Professional Documents

Culture Documents

Shell Varnish Removal Fluid Summary Sheet

Uploaded by

Salem IereebiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shell Varnish Removal Fluid Summary Sheet

Uploaded by

Salem IereebiCopyright:

Available Formats

SHELL

VARNISH REMOVAL FLUID

CHALLENGE

Varnish and deposits can result in Unplanned Loss of system

outages efficiency

⅓ of all units show signs of varnishing*

Solvents and chemical cleaners can degrade the properties of the in-service oil

and, if not completely removed, the new turbine oil. They also need extended time

offline for maintenance.

SOLUTION

The latest Shell Turbo oils Before switching, existing varnish can

help to minimise varnish formation. be removed using Shell Varnish

Removal Fluid.

New Shell Varnish Removal Fluid increases the solvency of in-service turbine oil, allowing

deposits and varnish to dissolve back into the oil for removal by fluid cleaning devices.

1. Its high varnish

dissolution capacity 2. The turbine remains

operational, maximising 3. It demonstrates excellent

compatibility without

enables the oil cleaning work efficiency reducing the flash point

device to remove the and reducing or degrading other oil

varnish effectively and maintenance properties, and any fluid

thus extending the oil life downtime. remaining after used-oil

and operating system flushing will not affect new

maintenance intervals. turbine oil performance.

*As reported in TIL 1528-3 GE Energy Services Technology

Using Shell Varnish Removal Fluid with Shell LubeOptimiser will maintain the high

Customer Technology services, 18 November 2005

work efficiency of system and protect equipment.

For more information, including advice on the use of Shell Varnish Removal Fluid and

Shell digitalized services, please contact the Shell technical help desk.

You might also like

- F9 Smart Study NotesDocument97 pagesF9 Smart Study NotesSteven Lino100% (5)

- Us-Vps-0300-En Vps Top Treat Oil System Cleaner Sell Sheet 1Document2 pagesUs-Vps-0300-En Vps Top Treat Oil System Cleaner Sell Sheet 1api-477120514No ratings yet

- Study For 33KV Sub-Marine Cable Crossings PDFDocument80 pagesStudy For 33KV Sub-Marine Cable Crossings PDFOGBONNAYA MARTINSNo ratings yet

- Kleentek 1Document7 pagesKleentek 1Maria GriffinNo ratings yet

- LHL System CatalogDocument12 pagesLHL System CatalogTarun GNo ratings yet

- OilmistcatalogDocument16 pagesOilmistcatalogtribologiaNo ratings yet

- Your Oil Is Talking Sensors and Filters Create Savings 1616525209Document13 pagesYour Oil Is Talking Sensors and Filters Create Savings 1616525209cristianNo ratings yet

- Turbine Oil Life - WhitepaperDocument16 pagesTurbine Oil Life - WhitepapercaesarchadmaNo ratings yet

- VDOPS Brochure (2017)Document6 pagesVDOPS Brochure (2017)Sugianto BarusNo ratings yet

- Lubricating Oil Analysing and Quality Follow-Up: Operating InstructionDocument8 pagesLubricating Oil Analysing and Quality Follow-Up: Operating InstructionDenim102No ratings yet

- Ultra EL: Formulated To Last Up To 16,000 HoursDocument4 pagesUltra EL: Formulated To Last Up To 16,000 Hourselperrote3No ratings yet

- Vacuum Oil Purifiers: E865A SeriesDocument4 pagesVacuum Oil Purifiers: E865A SeriesdanielcelNo ratings yet

- ROTAIR Lubricants Leaflet PDFDocument16 pagesROTAIR Lubricants Leaflet PDFPhuc DcNo ratings yet

- Trabajo Final Ingles TecnicoDocument9 pagesTrabajo Final Ingles TecnicoEduardo smith Mercado aguilarNo ratings yet

- Sentry Fluid Treatment System: For Varnish Removal in Oil SystemsDocument4 pagesSentry Fluid Treatment System: For Varnish Removal in Oil SystemsMohammadreza GalebanNo ratings yet

- 2 Mann Hummel CentrifugesDocument4 pages2 Mann Hummel CentrifugesMintomo IrawanNo ratings yet

- Product Description: Way and Slide LubricantsDocument3 pagesProduct Description: Way and Slide Lubricantsalexander900616No ratings yet

- Análisis-particulado-Shell Helix Ultra y ViscososDocument2 pagesAnálisis-particulado-Shell Helix Ultra y ViscososCable HondaNo ratings yet

