Professional Documents

Culture Documents

Usepa 515

Uploaded by

RispaAndriyaniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Usepa 515

Uploaded by

RispaAndriyaniCopyright:

Available Formats

SOP #515

Revision: 1

Date: July 29, 1998

Page 1 of 16

USEPA REGION 9 LABORATORY

RICHMOND, CALIFORNIA

STANDARD OPERATING PROCEDURE 515

DETERMINATION OF MERCURY IN WATER BY COLD VAPOR ATOMIC

ABSORPTION SPECTROMETRY

Prepared by:

Patrick Hirata, ESAT Region 9, LMES Date

Review by:

Richard Bauer, Team Leader Date

Approved by:

Brenda Bettencourt, Laboratory Director Date

Periodic Review:

Signature Title Date

USEPA Region 9 Lab. SOP 515

SOP #515

Revision: 1

Date: July 29, 1998

Page 2 of 16

STANDARD OPERATING PROCEDURE 515

DETERMINATION OF MERCURY IN WATER BY COLD VAPOR ATOMIC

ABSORPTION SPECTROMETRY

This SOP was prepared by Lockheed Martin Environmental Services (LMES) for the United

States Environmental Protection Agency (USEPA) under the Environmental Services Assistance

Team (ESAT) contract (EPA contract No. 68D60005).

APPROVED BY:

Patrick Hirata, LMES Date

Kathy O’Brien, QA/QC Coordinator, LMES Date

Jack Berges, ESAT Team Manager, LMES Date

ESAT Document Control Number: ESAT-9B-1129

USEPA Region 9 Lab. SOP 515

SOP #515

Revision: 1

Date: July 29, 1998

Page 3 of 16

CONTENTS

1 SCOPE AND APPLICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 METHOD SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 DEFINITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4 HEALTH AND SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5 SAMPLE HANDLING AND PRESERVATION . . . . . . . . . . . . . . . . . . . . . . . . 6

6 INTERFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7 APPARATUS AND MATERIALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

8 QUALITY CONTROL PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

9 ANALYTICAL PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

10 DOCUMENTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

11 REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Attachment A - Deviations from Reference Method

Attachment B - Leeman PS200 Mercury Run Log

Attachment C - Analytical Spreadsheet

Attachment D - QC Summary Report

Attachment E - Inorganic Standards and Reagents Preparation Log Book

USEPA Region 9 Lab. SOP 515

SOP #515

Revision: 1

Date: July 29, 1998

Page 4 of 16

1 SCOPE AND APPLICATION

1.1 This SOP describes the instrumental analytical procedures for mercury by cold vapor atomic

absorption (CVAA). This method is applicable for drinking, ground, surface, sea and brackish

water, domestic and industrial wastes. This method applies to the determination of total

mercury (organic + inorganic) by Method 245.1. Sample and standard preparation procedures

are described in SOP 415.

1.2 The reporting limit (RL) is 0.20 Fg/L for total mercury.

2 METHOD SUMMARY

An aliquot of a water sample is transferred to a BOD bottle or equivalent closed-system

container. The sample is digested with a dilute potassium permanganate-potassium persulfate

solution for two hours at 95EC. The digestion oxidizes all forms of mercury to Hg(II). The

Hg(II) in the digested water sample is reduced with stannous chloride to elemental mercury

which is sparged from the sample and detected by atomic absorption. The measurement step

is performed using an automated mercury analyzer.

3 DEFINITIONS

3.1 Analytical Sample - Any sample in which mercury is being determined, excluding standards,

method blanks, or QC reference samples.

3.2 Calibration Blank (CB) - A volume of reagent water fortified with the same matrix as the

calibration standards, but without the analytes.

3.3 Calibration Standard (CAL) - A solution prepared from the primary dilution standard solution

or stock standard solutions. The CAL solutions are used to calibrate the instrument response

with respect to analyte concentration.

3.4 Field Reagent Blank (FRB) - An aliquot of reagent water or other blank matrix that is placed

in a sample container in the laboratory and treated as a sample in all respects, including

shipment to the sampling site, exposure to the sampling site conditions, storage, preservation,

and all analytical procedures. The purposes of the FRB is to determine if contamination is

occurring in the field environment. Note: Field reagent blanks cannot be used for LD or LFM

analyses.

3.5 Field Duplicates (FD) - Two separate samples collected at the same time and placed under

identical circumstances and treated exactly the same throughout field and laboratory

procedures. Analyses of field duplicates indicate the precision associated with sample

collection and storage as well as with laboratory procedures.

USEPA Region 9 Lab. SOP 515

SOP #515

Revision: 1

Date: July 29, 1998

Page 5 of 16

3.6 Instrument Performance Check Solution (IPC) - A standard containing the analytes of interest

which is used to verify the accuracy of the analysis and monitor instrument drift. It is analyzed

periodically throughout an analysis sequence.

3.7 Laboratory Duplicate (LD) - An aliquot of sample prepared and analyzed separately with

identical procedures. Analysis of the sample and LD indicates precision associated with the

laboratory procedures, but not with sample collection, preservation or storage procedures.

3.8 Laboratory Fortified Blank (LFB) - An aliquot of reagent water or other blank matrix to which

known quantities of the method analyte is added in the laboratory. The LFB is analyzed

exactly like a sample, and its purpose is to determine whether the methodology is in control,

and whether the laboratory is capable of making accurate and precise measurements.

3.9 Laboratory Fortified Sample Matrix (LFM) - An aliquot of an analytical sample to which

known quantities of the method analyte is added in the laboratory. The LFM is analyzed

exactly like a sample, and its purpose is to determine whether the sample matrix contributes

bias to the analytical results. The background concentrations of the analyte in the sample

matrix must be determined in a separate aliquot and the measured values in the LFM corrected

for background concentrations.

