Professional Documents

Culture Documents

Compressorwashingstrainer

Uploaded by

aras aliCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compressorwashingstrainer

Uploaded by

aras aliCopyright:

Available Formats

OPERATION AND MAINTENANCE MANUAL Rev.

: C

COMPONENT LITERATURE Page : 1/9

COMPONENT LITERATURE

GE DEVICE CODE : N/A

KKS DEVICE CODE : N/A

DESIGNATION : FLANGED STAINLESS STEEL STRAINER

PART NUMBER : N/A

SUPPLIER : SFERACO

TYPE : 240

LITERATURE REFERENCE : REF. 240 (8 pages)

All right reserved copyright

OMML_BG140003-SD02 Approver: A.S. Date: 6 May 2015

REF. 240

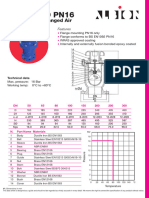

FLANGED STAINLESS STEEL STRAINER PN16

Size: DN 15 to DN 200

Ends : ISO PN16 Flanges R.F.

Min Temperature : - 20°C

Max Temperature : + 200°C

Max Pressure : 16 Bars

Specifiations : Removable stainless steel filter

Bolted bonnet with draining cap

Materials : Stainless steel

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 11/13 Rev.02

Page 1 sur 8

Information provided as an indication and subject to possible modification

REF. 240

FLANGED STAINLESS STEEL STRAINER PN16

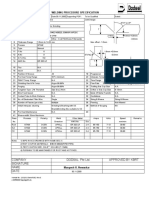

SPECIFICATIONS :

x Removable stainless steel filter

x ISO PN16 Flanges R.F.

x Horizontal or vertical position with descendant fluid (respect the flow direction indicated by the arrow )

x Mesh 8/10° mm ( 800 μ ) up to DN 50 , 10/10° mm from DN 65 to 80 and 30/10° over

x Bolted bonnet with draining cap threaded BSP

USE :

x For Chemical and pharmaceutical industries, petrochemical industries, hydraulic installation, compressed air

x Min Temperature Ts : - 20°C

x Max Temperature Ts :+ 200°C

x Max Pressure Ps : 16 bars ( see graph )

PRESSURE / TEMPERATURE GRAPH ( STEAM EXCLUDED ) :

FLOW COEFFICIENT Kvs ( M3 / h ) :

DN 15 20 25 32 40 50 65 80 100 125 150 200

Kvs ( m3/h ) 2.59 6.05 12.1 17.3 27.7 56.2 85.5 138.4 259.5 415.1 605.4 882.3

RANGE :

x ISO PN16 Flanges R.F. from DN 15 to DN 200 Ref.240

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 11/13 Rev.02

Page 2 sur 8

Information provided as an indication and subject to possible modification

REF. 240

FLANGED STAINLESS STEEL STRAINER PN16

HEAD LOSS GRAPH :

DN 15 - 40

Flow

DN 50 - 200

Flow

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 11/13 Rev.02

Page 3 sur 8

Information provided as an indication and subject to possible modification

REF. 240

FLANGED STAINLESS STEEL STRAINER PN16

MATERIALS :

Item Designation Materials

1 Body ASTM A351 CF8M

2 Filter SS 304

3 Bonnet ASTM A351 CF8M

4 Draining cap ASTM A351 CF8M

5 Gasket PTFE

6 Bonnet gasket PTFE

7 Washer SS 304

8 Screw SS 304

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 11/13 Rev.02

Page 4 sur 8

Information provided as an indication and subject to possible modification

REF. 240

FLANGED STAINLESS STEEL STRAINER PN16

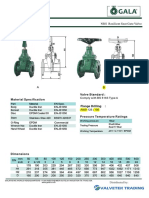

SIZE ( in mm ) :

Filter size :

