Professional Documents

Culture Documents

3125 ZF Sway Bar Lubrication

Uploaded by

Pablo PorrasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3125 ZF Sway Bar Lubrication

Uploaded by

Pablo PorrasCopyright:

Available Formats

Service Bulletin No.

3125

MODEL: TYPE: SECTION/GROUP: DATE:

J Series Service Information 12-SUSPENSION 10/07/2019

SUBJECT:

ZF Front Sway Bar Lubrication

CONDITIONS:

Service Information Only

Description:

Motor Coach Industries (“MCI”) is instructing customers hearing noise near the front sway

bar during driving to follow this procedure to apply anti-seize lubricant as per the instruction.

This procedure is applicable to MY18 to MY20 coaches within the VIN range: 68314-69657,

21000-21018

Read this entire procedure before beginning work.

Use Safe Shop Practices At All Times.

To avoid personal injury:

a. Proper Personal Protective Equipment (PPE) must be worn. Safety glasses and

protective gloves are required for working with DEF Fluid.

b. Turn the main battery disconnect switch to the OFF position.

c. Ensure that both the front and the rear wheels are chocked.

d. Position the ENGINE RUN and ENGINE START switches on the engine

compartment remote control box to the OFF position.

e. Allow enough time for components to cool down prior to working in the engine

compartment

Motor Coach Industries Ltd. Page 1 of 4

Service Bulletin No. 3125

1.0 Material requirements

No material required.

2.0 Special Tools

Anti-seize lubricant, MCI P/N: 23-01-0055 (Vendor: Permatex, VPN: 80078).

3.0 Lubricant application

Drain the air from the front suspension by releasing all the air in the front tank equipped

with an automatic drain valve.

Lift the coach to desired work height. Position safety stands underneath the coach in only

the specified locations shown in Section 3F in the MCI J4500 Maintenance Manual.

Motor Coach Industries Ltd. Page 2 of 4

Service Bulletin No. 3125

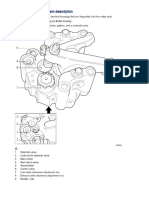

Identify the sway bar under the front suspension system.

Sway bar

Remove and save the 4 bolts and nuts securing the sway bar clamps on the driver side.

Remove and save

the hardware

Take the bushing out and apply anti-seize lubricant, MCI P/N: 23-01-0055, all over the

inside surface of it.

Apply lubricant all over

the inside surface

Motor Coach Industries Ltd. Page 3 of 4

Service Bulletin No. 3125

Install the bushing on the sway bar.

Apply anti-seize lubricant, MCI P/N: 23-01-0055, on the outside surface of the bushing

where it comes in contact with the clamp.

Apply lubricant

on the bushing

Reinstall the clamps using existing hardware and torque them to 206-226Ft-Lbs.

Torque the bolts to

206-226 Ft-Lbs

Repeat the process for the bushing on the curb side.

End of the procedure

Motor Coach Industries Ltd. Page 4 of 4

You might also like

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- 205-03 Front Drive Axle and Differential - Removal and Installation - Drive Pinion Flange and SealDocument7 pages205-03 Front Drive Axle and Differential - Removal and Installation - Drive Pinion Flange and SealCARLOS LIMADANo ratings yet

- 303-14 Electronic Engine Controls - Removal and Installation - Camshaft Position CMP SensorDocument6 pages303-14 Electronic Engine Controls - Removal and Installation - Camshaft Position CMP SensorCARLOS LIMADANo ratings yet

- 303-14 Electronic Engine Controls - Removal and Installation - Heated Oxygen Sensor HO2SDocument5 pages303-14 Electronic Engine Controls - Removal and Installation - Heated Oxygen Sensor HO2SCARLOS LIMADANo ratings yet

- Remove Engine BrakeDocument14 pagesRemove Engine BrakejeremyNo ratings yet

- 303-01 - 2.3L EcoBoost - Removal and Installation - Crackshaft Rear SealDocument10 pages303-01 - 2.3L EcoBoost - Removal and Installation - Crackshaft Rear SealCARLOS LIMADANo ratings yet

- 2001 TDI OilPanRemovalDocument5 pages2001 TDI OilPanRemovalh0m3s1ckNo ratings yet