3.10 Laboratory Reagent Blank (LRB) - An aliquot of reagent water or other blank matrix that is

treated exactly as a sample. The LRB is used to detect sample contamination resulting from

the procedures used to prepare and analyze the samples in the laboratory environment.

3.11 Linear Dynamic Range (LDR) - The concentration range over which the instrument response

to an analyte is linear.

3.12 Method Detection Limit (MDL) - The minimum concentration of an analyte in an that can be

identified, measured and reported with 99% confidence that the analyte concentration is

greater than zero.

3.13 Performance Evaluation Sample (PE) - A solution of method analyte distributed by the

Quality Assurance Research Division (QARD), Environmental Monitoring Systems

Laboratory (EMSL-Cincinnati), U.S. Environmental Protection Agency, Cincinnati, Ohio, to

multiple laboratories for analysis. A volume of the solution is added to a known volume of

reagent water and analyzed with procedures used for samples. Results of analyses are used

by QARD to determine statistically the accuracy and precision that can be expected when a

method is performed by a competent analyst. Analyte true values are unknown to the analyst.

USEPA Region 9 Lab. SOP 515

SOP #515

Revision: 1

Date: July 29, 1998

Page 6 of 16

3.14 Reporting Limit (RL) - The concentration at which confidence in the reported value requires

no qualifying remarks. The RL should be approximately 3-5 times the MDL. A standard is

run at the RL to verify acceptable data quality.

3.15 Quality Control Sample (QCS) - An independent solution of the method analyte of known

concentration. The QCS is obtained from a source external to the laboratory and different

from the source of calibration standards. It is used to check either laboratory or instrument

performance with externally prepared test materials.

3.16 Standard Addition (SA) - The addition of a known amount of analyte to the sample in order

to determine the relative response of the detector to an analyte within the sample matrix. The

relative response is then used to assess either an operative matrix effect or the sample analyte

concentration.

3.17 Stock Standard Solution (SSS) - A concentrated solution containing one or more method

analytes prepared in the laboratory using assayed reference materials or purchased from a

reputable commercial source.

4 HEALTH AND SAFETY

4.1 The toxicity and carcinogenicity of each reagent used in this method has not been fully

established. Each chemical should be regarded as a potential health hazard and exposure to

these compounds should be minimized by good laboratory practices. Specifically,

concentrated nitric and hydrochloric acids present various hazards and are moderately toxic

and extremely irritating to skin and mucus membranes. Use these reagents in a fume hood

whenever possible and if eye or skin contact occurs, flush with large amounts of water for at

least 15 minutes. Contact your Supervisor or Health and Safety Coordinator to determine if

additional treatment is required.

4.2 Mercury compounds are highly toxic if swallowed, inhaled, or absorbed through the skin.

Exhaust or carrier gases should be vented to a fume hood. The analyst should use chemical

resistant gloves when handling concentrated mercury standards.

4.3 The acidification of samples containing reactive materials may result in the release of toxic

gases, such as cyanides or sulfides. Acidification of samples should be done in a fume hood.

4.4 Areas of high, lethal voltages exist within the instrument. Never touch parts of the instrument

which are not intended for access by the instrument operator.

5 SAMPLE HANDLING AND PRESERVATION

USEPA Region 9 Lab. SOP 515

SOP #515

Revision: 1

Date: July 29, 1998

Page 7 of 16

5.1 Samples should be collected in plastic or glass bottles. All bottles must be thoroughly cleaned

and rinsed with reagent water. Volume collected should be sufficient to insure a representative

sample, allow for replicate analysis and minimize waste disposal.

5.2 Samples are received at the Region 9 Laboratory by EPA staff in Room 503. Sample IDs and

dates of collection are verified against the chain-of-custody form.

5.3 Samples must be received and stored at 4 ± 2EC. Any deviations from the 4 ± 2EC

temperature requirements must be noted in the case narrative.

5.4 Samples must be received preserved with HNO3 to pH<2. Any deviations from the

preservation must be noted in the case narrative.

5.5 Holding Time - The maximum sample holding time for mercury is 28 days from the time of

collection.

6 INTERFERENCES

6.1 Interferences have been reported for waters containing sulfide, chloride, copper and tellurium.

Organic compounds which have broad band UV absorbance (around 253.7 nm) are confirmed

interferences. The concentration levels for interferants are difficult to define. This suggests

that quality control procedures (Sect. 8) must be strictly followed.

6.2 Volatile materials (e.g. chlorine) which absorb at 253.7 nm will cause a positive interference.

In order to remove any interfering volatile materials, addition of stannous chloride solution

should be followed by swirling of the digestion vessel before pouring the contents into

autosampler vials.

6.3 Low level mercury sample preparation, digestion, and analysis may be subject to

environmental contamination if performed in areas with ambient backgrounds where mercury

was previously employed as an analytical reagent in analyses such as total Kjeldahl nitrogen

(TKN) or chemical oxygen demand (COD).

7 APPARATUS AND MATERIALS

7.1 Apparatus

7.1.1 Leeman PS200 Mercury Analyzer - includes the optical cell, mercury lamp, peristaltic

pump, drying tube, sample and reagent tubing and Leeman PS200 software.

7.1.2 Okidata Microline 320 printer, or equivalent.

7.1.3 Stirrer plate and stirring bars.

7.1.4 50-mL plastic standard cups (Leeman P/N 116-2102).

