Professional Documents

Culture Documents

PLEXIGLAS LED® White

Uploaded by

Misha SpiridonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PLEXIGLAS LED® White

Uploaded by

Misha SpiridonCopyright:

Available Formats

Technical Information

PLEXIGLAS® LED

For backlighting, white

WH14, WH72, WH51, WM51 (previously PLEXIGLAS truLED®, White)

Product broad processing latitude: light diffusion

and uniform illumination are ideal for a

These white translucent sheets were specially

broad range of options (shallow and deep

developed for backlighting with LEDs. Combining

routing)

LEDs with PLEXIGLAS® LED makes for maximum

efficiency and superior lighting technology, brilliant, extremely weather-stable

especially in illuminated signs, store fixtures and whiteness in incident light

exhibition booths.

no LED hot spots due to optimum light

PLEXIGLAS® LED for backlighting offers a high diffusion

degree of white opacity in incident light and

high luminous efficiency, and therefore

daylight. Its translucency has been optimized to

cost savings, through improved diffusion

offer extremely high transmission paired with

high light diffusion, which prevents any LED hot

spots. Two PLEXIGLAS® LED variants are offered in

high

WH14

thicknesses of 3-10 mm: WH14 with high WM51

Transmittance

transmission and WH72 with pronounced light

diffusion.

WH72 WH51

Grades WH51 and WM51 provide the same

low

properties in the form of thicker sheets. WH51

diffuses light to a greater extent and offers better 3 10 Thickness [mm] 30

white opacity in incident light and during the day.

For technical reasons, given balanced diffusion of

pronounced

WH72

LED light in incident and transmitted light, grades

WH51 and WM51 show identical properties in a

Whiteness in incident light

WH51

thickness of 30 mm (see Fig. 1). Therefore, WM51

is the only grade available from stock in 30mm

thickness.

moderate

WH14 WM51

Properties

3 10 Thickness [mm] 30

In addition to the well-known and proven

properties of PLEXIGLAS®, such as

Fig. 1: Transmittance (top) and white opacity in

extremely high weather resistance,

incident light as a function of thickness.

ease of fabrication,

100% recyclability,

PLEXIGLAS® LED WH14, WH72, WH51 and WM51

offer the following characteristics:

Evonik Performance Materials GmbH | PLEXIGLAS® | December 2015 Page 1/4

Applications

These properties make PLEXIGLAS® LED especially

suitable as:

a thin sheet (WH14, WH72) for advertising

signs: glowing letters, light boxes,

backlighting in exhibition booths and

store fixtures (see Fig. 2).

The lighting example in Fig. 1 shows

greater brightness with PLEXIGLAS® LED Fig. 3.2a: Backlighting with routing

than with a conventional grade with

comparable light diffusion.

a thick sheet/block (WH51, WM51) with a

material thickness of 12-40 mm:

routed letters in illuminated signs,

backlighting in furniture and store

fixtures. Figs. 3.1-3.3. show different

variants of these applications.

Fig. 3.2b: Indirect backlighting with routing

Fig. 2: Illuminated sign with a thin sheet

Fig. 3.3 : Backlighting with embedded flexible LED

strips (side emitters)

Fig. 3.1: Backlighting with a thick sheet

Evonik Performance Materials GmbH | PLEXIGLAS® | December 2015 Page 2/4

Machining The reverse side is usually covered with

white, highly reflective material (e.g. powder-

PLEXIGLAS® LED can be machined just like

coated aluminum sheet) or left open, or

standard PLEXIGLAS® GS. The following Guidelines

transparent to translucent, to create a corona

for Workshop Practice are available for

effect (Fig. 3.4).

PLEXIGLAS®:

LEDs can be embedded in routed cavities.

Machining PLEXIGLAS® (Ref. No. 311-1) The wall thickness should not be reduced to

Forming PLEXIGLAS® (Ref. No. 311-2) less than 40% of the original material

Joining PLEXIGLAS® (Ref. No. 311-3) thickness so that the light can be diffused to

Fabricating Tips for PLEXIGLAS® best effect. Walls should not be made thinner

Solid Sheet (Ref. No. 311-5) than 12 mm in 30mm-thick sheets.

