Professional Documents

Culture Documents

Manual Transmission

Uploaded by

Pablo PorrasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Transmission

Uploaded by

Pablo PorrasCopyright:

Available Formats

Manual Transmission P02.

02

Table of Contents

System Overview

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500

Components

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 600

Component Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 601

Troubleshooting

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 700

Cascadia Troubleshooting Manual, August 2007

Manual Transmission P02.02

500 — General Information

The transmission must efficiently transfer the engine’s power, in terms of torque, to the vehicle’s drive wheels.

Torque is the twisting force delivered by the engine’s flywheel. The transmission’s gear ratio increases or de-

creases torque depending on the requirements needed to move or start the load. Gearing also increases or

decreases speed. The gear ratios are correctly spaced so that the engine will operate in its most efficient rpm

range with progressive speed changes.

To meet the vehicle’s requirements, the transmission must have ratios low enough to start the vehicle moving,

maintain movement up grades, and keep the engine operating in its peak efficiency range. The transmission

must also provide an easy method for gear selection.

Refer to the transmission vendor for specific troubleshooting and service information. Look for the serial tag on

the transmission to identify which specific model transmission you have, then use this model number to refer-

ence the appropriate troubleshooting and service information. See Fig. 1.

04/09/2007 f261392

Fig. 1, Transmission Serial Tag

600 — Component Locations

04/09/2007 f311031

1. Transmission

Fig. 2, Transmission

Cascadia Troubleshooting Manual, August 2007 P02.02/1

P02.02 Manual Transmission

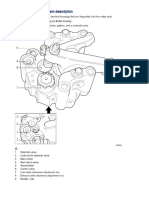

601 — Component Details

A B

10

1 8

7

2

6

5

4

3

02/26/2007 f261391

A. Front Section B. Auxiliary Section

1. Input Shaft 5. Mainshaft Gear 9. Output Shaft (Auxiliary

2. Main Drive Gear 6. Auxiliary Countershaft Mainshaft)

3. Sliding Clutch 7. Range Sliding Clutch 10. Auxiliary Drive Gear

4. Countershaft 8. Auxiliary Mainshaft Reduction

Gear

Fig. 3, Transmission Components

700 — Diagnosis

Refer to the transmission vendor’s literature for specific troubleshooting and service information. This information

can be viewed or downloaded from the internet, or paper manuals can be ordered from the vendor.

Possible Causes / General Complaints

Gear Jumpout— Jumpout usually occurs with the splitter gear set. If torque is not sufficiently broken during

splitter shifts, the sliding clutch gear may not have enough time to complete the shift before torque is reap-

plied to the gears. As torque is reapplied, the partially engaged clutch gear “jumps” out of the splitter gear.

Since the gears have torque applied to them, damage will be done to the clutching teeth of the mating gears.

Gear Slipout— When a sliding clutch is moved to engage with a main shaft gear, the mating teeth must be par-

allel. Tapered or worn clutching teeth will try to “walk” apart as the gears rotate.

Hard Shifting— Shift linkage is a common cause of hard shifting complaints. Another common cause is the

splines of a sliding clutch gear binding on the main shaft as a result of a twisted main shaft key, bent shift

yoke, or bowed main shaft key. Also, yoke bars binding in the bar housing as a result of cracked housing,

P02.02/2 Cascadia Troubleshooting Manual, August 2007

Manual Transmission P02.02

over-torqued shift block lock-screw, sprung yoke bar, or swelled areas of the yoke bar may cause hard shift-

ing.

Heat— Excessive heat may be caused by improper lubrication, operating consistently under 20 mph, high en-

gine rpm, high horsepower, overdrive operation, or coasting downhill with the clutch depressed.

Transmission Noise, Growling— A growling noise may be audible if there is an error in tooth spacing, which

can be caused by improper timing of the transmission during reassembly, or improper timing due to gear

turning on the countershaft.

Transmission Noise, High Pitched Whine or Squeal— High-pitched whining or squealing can be caused by

normal gear wear, including gear tooth pitting from excessive use (in advanced deterioration, a howl will re-

sult), mismatched gear sets (identifiable by an uneven wear pattern on the face of the gear teeth), or

pinched bearings (insufficient axial or radial clearance).

Transmission Noise, Knocking, or Thudding— Bumps or swells are present on gear teeth. Generally this

noise is more predominant when the gear is loaded; thus, the problem can be located as the noise occurs in

a specific gear position. Bumps or swells are caused by improper handling of gears before or during assem-

bly. Also, a gear cracked or broken by shock loading or by pressing on the shaft during installation will

produce this sound at low speeds (at high speeds a howl may be audible). Bearing noise comes in at low

shaft speeds in any position. It is caused by bearings with damaged balls or rollers, or with pitted and

spalled raceways.