- 007-017 Lubricating Oil Filter Head (Remote Mounted) : Preparatory StepsDocument7 pages007-017 Lubricating Oil Filter Head (Remote Mounted) : Preparatory StepsbejoythomasNo ratings yet

- XL 125 v1Document33 pagesXL 125 v1Oscar SolanoNo ratings yet

- 001-014 Connecting Rod: General InformationDocument13 pages001-014 Connecting Rod: General InformationWaad HarbNo ratings yet

- Montagem Motor 2.2 LDocument37 pagesMontagem Motor 2.2 LJose Luis Toco100% (1)

- MALIBU 2010 Brake Light TSBDocument19 pagesMALIBU 2010 Brake Light TSBRenato M FariaNo ratings yet

- 205-02 Rear Drive Axle and Differential - Removal and Installation - Drive Pinion FlangeDocument9 pages205-02 Rear Drive Axle and Differential - Removal and Installation - Drive Pinion FlangeCARLOS LIMADANo ratings yet

- Installmanual Cotta ArregladoDocument20 pagesInstallmanual Cotta ArregladoguillermoNo ratings yet

- SB658Document3 pagesSB658oscar horacio floresNo ratings yet

- Duratec 16v tTI-VCTDocument40 pagesDuratec 16v tTI-VCTStarsky UrblejoNo ratings yet

- 205-03 Front Drive Axle and Differential - General Procedures - Differential Draining and FillingDocument5 pages205-03 Front Drive Axle and Differential - General Procedures - Differential Draining and FillingCARLOS LIMADANo ratings yet

- 303-14 Electronic Engine Controls - Removal and Installation - Fuel Rail Pressure FRP SensorDocument5 pages303-14 Electronic Engine Controls - Removal and Installation - Fuel Rail Pressure FRP SensorCARLOS LIMADANo ratings yet

- Installation Instructions for B&M Precision Sport ShifterDocument9 pagesInstallation Instructions for B&M Precision Sport ShifterBuda BudaNo ratings yet

- MC 10168762 0001Document5 pagesMC 10168762 0001Vernon ParkerNo ratings yet

- Engine: 303-01C Engine - 3.2L Duratorq-Tdci (148Kw/200Ps) - Puma 2011 - 2014 Ranger AssemblyDocument23 pagesEngine: 303-01C Engine - 3.2L Duratorq-Tdci (148Kw/200Ps) - Puma 2011 - 2014 Ranger AssemblyCamille Fajardo Danganan100% (1)

- LTB00079 NAS2 ParkbrakeDocument6 pagesLTB00079 NAS2 Parkbrakeserdar akmanNo ratings yet

- Service BulletinDocument11 pagesService BulletinDave Green100% (1)

- Crankshaft Front Seal & Wear SleeveDocument4 pagesCrankshaft Front Seal & Wear SleeveRichard ChuaNo ratings yet

- Fastener Tightening Specifications: Application Specification Metric EnglishDocument10 pagesFastener Tightening Specifications: Application Specification Metric Englishmebarki aberraoufNo ratings yet

- Unit Injector - InstallDocument4 pagesUnit Injector - InstallJose PichinteNo ratings yet

- Engineered To Ride, Built To Last: Arnott Coil Spring Conversion Kit FOR Various Long Wheelbase GM SuvsDocument11 pagesEngineered To Ride, Built To Last: Arnott Coil Spring Conversion Kit FOR Various Long Wheelbase GM SuvsjacksonNo ratings yet

- Sti Technical Service BulletinsDocument70 pagesSti Technical Service BulletinsJoe FacchinoNo ratings yet

- 2010-10-18 005842 Wiper Motor Not ParkingDocument3 pages2010-10-18 005842 Wiper Motor Not ParkingSergiu CostinNo ratings yet

- Nissan Frontier Vq40 v6 Despiece MotorDocument210 pagesNissan Frontier Vq40 v6 Despiece Motorerik rojasNo ratings yet

- 303-04B Fuel Charging and Controls Turbocharger - Removal and Installation - Turbocharger Oil Supply TubeDocument12 pages303-04B Fuel Charging and Controls Turbocharger - Removal and Installation - Turbocharger Oil Supply TubeCARLOS LIMADANo ratings yet

- 303-05 Accessory Drive - Removal and Installation - Accessory Drive BeltDocument4 pages303-05 Accessory Drive - Removal and Installation - Accessory Drive BeltCARLOS LIMADANo ratings yet