Routing automatically changes the light

Notes on routing letters out of thick sheets (WH51 diffusion properties, i.e. the resulting

and WM51): workpiece has lower light diffusion and

higher light transmission. If routing leaves

Example: Cut out the contour of a letter 40% of the original thickness, as is usually

sized 300 x 300 mm with a laser or milling the case, the lighting values stay within a

cutter. The mirror is 60 mm wide. Cut a very positive range.

groove in the back of the piece and insert the

LED modules. You can order an example at The decision tree in Fig. 4 helps you to choose the

www.plexiplas-shop.com (search “LED correct material.

Demonstrator”).

Signage

Thick sheets/blocks

Thin Sheet

12 – 40 mm

3 to 10 mm

Thickness Thickness 30 mm

12 to 25 mm and more

Greater brightness

(higher transmittance)

WH72 WH14 WM51

Better white opacity in incident light

(higher light scattering)

LEDs glow through the

full material thickness

LEDs in deeply or through shallow

routed cavities routed areas

Greater brightness

(higher transmittance)

WH51 WM51

Better white opacity in incident light

(higher light scattering)

Fig. 4: Decision tree

Evonik Performance Materials GmbH | PLEXIGLAS® | December 2015 Page 3/4

Table 1: Brightness of a light box Delivery forms

Size: 3,050 mm x 2,030 mm, from a thickness

LED grade D65* Color Luminance

(see grade) (D65*) (Luminance) of 25 mm: 3,000 mm x 2,000 mm.

WH14 47 % White 1468 cd/m² | +22%

(WH02) (42 %) (1208 cd/m²) The complete product range can be found in the

PLEXIGLAS® sales handbook.

WH72 31 % White 1007 cd/m² | +41%

(WH73) (22 %) (633 cd/m²)

(WN070) (28%) (805 cd/m²) Information for processing the WM51 and WH51

varieties for milled lettering:

Measured with OSRAM BackLED BA01LA-W4F LED modules, with The top side of the sheets / blocks (just like the

115 modules/m² in the structure shown in Fig. 2. front of the letter) is marked by inkjet printing.

This product belongs to the PLEXIGLAS® LED

PLEXIGLAS® LED, Backlighting white product family and was specially developed for

the illuminated signage industry. You can find

other interesting products developed for LED

Thickness [mm] D65*

applications in the information sheet “PLEXIGLAS®

PLEXIGLAS® LED WH14 3 47 % LED Overview” (No. 212-6).

PLEXIGLAS® LED WH72 3 31 %

PLEXIGLAS® LED WH51 15, 20, 25 22 %

PLEXIGLAS® LED WM51 15 45 %

20 35 %

25 28 %

30 22 %

* Transmittance DIN 5033, ISO 13468-2.

® = registered trademark PLEXIGLAS is a registered trademark of Evonik Röhm GmbH, Darmstadt, Germany.

Certified to DIN EN ISO 9001 (Quality) and DIN EN ISO 14001 (Environment)

Evonik is a worldwide manufacturer of PMMA products sold under the PLEXIGLAS® trademark on the European, Asian, African and

Australian continents and under the ACRYLITE® trademark in the Americas.

This information and all further technical advice is based on our present knowledge and experience. However, it implies no liability or

other legal responsibility on our part, including with regard to existing third party intellectual property rights, especially patent rights.

In particular, no warranty, whether express or implied, or guarantee of product properties in the legal sense is intended or implied. We

reserve the right to make any changes according to technological progress or further developments. The customer is not released

from the obligation to conduct careful inspection and testing of incoming goods. Performance of the product described herein should

be verified by testing, which should be carried out only by qualified experts in the sole responsibility of a customer. Reference to trade

names used by other companies is neither a recommendation, nor does it imply that similar products could not be used.