Ref. DN 15 20 25 32 40 50 65 80 100 125 150 200

L 130 150 160 180 200 230 290 310 350 400 480 600

H 85 85 112 114 132 150 185 200 232 274 328 410

G ( drain ) 1/2“ 1/2“ 1/2“ 1/2“ 1/2“ 1/2“ 1/2“ 1/2“ 3/4“ 3/4“ 3/4“ 3/4“

240 ØD 19 24 27 40 43 54 65 85 103 128 154 208

H1 57 55 87 82 99.5 102 135 150 160 221 250 300

Mesh 0.8 0.8 0.8 0.8 0.8 0.8 1 1 3 3 3 3

Weight ( Kg ) 2 2.7 3.5 5 6.1 8.1 12.3 15.5 22 30 45.1 77.1

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 11/13 Rev.02

Page 5 sur 8

Information provided as an indication and subject to possible modification

REF. 240

FLANGED STAINLESS STEEL STRAINER PN16

ISO PN16 FLANGES SIZE ( in mm ) :

DN 15 20 25 32 40 50 65 80 100 125 150 200

ØC 45 58 68 78 88 102 122 138 158 188 212 268

ØD 95 105 115 140 150 165 185 200 220 250 285 340

ØK 65 75 85 100 110 125 145 160 180 210 240 295

Nb x Ø L 4 x 14 4 x 14 4 x 14 4 x 18 4 x 18 4 x 18 4 x 18 8 x 18 8 x 18 8 x 18 8 x 22 12 x 22

b 14 16 16 16 16 18 18 20 20 22 22 24

e 2 2 2 2 3 3 3 3 3 3 3 3

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 11/13 Rev.02

Page 6 sur 8

Information provided as an indication and subject to possible modification

REF. 240

FLANGED STAINLESS STEEL STRAINER PN16

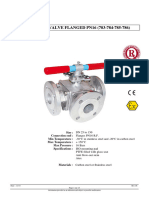

STANDARDS :

x Fabrication according to ISO 9001 : 2008

x DIRECTIVE 97/23/CE : CE N° 0035

Risk category III Module H

x Construction according to EN 12516-1

x Tests according to API 598

x Length according to EN 558 series1 (DIN 3202 F1 – NF 29354)

x ISO PN16 Flanges R.F. according to EN 1092-1

x ATEX Group II Category 2 G/2D Zone 1 & 21 Zone 2 &22 ( optional marking )

INSTALLATION POSITIONS :

Vertical position ( descendand fluid ) Horizontal position

ADVICE : Our opinion and our advice are not guaranteed and SFERACO shall not be liable for the consequences of damages.

The customer must check the right choice of the products with the real service conditions.

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 11/13 Rev.02

Page 7 sur 8

Information provided as an indication and subject to possible modification

REF. 240

FLANGED STAINLESS STEEL STRAINER PN16

INSTALLATION INSTRUCTIONS

GENERAL GUIDELINES :

x Ensure that the strainers to be used are appropriate for the conditions of the installation (type of

fluid,pressure and temperature).

x Be sure to have enough valves to be able to isolate the sections of piping as well as the appropriate

equipment for maintenance and repair.

x Ensure that the strainers to be installed are of correct strenght to be able to support the capacity of their

usage.

x Installation of all circuits should ensure that their function can be automatically tested on a regular

basis (at least two times a year).

INSTALLATION INSTRUCTIONS :

x Before installing the strainers, clean and remove any objects from the pipes (in particular bits of

sealing and metal) which could obstruct and block the strainers.

x Ensure that both connecting pipes either side of the strainer (upstream and downstream) are

aligned (if they’re not, the strainer may not work correctly).

x Make sure that the two sections of the pipe (upstream and downstream) match, the strainer unit will

not absorb any gaps. Any distortions in the pipes may affect the thightness of the connection, the

working of the strainer and can even cause a rupture. To be sure, place the kit in position to ensure the

assembling will work.

x Make sure flanges are cleaned.

x If sections of piping do not have their final support in place, they should be temporarily fixed. This

is to avoid unnecessary strain on the strainer.

x Tighten the bolts in cross.

x The pressurisation must be increased gradually.

x So that the maintenance operations could be easily done, place a stop valve before and after the

strainer.Thereby, the strainer could be isolated. During this operation, ensure to have a new bonnet gasket to avoid

a leakage during the restarting.

x Fluids in the strainer must not contain solid objects ( it could damaged the seat ).