Vibration— Although the effects of vibration will show up in the transmission, vibration usually originates some-

where else in the drivetrain. Vibration can usually be felt or heard by the driver; however, in some cases,

transmission damage caused by vibration will occur without the driver’s knowledge.

Diagnostic Tests

Refer to vendor literature for diagnostic tests.

References

See the following for additional diagnostic information:

• G05.01 — Vibration

• C01.06 — Air Supply System

• Eaton’s website, www.roadranger.com

• Meritor’s website, www.meritorhvs.com

Cascadia Troubleshooting Manual, August 2007 P02.02/3

You might also like

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (8)

- Datalink, Diagnostic CANDocument17 pagesDatalink, Diagnostic CANPablo Porras100% (1)

- Spare Parts Catalogue: CD-ROM 'ELCAT' 1/2004 10.07.2008Document43 pagesSpare Parts Catalogue: CD-ROM 'ELCAT' 1/2004 10.07.2008edascribd93% (14)

- Case ElectricDocument27 pagesCase ElectricMohamed Harb0% (1)

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Arctic Cat 2012 550 700 Service ManualDocument154 pagesArctic Cat 2012 550 700 Service ManualImad Remi RamzaniNo ratings yet

- Isuzu Engines 4bg1t 6bg1t Service ManualDocument10 pagesIsuzu Engines 4bg1t 6bg1t Service Manualdon100% (29)

- Manual Transmissions (Gearbox)Document29 pagesManual Transmissions (Gearbox)raviNo ratings yet

- Compresor: Servi CE Parts LI ST F or 05G BUS 41 CF M HGB MF R # 6GCH00GTA03404Document12 pagesCompresor: Servi CE Parts LI ST F or 05G BUS 41 CF M HGB MF R # 6GCH00GTA03404Pablo Porras100% (1)

- Isuzu Aw03 72lDocument12 pagesIsuzu Aw03 72lJose David Huanca Taype100% (3)

- Service Manual 6 Speed Eaton TransmissionDocument84 pagesService Manual 6 Speed Eaton TransmissionPatricio Alejandro Castro LopezNo ratings yet

- 2018 2020 MV SerieDocument1,762 pages2018 2020 MV SeriePablo Porras100% (1)

- Jinma 350 354Document125 pagesJinma 350 354totcsab100% (1)

- Arctic Cat 2011 450 550 650 700 1000 Service ManualDocument20 pagesArctic Cat 2011 450 550 650 700 1000 Service Manualjorge100% (25)

- SESV8006Document76 pagesSESV8006aliNo ratings yet

- Transmision Volvo FM400Document39 pagesTransmision Volvo FM400sugi yantoNo ratings yet

- ZF Automatica 2Document34 pagesZF Automatica 2chikoo49950% (2)

- Arctic Cat 2010 450 Service ManualDocument10 pagesArctic Cat 2010 450 Service Manualvictoria100% (50)

- Engine HarnessDocument13 pagesEngine HarnessIzz Bahar0% (1)

- Arctic Cat 2011 Atvs 450 550 650 700 1000 Service ManualDocument308 pagesArctic Cat 2011 Atvs 450 550 650 700 1000 Service ManualJeremy GoutNo ratings yet

- Lego BasicsDocument39 pagesLego BasicsPio_ChronicleNo ratings yet

- 232B, 242B, 252B & 262B Skid Steer Loaders Hydraulic System Dual Self Level - Raise & LowerDocument2 pages232B, 242B, 252B & 262B Skid Steer Loaders Hydraulic System Dual Self Level - Raise & LowerPablo Porras100% (1)

- Johndeere Funk TransmissionDocument16 pagesJohndeere Funk TransmissionBassim Wagih100% (1)

- Service Manual - Royal Enfield 500/535 EFI ABS - Feb 2017Document301 pagesService Manual - Royal Enfield 500/535 EFI ABS - Feb 2017Guilherme Biancarelli100% (3)

- M250-C20 Ceb-1165 PDFDocument7 pagesM250-C20 Ceb-1165 PDFturboshaftNo ratings yet

- 33 - Eaton 4106 5206 Transmission Service Manual PDFDocument90 pages33 - Eaton 4106 5206 Transmission Service Manual PDFSomadbsi100% (1)

- 91 Zf3 Zf5hp19 Inc FlaDocument14 pages91 Zf3 Zf5hp19 Inc FlaJohn Eduard Sierra VelandiaNo ratings yet