Evonik Performance Materials GmbH

Acrylic Polymers

Kirschenallee, 64293 Darmstadt, Germany

info@plexiglas.net www.plexiglas.net www.evonik.com

Ref. No. 222-25 December 2015

Evonik Performance Materials GmbH | PLEXIGLAS® | December 2015 Page 4/4

You might also like

- Gerry Mulligan DiscographyDocument491 pagesGerry Mulligan DiscographyIan SinclairNo ratings yet

- Ias PDFDocument56 pagesIas PDFMarco RamosNo ratings yet

- Science Experiment Week 5 Lesson PlanDocument5 pagesScience Experiment Week 5 Lesson Planapi-451266317No ratings yet

- Plexiglas Led 0V200 - enDocument2 pagesPlexiglas Led 0V200 - enmstevkaNo ratings yet

- Plexiglas Acrylic - PC SheetsDocument8 pagesPlexiglas Acrylic - PC SheetsSundarNo ratings yet

- Illuminnation Lumitex BrochureDocument8 pagesIlluminnation Lumitex Brochure4uengineerNo ratings yet

- Roller BlindsDocument4 pagesRoller BlindsBhanuNo ratings yet

- Hella Worklight Ultra Beam Led: Short Distance Lighting Long-Range IlluminationDocument2 pagesHella Worklight Ultra Beam Led: Short Distance Lighting Long-Range Illuminationie85No ratings yet

- Imc Insulations PDFDocument8 pagesImc Insulations PDFromeo pedranoNo ratings yet

- World-Leading Skylights and Roof Windows: Product Information and Price List 1st April 2020Document16 pagesWorld-Leading Skylights and Roof Windows: Product Information and Price List 1st April 2020Toni Rose Peliño CaNo ratings yet

- File Ap en 7Document2 pagesFile Ap en 7Rakib HossainNo ratings yet

- Re-Think The Ceiling: Technical Specifi CationsDocument2 pagesRe-Think The Ceiling: Technical Specifi CationsRizki MashudiNo ratings yet

- NSN Brochure - UnlockedDocument1 pageNSN Brochure - UnlockedGhostWheels SSSNo ratings yet

- Philips LuxspaceDocument22 pagesPhilips LuxspaceJohn AlvinNo ratings yet

- Allretailamended 160405122419Document97 pagesAllretailamended 160405122419LabdhiNo ratings yet

- Coverland Technical Guide 2015 - 72 - Low Res For EmailDocument2 pagesCoverland Technical Guide 2015 - 72 - Low Res For EmailCallaci Trottier DiegoNo ratings yet

- World-Leading Skylights and Roof Windows: Product Information and Price List 2018Document16 pagesWorld-Leading Skylights and Roof Windows: Product Information and Price List 2018nick rourkeNo ratings yet

- Epson EB X05Document3 pagesEpson EB X05Annstella SebastianNo ratings yet

- Enjoy The Big Screen Experience at Home and Deliver Sharp Presentations at The Office With This Portable 3,300 Lumens XGA ProjectorDocument3 pagesEnjoy The Big Screen Experience at Home and Deliver Sharp Presentations at The Office With This Portable 3,300 Lumens XGA ProjectorRonnie KharbamonNo ratings yet

- Ice Cold and Efficient: A New Generation of Surgical LightsDocument12 pagesIce Cold and Efficient: A New Generation of Surgical LightsNasr Eldin AlyNo ratings yet

- Ais 191Document3 pagesAis 191Hassan Ali SadiqNo ratings yet

- Heradesign SuperfineDocument7 pagesHeradesign SuperfineshanNo ratings yet

- AxcelDocument12 pagesAxcelJoenell Cardino GalveNo ratings yet

- Metawell Smart Ceilings 1Document66 pagesMetawell Smart Ceilings 1Amey GawadeNo ratings yet

- Mitsubishi Ex240u SpecsDocument2 pagesMitsubishi Ex240u SpecsRidho Pandu AbdillahNo ratings yet

- AurinioDocument32 pagesAurinioD2Z0 CONo ratings yet

- Tung Panel Premium 93119515 Tung Panel P 2x2 S 33w 840 19 DsDocument4 pagesTung Panel Premium 93119515 Tung Panel P 2x2 S 33w 840 19 DsEnrique PerdigueroNo ratings yet

- 47LFT30WDocument2 pages47LFT30WdocumentatiiNo ratings yet

- Product Data: Heradesign Superfi NeDocument6 pagesProduct Data: Heradesign Superfi NeP. IulianNo ratings yet

- Co W01.co w01 DatasheetDocument2 pagesCo W01.co w01 DatasheetRoberto Luis de SouzaNo ratings yet

