Professional Documents

Culture Documents

Neopolen Sup ® Sup +P+ +EPP+Foam+for+Heating+Technology

Uploaded by

Bradz Talpo0 ratings0% found this document useful (0 votes)

7 views1 pageOriginal Title

Neopolen_sup_®__sup_+P+_+EPP+Foam+for+Heating+Technology

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views1 pageNeopolen Sup ® Sup +P+ +EPP+Foam+for+Heating+Technology

Uploaded by

Bradz TalpoCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Neopolen® P: EPP foam for heating technology

Case Study

Designer outfit for thermal protection

BASF now offers a new and patented version of the

foam Neopolen® P (EPP: expanded polypropylene)

for devices used in heating, ventilation and sanitary

systems. The metallic-gray Neopolen® P 9335 mg is

noted for its thermal insulation which is 10 percent

better than standard EPP. Thanks to the versatile

properties of the new product, foamed Neopolen® P

molded parts are able to perform several functions at

the same time: The foam serves as efficient shock-

absorbing packaging for transportation, supports the

device as constructive carrier and replaces the metal

housing because it can be processed into thermally

insulating housings with an aesthetic surface.

Neopolen® P 9335 mg thus helps to meet the energy

standards of low-energy houses and for the

renovation of older buildings. Designed surfaces

Thanks to new tooling technologies, the foam can be

Several functions in one processed in such a way that high-quality surfaces

This presents new design options for devices such as are produced without the typical particle foam look

heat exchangers and solar storing units. Neopolen® and without nozzle imprints. The foam beads which

P 9335 mg can be used to foam highly resilient, expand uniformly adapt to the modified mold surface

elastic molded parts which replace conventional and as a result generate a homogeneous, aesthetic

metal or injection-molded housings. Without any designed surface, for example with a leather look.

elaborate mold design, undercuts can be produced in

the foam component easily and cost-effectively. This Neopolen® P – versatile and environmentally

provides new options for integrating additional friendly

functions into the housing such as airflow channels or Neopolen® P 9335 mg is a specialty foam from the

assembly fixings. As a result, the required number of tried-and-tested Neopolen® P product range. The

components can be reduced to a minimum. The expanded polypropylene (EPP) is noted for its very

thermal and electronic units are fastened directly into good shock absorption characteristics, low weight

the viscoplastic Neopolen® P housing. Thus, they and high temperature resistance. The particle foam

cannot be damaged during transportation. combines high energy absorption – even after

several impacts – with excellent resilience and

isotropic deformation performance. This interesting

When in use, the device is also thermally insulated in

combination of properties, which also includes low

an efficient way. The polymer matrix of Neopolen® P

water absorption and good resistance to chemicals,

9335 mg contains infrared absorbers which reflect

opens up a broad range of applications: from vehicle

thermal radiation like a mirror and thus considerably

construction, packaging and transport containers to

reduce the heat transfer compared to conventional

sports and leisure applications. Neopolen® P is 100

EPP. Neopolen® P is temperature-resistant from -

percent recyclable. It is manufactured and processed

40°C to +100°C.

without any CFCs (chlorofluorocarbons).

You might also like

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Valsir C PP l02882Document60 pagesValsir C PP l02882Budihardjo Sarwo SastrosudiroNo ratings yet

- Catalog VALSIR Canalizare PDFDocument60 pagesCatalog VALSIR Canalizare PDFAlexandru Ilioiu100% (1)

- Silo - Tips Answer Key Build An Atom Part I Atom Screen Build An Atom Simulation An AtomDocument6 pagesSilo - Tips Answer Key Build An Atom Part I Atom Screen Build An Atom Simulation An AtomFilip SalekNo ratings yet

- Clariant Brochure Exolit Flame Retardants For Thermoplastics 201306 EN PDFDocument24 pagesClariant Brochure Exolit Flame Retardants For Thermoplastics 201306 EN PDFxy2zjgNo ratings yet

- PolypropyleneDocument10 pagesPolypropylenePurushothama Nanje GowdaNo ratings yet

- Polycarbonate (PC) : PetrochemicalsDocument14 pagesPolycarbonate (PC) : PetrochemicalsAhmed MokhtarNo ratings yet