Sferaco 90 rue du Ruisseau 38297 St Quentin Fallavier Tel: + 33 (0) 474.94.15.90 Fax: + 33 (0) 474.95.62.08 Internet: www.sferaco.fr E-mail : sferaco@sferaco.fr

Date : 11/13 Rev.02

Page 8 sur 8

Information provided as an indication and subject to possible modification

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- F L A N G e D S T A I N L e S S S T e e L S T R A I N e R P N 1 6Document8 pagesF L A N G e D S T A I N L e S S S T e e L S T R A I N e R P N 1 6Miguel BentoNo ratings yet

- Y-Strainer - Data SheetDocument7 pagesY-Strainer - Data SheetŁukasz OlszewskiNo ratings yet

- Zawor 507 Karta-KatalogowaDocument8 pagesZawor 507 Karta-KatalogowaKarolNo ratings yet

- Sorb Cu Clapeta 2Document11 pagesSorb Cu Clapeta 2Cosmin BonghezNo ratings yet

- Eng BD Fta731Document19 pagesEng BD Fta731Lazar LilaNo ratings yet

- TDS-765-Technical Datasheet 2 Pieces Splitbody Ball Valve Stainless Steel Dinf4-F5 pn16 40Document12 pagesTDS-765-Technical Datasheet 2 Pieces Splitbody Ball Valve Stainless Steel Dinf4-F5 pn16 40ruiz sumarNo ratings yet

- 731 Technical - Datasheet - 3 - Pieces - Ball - Valve - Stainless - Steel - Flanged - pn40Document8 pages731 Technical - Datasheet - 3 - Pieces - Ball - Valve - Stainless - Steel - Flanged - pn40ruiz sumarNo ratings yet

- Stainless Steel Needle Valve PN 400 F/FDocument6 pagesStainless Steel Needle Valve PN 400 F/FOmarNo ratings yet

- SY Rubber Disc Check ValveDocument2 pagesSY Rubber Disc Check ValvePhú Song LongNo ratings yet

- Eng BD Fta380Document11 pagesEng BD Fta380Gabriel PiticasNo ratings yet

- Zawor Iglicowy 488 Karta KatalogowaDocument6 pagesZawor Iglicowy 488 Karta KatalogowacracoviamaszynaNo ratings yet

- Ref.744 790 791 792 - enDocument21 pagesRef.744 790 791 792 - enMikeNo ratings yet

- Valvula de Retencion A Clapeta Oscilante Din pn16 dn50 300Document2 pagesValvula de Retencion A Clapeta Oscilante Din pn16 dn50 300JOHNNY CALERONo ratings yet

- Technical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 SWDocument5 pagesTechnical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 SWBenny 37No ratings yet

- Technical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 BSPDocument5 pagesTechnical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 BSPBenny 37No ratings yet

- Technical Datasheet Forged Carbon Steel A105n Gate Valve Trim16 Class800 NPTDocument5 pagesTechnical Datasheet Forged Carbon Steel A105n Gate Valve Trim16 Class800 NPTBenny 37No ratings yet

- R3215-005041 Appendix A 2.0 - Datasheet For Corrosion CouponDocument1 pageR3215-005041 Appendix A 2.0 - Datasheet For Corrosion Couponsaiful anwarNo ratings yet

- Technical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 NPTDocument5 pagesTechnical Datasheet Forged Carbon Steel A105n Gate Valve Trim8 Class800 NPTBenny 37No ratings yet

- Technical Datasheet Resilient Seat Gate Valve f5 Atc Epdm Acs Flanged pn10-16Document14 pagesTechnical Datasheet Resilient Seat Gate Valve f5 Atc Epdm Acs Flanged pn10-16Benny 37No ratings yet

- Technical Datasheet Resilient Seat Gate Valve f5 CTC Epdm Flanged pn10-16Document14 pagesTechnical Datasheet Resilient Seat Gate Valve f5 CTC Epdm Flanged pn10-16Benny 37No ratings yet