- ZOE 2012 Brochure enDocument16 pagesZOE 2012 Brochure enZeljkoSipcicNo ratings yet

- Pirlite LED Panel ProDocument1 pagePirlite LED Panel ProshahzadNo ratings yet

- Epson Eb x05 Brochure enDocument3 pagesEpson Eb x05 Brochure enAjayGuptaNo ratings yet

- Polaris 100/200Document4 pagesPolaris 100/200Salvador MonteroNo ratings yet

- Epson EB-X41 ProjectorDocument3 pagesEpson EB-X41 ProjectorWaleed MuradNo ratings yet

- Catalogue Đèn MDocument12 pagesCatalogue Đèn MTuyen nguyen ngocNo ratings yet

- Catalog 2021Document9 pagesCatalog 2021Alex ChioreanNo ratings yet

- Tigal Brochure /PUIGMETAL®Document5 pagesTigal Brochure /PUIGMETAL®PUIGMETAL®No ratings yet

- Wa0001Document16 pagesWa0001WIDO SumbogoNo ratings yet

- Plexiglas: Optical & Transmission CharacteristicsDocument12 pagesPlexiglas: Optical & Transmission Characteristicsstephen_huangNo ratings yet

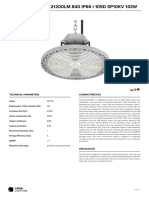

- OCULUS LED MINI 21200LM 840 IP66 I 105D SP10KV 143W: Detailed CardDocument3 pagesOCULUS LED MINI 21200LM 840 IP66 I 105D SP10KV 143W: Detailed CardDima LuninNo ratings yet

- LED Lighting Solutions Brochure PDFDocument7 pagesLED Lighting Solutions Brochure PDFAhmedBIowarNo ratings yet

- Epson EB-X41 XGA 3600 Lumens XGA 3LCD ProjectorDocument3 pagesEpson EB-X41 XGA 3600 Lumens XGA 3LCD ProjectorWebAntics.com Online Shopping StoreNo ratings yet

- Technical Data Sheet: PL® Acousti-SealDocument3 pagesTechnical Data Sheet: PL® Acousti-SealJohn TurnerNo ratings yet

- Ew270u BrochureDocument2 pagesEw270u BrochureRidho Pandu AbdillahNo ratings yet

- EnableThinner Stronger Collation Shrink Films Help Brand Owners Deliver Bundled Products Securely enDocument2 pagesEnableThinner Stronger Collation Shrink Films Help Brand Owners Deliver Bundled Products Securely enSajib BhattacharyaNo ratings yet

- DLP Trunking Led System PDFDocument16 pagesDLP Trunking Led System PDFPercy GoitsemangNo ratings yet

- VELUXDocument16 pagesVELUXEko SalamunNo ratings yet

- Lucent Matched CladDocument6 pagesLucent Matched CladPatrickJesusCordovaGarateNo ratings yet

- 91-0175-00-00 On Ip Eco: DescriptionDocument13 pages91-0175-00-00 On Ip Eco: DescriptionUmeshNo ratings yet

- MArket Survey GRP 10Document9 pagesMArket Survey GRP 10shraddhaNo ratings yet

- DS HERADESIGN Superfine ENDocument6 pagesDS HERADESIGN Superfine ENsebaNo ratings yet

- Co W01.co w01 DatasheetDocument2 pagesCo W01.co w01 DatasheetnadimNo ratings yet

- Sylvania Osran LedsDocument56 pagesSylvania Osran Ledsnoel antonio RamosNo ratings yet

- Teal and Navy Modern Professional Business Leadership PresentationDocument12 pagesTeal and Navy Modern Professional Business Leadership PresentationSilendrina MishaNo ratings yet

- EB S41 DatasheetDocument3 pagesEB S41 Datasheetgem lihanshNo ratings yet

- Sikagard - 550 W inDocument4 pagesSikagard - 550 W inbineetmishra1990No ratings yet

- AFGA RT Film - DatasheetDocument1 pageAFGA RT Film - DatasheetDilip PatilNo ratings yet

- Acrylite Endlighten BrochureDocument4 pagesAcrylite Endlighten BrochureSaeid MirNo ratings yet

- Complete 2017 Automotive Product PortfolioDocument28 pagesComplete 2017 Automotive Product Portfolioit4728No ratings yet