- SB658Document3 pagesSB658ricardo novoa saraviaNo ratings yet

- 205-02 Rear Drive Axle and Differential - Removal and Installation - Drive Pinion SealDocument5 pages205-02 Rear Drive Axle and Differential - Removal and Installation - Drive Pinion SealCARLOS LIMADANo ratings yet

- Motox N Operating ManualDocument39 pagesMotox N Operating ManualNina FelaNo ratings yet

- 303-01 - 2.3L EcoBoost - Removal and Installation - Oil PumpDocument22 pages303-01 - 2.3L EcoBoost - Removal and Installation - Oil PumpCARLOS LIMADANo ratings yet

- Maintenance enDocument23 pagesMaintenance enAline BritoNo ratings yet

- Unit Injector - Install: Disassembly and AssemblyDocument5 pagesUnit Injector - Install: Disassembly and AssemblyJoze 23No ratings yet

- 303-01 - 2.3L EcoBoost - Removal and Installation - Crackshaft PulleyDocument21 pages303-01 - 2.3L EcoBoost - Removal and Installation - Crackshaft PulleyCARLOS LIMADANo ratings yet

- 120g - Service ManualDocument2,569 pages120g - Service ManualFilipe Da Silva NascimentoNo ratings yet

- V8 Vantage rear axle recall inspectionDocument6 pagesV8 Vantage rear axle recall inspectionsaboor ashrafNo ratings yet

- 1997 PONTIAC TRANS SPORT Service Repair Manual PDFDocument45 pages1997 PONTIAC TRANS SPORT Service Repair Manual PDFjhjfnsnef100% (1)

- Pistons and Connecting Rods - InstallDocument3 pagesPistons and Connecting Rods - Installsergio blandon lNo ratings yet

- 001-016 Crankshaft: Preparatory StepsDocument28 pages001-016 Crankshaft: Preparatory StepsWaad HarbNo ratings yet

- 303-14 Electronic Engine Controls - Removal and Installation - Manifold Absolute Pressure and Temperature MAPT SensorDocument3 pages303-14 Electronic Engine Controls - Removal and Installation - Manifold Absolute Pressure and Temperature MAPT SensorCARLOS LIMADANo ratings yet

- Robin Ey15-3d - Ey20-3d Operations ManualDocument11 pagesRobin Ey15-3d - Ey20-3d Operations ManualEdgardo M. DiololaNo ratings yet

- UI Bulletin 124jDocument22 pagesUI Bulletin 124jJoshNo ratings yet

- Installation, Operation, & Maintenance For Car-Mon Exhaust Fans Series CMB, SL, & BxiDocument12 pagesInstallation, Operation, & Maintenance For Car-Mon Exhaust Fans Series CMB, SL, & BxiHernan RomeroNo ratings yet

- 2006-12 Jaguar XK 150 TSBsDocument84 pages2006-12 Jaguar XK 150 TSBsMariano Cal GarciaNo ratings yet

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 72-60-00Document62 pagesRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 72-60-00anony8103No ratings yet

- C9 Service Letter Injector ReplaceDocument6 pagesC9 Service Letter Injector Replaceharikrishnanpd3327No ratings yet

- 303-01 - 2.3L EcoBoost - Removal and Installation - CamshaftsDocument16 pages303-01 - 2.3L EcoBoost - Removal and Installation - CamshaftsCARLOS LIMADANo ratings yet

- 206-04 Rear Disc Brake - Removal and Installation - Brake PadsDocument5 pages206-04 Rear Disc Brake - Removal and Installation - Brake PadsCARLOS LIMADANo ratings yet

- 2003-2005 350Z Clicking Noise from Rear Axles FixDocument5 pages2003-2005 350Z Clicking Noise from Rear Axles FixSr. PolestarNo ratings yet

- CBN Series 2000 Emerson BrowningDocument20 pagesCBN Series 2000 Emerson BrowningLuis Ramón Argüello RealNo ratings yet

- 3141 D Coach TPMS Display RetrofitDocument10 pages3141 D Coach TPMS Display RetrofitHamilton Amilcar MirandaNo ratings yet

