Portrait WS 12 10Document52 pagesGea Westfalia Separator Group Company Portrait WS 12 10ElizavetaYarovaiaNo ratings yet

- SIEMENS Sinamics Perfect Harmony gh180 Catalog d17 Global 2018 PDFDocument75 pagesSIEMENS Sinamics Perfect Harmony gh180 Catalog d17 Global 2018 PDFJavier AriasNo ratings yet

- LSM-XT-BOP Training Manual - M14 - April 2016Document75 pagesLSM-XT-BOP Training Manual - M14 - April 2016Kim Layda BillonesNo ratings yet

- 2017 - Tools For Components Reliability PredictionDocument9 pages2017 - Tools For Components Reliability Predictioncrd1990No ratings yet

- Evaluation Method of Value Engineering ProjectsDocument15 pagesEvaluation Method of Value Engineering Projectsrip111176No ratings yet

- Comparison Between Vacuum and SF6 Circuit BreakerDocument12 pagesComparison Between Vacuum and SF6 Circuit BreakerecsanyiNo ratings yet

- KTR Kat10ep00Document68 pagesKTR Kat10ep00jmrozo3No ratings yet

- 2SK3053Document9 pages2SK3053Иегҵ ГемасснеNo ratings yet

- TotalValve 6820TRV PDFDocument4 pagesTotalValve 6820TRV PDFOswaldo GuerraNo ratings yet

- Goulds Model 3196 Chemical Process Pumps X-SeriesDocument20 pagesGoulds Model 3196 Chemical Process Pumps X-SeriesleoNo ratings yet

- Introduction To Eight Disciplines of Problem Solving (8D)Document9 pagesIntroduction To Eight Disciplines of Problem Solving (8D)Prasenjit PuriNo ratings yet

- GIS B105 245 KVDocument4 pagesGIS B105 245 KVDaniel Uculmana Lema50% (2)

- Liquid Liquid ExtractionTechnologyDocument12 pagesLiquid Liquid ExtractionTechnologyBrandonQuisiNo ratings yet

- Short Circuit Analysis Amd Over Current Relaying Protection of IEEE 9 Bus SystemDocument6 pagesShort Circuit Analysis Amd Over Current Relaying Protection of IEEE 9 Bus SystemAbdul HaseebNo ratings yet