- SESV8001Document144 pagesSESV8001aliNo ratings yet

- Manual Generador KatoDocument160 pagesManual Generador Katomass72100% (4)

- Analisis de Engranajes PDFDocument215 pagesAnalisis de Engranajes PDFliz huincho100% (1)

- CASE 580N EP Backhoe Loader Tier 4BDocument2,268 pagesCASE 580N EP Backhoe Loader Tier 4BCristian Fernando Tarifa Martinez67% (3)

- SRM230e Parts Catalogue 06 101911Document95 pagesSRM230e Parts Catalogue 06 101911Earl HarbertNo ratings yet

- Arctic Cat 2010 700 Diesel Service ManualDocument10 pagesArctic Cat 2010 700 Diesel Service Manualsusann100% (60)

- Repair and Reconditioning Specification For AC Squirrel-Cage Motors With Voltage Ratings of 2.3 KV To 13.2 KVDocument132 pagesRepair and Reconditioning Specification For AC Squirrel-Cage Motors With Voltage Ratings of 2.3 KV To 13.2 KVzulham100% (1)

- Packing ListDocument28 pagesPacking ListsryNo ratings yet

- Robomow Service Guide 2016-Ver01Document92 pagesRobomow Service Guide 2016-Ver01Calin Banciu100% (6)

- 3020-Plataforma 3020Document557 pages3020-Plataforma 3020Genival FaustinoNo ratings yet

- Caterpillar Applied Failure Analysis Threaded Fasteners Service TrainingDocument9 pagesCaterpillar Applied Failure Analysis Threaded Fasteners Service Trainingcarolyn98% (48)

- CM2150 PinoutDocument1 pageCM2150 PinoutPablo PorrasNo ratings yet

- DM30 II Instruction Manual (English) 005 035033Document520 pagesDM30 II Instruction Manual (English) 005 035033icatandhika77No ratings yet

- Ultrafreezer VWR Thermoscientific 5615Document77 pagesUltrafreezer VWR Thermoscientific 5615Cesar ValenzuelaNo ratings yet

- ClutchDocument12 pagesClutchPablo PorrasNo ratings yet

- Drivelines: System OverviewDocument14 pagesDrivelines: System Overviewr031n fNo ratings yet

- Arctic Cat 2007 Y12 90cc Service ManualDocument10 pagesArctic Cat 2007 Y12 90cc Service Manualroger100% (58)

- Arctic Cat 2012 650 Service ManualDocument10 pagesArctic Cat 2012 650 Service Manualroger100% (55)

- Arctic Cat 2012 550 700 Service ManualDocument10 pagesArctic Cat 2012 550 700 Service Manualdavid100% (53)

- 2010 Arctic Cat Cat 700 Diesel SD Service ManualDocument180 pages2010 Arctic Cat Cat 700 Diesel SD Service ManualTindaro PelleritiNo ratings yet

- Foreword: Product Service and Warranty Department Arctic Cat IncDocument143 pagesForeword: Product Service and Warranty Department Arctic Cat IncЕгор КузенкинNo ratings yet

- Ma 2604000 WMDocument55 pagesMa 2604000 WMCarlos ReyesNo ratings yet

- DVX 90 2010Document98 pagesDVX 90 2010WartuuthNo ratings yet

- Manual Pala Case 580NDocument1,820 pagesManual Pala Case 580Nmabertovallejo04No ratings yet

- BALEROSDocument17 pagesBALEROSjulio cesarNo ratings yet

- GES Drive Manual: Installation Operation & MaintenanceDocument11 pagesGES Drive Manual: Installation Operation & MaintenanceKovács EndreNo ratings yet

- Sercice Lantec 200 540 750Document27 pagesSercice Lantec 200 540 750ChristianReinosoNo ratings yet

- Manual de CatDocument64 pagesManual de CatGeorge Guerrero50% (2)

- Arctic Cat 2011 400trv 400 TRV Service ManualDocument10 pagesArctic Cat 2011 400trv 400 TRV Service Manualwade100% (49)

- Rev CounterDocument13 pagesRev CounterIndrajith RuberuNo ratings yet

- 19.1 2019-07 8000006651 Catálogos de Instalación y Mantenimiento y Guía RápidaDocument96 pages19.1 2019-07 8000006651 Catálogos de Instalación y Mantenimiento y Guía RápidaJuan QuirogaNo ratings yet

