Professional Documents

Culture Documents

Steel

Uploaded by

Chetna 16 M0 ratings0% found this document useful (0 votes)

2 views1 pageThis document outlines an assignment for a steel structure design course involving welded joints. It provides 24 questions related to welded joint types, weld sizing definitions, permissible stresses, load capacities, and design of specific welded joints. The assignment requires determining sizes, stresses, capacities and designs for various welded joints using steel grade Fe410 and addressing standards as outlined in IS codes.

Original Description:

questions of steel structure

Original Title

steel

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines an assignment for a steel structure design course involving welded joints. It provides 24 questions related to welded joint types, weld sizing definitions, permissible stresses, load capacities, and design of specific welded joints. The assignment requires determining sizes, stresses, capacities and designs for various welded joints using steel grade Fe410 and addressing standards as outlined in IS codes.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views1 pageSteel

Uploaded by

Chetna 16 MThis document outlines an assignment for a steel structure design course involving welded joints. It provides 24 questions related to welded joint types, weld sizing definitions, permissible stresses, load capacities, and design of specific welded joints. The assignment requires determining sizes, stresses, capacities and designs for various welded joints using steel grade Fe410 and addressing standards as outlined in IS codes.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

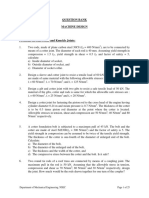

ASSIGNMENT NO 2

DATE OF SUBMISSION 24/2/23

STEEL STRUCTURE DESIGN YR JAN – JUNE 2023

6TH SEM CIVIL ENGINEERING MORNING SHIFT

1. Give advantages and disadvantages of welded joint.

2. What are different types of welded joint.

3. Define size of weld.

4. Define throat thickness

5. What will be permissible stress of shop weld for steel grade Fe410.

6. What will be permissible stress of field weld for steel grade Fe410.

7. What will be maximum size of fillet weld for used for 10 mm thick plate.

8. What will be maximum size of fillet weld used for angle 50 × 50×8 mm.

9. What is the throat thickness of a weld of size 8 mm.

10. Determine the load carry capacity of butt weld joining two plate of 8 mm thick with single V weld

of steel grade Fe 410.

11. Determine the load carry capacity of butt weld joining two plate of 8 mm thick with double V

weld of steel grade Fe 410.

12. Determine the load carry capacity of fillet weld joining two plate with weld size 8 mm thick with

double V weld of steel grade Fe 410.

13. Determine the length of the weld required for 100 KN of factored load using filled weld size 10

mm. Steel grade 410 S.

14. Find out the strength of the fillet weld size 6 mm for a unit length Steel grade 410 S.

15. Requirement of weld should confirm to IS ………………….

16. Fillet weld terminating at the ends should be returned continuously for a distance not less

than………… the size of the weld.

17. What will be minimum lap length in case of welded joint.

18. What is the minimum size of fillet weld.

19. Actual length of weld = Effective length + ……………………………..

20. What is the minimum length of the fillet weld.

21. What is minimum length of butt weld.

22. What is the size of minimum length of intermittent weld.

23. Design strength of fillet weld For steel grade Fe410 for shop weld.

24. Design welded lap joint for a plate of size 150 x 8 mm of grade Fe 410.

25. Design a single butt welded joint for two plate of size 150 × 8 mm of grade Fe 410.

You might also like

- Welding Pipeline HandbookDocument64 pagesWelding Pipeline HandbookJose Luis Roca Cordova100% (1)

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Welded Joint, Welded ConnectionsDocument45 pagesWelded Joint, Welded ConnectionsRaju Sharma67% (12)

- CE6603-Design of Steel Structures QBDocument7 pagesCE6603-Design of Steel Structures QBAarohiShirkeNo ratings yet

- CE6603-Design of Steel StructuresDocument12 pagesCE6603-Design of Steel StructuresIsrael VenkatNo ratings yet

- Welded FinDocument7 pagesWelded FinNatarajan RavisankarNo ratings yet

- U-1 L-6 Welded Connections - Fillet WeldDocument36 pagesU-1 L-6 Welded Connections - Fillet WeldNishanth NishiNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Chapterwise Question bank-DSR-22502Document5 pagesChapterwise Question bank-DSR-22502soumyasonawane100% (1)

