Professional Documents

Culture Documents

Sgebste1 21

Uploaded by

Ronnie1478Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sgebste1 21

Uploaded by

Ronnie1478Copyright:

Available Formats

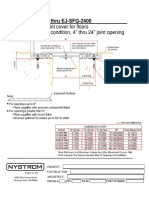

Bevel top surface to TABLE OF END BEARING DESIGNS

2" Sole PL

1 match beam grade

L Brg

Applicable to EE bearings only. 6

Neoprene Pad Sole Plate Flange Width Reactions (Unfactored) Max

Sole plate length = 11"

2 H S T Expansion

Min DL can be reduced by the ratio of Bearing 1 2

at C

Max

Pad length = 9" 3 Width Length Width Length Min Max

(actual exp length/max exp length). Type Max DL Total Length 1

Elastomer Min DL

3

Locate "Bearing Type" identification here. layers in in in in in in in in in kip kip kip ft

4"

1

4 EE1 or EF1 15 9 25.5 11 5.5 20.0 3.49 10 15 59 115 144 250

Locate permanent mark here.

EE2 or EF2 18 9 28.5 11 5.5 23.0 3.49 10 18 71 148 185 250

5

H

Min Bearing Seat width, normal to girder,

EE3 or EF3 21 9 31.5 11 5.5 26.0 3.49 11 21 83 181 226 250

T

is "S" + 8".

4 4

6 EE4 or EF4 24 9 34.5 11 5.5 29.0 3.49 14 24 95 215 269 250

See span details for beam grade (slope)

4"

at bearing locations. EE5 or EF5 27 9 37.5 11 5.5 32.0 3.49 17 27 106 249 312 250

8"

1

kind is m ade by TxDOT for any purpose whatsoever. TxDOT assum es no responsibility for the conversion

3

C

L Brg EE6 or EF6 30 9 40.5 11 5.5 35.0 3.49 20 30 118 284 355 250

6 at

7 ~ 0.105" thick

. No warranty of any

steel laminates

EE7 or EF7 32 9 42.5 11 5.5 37.0 3.49 22 32 126 307 384 250

EE8 or EF8 34 9 44.5 11 5.5 39.0 3.49 24 34 134 331 414 250

TYPE EE & EF

of this standard to other form ats or for incorrect results or dam ages resulting from its use.

Edge of brg seat 5

EE9 or EF9 36 9 46.5 11 5.5 41.0 3.49 26 36 142 355 443 250

Sole plate length LAMINATED ELASTOMERIC

3

1

2" Min 2 8" Dia Holes, BEARING DETAIL

EF brgs

(50 Durometer) (Vulcanize sole plate to elastomer)

Texas Engineering Practice Act"

Showing EF Bearing

L Cap,

face of

MATERIAL NOTES:

backwall

Fixed)

Provide anchor bolts conforming to ASTM F1554 Grade 105

or stem Sole plate width

C or ASTM A193 Grade B7. Provide nuts conforming to

L Brg

ASTM A563 Grade DH, heavy hex or A194 Grade 2H, heavy

(

hex. Provide washers conforming to ASTM F436. Provide pipe

1

4" C sleeves conforming to the requirements of ASTM A53 Grade B

C

L Girder L Cap,

Typ

Flange width

or A 500 Grade B. Hot-dip galvanize all anchor bolts (exposed

1 face of

4" end plus 6" Min), nuts not embedded in concrete, and pipe

backwall Heavy hex nut

sleeves as per Item 445, "Galvanizing".

or stem and washer

The use of this standard is governed by the "

For painted bridges, provide steel for sole plates conforming

C to ASTM A36 or A588. For unpainted (weathering) bridges,

L Brg

Proj

8"

Showing EE Bearing

M in

provide steel for sole plates conforming to ASTM A588.

Top of

brg seat

Expansion)

GENERAL NOTES:

The bearings shown on this standard are intended for use

with continuous and simple span rolled beams and plate

C

L Girder girders. None of the bearings shown are designed to resist

H

-3"

Em bed

1 uplift.

