Professional Documents

Culture Documents

19-001E LO Priming Pump Motor Internal Bearings Changed

Uploaded by

G_ARVALIS8470Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

19-001E LO Priming Pump Motor Internal Bearings Changed

Uploaded by

G_ARVALIS8470Copyright:

Available Formats

YANMAR SERVICE NEWS

LO Priming Pump Motor Issue No.: 19-2-G-09-001-O

Subject

Internal Bearings Changed Date: 2019.09

Use Marine Aux. Engines

Engine Model 6EY18(A)L,6EY22(A)L

Engine Nos.

Concerning some of LO priming pump motors, installed to the generator engine common bed, it was reported to us that the

motor bearings would not rotate smoothly (or were damaged.) in less than one year after delivery of the ship.

Upon inspecting the collected parts, we found that motor upper bearings (at anti-load side) were damaged. This priming pump,

since being stopped during engine operation, is prone to be affected by engine vibrations. We found that the upper motor

bearings, in particular, where increasing vibrations would be applied, tended to be damaged.

To prevent the problem, we have decided to employ the creep-free bearings (for both upper and lower bearings) in place of

the conventional bearings, (pls. refer to Fig.1.)

The creep-free bearing has O-rings installed in the circumference, which is instrumental in preventing the bearing from direct

metallic contact with the housing. Combined with the effect of vibration insulation rubber, we have verified that the service life

of the bearing can be extended.

In this relation, we recommend that the existing bearings for both the upper & lower bearings be replaced with the creep-free

bearings whenever the bearings are serviced for maintenance. The bearing cases, which remain not changed, can be re-used as

they are. However, when the case was damaged heavily, change both the bearing and the case to creep-free bearing and

bearing case as a set. Before installing the creep-free bearing, apply grease to the circumference of the bearing. The grease,

besides preventing the O-rings from being damaged, sealed inside two O-rings turns to oil film to work as a buffer media.

Although our operation manual does not specify the replacement interval for the bearing, in the case of the application for the

present pump, we recommend that the bearing be replaced every 8000~12000 hours, (bearing manufacturer recommendation).

As to the LO priming pump, which is exposed to engine vibration constantly even not being used, we recommend the LO priming

pump bearings be replaced every 1~1.5 years.

The creep-free bearings are introduced to production engines shipped from September 2019 and thereafter.

(The priming pump of 6EY18(A)L engines destined to the Japanese shipyards, because of differences of parts (made by

MANSEI INC.), are outside the scope of this Service News.)

Fig.1 Creep-free Bearing

Approved Checked Prepared

Customer Service Division

Large Power Products Management Division

Power Solution Business

Upper (anti-load side) bearing

Lower (load-side) bearing

LO Priming Motor

Fig.2 LO Priming Pump (Photo) and Motor Section

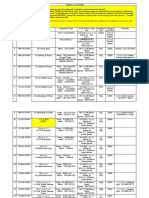

Table 1. Old & New Part Numbers

Engine Model 6EY18(A)L 6EY22(A)L

Pump Delivery Volume 4m3/h 5m3/h

Pump Manufacturer TAIKO KIKAI INDUSTRIES CO., LTD

Old New Old New

Pump Assembly Code 46130-061711 46130-061712 46130-061720 46130-061721

Motor Bare Unit Code 46130-063600 46130-063601 46130-063600 46130-063601

40000-025540 40000-025540

① Bearing Not established Not established

(AC6205ZZ (AC6205ZZ

(Bearing Type) (6205ZZ) (6205ZZ)

CM/5K) CM/5K)

② Motor Housing (anti-load

40000-025560 Same as at the left 40000-025560 Same as at the left

side)

③ Motor Housing (load-side) 40000-025570 Same as at the left 40000-025570 Same as at the left

④ Spring Washer 40000-025580 Same as at the left 40000-025580 Same as at the left

You might also like

- KBB ST5 - B - En10Document162 pagesKBB ST5 - B - En10G_ARVALIS847097% (32)

- Volvo EC160Document25 pagesVolvo EC160superbludnik100% (3)

- Hydraulic Pump&Motor Ref - GuideDocument188 pagesHydraulic Pump&Motor Ref - Guideomni_parts93% (45)

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (8)

- ExxonMobil Safety Criteria 2017 (Ocean Going Tanker)Document59 pagesExxonMobil Safety Criteria 2017 (Ocean Going Tanker)G_ARVALIS8470100% (8)