USEPA Region 9 Lab. SOP 515

SOP #515

Revision: 1

Date: July 29, 1998

Page 8 of 16

7.1.5 Disposable borosilicate autosampler vials, 16x100 mm (VWR P/N 60825-618)

7.1.6 Class “S” weights.

7.1.7 Plastic or Teflon spray bottle.

7.1.8 Analytical balance capable of weighing to the nearest 0.01 g.

7.1.9 Drying tubes.

7.2 Glassware

7.2.1 Volumetric Class “A” Flasks - 1000-mL, 500-mL, 250-mL and 100-mL.

7.2.2 Volumetric Class “A” Pipettes - 50-mL, 25-mL, 10-mL and 5-mL.

7.2.3 Glass or quartz wool.

7.3 Materials and Reagents

Reagents may contain elemental impurities which might affect analytical data. Only high-purity

reagents that conform to the American Chemical Society (ACS) specifications should be used.

If the purity of a reagent is in question, analyze for contamination.

7.3.1 Reagent water - All references to reagent water in this method refer to ASTM Type II

grade water.

7.3.2 Hydrochloric Acid (HCl), concentrated, trace metals grade or better.

7.3.3 Stannous Chloride, SnCl2, ACS Reagent Grade or better, suitable for mercury

determination..

7.3.4 10% SnCl2 in 10% HCl. Dissolve 100 g of stannous chloride (7.3.3) in 100 mL HCl

(7.3.2) and dilute to 1L with reagent water. Place a stirring bar into the solution. Record

the preparation of this reagent in the Inorganic Standards and Reagents Preparation Log

Book (Attachment E).

7.3.5 Argon gas, ICP grade.

7.3.7 Magnesium Perchlorate, powder or granular.

7.3.8 10% HCl. Add 200 mL HCl (7.3.2) to approximately 1.5 liters reagent water and dilute

to 2L with reagent water. Record the preparation of this reagent in the Inorganic

Standards and Reagents Preparation Log Book (Attachment E).

8 QUALITY CONTROL PROCEDURES

EPA Region 9 Laboratory operates a formal quality control (QC) program. As it relates to this

SOP, the QC program consists of an initial demonstration of laboratory capability, and the

periodic analysis of laboratory reagent blanks, fortified blanks, QCS samples and other

laboratory solutions as a continuing check on performance. The laboratory is required to

maintain performance records that define the quality of the data that are generated.

USEPA Region 9 Lab. SOP 515

SOP #515

Revision: 1

Date: July 29, 1998

Page 9 of 16

8.1 Initial Demonstration of Performance - Prior to use in routine analysis, the method must be

characterized in terms of calibration linearity and MDL.

8.1.1 LDR - Absorbance vs. mercury concentration is generally a linear function over a limited

concentration range. Prior to using this method for routine analysis, the calibration range

must be characterized and linearity demonstrated. The characterization must be verified

annually or whenever a significant change in instrument response is observed or expected

(e.g, a new optical cell is installed). The initial characterization is performed by analyzing

a calibration blank and a series of calibration standards with a concentration range

spanning the expected sample concentration range. The resultant absorbance vs.

concentration data are plotted and examined for linearity using professional judgement.

A calibration line is calculated by linear regression, using at least 4 data points. To be

considered linear, the correlation coefficient must exceed 0.995. Additionally, the

recovery for the standards used in the calibration line must be within 90 - 110%. The

recovery is calculated by entering the standard response back into the calibration line as

follows:

(Y − b) 1

%R = × × 100

m T

Where

%R = percent recovery of the standard

Y = peak-area or peak-height of standard

b = y-intercept of calibration line

m = slope of calibration line

T = true concentration of calibration standard

If the linearity criteria are not met, the calibration range must be adjusted until the criteria are

met.

8.1.2 MDL - The MDL must be established using reagent water fortified at a concentration of

two to three times the estimated instrument detection limit. An MDL in reagent water

represent a best case situation and does not reflect possible matrix effects of real world

samples.

To determine the MDL, process seven replicate aliquots of the fortified reagent water through

the entire analytical method. Perform all calculations defined in the method and report the

concentration values in the appropriate units. Calculate the MDL as follows:

MDL = t × s

Where

MDL= method detection limit

t = student t value (3.14 for n=7, 99% confidence interval)

USEPA Region 9 Lab. SOP 515

SOP #515

Revision: 1

Date: July 29, 1998

Page 10 of 16

s = standard deviation

If the relative standard deviation (RSD) from the analyses of the seven aliquots is <10%, the

mercury concentration in the reagent water may have been too high, which will bias the MDL

value. In such a case, the MDL study should be repeated with a lower mercury concentration.

The MDL should be determined annually or whenever analytical conditions are changed

significantly.

8.2 Routine Analytical Quality Control

8.2.1 IPC - The accuracy and stability of the calibration is verified by the periodic analysis of

an IPC standard. It must be analyzed immediately after calibration, after every 10

samples, and at the end of an analytical run. The recovery of analytes in the IPC is

calculated as follows;

M

%R = × 100

T

Where

%R = percent recovery of the standard

M = measured concentration of the analyte, Fg/L

T = true concentration of the analyte in the IPC

Recovery of the IPC analyzed immediately after calibration must be within 95-105% or the

analysis must be terminated. Subsequent analyses of the IPC solution must be within 90 -

110% or the analyses must be terminated. The cause of the poor recovery must be determined

and the problem corrected. The instrument must be re-calibrated and all samples not bracketed

by acceptable IPC results must be reanalyzed.

8.2.2 CB - The stability of the calibration curve baseline must be monitored by analyzing a CB

immediately after every IPC standard. If the absolute value of the CB result is less than

or equal to the RL, the result is acceptable. If the absolute value of the CB result exceeds

the RL, the analysis must be terminated. The cause of the high CB result must be

determined and the problem corrected. The instrument must be re-calibrated and all

samples not bracketed by acceptable CB results must be reanalyzed.