M in

1 1 2" Dia

1'

Face of cap 1 2" Dia See span details for bearing type and location.

Pad width 3

or corbel Anchor x 5 4" Std The bearing fabricator is required to develop a bearing

L Brg

bolts pipe sleeve layout which identifies location and orientation of all bearings.

Permanently mark each bearing in accordance with the bearing

at C

layout. A copy of the bearing layout is to be provided to the

Edge of 3 3 Template Engineer.

2 8" x 4 4" Slots,

brg seat 5

DISCLAIM ER:

1 Submit shop drawings for approval. Dimension sole plates

(PL 4 x 4)

EE brgs 1

2" S Heavy hex nut, to the nearest 16" based on required thickness at centerline

Pad length

tack weld to of bearing and slope of the girder in the finished structure.

(Typ)

template Thickness tolerance variation from the shop drawings is

See Span details

1

16" +/-, except the variation from a plane parallel to the

for dimension

1

theoretical top surface can not exceed 16" total.

PLAN FRONT ELEVATION SIDE ELEVATION Install anchor bolt nuts finger-tight or loosely snug.

Pipe sleeves, washers and nuts

not shown for clarity

END FIXED (EF) AND EXPANSION (EE) BEARINGS 7

Form hole with either plastic duct meeting the All bearings on this standard require

Paid for at unit price bid for "Elastomeric Bearing" as per Item 434. requirements of Item 426.2.2 or galvanized wood float bearing seat surfaces that

corrugated metal post-tensioning duct. Do not are clean and free of all loose

use PVC or other smooth plastic or steel duct. material before placement of bearings.

Do not drill hole.

If not casting bearing seat integral with cap,

ensure minimum anchor bolt projection will be 8

Fill void with a pre-qualified grout conforming to These bearings are not intended for

present after bearing seat construction.

DMS-4675 and capable of 4,000 psi compressive use with bridges over 100 ft wide.

strength. Void may also be filled with epoxy grout The anchor bolts are not designed to

Use upper template (same size as lower

using Type VIII epoxy conforming to DMS-6100. restrain temperature-induced lateral

template) and provide two nuts as

Top of Clean holes before filling. movement.

shown to hold template in place. Provide fully-threaded rod.

brg seat

Size is detailed elsewhere.

Temporary

C

elsewhere

M in proj

steel template L Brg

detailed

Slope to drain

SHEET 1 OF 3

Bridge

Top of cap

Division

Standard

M in em bed

elsewhere

Double nuts may

detailed

be used in lieu Form hole 7 ELASTOMERIC

of tack welding Permanent

nut to lower steel template

BEARING DETAILS

~

permanent Grout 8 After deck is cast remove gaps between sole

plate and girder prior to welding by using

template

steel shims or other methods approved by STEEL GIRDERS AND BEAMS

the Engineer. Maintain contact between the

Max Dia is

sole plate and the elastomeric pad. Do not

Bolt Dia plus 3" allow elastomeric bearing and sole plate to

loose contact with bearing seat.

ANCHOR BOLT SETTING DETAIL SGEB

OPTIONAL ANCHOR GIRDER TO SOLE PLATE WELD DETAIL FILE: sgebste1-21.dgn DN: TxDOT CK: TxDOT DW: TxDOT CK: TxDOT

Applies to all bearings on this standard. Verify and correct,

C TxDOT April 2019 CONT SECT JOB HIGHWAY

if necessary, anchor bolt location immediately after concrete BOLT SETTING DETAIL Applies to all end bearings on this standard. Small gaps between

REVISIONS

DATE:

placement, before initial set. girders and sole plates are anticipated under steel dead load only.

FILE:

12-21: Updated note 11.

Applies to all bearings on this standard. DIST COUNTY SHEET NO.

TABLE OF INTERIOR BEARING DESIGNS

Neoprene Pad Sole Plate Flange Width Reactions (Unfactored) Max

2

Min DL can be reduced by the ratio of Bearing H S T Expansion

9 2 Max

(actual exp length/max exp length). Width Length Width Length Min Max Length 9

Type Min DL Max DL Total

3

Locate "Bearing Type" identification here. in in in in in in in in in kip kip kip ft

4 E1 or F1 15 10 27.0 12 5.1 20.5 3.09 10 15 66 180 225 206

Locate permanent mark here.