- 8953-Specifications For Doosan Man 9l21 31Document7 pages8953-Specifications For Doosan Man 9l21 31Bae Juyeon100% (1)

- Field Engineering Bulletin: Improved Tapered Land Thrust BearingDocument2 pagesField Engineering Bulletin: Improved Tapered Land Thrust BearingMichel FloresNo ratings yet

- RT 137A2 Issue2Document7 pagesRT 137A2 Issue2G_ARVALIS8470No ratings yet

- Instruction Manual For Diesel Generator DOOSAN MAN DIESEL 5L23 30H 720RPMDocument1,058 pagesInstruction Manual For Diesel Generator DOOSAN MAN DIESEL 5L23 30H 720RPMdionpanag94% (16)

- Ючай каталог 1Document78 pagesЮчай каталог 1Евгений100% (1)

- OMTSI-13015-W Thrust Bering F200BDocument4 pagesOMTSI-13015-W Thrust Bering F200Bjorge alonsoNo ratings yet

- 18-008E Parts No. Change of FO Injection Pump Deflector (Protector)Document1 page18-008E Parts No. Change of FO Injection Pump Deflector (Protector)G_ARVALIS8470No ratings yet

- Yuchai-YC4B105Z-T20 Yuchai Yc6b125 Engine Diesel Truck Spare Parts CatalogueDocument68 pagesYuchai-YC4B105Z-T20 Yuchai Yc6b125 Engine Diesel Truck Spare Parts CatalogueCINA auto parts100% (1)

- Part Catalog YUCHAI - YC6J125Z-T20 (J8004) PDFDocument80 pagesPart Catalog YUCHAI - YC6J125Z-T20 (J8004) PDFAndre STA100% (1)

- YC6J125Z Diesel Engine Parts CatalogueDocument80 pagesYC6J125Z Diesel Engine Parts CatalogueMohammadazmy Sobursyakur100% (3)

- Pistoes c7Document6 pagesPistoes c7Alaina SousaNo ratings yet

- Parts Catalog of YC6A260-33 (A1016) Diesel EngineDocument73 pagesParts Catalog of YC6A260-33 (A1016) Diesel Enginem h habib m h kassamNo ratings yet

- CPD20SQ-GE2Li WholeDocument211 pagesCPD20SQ-GE2Li Wholeuri.cruz.zamoraNo ratings yet

- Yuchai YC4A115Z T20Document74 pagesYuchai YC4A115Z T20João Roberto Guedes PrazeresNo ratings yet

- YC6J125Z T20 (J8004) 中英文图册Document80 pagesYC6J125Z T20 (J8004) 中英文图册Bruno RodriguesNo ratings yet

- Yc 108 GDocument72 pagesYc 108 Gyewlim100% (1)

- Improved Tapered Land Thrust Bearing 40-20-38 Field Engineering BulletinDocument2 pagesImproved Tapered Land Thrust Bearing 40-20-38 Field Engineering Bulletinjamil ahmedNo ratings yet

- YC6A260 T302 (AYJ600) 柴油机零件图册 JT2017022402下发2017年3月3日 玉林Document79 pagesYC6A260 T302 (AYJ600) 柴油机零件图册 JT2017022402下发2017年3月3日 玉林asim ghoshNo ratings yet

- Yunchai YC6B125-T20Document72 pagesYunchai YC6B125-T20Vüsal 1100% (3)

- Power Steering GearsDocument5 pagesPower Steering GearsDarren ANo ratings yet

- Pump Upgraded LMX BMX 33x Gearbox 40-20-25 Field Engineering BulletinDocument4 pagesPump Upgraded LMX BMX 33x Gearbox 40-20-25 Field Engineering Bulletinjamil ahmedNo ratings yet

- Substituição Do Redutor J2 e J3 - R2000iADocument21 pagesSubstituição Do Redutor J2 e J3 - R2000iAmarino5trischNo ratings yet

- Ra 10551Document24 pagesRa 10551xuanphuong2710No ratings yet

- E40G/EK40G E40J/EK40J: Service GuideDocument23 pagesE40G/EK40G E40J/EK40J: Service Guidemichael pachecoNo ratings yet