- Technical Datasheet Forged Carbon Steel A105n Gate Valve Trim16 Class800 SWDocument5 pagesTechnical Datasheet Forged Carbon Steel A105n Gate Valve Trim16 Class800 SWBenny 37No ratings yet

- Temp. Control ValveDocument7 pagesTemp. Control Valvesaurabh kumarNo ratings yet

- Spirax Sarco Fig 33Document2 pagesSpirax Sarco Fig 33Jacobus CalvelageNo ratings yet

- Piping Material Specification Rev0 PDF FreeDocument25 pagesPiping Material Specification Rev0 PDF FreeBenyamin heidariNo ratings yet

- Technical Datasheet 2 Pieces High Pressure Ball Valve Carbon Steel Female BSPDocument8 pagesTechnical Datasheet 2 Pieces High Pressure Ball Valve Carbon Steel Female BSPBenny 37No ratings yet

- Technical Datasheet 2 Pieces Forged Carbon Steel Ball Valve 800lbs Wedling EndsDocument11 pagesTechnical Datasheet 2 Pieces Forged Carbon Steel Ball Valve 800lbs Wedling EndsBenny 37No ratings yet

- ART 1450 PN16 Rev1Document1 pageART 1450 PN16 Rev1mohdmmedniyaz786No ratings yet

- Y Type StrainerDocument5 pagesY Type StrainerEHTESHAM NaveedNo ratings yet

- FK 21.63 (3) GB Wedge Gate Valves: Primary CharacteristicsDocument2 pagesFK 21.63 (3) GB Wedge Gate Valves: Primary CharacteristicsNguyen KhaNo ratings yet

- Fdez. Jove - Valvula 3 Vías - (SFERACO)Document12 pagesFdez. Jove - Valvula 3 Vías - (SFERACO)Pedro VarelaNo ratings yet

- 7.1 ΒΑΝΕΣ ΕΛ.ΕΜΦΡΑΞΗΣ ΦΥΛΛΑΔΙΟ PDFDocument19 pages7.1 ΒΑΝΕΣ ΕΛ.ΕΜΦΡΑΞΗΣ ΦΥΛΛΑΔΙΟ PDFAthanasoulis KostasNo ratings yet

- TUV (Ferrite Count)Document5 pagesTUV (Ferrite Count)AMAHAS ENGINEERINGNo ratings yet

- SY Y StranerDocument2 pagesSY Y StranerPhú Song LongNo ratings yet

- 1 Gala Ci Gate Valve Resilient Seated Nrs NRGV 3243Document1 page1 Gala Ci Gate Valve Resilient Seated Nrs NRGV 3243Non Etabas GadnatamNo ratings yet

- 170 172 176 RegadaDocument8 pages170 172 176 RegadaOreavu BuzauNo ratings yet

- Extended Diaphragm SealDocument2 pagesExtended Diaphragm SealShankar PediredlaNo ratings yet

- VA1-BSWS-00100-M-M3-SPC-0011 Rev B Piping Material%2Document7 pagesVA1-BSWS-00100-M-M3-SPC-0011 Rev B Piping Material%2Tam Huynh ThanhNo ratings yet

- 5SV9FA30: Operating DataDocument4 pages5SV9FA30: Operating DataJehana NaolNo ratings yet

- Vdocuments - MX Rubber Expansion Joint Teguflex P Red Rubber Expansion Joint Teguflex PDocument12 pagesVdocuments - MX Rubber Expansion Joint Teguflex P Red Rubber Expansion Joint Teguflex PmohamedNo ratings yet

- Technical Datasheet 2 Pieces Forged Carbon Steel Ball Valve 800lbsDocument7 pagesTechnical Datasheet 2 Pieces Forged Carbon Steel Ball Valve 800lbsBenny 37No ratings yet

- TLDD-2016-2AAG-D06-0001 - Code 2Document5 pagesTLDD-2016-2AAG-D06-0001 - Code 2Cao Huu Tung100% (1)