5 E2 or F2 18 10 30.0 12 5.1 23.5 3.09 10 18 79 216 270 206

Min Bearing Seat width, normal to girder,

is "S" + 8". E3 or F3 21 10 33.0 12 5.1 26.5 3.09 11 21 92 252 315 206

6 E4 or F4 24 14 38.5 16 6.4 30.5 4.45 12 24 147 403 504 321

See span details for beam grade (slope)

at bearing locations.

E5 or F5 27 14 41.5 16 6.4 33.5 4.45 15 27 165 454 567 321

kind is m ade by TxDOT for any purpose whatsoever. TxDOT assum es no responsibility for the conversion

9 E6 or F6 30 14 44.5 16 6.4 36.5 4.45 18 30 184 504 630 321

See Table of Anchor Applicable to E bearings only.

. No warranty of any

Bolt Dimensions for

Edge of E7 or F7 32 16 48.0 18 6.9 39.0 4.93 19 32 224 614 768 355

hole size Sole plate length

brg seat 5

E8 or F8 34 16 50.0 18 6.9 41.0 4.93 21 34 238 653 816 355

of this standard to other form ats or for incorrect results or dam ages resulting from its use.

E9 or F9 36 16 52.0 18 6.9 43.0 4.93 23 36 252 691 864 355

Face of

Texas Engineering Practice Act"

cap Sole plate width

C

C L Brg

Showing F Bearing

L Cap

Anchor bolt

M in Proj

Fixed)

1

4"

Typ Heavy hex nut

1

4" and washer

(

C C

L Brg L Girder

Flange W idth

The use of this standard is governed by the "

Top of

Showing E Bearing

Face of brg seat

cap

Expansion)

C

L Girder

Em bed

M in

H

Standard

Pad width

pipe sleeve

at � Brg

See Table of Anchor

Bolt Dimensions for Template

slotted hole size 1 1

(PL 4 x 4 2)

Heavy hex nut,

Edge of tack weld to

brg seat 5

DISCLAIM ER:

Pad length 1 template

2 4" S

(Typ)

PLAN FRONT ELEVATION SIDE ELEVATION

Pipe sleeves, washers and nuts

not shown for clarity

INTERIOR FIXED (F) AND EXPANSION (E) BEARINGS

Paid for at unit price bid for "Elastomeric Bearing" as per Item 434.

Bevel top surface to

match beam grade 6

Sole plate length TABLE OF ANCHOR BOLT DIMENSIONS

F4/E4 thru F6/E6

F7/E7 thru F9/E9

F1/E1 thru F3/E3

2" Sole PL

Pad length FOR TYPE E AND F BEARINGS

L Brg

Bearing Anchor Pipe Sleeve Sole Plate Anchor Bolt

0.105" thick

at C

3 Type Bolt Size Hole Size

steel laminates

Dia (Dia x Length) Embed Proj

4"

1

F1 thru F3 1

3 3 3 1'- 6" 8" SHEET 2 OF 3

4" 2" x 5 8" 2 4" Dia

F4 thru F6 1 1 5 1 2'- 0" 1

2 4" 2 2" x 6 8" 3 4" Dia 9 2" Bridge

H

Division

F7 thru F9 1 1 7 2'- 1" 1

2 2" 3" x 7 4" 3 8" Dia 10 2" Standard

T

4 4

E1 thru E3 3 3 3 1 1'- 6" 8"

1 4" 2" x 5 8" 2 4" x 4 2"

E4 thru E6 1 1 5 1 1 2'- 0" 1 ELASTOMERIC

8"

8"

4"

2 4" 2 2" x 6 8" 3 4" x 6 4" 9 2"

4"

3

1

1

C 1 1 7 1

L Brg E7 thru E9 2'- 1"

8 at

9 at

7 at

2 2" 3" x 7 4" 3 8" x 7" 10 2"

BEARING DETAILS

STEEL GIRDERS AND BEAMS

Elastomer

layers

TYPE E & F LAMINATED ELASTOMERIC BEARING DETAIL SGEB

FILE: sgebste1-21.dgn DN: TxDOT CK: TxDOT DW: TxDOT CK: TxDOT

(50 Durometer) (Vulcanize sole plate to elastomer)

C TxDOT April 2019 CONT SECT JOB HIGHWAY

REVISIONS

DATE:

FILE:

12-21: Updated note 11.

