Professional Documents

Culture Documents

Impact Test

Uploaded by

sajadbe3792Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Impact Test

Uploaded by

sajadbe3792Copyright:

Available Formats

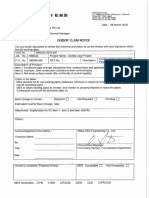

Please advice whether

production impact test coupon (PTC) as per UG-84 (i) is required?

per UCS-66, Curve A material, MDMT at 12mm is slightly below 0 C, it would appear impact test is not

required. Note that governing thickness of head is 12mm, thinner of the two parts joined.

3.Is there any flow chart/charts available to decide on PTC for carbon steel & alloy steel material?

Fig UCS-66.2, Appendix L, L-9

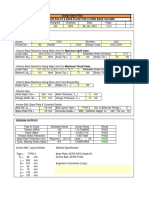

tr from internal pressure = 7.8 mm

tr from external pressure = 28.2 mm

from which tr, to determine MDMT ratio = (tr*E)/(tn-ca)

Codecalc result show that it take tr from internal pressure, why?

If you are following the ASME Code to the letter then it appears that the tr should be the

largest tr calculated. This would be based upon the external pressure calculation and not

the internal pressure MDMT. From a practical perspective Part UCS was developed based

upon tensile membrane stress and the potential for brittle fracture (the main purpose of

MDMT) is increased with increased tensile membrane stress.

Since UG-116 does not define an MDMT at MAEWP then it may not be required.

I am not a "Vessel Man", but it should surely be more economical to ADD stiffening rings

to reduce the thickness required for external pressure as long as your design temp. is

not excessive (say <= 800 F, thermal gradient stresses typically reasonable).

I will use tr of shell from internal pressure at MDMT since external pressure don't

produce general primary membrane tensile stress.

You might also like

- The New Penstock For The High Head Hydropower Plant KaunertalDocument9 pagesThe New Penstock For The High Head Hydropower Plant KaunertalStalyn SimbañaNo ratings yet

- Lecture 6Document14 pagesLecture 6Joe AllanNo ratings yet

- Minimum Design Metal Temperature (MDMT) and Impact TestDocument8 pagesMinimum Design Metal Temperature (MDMT) and Impact Testramyatan SinghNo ratings yet

- Mini ProjectDocument3 pagesMini ProjectSyafiq KamilNo ratings yet

- PV Elite (Construccion de Recipiente) MDMTDocument8 pagesPV Elite (Construccion de Recipiente) MDMTAlejandro CanoNo ratings yet

- E.3.2 - MDMT Using MathcadDocument2 pagesE.3.2 - MDMT Using MathcadrobertantoreniNo ratings yet

- Design of Piping Systems by Tengku SyahdilanDocument115 pagesDesign of Piping Systems by Tengku SyahdilanRagerishcire KanaalaqNo ratings yet

- Compact Thermal ModelingDocument6 pagesCompact Thermal ModelingteomondoNo ratings yet

- Machine Design Model PaperDocument2 pagesMachine Design Model PaperVinay Karanam100% (1)

- Data Sheet of Process Equipment Design: PROJECT Sokoria ProjectDocument22 pagesData Sheet of Process Equipment Design: PROJECT Sokoria ProjectarisandiyusufNo ratings yet

- Hdpe Pipe Wall Thickness CalculationsDocument1 pageHdpe Pipe Wall Thickness CalculationsTsouki TsoukiNo ratings yet

- The Investigation of Die Back Edge Cracking in Flip Chip Ceramic Ball Grid Array Package (FC-CBGA)Document12 pagesThe Investigation of Die Back Edge Cracking in Flip Chip Ceramic Ball Grid Array Package (FC-CBGA)faizal99No ratings yet

- Mtech 2013 DPVP Model QuestionDocument2 pagesMtech 2013 DPVP Model QuestionMathew JohnNo ratings yet

- A Method For Calculation of Fastener Torque Specifications Which Includes Statistical TolerancingDocument12 pagesA Method For Calculation of Fastener Torque Specifications Which Includes Statistical Tolerancingdavlasc100% (1)