- 19-013E - Introduction of Improved Exhaust Valve For 6NY16 (L)Document1 page19-013E - Introduction of Improved Exhaust Valve For 6NY16 (L)G_ARVALIS8470No ratings yet

- Charging System PDFDocument19 pagesCharging System PDFSSEVERAiTJUGANo ratings yet

- Cabeçote Motor c7-2Document8 pagesCabeçote Motor c7-2Alaina SousaNo ratings yet

- YC4A90 T20 (A93A1) 中英文图册Document68 pagesYC4A90 T20 (A93A1) 中英文图册Khee SoonNo ratings yet

- Gear Group (Front) - Install - Idler Gear Only: Desmontagem e MontagemDocument6 pagesGear Group (Front) - Install - Idler Gear Only: Desmontagem e MontagemJose nildo lobato Mendes MendesNo ratings yet

- Base EngineDocument67 pagesBase EngineRohmanNo ratings yet

- SPT 09T1-16 - Ferrous Cast Ductile PistonDocument4 pagesSPT 09T1-16 - Ferrous Cast Ductile PistonMussardNo ratings yet

- Tomei Manual EnglishDocument5 pagesTomei Manual EnglishMuaiyad AL-baluchi100% (1)

- JCB 3CX - 4CX - 214 - 214e - 215 - 217 PDF Service Manual - Part178Document5 pagesJCB 3CX - 4CX - 214 - 214e - 215 - 217 PDF Service Manual - Part178mojbarNo ratings yet

- Service Bulletin: Issued by Canon Europa N.VDocument2 pagesService Bulletin: Issued by Canon Europa N.VokeinfoNo ratings yet

- 2013 Cummins ISX New Valve Camshaft Roller and Rocker LeversTSB - 100551Document1 page2013 Cummins ISX New Valve Camshaft Roller and Rocker LeversTSB - 100551juanNo ratings yet

- Fuel Injection Pump: SpecificationsDocument2 pagesFuel Injection Pump: SpecificationssxturboNo ratings yet

- XJS 3.6 Service CoolingDocument57 pagesXJS 3.6 Service CoolingᎻᎯᎷᎯᎠᎥ ᎯᏞᎰᎥᎿᏫᎡᎬᎽNo ratings yet

- Lubricating Oil Grease For Rotating Equipment of All Sumsel 5 PlantDocument62 pagesLubricating Oil Grease For Rotating Equipment of All Sumsel 5 Plantarief fardy yuskaNo ratings yet

- Design Change of Cooling Water Pump ImpellerDocument2 pagesDesign Change of Cooling Water Pump ImpellerEsteban GiurovichNo ratings yet

- Service Manual: 320 & 320L ExcavatorDocument30 pagesService Manual: 320 & 320L ExcavatorSri hartati100% (1)

- Oiling & GreasingDocument18 pagesOiling & Greasinghassan SardarNo ratings yet

- Marina 2201 (Tug Boat) : Nama Kapal (Name of Ship) No. Register (Register No.) No. Imo (Imo No.) StatusDocument5 pagesMarina 2201 (Tug Boat) : Nama Kapal (Name of Ship) No. Register (Register No.) No. Imo (Imo No.) StatusDolfin YohanesNo ratings yet

- Lubricating Oil Pump Bearing inspection-WS18V005Document1 pageLubricating Oil Pump Bearing inspection-WS18V005tomiNo ratings yet

- Syskey 2183452&from BcpiDocument6 pagesSyskey 2183452&from BcpiGummiArchZzNo ratings yet

- Honda XR200 engine tuning optionsDocument14 pagesHonda XR200 engine tuning optionsCamilo Gomez100% (1)

- Agnee - Altima - Worm GBDocument21 pagesAgnee - Altima - Worm GBVaibhav KumarNo ratings yet

- 55F SSS A245r3Document6 pages55F SSS A245r3mtworusNo ratings yet

- Engine Modification Parts and Estimated Prices for SOx ComplianceDocument8 pagesEngine Modification Parts and Estimated Prices for SOx ComplianceVivek KumarNo ratings yet

- Fuel Injection Pump - InstallDocument8 pagesFuel Injection Pump - Installedwin100% (1)

- Johnson 6HP 1965-68Document8 pagesJohnson 6HP 1965-68Brtnik1100% (1)