- Q2 M2 Octet-Rule-And-Lewis-StructureDocument18 pagesQ2 M2 Octet-Rule-And-Lewis-StructureElysha Mae RamirezNo ratings yet

- Poly PropyleneDocument14 pagesPoly PropyleneDrizzle Rajput100% (1)

- PolypropyleneDocument29 pagesPolypropyleneZeny Naranjo100% (1)

- What Is PolypropyleneDocument7 pagesWhat Is PolypropyleneSadaf SheikhNo ratings yet

- Lummus PolypropyleneDocument2 pagesLummus PolypropyleneÜmit Düngel100% (1)

- Guidelines For Winterization in Chemical PlantsDocument11 pagesGuidelines For Winterization in Chemical Plantsmtrj59No ratings yet

- Aspen Aerogels Industrial InsulationDocument4 pagesAspen Aerogels Industrial InsulationGino De LandtsheerNo ratings yet

- Intro To PP. Introduction To Polypropylene by LyondellbasellDocument3 pagesIntro To PP. Introduction To Polypropylene by Lyondellbasellyamakun100% (1)

- High Performance Plastics Materials Guide: Craftech Industries'Document20 pagesHigh Performance Plastics Materials Guide: Craftech Industries'akirloskarNo ratings yet

- PolypropyleneDocument12 pagesPolypropyleneTal PeraltaNo ratings yet

- Wisdom: Hype About Discontinuing Hypalon®Document1 pageWisdom: Hype About Discontinuing Hypalon®Dwi Hermanto SetiawanNo ratings yet

- Glowing Eco DiscDocument33 pagesGlowing Eco DiscKhitish MohapatraNo ratings yet

- Spaceloft DS 1.1Document1 pageSpaceloft DS 1.1raeggaemanNo ratings yet

- Modern Technology Assignment FinalDocument15 pagesModern Technology Assignment FinalchuchuNo ratings yet

- 13A2303X00 Wire Wisdom Hypalon en USDocument1 page13A2303X00 Wire Wisdom Hypalon en USFelipe GustavoNo ratings yet

- Consumer Goods - Low Cost and Easy Processability Make HDPE A Material of Choice inDocument5 pagesConsumer Goods - Low Cost and Easy Processability Make HDPE A Material of Choice inDwi YuliantoNo ratings yet

- Catalloy Tpo Resins Brochure Eu1Document12 pagesCatalloy Tpo Resins Brochure Eu1Julio GarcíaNo ratings yet

- Presentation On Lexan (Co-Polymer)Document26 pagesPresentation On Lexan (Co-Polymer)Saleha SohailNo ratings yet

- Insulation Detail Calc LloydDocument1 pageInsulation Detail Calc LloydSatish SonawaneNo ratings yet

- Exolit AP 766Document24 pagesExolit AP 766kishxcxNo ratings yet

- Profilit With Nanogel - FAQsDocument3 pagesProfilit With Nanogel - FAQsCatalin FilipNo ratings yet

- Brochure Isoplan GREENLINE enDocument4 pagesBrochure Isoplan GREENLINE enFidel Toldrá ReigNo ratings yet

- PR Ése NtationDocument14 pagesPR Ése NtationImane CanadaNo ratings yet

- It'S Our Nature: NewschatDocument23 pagesIt'S Our Nature: Newschat郭哲宏No ratings yet

- Tribute To Giulio Natta: Industrial Chemisty: PolimericDocument11 pagesTribute To Giulio Natta: Industrial Chemisty: PolimericNguyễn Hoàng ThànhNo ratings yet

- IMPER Brochure TPO ING WebDocument20 pagesIMPER Brochure TPO ING WebCristina DogariNo ratings yet

- Group Assignment No. 8 PlasticsDocument27 pagesGroup Assignment No. 8 PlasticssuzunoemNo ratings yet

- DPVS BrochureDocument5 pagesDPVS BrochureRamiro Damian RoteloNo ratings yet

- Geolan CatalogueDocument20 pagesGeolan CataloguelajharkaNo ratings yet

- Aeropan 2017 GBDocument20 pagesAeropan 2017 GBPaulo DiasNo ratings yet

- Armaflex Product BrochureDocument6 pagesArmaflex Product Brochureraameesh100% (1)

- Property (Unit) Typical Value Test MethodDocument2 pagesProperty (Unit) Typical Value Test MethodAlejandro MartinezNo ratings yet