- FUOOTECH Series LOP Vacuum Lubricating Oil PurifierDocument15 pagesFUOOTECH Series LOP Vacuum Lubricating Oil PurifierKevin ChiangNo ratings yet

- Oil Filtration ComparisonDocument1 pageOil Filtration Comparisonsatyam109No ratings yet

- 1 BdacbDocument4 pages1 BdacbROBERT PONCENo ratings yet

- Steam Turbine Oil Eyeopening ArticleDocument15 pagesSteam Turbine Oil Eyeopening ArticleRajeswaran NatarajanNo ratings yet

- Alexia 70Document2 pagesAlexia 70Parthiban SowndararajanNo ratings yet

- Shell Turbo Family BrochureDocument4 pagesShell Turbo Family BrochureLuqman Cuopreakt'zNo ratings yet

- Products Catalog - ACORE Filtration Co - LTDDocument22 pagesProducts Catalog - ACORE Filtration Co - LTDMauricio RaúlNo ratings yet

- Shell Helix Ultra 5W-40 Technical Data SheetDocument2 pagesShell Helix Ultra 5W-40 Technical Data Sheetz6hsdcqqnhNo ratings yet

- Oil Cleaning Device For AAF ViscobathDocument5 pagesOil Cleaning Device For AAF ViscobathMUHAMMAD AHMEDNo ratings yet

- IndustryNews 2Document2 pagesIndustryNews 2nyarfas.karolyNo ratings yet

- Lube Oil AnalysisDocument8 pagesLube Oil AnalysisVuthpalachaitanya KrishnaNo ratings yet

- Maersk Blending On Board (BOB) - OKHHDocument8 pagesMaersk Blending On Board (BOB) - OKHHCalandrasReyCalandrasreyNo ratings yet

- LM Product BrochureDocument20 pagesLM Product BrochurekashishNo ratings yet

- 001A9013 - Helix Ultra 5W-40 PDFDocument2 pages001A9013 - Helix Ultra 5W-40 PDFGaruda CybercafeNo ratings yet

- 6481-6482 Product InfoDocument8 pages6481-6482 Product InfoNima FakherNo ratings yet

- Technical Topic - Turbine Flush GuideDocument3 pagesTechnical Topic - Turbine Flush Guidedhavit wijayantoNo ratings yet

- LubricantsDocument8 pagesLubricantsMd Mujibur RahmanNo ratings yet

- Varnish Removal SystemDocument4 pagesVarnish Removal SystemHANIF AKBARNo ratings yet

- Oil Cleaning: Removal of Particles and Water From Gear Oil. Marine Propulsion SystemsDocument4 pagesOil Cleaning: Removal of Particles and Water From Gear Oil. Marine Propulsion SystemsAlbertoNo ratings yet

- Varnish in Turbine OilsDocument6 pagesVarnish in Turbine OilsToppy Toppy100% (1)

- Liebherr Brochure Lubricants en PDFDocument20 pagesLiebherr Brochure Lubricants en PDFSara Mayerlin Ramos PáezNo ratings yet

- Technical Topic - Developing Turbine Oils Beyond RPVOTDocument3 pagesTechnical Topic - Developing Turbine Oils Beyond RPVOTdhavit wijayantoNo ratings yet

- Electric Motor Bearing Grease SelectionDocument1 pageElectric Motor Bearing Grease SelectionProject Sales CorpNo ratings yet

- Improving The Viscosity Index of Used Lubricating Oil by SolventDocument5 pagesImproving The Viscosity Index of Used Lubricating Oil by SolventJorge EliasNo ratings yet

- Heavy Fuel Oil Cleaning: Service Letter SL2017-640/LNWDocument6 pagesHeavy Fuel Oil Cleaning: Service Letter SL2017-640/LNWStefas DimitriosNo ratings yet

- Varnish Removal Systems (VRS)Document4 pagesVarnish Removal Systems (VRS)HANIF AKBARNo ratings yet

- TDS - Shell Alexia 70Document10 pagesTDS - Shell Alexia 70Ohood AlameerNo ratings yet

- FILTERSDocument8 pagesFILTERSHisham AreekkanNo ratings yet

- MobilCut Series PdsDocument4 pagesMobilCut Series PdsNoche de EstrellasNo ratings yet