- Aa01069 PW170-6Document4 pagesAa01069 PW170-6joaquin suarezNo ratings yet

- 1384 3942 00 en General Arrangement Drawing Omega 50 HzDocument32 pages1384 3942 00 en General Arrangement Drawing Omega 50 Hzmohamed ghareebNo ratings yet

- Kta50 Injector TimingDocument17 pagesKta50 Injector TimingSebastian Nicușor PărăoanuNo ratings yet

- Xeng 9Document3 pagesXeng 9haris syamsudinNo ratings yet

- Shanghai Unicoter Import and Export Co.,LtdDocument35 pagesShanghai Unicoter Import and Export Co.,LtddulichandNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- 18-010E - Rev1 - 6EY17 Intercooler Case CorrosionDocument2 pages18-010E - Rev1 - 6EY17 Intercooler Case CorrosionG_ARVALIS8470No ratings yet

- 19-013E - Introduction of Improved Exhaust Valve For 6NY16 (L)Document1 page19-013E - Introduction of Improved Exhaust Valve For 6NY16 (L)G_ARVALIS8470No ratings yet

- 20-003E - Addition of Fuel Injection Nozzle Body IdentificatioDocument1 page20-003E - Addition of Fuel Injection Nozzle Body IdentificatioNAZISHNo ratings yet

- 02 2 G 07 016 Lrev1EDocument1 page02 2 G 07 016 Lrev1EG_ARVALIS8470No ratings yet

- 19-007E Tightening Torque For Old & New SCR Urea Water PackingsDocument1 page19-007E Tightening Torque For Old & New SCR Urea Water PackingsG_ARVALIS8470No ratings yet

- 19-011E - Fuel Injection Valve SpecDocument1 page19-011E - Fuel Injection Valve SpecG_ARVALIS8470No ratings yet

- 2019 Bwms Best Practices PDFDocument172 pages2019 Bwms Best Practices PDFG_ARVALIS8470No ratings yet

- 19-004E - Rev2 - Change of Mercury ThermometerDocument10 pages19-004E - Rev2 - Change of Mercury ThermometerG_ARVALIS8470No ratings yet

- BOMBAS Rexroth 2Document4 pagesBOMBAS Rexroth 2eliasgolf296No ratings yet

- Yamaha YZF-R1 1998 Service Manual 4XV1-AE1Document418 pagesYamaha YZF-R1 1998 Service Manual 4XV1-AE1jodadaniel85% (13)

- Air Bubble LubricationDocument3 pagesAir Bubble LubricationG_ARVALIS8470No ratings yet

- SAACKE Feed Water Treatment ManualDocument25 pagesSAACKE Feed Water Treatment ManualG_ARVALIS8470No ratings yet

- Air Bubble LubricationDocument3 pagesAir Bubble LubricationG_ARVALIS8470No ratings yet

- Stick Electrode Welding GuideDocument44 pagesStick Electrode Welding GuideTrajan AureliusNo ratings yet

- How To Copy FlexView FilesDocument6 pagesHow To Copy FlexView FilesG_ARVALIS8470100% (1)

- MAN ME-C/B EDS Quick RefDocument20 pagesMAN ME-C/B EDS Quick RefG_ARVALIS8470No ratings yet

- MAN ME-C MPC LedDocument7 pagesMAN ME-C MPC LedG_ARVALIS8470No ratings yet

- 25412, Ballast Water Guide 2013Document41 pages25412, Ballast Water Guide 2013KREAPTONNo ratings yet

- Shielded Metal Arc Welding SMAW Vertical Down and Vertical Up Welding of PipelinesDocument48 pagesShielded Metal Arc Welding SMAW Vertical Down and Vertical Up Welding of PipelinesspahicdaniloNo ratings yet

- Procedure for Radiographic Testing of Welded Steel JointsDocument30 pagesProcedure for Radiographic Testing of Welded Steel JointsG_ARVALIS8470No ratings yet

- Lincoln GMAW Welding GuideDocument96 pagesLincoln GMAW Welding GuideМич БјукенонNo ratings yet

- DNV Technical Enewsletter PV Valve Jan2012Document1 pageDNV Technical Enewsletter PV Valve Jan2012G_ARVALIS8470No ratings yet

- C 550Document56 pagesC 550Denny van BeuzekomNo ratings yet

- Iqi'sDocument6 pagesIqi's24inspector100% (1)