- Tods-5 QBDocument2 pagesTods-5 QBSayyam SanchetiNo ratings yet

- Assignment No 2:-: Subject CodeDocument2 pagesAssignment No 2:-: Subject CodeSambit DuttaNo ratings yet

- Tut 1 4 - SD I SteelDocument4 pagesTut 1 4 - SD I SteelChirag N PatelNo ratings yet

- Design of Steel Structure (3350601)Document11 pagesDesign of Steel Structure (3350601)அபினேஷ்குமார்No ratings yet

- Assignment IDocument2 pagesAssignment IPratik SolankiNo ratings yet

- Amity School of Engineering and Technology Iv Semester B.Tech. (Civil Engineering) BTV 405 Structural Steel-I Assignment-1Document1 pageAmity School of Engineering and Technology Iv Semester B.Tech. (Civil Engineering) BTV 405 Structural Steel-I Assignment-1Vaibhav SoniNo ratings yet

- Assignment No 3Document4 pagesAssignment No 3HarshitkumarNo ratings yet

- Headed Studs NELSONDocument1 pageHeaded Studs NELSONNuno Telmo LopesNo ratings yet

- Steel Connection - Tutorial 1Document3 pagesSteel Connection - Tutorial 1Abhishek GuptaNo ratings yet

- DRC Unit WiseDocument12 pagesDRC Unit WiseSasikumar Viswanathan100% (1)

- Worksheet 2021Document3 pagesWorksheet 2021Layike AlemayehuNo ratings yet

- Take Home Exam 1Document1 pageTake Home Exam 1Chloe OlazoNo ratings yet

- Experimental Investigation of Ultimate Capacity of Wired Mesh-Reinforced Cementitious SlabsDocument9 pagesExperimental Investigation of Ultimate Capacity of Wired Mesh-Reinforced Cementitious SlabsSulaiman Mohsin AbdulAzizNo ratings yet

- Part - A (Short Answer Questions) : S.No Unit-I Design Concepts, Design of BeamsDocument22 pagesPart - A (Short Answer Questions) : S.No Unit-I Design Concepts, Design of BeamsVenkatesanNo ratings yet

- Dss - Question BankDocument10 pagesDss - Question Bankapi-306484475No ratings yet

- RCC Question PaperDocument4 pagesRCC Question PaperREVANTH KUMAR KNo ratings yet

- Unit - I: Subject Name: Design of RC ElementsDocument10 pagesUnit - I: Subject Name: Design of RC ElementsManikandan SelvamNo ratings yet

- Question Bank Machine Design A: Numerical Problems: Problems On Pin, Cotter and Knuckle JointsDocument25 pagesQuestion Bank Machine Design A: Numerical Problems: Problems On Pin, Cotter and Knuckle Jointsamol pogakeNo ratings yet

- CE 2306 Design of RC Elements Question Bank Download HereDocument11 pagesCE 2306 Design of RC Elements Question Bank Download HereViswanathan NatesanNo ratings yet

- SD 1 AssignmentDocument17 pagesSD 1 AssignmentAnuj Chandiwala100% (1)

- 1.-BTCVC601 DCS-I UpdatedDocument4 pages1.-BTCVC601 DCS-I UpdatedAmaan ShaikhNo ratings yet

- Assignment 2 DoSSDocument2 pagesAssignment 2 DoSS4091 Varun SharmaNo ratings yet

- DRC Important QuestionsDocument11 pagesDRC Important QuestionsAdithya31No ratings yet

- Ce2306-Design of RC ElementsDocument8 pagesCe2306-Design of RC ElementsAnu PartheeNo ratings yet

- Tutorial-I DESIGN OF RCC: Year Group Semester TutorialDocument2 pagesTutorial-I DESIGN OF RCC: Year Group Semester TutorialPramod RijalNo ratings yet

- Avkis: College of Engineering, HassanDocument2 pagesAvkis: College of Engineering, HassankiranNo ratings yet

- Department of Mechanical Engineering Government College of Engineering, Tirunelveli Me6503 Design of Machine Elements Assignment Ii Part ADocument2 pagesDepartment of Mechanical Engineering Government College of Engineering, Tirunelveli Me6503 Design of Machine Elements Assignment Ii Part Akingsurya6091022No ratings yet