8.2.3 RL - The accuracy of the calibration at the reporting limit shall be verified by the periodic

analysis of an RL standard. The RL must be analyzed at the beginning of each analytical

run, immediately after the QCS. The recovery of mercury in the RL is calculated as

follows;

M

%R = × 100

T

Where

USEPA Region 9 Lab. SOP 515

SOP #515

Revision: 1

Date: July 29, 1998

Page 11 of 16

%R = percent recovery of the standard

M = measured concentration of the analyte, Fg/L

T = true concentration of the mercury in the RL

If the RL recovery exceeds the limits of 60 - 140%, the analysis shall be terminated. The cause

of the poor recovery must be determined and the problem corrected. The instrument must be

re-calibrated and all affected samples must be reanalyzed. If, after recalibration, the RL

recovery still exceeds the 60-140% limits, the calibration standards must be reprepared and the

instrument recalibrated.

8.2.4 LRB - The laboratory must analyze at least one LRB daily or with each batch of 20 or

fewer samples of the same matrix, whichever is more frequent. LRB data are used to

assess contamination from the laboratory environment. LRB values that exceed the

reporting limit indicate potential laboratory contamination. If the potential contamination

significantly impacts the analytical results, the LRB must be re-prepared along with the

affected samples, and re-analyzed. Unless specified otherwise by project DQOs, the

following statements describe when samples must be re-prepared and re-analyzed;

1) If the sample mercury concentration is greater than or equal to 10 times the MDL and the

LRB mercury concentration is greater than 10% of the sample mercury concentration, the

LRB and sample must be re-prepared and re-analyzed

2) If the sample mercury concentration is less than 10 times the MDL and the LRB mercury

concentration is greater than 2.2 times the MDL, the LRB and sample must be re-

prepared and re-analyzed.

8.2.5 LFB - One LFB must be prepared and analyzed with each analytical run. The recovery

of mercury in the LFB is calculated as follows:

LFB

%R = × 100

s

Where

%R = percent recovery

LFB = measured concentration of mercury in the LFB

s = expected mercury concentration in the LFB

The recovery of mercury in the LFB must be within the 85-115% limits. If the recovery of

mercury exceeds the limits, it is judged to be out-of-control, and the source of the problem must

be identified and resolved before continuing analyses.

8.2.6 LFM - The LFM is designed to provide information about the effect of sample matrix on

the measurement system. One LFM must be prepared for every 10 routine samples of the

same matrix in a sample batch (e.g., 1 LFM for a batch containing 1-10 routine samples,

USEPA Region 9 Lab. SOP 515

SOP #515

Revision: 1

Date: July 29, 1998

Page 12 of 16

2 LFMs for a batch containing 1-20 routine samples, etc.). Samples identified as field

blanks cannot be used for duplicate sample analysis. The recovery of mercury in the LFM

is calculated as follows:

Clfm − C

%R = × 100

s

Where

%R = percent recovery

Clfm = measured concentration in the LFM corrected for sample

preparation and any dilutions

C = measured concentration of mercury in the routine sample

corrected for sample preparation and any dilutions

s = expected mercury concentration in the LFM, corrected for sample

preparation and any dilutions

If the value of s exceeds 3.3 times the value of C, the acceptance window for %R is 70-130%.

If the recovery of mercury falls outside the acceptance window other QC data must be

examined to determine if a matrix problem exists. If the laboratory performance is in control

(i.e., the IPC, QCS, and LFB results are acceptable), the poor LFM recovery is most likely

matrix related. Lab duplicate results should also be examined to gain additional insight as to

whether the matrix components or matrix heterogeneity are the cause of the unacceptable

recovery. In either case, the problem should be discussed in the case narrative and the data user

informed that the result for mercury in the unfortified sample is suspect due either to

heterogeneous nature of the sample or a matrix effect. Flag any out-of-control results with an

“N”.

8.2.7 LD - Sample homogeneity can affect the quality and interpretation of the data. LD results

can be used to assess sample homogeneity. One LD must be prepared for every 10routine

samples of the same matrix in a sample batch (e.g., 1 LD for a batch containing 1-10

routine samples, 2 LDs for a batch containing 11-20 routine samples, etc.). Samples

identified as field blanks cannot be used for duplicate sample analysis. Homogenize the

routine sample selected as the LD, obtain a representative aliquot, and proceed with

sample preparation and analysis, treating the LD sample as a routine sample. Calculate

the relative percent difference using the following equation;

| Cld − C|

% RPD = × 100

(Cld + C ) / 2

Where

%RPD = relative percent difference

Cld = measured mercury in the LD

C = measured mercury in the routine sample

USEPA Region 9 Lab. SOP 515

SOP #515

Revision: 1

Date: July 29, 1998

Page 13 of 16

The relative percent difference (RPD) must be <20% for samples with mercury levels greater

than or equal to 0.2 Fg/L. The absolute difference between duplicate results must be less than

the reporting limit for samples containing less than for 0.2 Fg/L. If the control limits are

exceeded, flag all associated mercury results with an asterisk (*). Document actions in the case

narrative.

8.2.8 QCS Analysis - The mercury concentrations in a QCS sample must be measured daily or

once per batch of 20 samples, whichever is more frequent. The concentration of analyte

in the QCS should be in the upper half of the calibrated range. The recoveries must be

within 90-110% or the samples in the batch must be reanalyzed.

Cm

%R = × 100

Ct

Where

%R = relative percent recovery

Cm = measured mercury concentration in the QCS

Ct = true mercury concentration in the QCS

9 ANALYTICAL PROCEDURES

9.1 Sample Preparation - The sample and standard preparation procedure for mercury analysis is

found in SOP 415.