- Design of Cylinder CoversDocument4 pagesDesign of Cylinder Coversjaison jacobNo ratings yet

- Memory Thermal Management 101:) Is The Term Used To Describe The Temperature of The Die Inside ADocument11 pagesMemory Thermal Management 101:) Is The Term Used To Describe The Temperature of The Die Inside Aketab_doostNo ratings yet

- YLAC-1808 应力分析报告(Stress Analysis-1808)Document19 pagesYLAC-1808 应力分析报告(Stress Analysis-1808)arisandiyusufNo ratings yet

- Buffer Tank DesignDocument1 pageBuffer Tank DesignSuresh Damu BhadNo ratings yet

- Pressure Testing of Unfired Pressure Vessels: ScopeDocument9 pagesPressure Testing of Unfired Pressure Vessels: Scopebenedicto soto mestanzaNo ratings yet

- Design by AnalysisDocument22 pagesDesign by AnalysisJEELE77No ratings yet

- Level-3 Shell EvalautionDocument17 pagesLevel-3 Shell EvalautionVipin NairNo ratings yet

- Section Design For Crack WidthDocument8 pagesSection Design For Crack WidthYou TubeNo ratings yet

- Overview of Lubrication and Tubular ConnectionDocument10 pagesOverview of Lubrication and Tubular ConnectionSaeed AraNo ratings yet

- Me 42 PDFDocument5 pagesMe 42 PDFMohamed Rafeek0% (1)

- 1.1 - Ag Plated Surfaces Status Affecting Thermomechanical Performance of Sintering Solder Joint - GiCo - MaSa - ST - V3Document21 pages1.1 - Ag Plated Surfaces Status Affecting Thermomechanical Performance of Sintering Solder Joint - GiCo - MaSa - ST - V3moyinglong1126No ratings yet

- IGS-M-TP-014-2-C (2) Sep. 2008: 3 Ply Co-Extruded Plastic Tape For Field Joint and Rehabilitation of Steel PipelineDocument13 pagesIGS-M-TP-014-2-C (2) Sep. 2008: 3 Ply Co-Extruded Plastic Tape For Field Joint and Rehabilitation of Steel PipelineTa GiNo ratings yet

- Compact Tension Specimen Fatigue Life CalculationDocument7 pagesCompact Tension Specimen Fatigue Life CalculationFarhan ZamirNo ratings yet

- What Is The Difference Between "Required", "Nominal" and "Analysis" Pipe Wall Thickness?Document3 pagesWhat Is The Difference Between "Required", "Nominal" and "Analysis" Pipe Wall Thickness?ÅdnAn MehmOodNo ratings yet

- An Integrated Approach To Random Analysis Using NastranDocument23 pagesAn Integrated Approach To Random Analysis Using Nastransons01No ratings yet

- 73 ThermalDocument10 pages73 ThermalShashank DubeyNo ratings yet

- Stress Classification ASME DIV2 Sec5 V1Document13 pagesStress Classification ASME DIV2 Sec5 V1pajadhavNo ratings yet

- Design of Piping SystemsDocument115 pagesDesign of Piping SystemsDushyant Varshney100% (2)

- Internal CoilDocument2 pagesInternal CoilwhngomjNo ratings yet

- Whitepaper - Mechanical Testing of DMLS PartsDocument10 pagesWhitepaper - Mechanical Testing of DMLS PartstanNo ratings yet

- KISSsoft, Shaft Analysis - Introduction To DIN 743, October 2000Document8 pagesKISSsoft, Shaft Analysis - Introduction To DIN 743, October 2000Tomas PinheiroNo ratings yet

- On The Way To Zero Defect of Plastic-Encapsulated Electronic Power DevicesPart I MetallizationDocument10 pagesOn The Way To Zero Defect of Plastic-Encapsulated Electronic Power DevicesPart I MetallizationJiyang WangNo ratings yet

- Thermal Interface Material (TIM) Design Guidance For Flip Chip BGA Package Thermal PerformanceDocument6 pagesThermal Interface Material (TIM) Design Guidance For Flip Chip BGA Package Thermal PerformancekpNo ratings yet