- Technical Datasheet 2 Pieces Ball Valve Stainless Steel Dry Cleaned Oxygen BSPDocument6 pagesTechnical Datasheet 2 Pieces Ball Valve Stainless Steel Dry Cleaned Oxygen BSPBenny 37No ratings yet

- Wafer 150Document1 pageWafer 150torobelkaNo ratings yet

- Klinger Ball Valve KHCDocument4 pagesKlinger Ball Valve KHCFood andfoodNo ratings yet

- Technical Datasheet Gas Brass All Valve BSP NF RobgazDocument5 pagesTechnical Datasheet Gas Brass All Valve BSP NF RobgazBenny 37No ratings yet

- Fig - 33 TI S60 03 ENDocument5 pagesFig - 33 TI S60 03 ENAditomo PutrantoNo ratings yet

- Eng BD Fta301Document9 pagesEng BD Fta301Lazar LilaNo ratings yet

- Swing Check DrawDocument1 pageSwing Check DrawPriyanka rajpurohitNo ratings yet

- Technical Datasheet 2 Pieces Forged Stainless Steel Ball Valve 800lbsDocument7 pagesTechnical Datasheet 2 Pieces Forged Stainless Steel Ball Valve 800lbsBenny 37No ratings yet

- Eng BD Fta178Document9 pagesEng BD Fta178Monica ZlatiNo ratings yet

- FlowconME Valves Catalogue 14Document1 pageFlowconME Valves Catalogue 14mohansafNo ratings yet

- BOQ For Pipe Fittings For Purified Water PDFDocument1 pageBOQ For Pipe Fittings For Purified Water PDFsppatilNo ratings yet

- 783 784 785 786Document8 pages783 784 785 786lesonspkNo ratings yet

- Technical Datasheet 2 Pieces Ball Valve Stainless Steel Male Male BSPDocument6 pagesTechnical Datasheet 2 Pieces Ball Valve Stainless Steel Male Male BSPBenny 37No ratings yet

- XXXX-DS-PI-001-Rev.00-GATE VALVE DATASHEETDocument8 pagesXXXX-DS-PI-001-Rev.00-GATE VALVE DATASHEETDương HoàngNo ratings yet

- A101747A Item 13 Deck HeadDocument8 pagesA101747A Item 13 Deck HeadВячеслав ГоряшинNo ratings yet

- Swing Check Valve Rubber DiscDocument2 pagesSwing Check Valve Rubber DiscsathishNo ratings yet

- 11 IM 240ANE HC Parts ListDocument38 pages11 IM 240ANE HC Parts ListBhavana ChaudharyNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Pump GMBrochureDocument4 pagesPump GMBrochurearas aliNo ratings yet

- PumpROYTRONICP BrochureDocument2 pagesPumpROYTRONICP Brochurearas aliNo ratings yet

- LMIB9 SeriesDocument2 pagesLMIB9 Seriesaras aliNo ratings yet

- Adaptor UnionDocument1 pageAdaptor Unionaras aliNo ratings yet

- Datasheet Rigid CouplingDocument6 pagesDatasheet Rigid Couplingaras aliNo ratings yet

- Static MixerDocument1 pageStatic Mixeraras aliNo ratings yet

- Trip Simple Alarm Simple Name NoDocument1 pageTrip Simple Alarm Simple Name Noaras aliNo ratings yet

- Walworth - Swing Check Valve - 4in 5341RF UT WCBDocument27 pagesWalworth - Swing Check Valve - 4in 5341RF UT WCBRahmat KDPNo ratings yet

- +pavement DesgnDocument574 pages+pavement DesgnCarlos Roberto Torres75% (4)

- Proofex GP PDFDocument2 pagesProofex GP PDFmilanbrasinaNo ratings yet

- ACIL ProfileDocument16 pagesACIL ProfileRadheshyam KushwahaNo ratings yet

- Mabey Propping and Jacking Brochure WebDocument27 pagesMabey Propping and Jacking Brochure WebezzularabNo ratings yet

- Milton Roy Metering Pumps PL1999Document4 pagesMilton Roy Metering Pumps PL1999Alfredo Anzures EearnNo ratings yet