- Skylite IndDocument2 pagesSkylite IndObbiemNo ratings yet

- Oops MCQ (Unit-1)Document7 pagesOops MCQ (Unit-1)Jee Va Ps86% (14)

- Pressure Transducer Davs 311-1-0 Volt - XCMG PartsDocument1 pagePressure Transducer Davs 311-1-0 Volt - XCMG Partsej ejazNo ratings yet

- Graduate Study at KIMEPDocument20 pagesGraduate Study at KIMEPKIMEPNo ratings yet

- Sand Cone Test ResultsDocument71 pagesSand Cone Test ResultsGayan Indunil JayasundaraNo ratings yet

- MGT-01 (14.03.23) - QPDocument19 pagesMGT-01 (14.03.23) - QPSrinivas VakaNo ratings yet

- ACCSA Module 1 - 8 Practice Dimensions & Skillsets of Addiction CounsellingDocument148 pagesACCSA Module 1 - 8 Practice Dimensions & Skillsets of Addiction Counsellingskye42817No ratings yet

- Recommended Reads by David PerellDocument3 pagesRecommended Reads by David PerellRonit MandalNo ratings yet

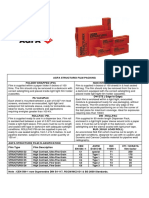

- Fraction Selection BrochureDocument2 pagesFraction Selection Brochureapi-186663124No ratings yet

- Questionnaire On Teaching Learning 1Document4 pagesQuestionnaire On Teaching Learning 1Sonia Agustin100% (1)

- Maintenance of Building ComponentsDocument4 pagesMaintenance of Building ComponentsIZIMBANo ratings yet

- Server Preparation Details LinuxDocument9 pagesServer Preparation Details Linuxbharatreddy9No ratings yet

- DX-790-960-65-17.5i-M: Electrical PropertiesDocument2 pagesDX-790-960-65-17.5i-M: Electrical PropertiesАлександрNo ratings yet

- The Impact On Digital Marketing During Pandemic Outbreak COVID-19 On Business DevelopmentDocument5 pagesThe Impact On Digital Marketing During Pandemic Outbreak COVID-19 On Business DevelopmentInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Pantos 16: Panoramic X-Ray SystemDocument6 pagesPantos 16: Panoramic X-Ray SystemAlbaz BiomedNo ratings yet

- Youth Worker Course Gold CoastDocument6 pagesYouth Worker Course Gold Coastf5dq3ch5100% (2)

- Passive Voice PDFDocument5 pagesPassive Voice PDFJohan FloresNo ratings yet

- Rexroth 4we10 Data Sheet PDFDocument10 pagesRexroth 4we10 Data Sheet PDFSIVARAMANJAGANATHANNo ratings yet

- Service Manual: MS-A18WV - MS-A24WV - MS-A30WVDocument32 pagesService Manual: MS-A18WV - MS-A24WV - MS-A30WVCesc BonetNo ratings yet

- Momo Nation Cafe ProfileDocument28 pagesMomo Nation Cafe ProfileMain AparchitNo ratings yet

- NF en 12953-14Document14 pagesNF en 12953-14Prasanna UmapathyNo ratings yet

- AY2017 2018CourseworkFees MOEDocument22 pagesAY2017 2018CourseworkFees MOEYotrisno LangNo ratings yet

- CMNS Week 3.2 Memo AssignmentDocument2 pagesCMNS Week 3.2 Memo AssignmentPulkit KalhanNo ratings yet

- QQQQ PDFDocument484 pagesQQQQ PDFSagor Saha100% (1)

- NDC Format For Billing PADDocument3 pagesNDC Format For Billing PADShantkumar ShingnalliNo ratings yet

- UNA010F-0-V2: Electrical SpecificationsDocument2 pagesUNA010F-0-V2: Electrical SpecificationsNiko ZabalaNo ratings yet

- 2006 Estes Model Rocketry CatalogDocument44 pages2006 Estes Model Rocketry CatalogMisesWasRightNo ratings yet

- Grade 6 - HEALTH - Q4 Module 1 - W1Document12 pagesGrade 6 - HEALTH - Q4 Module 1 - W1Love Lei67% (3)