- Petronas Disrol 120: Premium Quality 12 TBN Medium Speed Diesel Engine OilsDocument1 pagePetronas Disrol 120: Premium Quality 12 TBN Medium Speed Diesel Engine OilsHazrulnizam HassanNo ratings yet

- Varnish Potential Analysis - TestOilTestOilDocument5 pagesVarnish Potential Analysis - TestOilTestOilCristiano TaddeiNo ratings yet

- Machinery Lubrication November December 2017Document89 pagesMachinery Lubrication November December 2017Jorge Cuadros BlasNo ratings yet

- Machinery Lubrication November December 2017 PDFDocument89 pagesMachinery Lubrication November December 2017 PDFJorge Cuadros BlasNo ratings yet

- FUOOTECH Series TY Vacuum Turbine Oil PurifierDocument15 pagesFUOOTECH Series TY Vacuum Turbine Oil PurifierKevin Chiang100% (1)

- Shell Helix HX7 5W-30: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Helix HX7 5W-30: Performance, Features & Benefits Main ApplicationsAwais A.No ratings yet

- Mobil SHC Cibus™ Series: High Performance NSF H1 Registered Lubricants For Food MachineryDocument3 pagesMobil SHC Cibus™ Series: High Performance NSF H1 Registered Lubricants For Food MachineryΓεώργιος ΝάτσκοςNo ratings yet

- Cetus Hipersyn Oils: Product Data SheetDocument2 pagesCetus Hipersyn Oils: Product Data SheetAymanSayedElantableeNo ratings yet

- OSC OSD Oil Water Separator Tcm45-622649Document8 pagesOSC OSD Oil Water Separator Tcm45-622649Muhammad Abdul RaufNo ratings yet

- Investigation Into Early Loss of Lubricant Viscosity in Agitator Gear Box at CIL Plant at Goldfields Ghana LimitedDocument4 pagesInvestigation Into Early Loss of Lubricant Viscosity in Agitator Gear Box at CIL Plant at Goldfields Ghana LimitedInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Optimizing Wind Farm Performance: With SKF Windlub Automatic Lubrication SystemsDocument20 pagesOptimizing Wind Farm Performance: With SKF Windlub Automatic Lubrication SystemsSolomon NebiyuNo ratings yet

- Shell Turbo Oil BrochureDocument6 pagesShell Turbo Oil Brochureman_iphNo ratings yet

- Delta Lube 06 (PDB) - en - GB TechnicalDocument3 pagesDelta Lube 06 (PDB) - en - GB TechnicalRezk SifeNo ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3 out of 5 stars3/5 (4)

- 2010 Accord CoupeDocument404 pages2010 Accord CoupeSalem IereebiNo ratings yet

- 4625 EnuDocument2 pages4625 EnuSalem IereebiNo ratings yet

- GL XX Mobil Pegasus 805Document3 pagesGL XX Mobil Pegasus 805Salem IereebiNo ratings yet

- Wind Aftermarket Brochure NADocument8 pagesWind Aftermarket Brochure NASalem IereebiNo ratings yet

- Deep Groove Ball Bearing: Dimensions PerformanceDocument2 pagesDeep Groove Ball Bearing: Dimensions PerformanceSalem IereebiNo ratings yet

- Hydraulic and Lubricating Oil For Rust Protection inDocument3 pagesHydraulic and Lubricating Oil For Rust Protection inSalem IereebiNo ratings yet

- Shell Spirax S4 CX 30: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Spirax S4 CX 30: Performance, Features & Benefits Main ApplicationsDarmawan PutrantoNo ratings yet

- GLXXMobilgrease XHP 220 SeriesDocument3 pagesGLXXMobilgrease XHP 220 SeriesJavier Cayampi PomallihuaNo ratings yet

- International Price List 90.3Document36 pagesInternational Price List 90.3Salem IereebiNo ratings yet

- GL XX Mobilith SHC SeriesDocument4 pagesGL XX Mobilith SHC Seriessyuhaimi82No ratings yet

- GPCDOC Local TDS United Kingdom Shell Gadus S3 V770D 1 (en-GB) TDSDocument2 pagesGPCDOC Local TDS United Kingdom Shell Gadus S3 V770D 1 (en-GB) TDSSalem IereebiNo ratings yet

- Shell LubeAdvisor Brochure 20210917Document4 pagesShell LubeAdvisor Brochure 20210917Salem IereebiNo ratings yet