DIST COUNTY SHEET NO.

TABLE OF END SLIDING BEARING DESIGNS

Neoprene Pad Sole Plate Flange Width Reactions (Unfactored) Max

3 Locate "Bearing Type" identification here. Bearing H S T Expansion

Max

Width Length Width Length Min Max Length

4 Type Max DL Total

Locate permanent mark here.

in in in in in in in in in kip kip ft

5 Min bearing seat width, normal to girder,

is "S" + 8". ES1 15 9 25.5 17 5.5 20.0 2.65 10 15 108 203 500

6 ES2 18 9 28.5 17 5.5 23.0 2.65 10 18 130 243 500

See span details for beam grade (slope)

at bearing locations. ES3 21 9 31.5 17 5.5 26.0 2.65 11 21 151 284 500

Sole plate length 1'-5" 10 Bond PTFE to 1 " plate with an approved adhesive. ES4 24 9 34.5 17 5.5 29.0 2.65 14 24 173 324 500

2

3 1 3

4" 1'-3 2" 4" ES5 27 9 37.5 17 5.5 32.0 2.65 17 27 194 365 500

11 Provide steel for 1 " plate conforming to ASTM A36.

kind is m ade by TxDOT for any purpose whatsoever. TxDOT assum es no responsibility for the conversion

2

Stainless steel ES6 30 9 40.5 17 5.5 35.0 2.65 20 30 216 405 500

Vulcanize plate to elastomer. Paint plate (in the

. No warranty of any

1

2" Min Edge of shop) with System III-B in accordance with Item 446. ES7 32 9 42.5 17 5.5 37.0 2.65 22 32 230 432 500

stainless No paint is permitted in recess or on PTFE.

ES8 34 9 44.5 17 5.5 39.0 2.65 24 34 245 459 500

steel

of this standard to other form ats or for incorrect results or dam ages resulting from its use.

3 1

2 8" x 7 2" Slots

C ES9 36 9 46.5 17 5.5 41.0 2.65 26 36 259 486 500

L Cap,

face of

backwall

or stem

Texas Engineering Practice Act"

4"

Sole plate width

C

3

L Brg

4

1 See

4"

C Detail "A"

Flange width

L Girder Typ

stainless

C

Edge of

1 L Cap, Heavy hex nut

4"

face of bkwl and washer

steel

or stem

Proj

8"

M in

Top of

The use of this standard is governed by the "

C

L Brg Face of cap

brg seat

or corbel

C

L Girder

-3"

Em bed

H

M in

1'

1

1 Pad width 1 2" Dia

1 2" Dia

L Brg

3

x 5 4" Std

Anchor

pipe sleeve

4"

bolts

at C

3

Template

4

1

(PL 4 x 4)

Edge of Pad length

2" S Heavy hex nut,

brg seat

tack weld to

(Typ) 5 (Typ)

DISCLAIM ER:

template

See Span details

for dimension

PLAN FRONT ELEVATION SIDE ELEVATION

Pipe sleeves, washers and nuts

not shown for clarity

END SLIDING (ES) EXPANSION BEARINGS

Paid for at unit price bid for "Sliding Elastomeric Bearing" as per Item 434.