- RW 1016Document105 pagesRW 1016Jerônimo RafaelNo ratings yet

- Illustrated Parts List: RTO-10910B-AS2 November 2008Document30 pagesIllustrated Parts List: RTO-10910B-AS2 November 2008Javier Estrada ColindresNo ratings yet

- F4AF7DE0d01 PDFDocument112 pagesF4AF7DE0d01 PDFyako1511No ratings yet

- SAE J1418-2015 Fuel Injection Pumps - High Pressure Pipes (Tubing) For TestingDocument3 pagesSAE J1418-2015 Fuel Injection Pumps - High Pressure Pipes (Tubing) For TestingProvocateur SamaraNo ratings yet

- MAGNUMDocument60 pagesMAGNUMeaglego00No ratings yet

- Power WindowsDocument9 pagesPower WindowsEckard GuendelNo ratings yet

- M250-C20 Ceb-1165Document7 pagesM250-C20 Ceb-1165turboshaftNo ratings yet

- Iom Biffi Morin Series A B C S en en Us 6089118Document37 pagesIom Biffi Morin Series A B C S en en Us 6089118Anonymous Wu6FDjbNo ratings yet

- VERADO 8a - 092437Document28 pagesVERADO 8a - 092437Jaime ZamNo ratings yet

- Raptor XDX 60 941518CEDocument64 pagesRaptor XDX 60 941518CEq9tzbypdgtNo ratings yet

- Manual Farr 14-50Document166 pagesManual Farr 14-50JAVIER EDUARDO MANTILLA BUITRAGO100% (1)

- Altronics AV SRVC MNL 12-1996 PDFDocument15 pagesAltronics AV SRVC MNL 12-1996 PDFSMcNo ratings yet

- BRD - Klee-SOLSTART Instruction ManualDocument16 pagesBRD - Klee-SOLSTART Instruction ManualElectricos MTC LtdaNo ratings yet

- Crusader 6.0 Mpi PDFDocument65 pagesCrusader 6.0 Mpi PDFOperaciones Max Diesel ProNo ratings yet

- Ac Motoren FCPL 60h Brake Motor Installation Guide en Iss201710 B 5282Document16 pagesAc Motoren FCPL 60h Brake Motor Installation Guide en Iss201710 B 5282Eric CNo ratings yet

- Performance-Based Gear Metrology: Kinematic - Transmission - Error Computation and DiagnosisFrom EverandPerformance-Based Gear Metrology: Kinematic - Transmission - Error Computation and DiagnosisNo ratings yet

- CV SeriesDocument1,183 pagesCV SeriesPablo Porras100% (1)

- Application Data - Minimizing Line Vibration: Recommendations To Minimize Refrigerant Line VibrationsDocument13 pagesApplication Data - Minimizing Line Vibration: Recommendations To Minimize Refrigerant Line VibrationsPablo PorrasNo ratings yet

- Discover® Wheel Seal 373-0223Document2 pagesDiscover® Wheel Seal 373-0223Pablo PorrasNo ratings yet

- PV776 89202572Document2 pagesPV776 89202572Pablo PorrasNo ratings yet

- VenturiDocument1 pageVenturiPablo PorrasNo ratings yet

- EPA07 DD13 Motor Control Module (MCM) Engine HarnessDocument2 pagesEPA07 DD13 Motor Control Module (MCM) Engine HarnessPablo PorrasNo ratings yet

- PV776 89091423Document31 pagesPV776 89091423Pablo PorrasNo ratings yet

- PV776 89026405Document21 pagesPV776 89026405Pablo PorrasNo ratings yet

- Back-Pressure ValveDocument1 pageBack-Pressure ValvePablo PorrasNo ratings yet

- PV776 89200449Document7 pagesPV776 89200449Pablo PorrasNo ratings yet

- Lubricating Oil System CircuitDocument2 pagesLubricating Oil System CircuitPablo PorrasNo ratings yet

- MX Eng Brake System Description, GeneralDocument2 pagesMX Eng Brake System Description, GeneralPablo PorrasNo ratings yet

- TQ SpecDocument1 pageTQ SpecPablo PorrasNo ratings yet

- Egr System DescriptionDocument2 pagesEgr System DescriptionPablo PorrasNo ratings yet

- MX Epa10 VGT R&RDocument8 pagesMX Epa10 VGT R&RPablo PorrasNo ratings yet

- TQ SpecDocument1 pageTQ SpecPablo PorrasNo ratings yet

- 3122 - Disabling Prognostic Features For AllisonDocument5 pages3122 - Disabling Prognostic Features For AllisonPablo PorrasNo ratings yet