- 313F L GC: Hydraulic ExcavatorDocument10 pages313F L GC: Hydraulic ExcavatorAntónio Pedro TavaresNo ratings yet

- Za Sans 204 2011 PDFDocument67 pagesZa Sans 204 2011 PDFbirolmedNo ratings yet

- Calcareous Fly Ash in Hydraulic Road Binders - Long Term Observation On Existing Roads Versus Laboratory TestDocument12 pagesCalcareous Fly Ash in Hydraulic Road Binders - Long Term Observation On Existing Roads Versus Laboratory TestDimitrios MavromatidisNo ratings yet

- Design of Piping SupportsDocument15 pagesDesign of Piping SupportsPedro Luis Choque MamaniNo ratings yet

- Epcon C8: Steel Reinforcement Fixings For Reinforced ConcreteDocument3 pagesEpcon C8: Steel Reinforcement Fixings For Reinforced ConcreteAhmed Samir SalimNo ratings yet

- Procedure WrappingDocument6 pagesProcedure Wrappingyogacruise100% (1)

- Refrieration Unit Lab ReportDocument29 pagesRefrieration Unit Lab ReportNor Elina Ahmad100% (9)

- Moisture Content Test: Tugas AkhirDocument2 pagesMoisture Content Test: Tugas AkhirRajinda BintangNo ratings yet

- Feasible Foundation SystemDocument4 pagesFeasible Foundation SystemAKELLA RAMPRASADNo ratings yet

- Differientiation Through The Weave PU Hoses From 3 Ply PU HosesDocument9 pagesDifferientiation Through The Weave PU Hoses From 3 Ply PU HosesAaron Homing NiNo ratings yet

- Civil Engennering - CurriculumDocument2 pagesCivil Engennering - CurriculumLuiz Fernando de CaprioNo ratings yet

- RW PDFDocument6 pagesRW PDFnbharath1988No ratings yet

- Steel Structure Bolted Connections DesignDocument4 pagesSteel Structure Bolted Connections Designramu karriNo ratings yet

- Planning, Analysis and Design of (C+G+7) Storey RCC Framed Residential Building Using Staad Pro. PaperDocument2 pagesPlanning, Analysis and Design of (C+G+7) Storey RCC Framed Residential Building Using Staad Pro. Paperabdul kareemNo ratings yet

- BINDA 2021 - ExportDocument20 pagesBINDA 2021 - ExportGilles BrunengoNo ratings yet

- Equitone Uaim Ianuarie 2023Document58 pagesEquitone Uaim Ianuarie 2023Hustiuc RomeoNo ratings yet

- Peter Culley, John Pascoe-Sports Facilities and Technologies-Routledge (2009) PDFDocument289 pagesPeter Culley, John Pascoe-Sports Facilities and Technologies-Routledge (2009) PDFMehdi Bostan Shirin100% (1)

- ASTM Standards: Range of Products & Material GradeDocument1 pageASTM Standards: Range of Products & Material Gradeeko kusumoNo ratings yet

- City of Oceanside 2013 PDP SWQMP Template-Version Feb 16 2016Document77 pagesCity of Oceanside 2013 PDP SWQMP Template-Version Feb 16 2016Sean CrossNo ratings yet

- FRP New Products in VesselDocument4 pagesFRP New Products in VesselA.Subin DasNo ratings yet

- Supporting Doc For 210.19 (A) (5) - NEC 250.4 (A) (5) Et AlDocument1 pageSupporting Doc For 210.19 (A) (5) - NEC 250.4 (A) (5) Et AlPaul KeleherNo ratings yet

- 281 FFE MaintenaceDocument11 pages281 FFE MaintenaceNeelakantan SankaranarayananNo ratings yet

- Grounding and BondingDocument12 pagesGrounding and BondingGia Minh Tieu Tu100% (1)

- DEPO Standard Mandrini (20 - 11 - 2015) PDFDocument56 pagesDEPO Standard Mandrini (20 - 11 - 2015) PDFPeroni FamigliaNo ratings yet