9.2 Calibration and Standardization - The analyst is advised to follow the recommended operating

conditions provided by the manufacturer. It is the responsibility of the analyst to verify that the

instrument configuration and operating conditions satisfy the analytical requirements, and to

maintain quality control data verifying instrument performance. Typical operating parameters

for the Leeman PS200 Mercury Analyzer are as follows:

Parameter Setting

Argon Flow Rate 0.30 LPM

Pump Rate 5.0 mL/min

9.3 Analytical Run Sequence -

9.3.1 Set-up and configure the instrument and data system. The Leeman PS200 mercury

analyzer will be operational from a cold start (i.e. Leeman PS200 turned off) after an

approximate 2.5 hour warm-up period. Inspect the pump tubing for pinching. Replace

the pump tubing if excessive wear is apparent. Clamp the pump tubings in the holder and

snap to seal. Prepare a fresh magnesium perchlorate drying tube by inserting some glass

USEPA Region 9 Lab. SOP 515

SOP #515

Revision: 1

Date: July 29, 1998

Page 14 of 16

or quarz wool into a clean, dry tube, and adding magnesium perchlorate to fill the tube

up to the neck. Tap the tube to allow magnesium perchlorate to settle (do not compact

the magnesium perchlorate), plug the drying tube with some more glass or quartz wool

and attach the drying-tube fittings so that they are finger-tight. Pour out the reservoir

containing reagent water into a waste container and add 10% hydrochloric acid (7.3.8)

to a level approximately 1 inch from the top. Lightly oil the autosampler traverse arm

and wipe clean.

9.3.2 After the 2.5 hour warm-up sequence has been completed, check the aperture reading by

getting into the Utility menu and then into the Diagnostics menu. The aperture should

be -100 to +100 (an ideal reading is zero); if not, take off the front panel of the PS200

and, using the hex wrench provided, gently adjust the bottom nut (if the value is negative)

or the top nut (if the value is positive) so that the aperture reading is within the range and

then replace the front panel. Use the User Name menu to enter analyst initials and then

get back to the Main Menu. Select the Protocol (Mercury) and enter in a file name (for

example, 20729981 which corresponds to instrument #2, the date, and the first run of the

day). Transfer the calibration standards (in order, 0, 0.2, 0.5, 1.0, 5.0 and 15.0 ug/L

mercury) into the first 6 spots in the 50mL standards tube rack. Place the bottle of 10%

SnCl2 in 10% HCl onto a stirring plate, stir, and put the tubing for the reductant into the

container.

Operating parameters for Mercury protocol are:

Parameter Setting

Argon Flow Rate 0.30 LPM

Pump Rate 5.0 mL/min

9.3.3 Transfer the QA/QC standards and samples into clean autosampler vials and place into

the 44-sample capacity rack.

9.3.4 Enter the autosampler loading list into data system using Rack Entry and Setup,

including all required QC and routine samples. Print the autosampler entries by pressing

the F3 key.

9.3.5 Calibrate the instrument using the six standards. After calibration, get into Calibration

on the Main Menu and then get into the Line Calibration menu. The current curve will

be highlighted on the graph. Check the correlation coefficient (r); the correlation

coefficient of the curve must be >0.995 or the instrument must be recalibrated. If the

correlation coefficient meets the 0.995 requirement, press the A key to Accept the curve

and press the F3 key to print the curve.

USEPA Region 9 Lab. SOP 515

SOP #515

Revision: 1

Date: July 29, 1998

Page 15 of 16

9.3.6 Start autosampler analysis sequence and analyze samples. Review results for QC

compliance and off-scale results. Identify samples which must be re-analyzed in a

different analytical run. Samples having analytes at concentrations higher than the linear

dynamic range must be diluted into range and re-analyzed.

An example of a loading list for an analytical run sequence is listed in the table below.

Seq. Desc. Seq. Desc. Seq. Desc. Seq. Desc.

1 IPC 13 IPC 25 IPC 37

2 CB 14 CB 26 CB 38

3 QCS 15 S5 27 S13 39

4 RL 16 S6 28 S14 40

5 LRB 17 S7 29 S15 41

6 LFB 18 S8 30 S16 42

7 S1 19 S09 31 S17 43

8 S1-LD 20 S10 32 S18 44

9 S1-LFM 21 S11 33 S19 45

10 S2 22 S11-LD 34 S20

11 S3 23 S11-LFM 35 IPC

12 S4 24 S12 36 CB

9.4 Data Reduction and Reporting - After set-up and calibration the instrument reports results for

the analyzed solution in the units of Fg/L. The concentrations reported by the instrument must

be corrected for any dilutions performed as part of the sample preparation or analysis process.

All results should be reported using no more than three significant figures; however, no values

of less significance than the MDL may be reported (i.e., values near the MDL will be reported

with only two significant figures).

9.5 Aqueous Samples - Data for aqueous samples should be reported in units of Fg/L using the

following calculation;

where:

C= MxD

C = final reported concentration, in Fg/L

M = measured concentration reported by instrument, in Fg/L

D = dilution factor, to account for dilution performed after sample

preparation

USEPA Region 9 Lab. SOP 515

SOP #515

Revision: 1

Date: July 29, 1998

Page 16 of 16

9.6 Rounding - For rounding results, adhere to the following rules:

a) If the number following those to be retained is less than 5, round down;

b) If the number following those to be retained is greater than 5, round up; or

c) If the number following the last digit to be retained is equal to 5, round down if the

digit is even, or round up if the digit is odd.

10 DOCUMENTATION

10.1 Leeman PS200 Mercury Run Log - Entries are made for the case number, SDG number, date

of analysis, site name, file name, analyst initials, lab sample IDs, client sample IDs, and

comments, if any. The run log is maintained in Room 302.

10.2 Standards Documentation - Copies of all standard solution preparation entries (CAL, IPC, RL,

LFB, LFM, QCS, etc.) must be submitted with each data package. (Attachment E)

10.3 Case Narrative and Deliverable

The data package consists of the case narrative, reports and data, as listed in the table below.

Data Package Contents

Case Narrative: Discusses any problems encountered, both technical and administrative,

the corrective action taken, and the resolution. All universal analytical flags should also

be discussed in the case narrative.