- How To Get Service Level KeyDocument1 pageHow To Get Service Level KeyPablo PorrasNo ratings yet

- MX Eng Brake System DescriptionDocument4 pagesMX Eng Brake System DescriptionPablo PorrasNo ratings yet

- D5N CFH00442 Sist. Elec.Document4 pagesD5N CFH00442 Sist. Elec.Pablo PorrasNo ratings yet

- 3134 Enabling Prognostic Features For Allison Transmission DRAFTDocument3 pages3134 Enabling Prognostic Features For Allison Transmission DRAFTPablo PorrasNo ratings yet

- D9T Electrical SystemDocument4 pagesD9T Electrical SystemPablo PorrasNo ratings yet

- 3125 ZF Sway Bar LubricationDocument4 pages3125 ZF Sway Bar LubricationPablo PorrasNo ratings yet

- TP02173Document8 pagesTP02173Pablo PorrasNo ratings yet

- 216B, 226, 232B, 236, 242, 246, 248, 252, 262, and 268 Skid Steer Loaders and 247, 257, 267, 277, and 287 Multi Terrain Loader Sist. Elect.Document4 pages216B, 226, 232B, 236, 242, 246, 248, 252, 262, and 268 Skid Steer Loaders and 247, 257, 267, 277, and 287 Multi Terrain Loader Sist. Elect.Pablo PorrasNo ratings yet

- Workcentre 3655Document32 pagesWorkcentre 3655asdfNo ratings yet

- ASE A3 Manual Drive TrainDocument4 pagesASE A3 Manual Drive TrainDylan SmithNo ratings yet

- Fig. 18 Charging Pump (Tor-Con Type) :, JCPQD20/25N-RW11, S CPQD20/25N-RW7Document3 pagesFig. 18 Charging Pump (Tor-Con Type) :, JCPQD20/25N-RW11, S CPQD20/25N-RW7Walter FormigoniNo ratings yet

- Fig. 21 Inching Valve (Tor-Con Type) :, JCPQD20/25N-RW11, S CPQD20/25N-RW7Document3 pagesFig. 21 Inching Valve (Tor-Con Type) :, JCPQD20/25N-RW11, S CPQD20/25N-RW7Walter FormigoniNo ratings yet

- SAIMH What Is A Belt ConveyorDocument17 pagesSAIMH What Is A Belt Conveyor15abcvNo ratings yet

- 07 Fluid CouplingDocument18 pages07 Fluid Couplingananttomar80361No ratings yet

- Cenovnik MOTORI Final 05-03-2012Document1 pageCenovnik MOTORI Final 05-03-2012libero973No ratings yet

- Automotive TransmissionDocument146 pagesAutomotive TransmissionTony Neal100% (1)

- L&T 9020 - 380740186-WL9020-SPC-L-T-9020 Parts CatalogDocument10 pagesL&T 9020 - 380740186-WL9020-SPC-L-T-9020 Parts Catalogayush bansalNo ratings yet

- 27 Rear Axle 123Document35 pages27 Rear Axle 123Pafuncio de AlecrimNo ratings yet

- Gear Forces: Forces in Spur GearsDocument6 pagesGear Forces: Forces in Spur GearsGabriel IulianNo ratings yet

- PT Solusi Bangun Andalas - Lhoknga Plant: 1. SafetyDocument3 pagesPT Solusi Bangun Andalas - Lhoknga Plant: 1. SafetyahmadNo ratings yet

- Luk Product Info GearBOX VW 02TDocument2 pagesLuk Product Info GearBOX VW 02Tcec985458No ratings yet

- Piv Chain DriveDocument2 pagesPiv Chain DriveAbhijeet Ranveer100% (1)

- 440-T4 / 4T60E / 4T65E: FWD 4 SpeedDocument8 pages440-T4 / 4T60E / 4T65E: FWD 4 SpeedjosueNo ratings yet

- RA Removing and Installing - Replacing Starter Motor (M54Document2 pagesRA Removing and Installing - Replacing Starter Motor (M54luis guevaraNo ratings yet

- Gear Ratios: Grade-Up Parts Matching List Mini 4WDDocument1 pageGear Ratios: Grade-Up Parts Matching List Mini 4WDGede SantosaNo ratings yet

- Torsen Differential White PaperDocument8 pagesTorsen Differential White PaperPadmAnabhNo ratings yet

- Worm GearsDocument31 pagesWorm GearsYose MustNo ratings yet

- B6 Industrial+Elbe2013-7lrDocument160 pagesB6 Industrial+Elbe2013-7lrhernan dueñasNo ratings yet