- ZFDocument3 pagesZFMohammed MochrifNo ratings yet

- 2008-07-20 015947 tsb04-15-03 Rain Hat Repair Taurus SableDocument6 pages2008-07-20 015947 tsb04-15-03 Rain Hat Repair Taurus Sableecastro111No ratings yet

- Pistons and Connecting Rods - Install: Desmontagem e MontagemDocument3 pagesPistons and Connecting Rods - Install: Desmontagem e MontagemJefferson SilvaNo ratings yet

- 2018 2020 MV SerieDocument1,762 pages2018 2020 MV SeriePablo Porras100% (1)

- Discover® Wheel Seal 393-0203Document2 pagesDiscover® Wheel Seal 393-0203Pablo PorrasNo ratings yet

- Discover® Wheel Seal 383-0239Document2 pagesDiscover® Wheel Seal 383-0239Pablo PorrasNo ratings yet

- CV SeriesDocument1,183 pagesCV SeriesPablo Porras100% (1)

- Discover® Wheel Seal 383-0239Document2 pagesDiscover® Wheel Seal 383-0239Pablo PorrasNo ratings yet

- Discover® Wheel Seal 373-0223Document2 pagesDiscover® Wheel Seal 373-0223Pablo PorrasNo ratings yet

- PV776 89202572Document2 pagesPV776 89202572Pablo PorrasNo ratings yet

- PV776 89091423Document31 pagesPV776 89091423Pablo PorrasNo ratings yet

- Discover® Wheel Seal 373-0223Document2 pagesDiscover® Wheel Seal 373-0223Pablo PorrasNo ratings yet

- MX Engine Brake system descriptionDocument2 pagesMX Engine Brake system descriptionPablo PorrasNo ratings yet

- Compressor: Model 05G and 05G BusDocument23 pagesCompressor: Model 05G and 05G BusJOSE GUTIERREZNo ratings yet

- Compresor: Servi CE Parts LI ST F or 05G BUS 41 CF M HGB MF R # 6GCH00GTA03404Document12 pagesCompresor: Servi CE Parts LI ST F or 05G BUS 41 CF M HGB MF R # 6GCH00GTA03404Pablo Porras100% (1)

- TQ SpecDocument1 pageTQ SpecPablo PorrasNo ratings yet

- PV776 89200449Document7 pagesPV776 89200449Pablo PorrasNo ratings yet

- VenturiDocument1 pageVenturiPablo PorrasNo ratings yet

- Back-Pressure ValveDocument1 pageBack-Pressure ValvePablo PorrasNo ratings yet

- PV776 89026405Document21 pagesPV776 89026405Pablo PorrasNo ratings yet

- MX Epa10 VGT R&RDocument8 pagesMX Epa10 VGT R&RPablo PorrasNo ratings yet

- TQ SpecDocument1 pageTQ SpecPablo PorrasNo ratings yet

- Lubricating Oil System CircuitDocument2 pagesLubricating Oil System CircuitPablo PorrasNo ratings yet

- Egr System DescriptionDocument2 pagesEgr System DescriptionPablo PorrasNo ratings yet

- Enable Allison Transmission DiagnosticsDocument3 pagesEnable Allison Transmission DiagnosticsPablo PorrasNo ratings yet

- MX Eng Brake System DescriptionDocument4 pagesMX Eng Brake System DescriptionPablo PorrasNo ratings yet

- D9T Electrical SystemDocument4 pagesD9T Electrical SystemPablo PorrasNo ratings yet

- Allison Transmission Prognostic Disabling ProcedureDocument5 pagesAllison Transmission Prognostic Disabling ProcedurePablo PorrasNo ratings yet

- How To Get Service Level KeyDocument1 pageHow To Get Service Level KeyPablo PorrasNo ratings yet

- D5N CFH00442 Sist. Elec.Document4 pagesD5N CFH00442 Sist. Elec.Pablo PorrasNo ratings yet

- TP02173Document8 pagesTP02173Pablo PorrasNo ratings yet

- File 41 ADocument178 pagesFile 41 AHamiltonNo ratings yet

- Off Road and Military Vehicles Off Road Vehicles Agrale Marruaam200 1Document2 pagesOff Road and Military Vehicles Off Road Vehicles Agrale Marruaam200 1Victor SilvaNo ratings yet