- WS1 InstructionsDocument2 pagesWS1 InstructionsG_ARVALIS8470No ratings yet

- TheShippingKPIStandardv16APPROVED DistributionversionDocument137 pagesTheShippingKPIStandardv16APPROVED DistributionversionG_ARVALIS8470No ratings yet

- Gd825a 2Document8 pagesGd825a 2Leo Manaure Rada100% (1)

- 2 EFC280 FD 01Document20 pages2 EFC280 FD 01nazar750No ratings yet

- TM 5 3810 307 24 2 1Document281 pagesTM 5 3810 307 24 2 1MontasserNo ratings yet

- O-320-A2B,-A3 Parts Catalog PC-203-1Document81 pagesO-320-A2B,-A3 Parts Catalog PC-203-1Alberto MolinaNo ratings yet

- Cane Loaders: I 125A 3 Cylinder L 125A 4 Cylinder I 125A 4 Cylinder (Regulated) I 220A 4 CylinderDocument12 pagesCane Loaders: I 125A 3 Cylinder L 125A 4 Cylinder I 125A 4 Cylinder (Regulated) I 220A 4 CylinderTrupp2785100% (1)

- Spur Gear Design Learn EngineeringDocument4 pagesSpur Gear Design Learn EngineeringImran Sajid ShahidNo ratings yet

- C0SA8060Document48 pagesC0SA8060Mesafint kassieNo ratings yet

- Maritime Propulsion - Oshima ECO-ship 2020Document2 pagesMaritime Propulsion - Oshima ECO-ship 2020MaximusNo ratings yet

- 601 - Helicopter Turboshaft EngineDocument13 pages601 - Helicopter Turboshaft EngineVishnu SankarNo ratings yet

- Hydraulic System 1Document28 pagesHydraulic System 1Udhaya Kumar100% (1)

- Mechanical Engineering Interview Questions and Answers Set3 - Preparation For EngineeringDocument9 pagesMechanical Engineering Interview Questions and Answers Set3 - Preparation For EngineeringRajneesh Patel100% (1)

- Scania Worst CaseDocument17 pagesScania Worst CaseRavi HarperNo ratings yet

- 8 Workshop - Manual - Autobooks PDFDocument135 pages8 Workshop - Manual - Autobooks PDFpaulo0alexandre-16No ratings yet

- (1920) Deming Pumps For Hand & Power Catalogue No.26Document264 pages(1920) Deming Pumps For Hand & Power Catalogue No.26Herbert Hillary Booker 2nd100% (6)

- Engineering Economy Module 6Document52 pagesEngineering Economy Module 6shaitoNo ratings yet

- Tuty Court Genset ESTIMATES NewDocument42 pagesTuty Court Genset ESTIMATES NewRajaDurai RamakrishnanNo ratings yet

- Alat SMK 2018Document16 pagesAlat SMK 2018Jae Tama Grand'sNo ratings yet

- QB - SsepDocument69 pagesQB - Ssepjohndmariner1230% (1)

- Directory List: PVC Wall Panel Production LineDocument13 pagesDirectory List: PVC Wall Panel Production Linearg3112No ratings yet

- Fuel Pro Fleetguard fh230 - Installation - enDocument6 pagesFuel Pro Fleetguard fh230 - Installation - enSudar MonoNo ratings yet

- HPS3000 Pump & GearboxDocument2 pagesHPS3000 Pump & GearboxFrederik CañabiNo ratings yet

- OPTI 4000 6800 DE SDE - Usersmanual - PDGDocument64 pagesOPTI 4000 6800 DE SDE - Usersmanual - PDG2078oxfordNo ratings yet

- ERKE Group, FUWA QUY 400A Crawler Crane CatalogDocument104 pagesERKE Group, FUWA QUY 400A Crawler Crane CatalogerkegroupNo ratings yet

- FMDocument14 pagesFMJorge Gonzalez LopezNo ratings yet

- SL07 480Document5 pagesSL07 480GianNo ratings yet

- Survey of Materials and Equipment for Classification of Ships and Offshore UnitsDocument90 pagesSurvey of Materials and Equipment for Classification of Ships and Offshore UnitsHieu Do TatNo ratings yet

- Aurora Diesel Engine Driven FP SelectionDocument48 pagesAurora Diesel Engine Driven FP Selectionsyed mustafa aliNo ratings yet