Tabulated sample results on an analytical spreadsheet, with units, sample collection

dates, client sample IDs, laboratory IDs and station locations. (Attachment C)

Method blank data included on the analytical spreadsheet. (Attachment C)

Duplicate results on a QC summary report with calculated relative percent difference

(RPD). (Attachment D)

QCS, LFM and LFB results on a QC summary report with calculated percent recoveries

(%R). (Attachment D)

Raw sample, standard and QC data, including run logs and any work sheets, if

applicable. (Attachment B)

11 REFERENCES

11.1 Determination of Mercury in Water by Cold Vapor Atomic Absorption Spectrometry, EPA

Method 245.1, Environmental Monitoring Systems Laboratory, Revision 3.0, May 1994.

11.2 Leeman PS200 Operation and Maintenance Manual, Leeman Labs, Hudson, New Hampshire

03051, 1993.

11.3 Region 9 SOP 125, Sample Disposal.

11.4 Region 9 SOP 610, Inorganic Data Package Assembly.

11.5 Region 9 SOP 110, Sample Receipt, Log-in and Storage.

USEPA Region 9 Lab. SOP 515

11.6 Region 9 SOP 415, Preparation of Water Samples for Mercury Analysis.

Attachment A

Deviations From Reference Method

A.1 The sample and standard preparation procedures are covered in SOP 415.

A.2 This SOP uses the Leeman PS200 Mercury Analyzer (an automated instrument) which requires

only a small sample aliquot (approximately 5 mL) to perform the mercury analysis. Method

245.1 as written requires purging of the headspace in the digestion vessel, the addition of

stannous chloride solution to the entire digested sample and then analysis of the sample. It is

a destructive technique in that the entire sample is used. Samples which are over-range require

dilution and redigestion in a subsequent digestion batch. This SOP allows for dilution of over-

range samples since only 5 mL of sample was used during the initial analysis

You might also like

- Validation of Laminar Air Flow SOPDocument2 pagesValidation of Laminar Air Flow SOPRahul Patil100% (5)

- Procedures PM2.5 QADocument262 pagesProcedures PM2.5 QAJuan Pablo VivasNo ratings yet

- Analytical ValidationDocument44 pagesAnalytical Validationsairam_ski100% (2)

- 1602041044-MD-04-MT-RSANA-PD-076 Rev.00 Maintenance Procedure For TOC-COD Analyzer PDFDocument20 pages1602041044-MD-04-MT-RSANA-PD-076 Rev.00 Maintenance Procedure For TOC-COD Analyzer PDFKy Nguyen TrongNo ratings yet

- Permenkes 72-2016 Standar Pelayanan Kefarmasian Di Rumah Sakit-1Document20 pagesPermenkes 72-2016 Standar Pelayanan Kefarmasian Di Rumah Sakit-1Seal FireNo ratings yet

- Lab. QADocument205 pagesLab. QAMai HanyNo ratings yet

- Gas Chromatography and Mass Spectrometry: A Practical GuideFrom EverandGas Chromatography and Mass Spectrometry: A Practical GuideRating: 5 out of 5 stars5/5 (3)

- CJP - Marpol Certification Test Plan Rev 1Document15 pagesCJP - Marpol Certification Test Plan Rev 1adityajailani19No ratings yet

- Chemical Analysis Lab ProceduresDocument186 pagesChemical Analysis Lab Proceduresqiwe0001No ratings yet

- Field Measurement of ORPDocument21 pagesField Measurement of ORPWONG TSNo ratings yet

- Flow Measurement GuidelinesDocument27 pagesFlow Measurement GuidelinesAkram DriraNo ratings yet

- Astm D5463Document5 pagesAstm D5463ponnusjNo ratings yet

- 2014 Electronic Cigarette Aerosol Parameters StudyDocument89 pages2014 Electronic Cigarette Aerosol Parameters StudyRigoberto CastroNo ratings yet

- EPA pH Meter Calibration SOPDocument13 pagesEPA pH Meter Calibration SOPNavnath BorseNo ratings yet

- Sampling and Analysis of Environmental Chemical Pollutants: A Complete GuideFrom EverandSampling and Analysis of Environmental Chemical Pollutants: A Complete GuideNo ratings yet

- Techniques of Gas Spot SamplingDocument5 pagesTechniques of Gas Spot Samplingjuan carlosNo ratings yet

- Contract Laboratory Audit Report TemplateDocument21 pagesContract Laboratory Audit Report Templaterodcam1No ratings yet

- D1.4 Diagnostic Methods For Automotive Fuel Cell SystemsDocument32 pagesD1.4 Diagnostic Methods For Automotive Fuel Cell SystemsAdrien EmerichNo ratings yet

- 2000AKCXDocument124 pages2000AKCXDiosa JunoNo ratings yet

- 03 VP MitigationDocument52 pages03 VP Mitigationario13No ratings yet

- Handbook of Solid Phase MicroextractionFrom EverandHandbook of Solid Phase MicroextractionJanusz PawliszynRating: 5 out of 5 stars5/5 (2)

- PETROFLAG ManualDocument22 pagesPETROFLAG ManualRebeca PedrazaNo ratings yet

- SOP-QA-8 V3 Title: Investigator Site File (ISF)Document2 pagesSOP-QA-8 V3 Title: Investigator Site File (ISF)Olja PopovicNo ratings yet

- Ash SamplingDocument33 pagesAsh SamplingAntoine LopezNo ratings yet

- Coulter AC.T 5 Diff ProcedureDocument12 pagesCoulter AC.T 5 Diff ProcedureLuis Ferdinand Dacera-Gabronino Gamponia-NonanNo ratings yet

- Epa Method Io3-1Document30 pagesEpa Method Io3-1Eddie MendozaNo ratings yet

- Analyser Sample Handling System DesignDocument28 pagesAnalyser Sample Handling System Designmilton1987No ratings yet