- 46 - 2.vendor Claim Notice No. HB8242-2019-001 - 0001Document30 pages46 - 2.vendor Claim Notice No. HB8242-2019-001 - 0001karthikaNo ratings yet

- Comparitive Study of Design of Piping SupportDocument18 pagesComparitive Study of Design of Piping SupportbkguptazNo ratings yet

- Annex C Residual Stress Profiles: Fitnet Mk7Document62 pagesAnnex C Residual Stress Profiles: Fitnet Mk7Muhammad Fitransyah Syamsuar PutraNo ratings yet

- Numerical Weld Modeling - A Method For Calculating Weld-Induced Residual StressesDocument12 pagesNumerical Weld Modeling - A Method For Calculating Weld-Induced Residual StressesSwarupendra BhattacharyyaNo ratings yet

- TI-IC Package Thermal MetricsDocument13 pagesTI-IC Package Thermal Metricssr_durNo ratings yet

- On The Way To Zero Defect of Plastic-Encapsulated Electronic Power DevicesPart III Chip Coating Passivation and DesignDocument8 pagesOn The Way To Zero Defect of Plastic-Encapsulated Electronic Power DevicesPart III Chip Coating Passivation and DesignJiyang WangNo ratings yet

- Design & Construction of Piping SystemsDocument115 pagesDesign & Construction of Piping SystemsSuresh Babu100% (13)

- Design & Const. of Piping SystemsDocument10 pagesDesign & Const. of Piping Systemsunique wordlNo ratings yet

- Design Input:: Design Sheet Title: Design of Anchor Bolts & Base Plate For A Fixed Base Column Ameya STDDocument4 pagesDesign Input:: Design Sheet Title: Design of Anchor Bolts & Base Plate For A Fixed Base Column Ameya STDSuryaSinghNo ratings yet

- An Integrated Approach To Random Analysis Using MSC/PATRAN With MSC/NASTRANDocument23 pagesAn Integrated Approach To Random Analysis Using MSC/PATRAN With MSC/NASTRANmijobitoNo ratings yet

- Miet2072 C7Document17 pagesMiet2072 C7vincent02hk_57881301No ratings yet

- Method For Finding Stress in Cylinders With Radial NozzlesDocument10 pagesMethod For Finding Stress in Cylinders With Radial NozzlesmatodelanusNo ratings yet

- Three Hours: Structural IntegrityDocument21 pagesThree Hours: Structural IntegrityLi'sNo ratings yet

- Intro To DIN 743Document8 pagesIntro To DIN 743droessaert_stijnNo ratings yet

- TRD 301 Annex 1 DesignDocument14 pagesTRD 301 Annex 1 Designksjin0226100% (1)

- Design for High Performance, Low Power, and Reliable 3D Integrated CircuitsFrom EverandDesign for High Performance, Low Power, and Reliable 3D Integrated CircuitsNo ratings yet

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- Wind Turbines in Cold Climates: Icing Impacts and Mitigation SystemsFrom EverandWind Turbines in Cold Climates: Icing Impacts and Mitigation SystemsNo ratings yet

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- FormingDocument1 pageFormingsajadbe3792No ratings yet

- TN 420220925424 - Signed 1Document1 pageTN 420220925424 - Signed 1sajadbe3792No ratings yet

- TN-420220925424 SignedDocument1 pageTN-420220925424 Signedsajadbe3792No ratings yet

- Div 1 E.4.3.1.CYLIDRICAL SHELLDocument3 pagesDiv 1 E.4.3.1.CYLIDRICAL SHELLsajadbe3792No ratings yet

- Div 1 E.4.4.1 Ext. PRDocument4 pagesDiv 1 E.4.4.1 Ext. PRsajadbe3792No ratings yet

- Div 1 E.4.3.5.ELIPTICAL HEADDocument3 pagesDiv 1 E.4.3.5.ELIPTICAL HEADsajadbe3792No ratings yet

- Div 1 E.4.5.3. NOZZLEDocument6 pagesDiv 1 E.4.5.3. NOZZLEsajadbe3792No ratings yet

- E4 16 1-FlangeDocument7 pagesE4 16 1-Flangesajadbe3792No ratings yet