- Search P "Aromatic+Polyester"&Ei UTF 8&Fl 0&Fr FP Tab WeDocument11 pagesSearch P "Aromatic+Polyester"&Ei UTF 8&Fl 0&Fr FP Tab WeA MahmoodNo ratings yet

- PP Foams Nanofibrillar CompositesDocument11 pagesPP Foams Nanofibrillar CompositesPrashant Mani ShandilyaNo ratings yet

- Earthwool® Glasswool Insulation Commercial RollsDocument3 pagesEarthwool® Glasswool Insulation Commercial RollsJhay SalvatierraNo ratings yet

- Ijetae 0814 99Document5 pagesIjetae 0814 99Anonymous qTRpAYDNo ratings yet

- History of PolypropyleneDocument3 pagesHistory of PolypropyleneMayank GuptaNo ratings yet

- Materials in MechatronicsDocument4 pagesMaterials in MechatronicsvirenNo ratings yet

- Material Description: PolyvinylsDocument13 pagesMaterial Description: Polyvinylsyuvaraja.dhanabalNo ratings yet

- 1 s2.0 S138589472103610X MainDocument12 pages1 s2.0 S138589472103610X MainMahmoud YounesNo ratings yet

- TOPAS Brochure E 2014 06 PDFDocument20 pagesTOPAS Brochure E 2014 06 PDFanon_936760200No ratings yet

- Thermoplastic Carbonate Groups ToughDocument3 pagesThermoplastic Carbonate Groups ToughAnish KumarNo ratings yet

- Polymers 15 01074Document18 pagesPolymers 15 01074Jasna San MartínNo ratings yet

- Spectraplan TPE Sales Brochure PDFDocument20 pagesSpectraplan TPE Sales Brochure PDFydrasNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Hempaxane BrochureDocument12 pagesHempaxane Brochuresorion61No ratings yet

- Application Note Plastics ENDocument10 pagesApplication Note Plastics ENangelica alejandra azaeda ariasNo ratings yet

- Lecture 4Document16 pagesLecture 4Rahmeh EL saaiedehNo ratings yet

- PolymerDocument15 pagesPolymerBernaliza SenoNo ratings yet

- PolypolyDocument15 pagesPolypolyrecoil nineNo ratings yet

- HIPOLEN TDS MA 1 - 01 - EngDocument1 pageHIPOLEN TDS MA 1 - 01 - EngCarol JacksonNo ratings yet

- Polypropylene RecycleDocument1 pagePolypropylene RecyclealaneeeedNo ratings yet

- Neopor F 5300 PlusDocument3 pagesNeopor F 5300 PlusАлександр МихайловичNo ratings yet

- Neopor F 2300Document3 pagesNeopor F 2300Александр МихайловичNo ratings yet

- Thermoplastic - WikipediaDocument5 pagesThermoplastic - Wikipediakirthi83No ratings yet

- Pyrolysis of Spent Ion Exchange Resins: Kernkraftwerke in Deutschland: Betriebsergebnisse - July 2011Document20 pagesPyrolysis of Spent Ion Exchange Resins: Kernkraftwerke in Deutschland: Betriebsergebnisse - July 2011mihaela_filip_8No ratings yet

- Chloroprene Sponge CordDocument2 pagesChloroprene Sponge CordBradz TalpoNo ratings yet

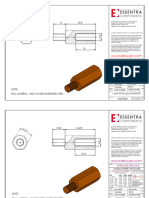

- Technical-DrawingDocument2 pagesTechnical-DrawingBradz TalpoNo ratings yet

- 7400i AW Installation ManualDocument28 pages7400i AW Installation ManualBradz TalpoNo ratings yet

- Flyer ZAplusDocument12 pagesFlyer ZAplusBradz TalpoNo ratings yet

- 41 Important Engineering KPIs (With Definitions)Document12 pages41 Important Engineering KPIs (With Definitions)Bradz TalpoNo ratings yet

- 787-Article Text-4132-6514-10-20190526Document14 pages787-Article Text-4132-6514-10-20190526Bradz TalpoNo ratings yet

- Tkmpe Hot Dip Coated Sheet Scalur Z en 20190807Document7 pagesTkmpe Hot Dip Coated Sheet Scalur Z en 20190807Bradz TalpoNo ratings yet