- Steel Assignment SA2023Document3 pagesSteel Assignment SA2023RitikNo ratings yet

- Dss Question Bank 2022Document7 pagesDss Question Bank 2022vcb57xbtd5No ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological UniversityJaineshNo ratings yet

- Final A-315 B Arch SteelDocument2 pagesFinal A-315 B Arch SteelSanjay TiwariNo ratings yet

- B Arch Structure 3Document3 pagesB Arch Structure 3Sanjay TiwariNo ratings yet

- 2Document4 pages2Shem YusoyaNo ratings yet

- CE2404-Prestressed Concrete StructuresDocument8 pagesCE2404-Prestressed Concrete StructuresJayakumar VenkataramanNo ratings yet

- ST7203 SteelStructuresquestionbankDocument12 pagesST7203 SteelStructuresquestionbankAshok AmmaiyappanNo ratings yet

- Gujarat Technological University: Subject Code: 1055004 Subject Name: Structure V Time: 02:30 PM To 04:30 PMDocument1 pageGujarat Technological University: Subject Code: 1055004 Subject Name: Structure V Time: 02:30 PM To 04:30 PMwehoxak452No ratings yet

- Cycle Test 1Document3 pagesCycle Test 1Santhi KaruppiahNo ratings yet

- Ce6505 RCDocument12 pagesCe6505 RCpwd2007No ratings yet

- Design of Machine ElementDocument30 pagesDesign of Machine ElementVigneswaran K100% (1)

- AN - 40137 (AR8401) Design of Structure - IDocument3 pagesAN - 40137 (AR8401) Design of Structure - Iaurora krishreddyNo ratings yet

- HSFG Bolts On BridgesDocument16 pagesHSFG Bolts On BridgesParchuri PraveenNo ratings yet

- Question Bank - 8 MarksDocument2 pagesQuestion Bank - 8 MarksSyed K INo ratings yet

- DRCE IAT 1 - 15.09.23 - StudentsDocument2 pagesDRCE IAT 1 - 15.09.23 - Studentsandalsureshkumar123No ratings yet

- CE2306 Design of RC Elements Anna University Question Bank Question Paper 2 Marks and 16 MarksDocument12 pagesCE2306 Design of RC Elements Anna University Question Bank Question Paper 2 Marks and 16 MarksBalaji KumarNo ratings yet

- MdId Gtu PaperDocument3 pagesMdId Gtu PaperhukNo ratings yet

- Model Question Paper eDocument2 pagesModel Question Paper evamshikasoju1656No ratings yet

- RCC and Steel Conventional QuestionsDocument4 pagesRCC and Steel Conventional QuestionsICE Group of Education BhopalNo ratings yet

- Kings: Department of Mechanical EngineeringDocument14 pagesKings: Department of Mechanical EngineeringAdam AhmadNo ratings yet

- Ce6603 Design of Steel Structures Important Questions PART - A (2 MarksDocument2 pagesCe6603 Design of Steel Structures Important Questions PART - A (2 MarksKaarthic EmayNo ratings yet

- Pre Stressed ConcreteDocument9 pagesPre Stressed Concretedraj1875977No ratings yet

- 4 Fasteners: Hybrid Wood and Steel Details-Builder's GuideDocument24 pages4 Fasteners: Hybrid Wood and Steel Details-Builder's GuidetribleprinceNo ratings yet

- Cma Chap 6Document10 pagesCma Chap 6Chetna 16 MNo ratings yet

- Highway and Airport Engineering (HAE) : Lecture NotesDocument139 pagesHighway and Airport Engineering (HAE) : Lecture NotesChetna 16 MNo ratings yet

- RCC Theory AssignmentDocument3 pagesRCC Theory AssignmentChetna 16 MNo ratings yet

- Numerical RivetDocument11 pagesNumerical RivetChetna 16 MNo ratings yet

- Tension MembersDocument10 pagesTension MembersChetna 16 MNo ratings yet

- Assignment 4Document1 pageAssignment 4Chetna 16 MNo ratings yet

- ESDD-6th Sem-Sessional 02Document1 pageESDD-6th Sem-Sessional 02Chetna 16 MNo ratings yet

- Assignment No 3Document1 pageAssignment No 3Chetna 16 MNo ratings yet