- 1N4001S THRU 1N4007S: General Purpose Silicon RectifierDocument2 pages1N4001S THRU 1N4007S: General Purpose Silicon RectifierBhadreshkumar SharmaNo ratings yet

- 1,16Document138 pages1,16niztgirlNo ratings yet

- JAOP Progress ReportDocument36 pagesJAOP Progress ReportnidhisasidharanNo ratings yet

- Hurqalya - HavarqalyaDocument64 pagesHurqalya - HavarqalyaBVILLARNo ratings yet

- D.K.Pandey: Lecture 1: Growth and Decay of Current in RL CircuitDocument5 pagesD.K.Pandey: Lecture 1: Growth and Decay of Current in RL CircuitBBA UniversityNo ratings yet

- 5 Commandments of DatingDocument8 pages5 Commandments of DatingBariki MwasagaNo ratings yet

- Manual stack emission monitoring standardDocument29 pagesManual stack emission monitoring standardsantisal11No ratings yet

- Hospitality Case StudiesDocument26 pagesHospitality Case StudiesKarthik PalaniswamyNo ratings yet

- Syngo - Via: HW Data SheetDocument4 pagesSyngo - Via: HW Data SheetCeoĐứcTrườngNo ratings yet

- VTBS 20-3DDocument1 pageVTBS 20-3Dwong keen faivNo ratings yet

- NIA045462022 KL 13 AR 1130 Royal Enfield Motors LTD Classic X 350 ESDocument10 pagesNIA045462022 KL 13 AR 1130 Royal Enfield Motors LTD Classic X 350 ESAkhil DasNo ratings yet

- Declaration Letter - Vetagro To GSDocument3 pagesDeclaration Letter - Vetagro To GSVíctor RodríguezNo ratings yet

- Namma Kalvi 12th Maths Book Back 1 Mark Questions em 216251Document29 pagesNamma Kalvi 12th Maths Book Back 1 Mark Questions em 21625111B CHARAN ANANDNo ratings yet

- DTP - Digital Transformer ProtectionDocument13 pagesDTP - Digital Transformer ProtectionHBNBILNo ratings yet

- SP18368 Automotive Radar Comparison 2018 Sample 2Document33 pagesSP18368 Automotive Radar Comparison 2018 Sample 2Chipisgood YuNo ratings yet

- TN 015 Overrides 15Document8 pagesTN 015 Overrides 15Luis SantosNo ratings yet

- DD 24 DD 22Document2 pagesDD 24 DD 22evega97No ratings yet

- Nature 1Document6 pagesNature 1Susanty SainudinNo ratings yet

- Bitumen Water ProofingDocument23 pagesBitumen Water ProofingAkshthagowda848_1952No ratings yet

- MAGA Training ReportDocument56 pagesMAGA Training ReportChaturanga WagaArachchige67% (3)

- DSBV87ALP Two-Stage Differential Pressure Control Valve SpecsDocument2 pagesDSBV87ALP Two-Stage Differential Pressure Control Valve SpecsadrianioantomaNo ratings yet

- PWR Bi2Document11 pagesPWR Bi2GOMTINo ratings yet

- Mbbs BooksDocument7 pagesMbbs Booksbakhem7hbk2002190% (1)

- Wiring Harness Installation Instructions: For InstallersDocument12 pagesWiring Harness Installation Instructions: For Installersnirut_niceguyNo ratings yet

- Environmental Accounting in The Philippines: by Romulo A. Virola, Sylvia M. de Perio and Eduardo T. AngelesDocument27 pagesEnvironmental Accounting in The Philippines: by Romulo A. Virola, Sylvia M. de Perio and Eduardo T. AngelesLaraNo ratings yet

- #Healthy Food Recipes EasyDocument4 pages#Healthy Food Recipes EasyTHE NEXT GENNo ratings yet

- Analyzing the Effects of Changing the Values of a, b, and c in the Equation of a Quadratic Function on Its GraphDocument13 pagesAnalyzing the Effects of Changing the Values of a, b, and c in the Equation of a Quadratic Function on Its GraphRamil NacarioNo ratings yet

- Des Piece F Se 2003 MotorDocument26 pagesDes Piece F Se 2003 MotorPACHYYNNo ratings yet

- Remote Sensing Mineral Exploration LithiumDocument16 pagesRemote Sensing Mineral Exploration LithiumGerald Darshan MogiNo ratings yet