- Gas Absorption in Wet ScrubbersDocument52 pagesGas Absorption in Wet ScrubbersJohan ConradieNo ratings yet

- Unit 1.1.40 Protein, Moisture and Kolbach Index Rapid Determination by NIRDocument8 pagesUnit 1.1.40 Protein, Moisture and Kolbach Index Rapid Determination by NIRRiyanNo ratings yet

- SNI 6989 2 2009 Cara Uji Kebutuhan Oksigen Kimiawi COD Dengan Refluks Tertutup Secara Spektrofotometri PDFDocument5 pagesSNI 6989 2 2009 Cara Uji Kebutuhan Oksigen Kimiawi COD Dengan Refluks Tertutup Secara Spektrofotometri PDFZenal AbidinNo ratings yet

- Aarti Drugs Audit Report Finds Issues with Change Management and EDC MonitoringDocument12 pagesAarti Drugs Audit Report Finds Issues with Change Management and EDC MonitoringVijay KotwalNo ratings yet

- SMP For Silica Hach 5500scDocument7 pagesSMP For Silica Hach 5500scPrince MaheshNo ratings yet

- GEM 4000 Training PlanDocument18 pagesGEM 4000 Training Planjose_mario1128No ratings yet

- READY BIODEGRADABILITY OECD 301F Manometric Respirometry Test Biodeg - Light Hydrocracked Gas OilDocument50 pagesREADY BIODEGRADABILITY OECD 301F Manometric Respirometry Test Biodeg - Light Hydrocracked Gas OilDena MilanyNo ratings yet

- Analytica Chimica ActaDocument33 pagesAnalytica Chimica ActaAlejandro Rojas GarcíaNo ratings yet

- Soxhlet Extraction Method: EPA 3540CDocument11 pagesSoxhlet Extraction Method: EPA 3540CNate MercerNo ratings yet

- Oceanic Methane Hydrates: Fundamentals, Technological Innovations, and SustainabilityFrom EverandOceanic Methane Hydrates: Fundamentals, Technological Innovations, and SustainabilityNo ratings yet

- Media Fill Tech Re PDFDocument21 pagesMedia Fill Tech Re PDFnetelsrt1298100% (1)

- Artificial atmospheres test reportDocument8 pagesArtificial atmospheres test reportAs Ad Ali MutakinNo ratings yet

- Experiment 4 Group 4Document23 pagesExperiment 4 Group 4amirul ashrafNo ratings yet

- GCC 2014 GC Troubleshooting Tips and Tricks 1Document64 pagesGCC 2014 GC Troubleshooting Tips and Tricks 1Duy DangNo ratings yet

- HEI-IMS-CHEM-SOP013 Chemical Laboratory Monitoring and AnalysisDocument69 pagesHEI-IMS-CHEM-SOP013 Chemical Laboratory Monitoring and Analysisrizwan chNo ratings yet

- Redox Indicators. Characteristics and ApplicationsFrom EverandRedox Indicators. Characteristics and ApplicationsRating: 5 out of 5 stars5/5 (1)

- Bennett Casey Wayne 1985Document319 pagesBennett Casey Wayne 1985gpepe pepeNo ratings yet

- Experiment 4 Group 4Document23 pagesExperiment 4 Group 4amin shukriNo ratings yet

- FWD CALCULATION NOTESDocument10 pagesFWD CALCULATION NOTESMuhammad Ashraful ArifinNo ratings yet

- General Workplace Safety: JUNE 2006Document149 pagesGeneral Workplace Safety: JUNE 2006masoud132No ratings yet

- Doxpol F MetDocument69 pagesDoxpol F Metsabrina amaralNo ratings yet

- Standard Test Method For: Designation: E2866 12 (Reapproved 2016)Document15 pagesStandard Test Method For: Designation: E2866 12 (Reapproved 2016)Alevj DbNo ratings yet

- Standard Operating Handling and Preparation of Soil Samples For Chemical and Physical AnalysesDocument13 pagesStandard Operating Handling and Preparation of Soil Samples For Chemical and Physical AnalysesPhước LêNo ratings yet

- Water System PQDocument47 pagesWater System PQsainzb8389% (9)

- SOP-QA-6 V4 Study Start-UpDocument4 pagesSOP-QA-6 V4 Study Start-UpOlja PopovicNo ratings yet

- Sampling of Ambient Air For PM Concentration Using The Rupprecht and Patashnick (R&P) Low Volume Partisol® SamplerDocument40 pagesSampling of Ambient Air For PM Concentration Using The Rupprecht and Patashnick (R&P) Low Volume Partisol® SamplerkhtibNo ratings yet

- Io-2.3. PM10. LVDocument40 pagesIo-2.3. PM10. LVchristopher lee mercadoNo ratings yet

- Sampling Methods Guide Northern Territory MinesDocument14 pagesSampling Methods Guide Northern Territory Mineshitman1363No ratings yet

- AN256 LC VitaminB12 Beverages 01sep2010 LPN2574Document11 pagesAN256 LC VitaminB12 Beverages 01sep2010 LPN2574RispaAndriyaniNo ratings yet

- Determination of Cyanocobalamin in Multivitamin Tablets by Multimode High-Performance Liquid ChromatographyDocument5 pagesDetermination of Cyanocobalamin in Multivitamin Tablets by Multimode High-Performance Liquid ChromatographyRispaAndriyaniNo ratings yet

- 5990 8158enDocument2 pages5990 8158enRispaAndriyaniNo ratings yet

- Department of Chemistry, Ramnarain Ruia College, Mumbai - 400019, IndiaDocument8 pagesDepartment of Chemistry, Ramnarain Ruia College, Mumbai - 400019, IndiaRispaAndriyaniNo ratings yet