- GPCDOC Local TDS Bangladesh Shell Spirax S2 G 140 (BN-BD) TDS v1Document2 pagesGPCDOC Local TDS Bangladesh Shell Spirax S2 G 140 (BN-BD) TDS v1Ayon HossenNo ratings yet

- Shell Gadus S2 V100 2Document2 pagesShell Gadus S2 V100 2Muhammad SaputraNo ratings yet

- 50 Hotelierstalk MinDocument16 pages50 Hotelierstalk MinPadma SanthoshNo ratings yet

- OMS - Kangaroo Mother CareDocument54 pagesOMS - Kangaroo Mother CareocrissNo ratings yet

- 2023 Reso-01Document3 pages2023 Reso-01John Mark Mercado JubelagNo ratings yet

- Price Action Trading Strategies - 6 Patterns That Work (Plus Free Video Tutorial)Document22 pagesPrice Action Trading Strategies - 6 Patterns That Work (Plus Free Video Tutorial)kalpesh kathar100% (1)

- Hex Bucket InspectionDocument1 pageHex Bucket InspectionSixto Guarniz AnticonaNo ratings yet

- Estanislao Vs CADocument2 pagesEstanislao Vs CAChammy0% (1)

- Assignment 03 Investments in Debt SecuritiesDocument4 pagesAssignment 03 Investments in Debt SecuritiesJella Mae YcalinaNo ratings yet

- Agile Marketing Reference CardDocument2 pagesAgile Marketing Reference CardDavid BriggsNo ratings yet

- Design of Accurate Steering Gear MechanismDocument12 pagesDesign of Accurate Steering Gear Mechanismtarik RymNo ratings yet

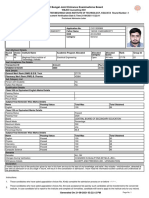

- West Bengal Joint Entrance Examinations Board: Provisional Admission LetterDocument2 pagesWest Bengal Joint Entrance Examinations Board: Provisional Admission Lettertapas chakrabortyNo ratings yet

- Reterta V MoresDocument13 pagesReterta V MoresRam Migue SaintNo ratings yet

- French Revolution EssayDocument2 pagesFrench Revolution Essayapi-346293409No ratings yet

- 7MWTW1710YM0Document8 pages7MWTW1710YM0Izack-Dy JimZitNo ratings yet

- Guide To Networking Essentials Fifth Edition: Making Networks WorkDocument33 pagesGuide To Networking Essentials Fifth Edition: Making Networks WorkKhamis SeifNo ratings yet

- Module 2 Lesson 2 Communication and TechnologyDocument7 pagesModule 2 Lesson 2 Communication and TechnologyClarence EscopeteNo ratings yet

- Factors Affecting The Implementation of Green Procurement: Empirical Evidence From Indonesian Educational InstitutionDocument12 pagesFactors Affecting The Implementation of Green Procurement: Empirical Evidence From Indonesian Educational InstitutionYeni Saro ManaluNo ratings yet

- Digest of Ganila Vs CADocument1 pageDigest of Ganila Vs CAJohn Lester LantinNo ratings yet

- PRI SSC TutorialDocument44 pagesPRI SSC TutorialSantosh NarayanNo ratings yet

- LS Series Hand Crimping ToolsDocument4 pagesLS Series Hand Crimping ToolsbaolifengNo ratings yet

- Philippine First Insurance V HartiganDocument3 pagesPhilippine First Insurance V HartiganAlexander Genesis DungcaNo ratings yet

- BBI2002 SCL 7 WEEK 8 AdamDocument3 pagesBBI2002 SCL 7 WEEK 8 AdamAMIRUL RIDZLAN BIN RUSIHAN / UPMNo ratings yet

- Advanced Excel Training ManualDocument6 pagesAdvanced Excel Training ManualAnkush RedhuNo ratings yet

- Ab 1486 Developer Interest ListDocument84 pagesAb 1486 Developer Interest ListPrajwal DSNo ratings yet

- User Custom PP Install74Document2 pagesUser Custom PP Install74Zixi FongNo ratings yet

- Median FilteringDocument30 pagesMedian FilteringK.R.RaguramNo ratings yet

- Sop Urilyzer 100Document4 pagesSop Urilyzer 100misriyantiNo ratings yet

- Hyflow: Submersible PumpsDocument28 pagesHyflow: Submersible PumpsmanoNo ratings yet

- Easy Pictionary Words: Angel Eyeball PizzaDocument3 pagesEasy Pictionary Words: Angel Eyeball Pizzakathy158No ratings yet