- 4WV Installation GuidanceDocument3 pages4WV Installation GuidanceBradz TalpoNo ratings yet

- Neopolen Sup ® Sup +P+9270Document4 pagesNeopolen Sup ® Sup +P+9270Bradz TalpoNo ratings yet

- Neopolen Sup ® Sup +P+9270Document4 pagesNeopolen Sup ® Sup +P+9270Bradz TalpoNo ratings yet

- Neopolen Sup ® Sup +P+9255Document4 pagesNeopolen Sup ® Sup +P+9255Bradz TalpoNo ratings yet

- Colligative Properties: Cryoscopy & EbulliosDocument30 pagesColligative Properties: Cryoscopy & EbulliosRSL100% (1)

- 19-3 Electrolysis of WaterDocument3 pages19-3 Electrolysis of WaterHriday MehtaNo ratings yet

- Effect of Sm3+ Doping On Optical Properties of Mg2p2o7Document10 pagesEffect of Sm3+ Doping On Optical Properties of Mg2p2o7Amina MAJIDOUNo ratings yet

- Solids Liquids and GasesDocument25 pagesSolids Liquids and GasesJane Seymour100% (1)

- Super AlloysDocument13 pagesSuper Alloyshgahagohod100% (1)

- Pipe Looks FamDocument120 pagesPipe Looks FamCyron Elden Senarillos-Talita Bangis-BodegasNo ratings yet

- Advanced Organic ChemistryDocument15 pagesAdvanced Organic ChemistryJamaica FielNo ratings yet

- PearsonDocument7 pagesPearsonJimmy M TaopanNo ratings yet

- Physical Science ReviewerDocument8 pagesPhysical Science ReviewerAliana FemiNo ratings yet

- Clean Coal Initiatives of Bhel: Conference On Clean Coal and Carbon Capture and Storage TechnologiesDocument51 pagesClean Coal Initiatives of Bhel: Conference On Clean Coal and Carbon Capture and Storage TechnologiessvvsnrajuNo ratings yet

- Design of de Laval NozzleDocument6 pagesDesign of de Laval NozzleTalish Mahmood TalishNo ratings yet

- AN194 Particle Size Analysis of Gold NanoparticlesDocument4 pagesAN194 Particle Size Analysis of Gold NanoparticlesСергей ГубскийNo ratings yet

- EquilibriumDocument7 pagesEquilibriumPassmore DubeNo ratings yet

- Artikel PDFDocument20 pagesArtikel PDFJanuar AnharNo ratings yet

- JEE Main Physics SyllabusDocument1 pageJEE Main Physics Syllabushari kishoreNo ratings yet

- Lab Report 6 Plant PhysiologyDocument7 pagesLab Report 6 Plant Physiologyapi-384857069No ratings yet

- Heat Transfer in Solids FinalDocument31 pagesHeat Transfer in Solids FinalMandrusca CatalinNo ratings yet

- Approved Few P&Bits R&Taassj: Disirlbböesi UsDocument231 pagesApproved Few P&Bits R&Taassj: Disirlbböesi UsEne FlorinNo ratings yet

- Experiment 4Document8 pagesExperiment 4Maelyn Nicole Tan RominNo ratings yet

- AS (AQA 7407) Physics: Paper 1A - Particles, Waves & OpticsDocument18 pagesAS (AQA 7407) Physics: Paper 1A - Particles, Waves & Opticsprithu shandilyaNo ratings yet

- Tide Load InstrDocument13 pagesTide Load InstrLilo17xiNo ratings yet

- The Three Laws of ThermodynamicsDocument18 pagesThe Three Laws of ThermodynamicsHoney Nhassie Marie GonzagaNo ratings yet

- Fizik Tingkatan 4Document2 pagesFizik Tingkatan 4download notesNo ratings yet

- CHS 3531Document47 pagesCHS 3531N.RHILWANANo ratings yet

- Amspec Techtalk P Stands For Pour Point 2Document3 pagesAmspec Techtalk P Stands For Pour Point 2علاء كريمNo ratings yet

- Unit-2 Battery TechnologyDocument47 pagesUnit-2 Battery TechnologyYash WaghmareNo ratings yet

- DPP 9 Chem XiDocument2 pagesDPP 9 Chem XiamansheelNo ratings yet