- -α-Tocopherol: d d d dDocument2 pages-α-Tocopherol: d d d dRispaAndriyaniNo ratings yet

- Standard Operating ProceduresDocument16 pagesStandard Operating ProceduresRispaAndriyaniNo ratings yet

- JAdvPharmTechRes34210-1177497 - 031614 - Glycyrrhizic AcidDocument6 pagesJAdvPharmTechRes34210-1177497 - 031614 - Glycyrrhizic AcidRispaAndriyaniNo ratings yet

- MBS025761Document4 pagesMBS025761RispaAndriyaniNo ratings yet

- Installing Juniper Router OS JunOS 10 1 in Qemu VM For GNS3Document4 pagesInstalling Juniper Router OS JunOS 10 1 in Qemu VM For GNS3Adrian Ionut NituNo ratings yet

- Leading Causes of MortalityDocument12 pagesLeading Causes of MortalityJayricDepalobosNo ratings yet

- Grade 7 Lesson: Module 4 - Acids and BasesDocument3 pagesGrade 7 Lesson: Module 4 - Acids and BasesJoedelyn Wagas100% (4)

- SIHI - Control Narrative Proc Compressor UnitDocument5 pagesSIHI - Control Narrative Proc Compressor Unitman_y2k100% (1)

- PR & PublicityDocument16 pagesPR & PublicityVipul Partap100% (2)

- New Technique for Producing 3D Fabrics Using Conventional LoomDocument1 pageNew Technique for Producing 3D Fabrics Using Conventional LoomSujit GulhaneNo ratings yet

- CIC-presentation of RP-577 PresentationDocument181 pagesCIC-presentation of RP-577 PresentationIbrahim Eldesoky75% (4)

- 255 Introduction Vocational Service enDocument12 pages255 Introduction Vocational Service enDmitri PopaNo ratings yet

- Second Travel of Rizal: Week 8 Unit 3Document22 pagesSecond Travel of Rizal: Week 8 Unit 3John Russell GasangNo ratings yet

- The Bourne Identity ReviewDocument3 pagesThe Bourne Identity ReviewBoldizsár Zeyk AnnaNo ratings yet

- Company Introduction PT GEADocument8 pagesCompany Introduction PT GEABegawan Half DoneNo ratings yet

- New Product Performance Advantages For Extending Large, Established Fast Moving Consumer Goods (FMCG) BrandsDocument18 pagesNew Product Performance Advantages For Extending Large, Established Fast Moving Consumer Goods (FMCG) Brandssmart_kidzNo ratings yet

- Murder Conviction UpheldDocument9 pagesMurder Conviction UpheldBobNo ratings yet

- Dual Domain Image Encryption Using Bit Plane Scrambling and Sub - Band ScramblingDocument16 pagesDual Domain Image Encryption Using Bit Plane Scrambling and Sub - Band Scramblingraja rishyantNo ratings yet

- Individualized Learning Program Project Evaluation FormDocument3 pagesIndividualized Learning Program Project Evaluation Formakbisoi1No ratings yet

- The Next Questions Will Depend On Your Answer(s) in Question Number 4: 6. The Next Questions Will Depend On Your Answer(s) in Question Number 4: 6Document1 pageThe Next Questions Will Depend On Your Answer(s) in Question Number 4: 6. The Next Questions Will Depend On Your Answer(s) in Question Number 4: 6cgranzore8833% (3)

- Flared Separable FittingDocument9 pagesFlared Separable FittingbenNo ratings yet

- The University of QueenslandDocument2 pagesThe University of Queenslandimmanuel nauk elokpereNo ratings yet

- The Science and Art of DSGE ModellingDocument9 pagesThe Science and Art of DSGE ModellingkeyyongparkNo ratings yet

- WRBS Quarter 1 Modules WEEK-1-8Document32 pagesWRBS Quarter 1 Modules WEEK-1-8Sir Kindred VillaruzNo ratings yet

- AWS Architecture Icons Deck For Light BG 20190729 LegacyDocument111 pagesAWS Architecture Icons Deck For Light BG 20190729 LegacyHenson ChinNo ratings yet

- ENGLISH CONTENT UNIT 4 2022 5tos.Document9 pagesENGLISH CONTENT UNIT 4 2022 5tos.Dylan QuiñónezNo ratings yet

- Regina Downtown Community Support Team ReportDocument28 pagesRegina Downtown Community Support Team ReportJeremy SimesNo ratings yet

- Spelling Bee Word ListDocument26 pagesSpelling Bee Word Listsan_6303No ratings yet

- Arm Cortex InstructionsDocument14 pagesArm Cortex InstructionsHamsini ShreenivasNo ratings yet

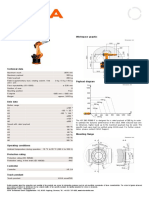

- KR 280 R3080 F technical specificationsDocument1 pageKR 280 R3080 F technical specificationsDorobantu CatalinNo ratings yet

- Sidhil - ICT Design EngineerDocument3 pagesSidhil - ICT Design Engineeratif_aman123No ratings yet

- Accenture Sustainable ProcurementDocument2 pagesAccenture Sustainable ProcurementAnupriyaSaxenaNo ratings yet

- 7Document19 pages7Maria G. BernardinoNo ratings yet

- Senthamarai Kannan S V (Kannan) Oracle SCM and Oracle MFG, Oracle ASCP (PTP/OTC/WMS/ASCP/INV/PIM/OPM) Manager/Sr Manager/Functional LeadDocument8 pagesSenthamarai Kannan S V (Kannan) Oracle SCM and Oracle MFG, Oracle ASCP (PTP/OTC/WMS/ASCP/INV/PIM/OPM) Manager/Sr Manager/Functional LeadKarunya KannanNo ratings yet