1"

Bevel top surface to

match beam grade Edge of PTFE Edge of

6

Sole plate length = 17" stainless

2" Sole PL

steel

L Brg

Pad length = 9"

Sole plate

Stainless

(2" thick at C

at C

10 3 L Brg)

16"

steel

1

11 1 4" PTFE 1

2" Typ 4" PTFE sheet,

3

2" PL

1

recessed 8" in

8"

1

steel 2" PL 10

~

1

3

16" Stainless steel, SHEET 3 OF 3

8"

welded to sole PL

1

Bridge

H

Division

1

8" Bevel, all around Standard

T

4 4

1 ELASTOMERIC

2"Steel PL

4"

8"

vulcanized to pad 11

BEARING DETAILS

1

C

L Brg

5 at

5 ~ 0.105" thick

steel laminates

Pad

STEEL GIRDERS AND BEAMS

Elastomer

layers 1

2"

TYPE ES ELASTOMERIC BEARING DETAIL

Typ SGEB

(70 Durometer)

FILE: sgebste1-21.dgn DN: TxDOT CK: TxDOT DW: TxDOT CK: TxDOT

C TxDOT April 2019 CONT SECT JOB HIGHWAY

DETAIL "A" REVISIONS

DATE:

FILE:

12-21: Updated note 11.

DIST COUNTY SHEET NO.

You might also like

- Instant Assessments for Data Tracking, Grade 1: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: MathFrom EverandInstant Assessments for Data Tracking, Grade 1: MathRating: 4 out of 5 stars4/5 (1)

- Instant Assessments for Data Tracking, Grade 4: MathFrom EverandInstant Assessments for Data Tracking, Grade 4: MathRating: 5 out of 5 stars5/5 (2)

- Instant Assessments for Data Tracking, Grade 5: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 5: Language ArtsNo ratings yet

- Ready to Go Guided Reading: Synthesize, Grades 3 - 4From EverandReady to Go Guided Reading: Synthesize, Grades 3 - 4Rating: 5 out of 5 stars5/5 (1)

- Ready to Go Guided Reading: Determine Importance, Grades 3 - 4From EverandReady to Go Guided Reading: Determine Importance, Grades 3 - 4No ratings yet

- QSS2 Jeg CW RF DR M 3720 D4.C02Document1 pageQSS2 Jeg CW RF DR M 3720 D4.C02Nideesh RobertNo ratings yet

- Instant Assessments for Data Tracking, Grade 2: MathFrom EverandInstant Assessments for Data Tracking, Grade 2: MathNo ratings yet

- Ready to Go Guided Reading: Question, Grades 5 - 6From EverandReady to Go Guided Reading: Question, Grades 5 - 6Rating: 5 out of 5 stars5/5 (1)

- 03 120000 4800000522 Amt Elv DRG 100003Document1 page03 120000 4800000522 Amt Elv DRG 100003Mosab DowaNo ratings yet

- 03 12000 48000441 Boc Inf DRG 000011 - 02Document1 page03 12000 48000441 Boc Inf DRG 000011 - 02Yasir Nisar SyedNo ratings yet

- Instant Assessments for Data Tracking, Grade 3: MathFrom EverandInstant Assessments for Data Tracking, Grade 3: MathRating: 5 out of 5 stars5/5 (2)

- Logistic Warehouse - Drainage Schematic ServiceDocument1 pageLogistic Warehouse - Drainage Schematic ServiceWuillNo ratings yet

- Project #5Document8 pagesProject #5indyecraftsNo ratings yet

- Ready to Go Guided Reading: Determine Importance, Grades 1 - 2From EverandReady to Go Guided Reading: Determine Importance, Grades 1 - 2No ratings yet

- 03 12000 48000441 Boc Inf DRG 000010 - 02Document1 page03 12000 48000441 Boc Inf DRG 000010 - 02Yasir Nisar SyedNo ratings yet

- Supatá-ALC-ALT 1-COMBINADO-Versión 1 AutoCAD-Presentación4Document1 pageSupatá-ALC-ALT 1-COMBINADO-Versión 1 AutoCAD-Presentación4Andres Bonilla RNo ratings yet

- B Side: N7Tw - Power.Pcb 1LG4B10Y04300Document2 pagesB Side: N7Tw - Power.Pcb 1LG4B10Y04300Dario EzequielNo ratings yet

- Ready to Go Guided Reading: Determine Importance, Grades 5 - 6From EverandReady to Go Guided Reading: Determine Importance, Grades 5 - 6No ratings yet

- Igebsts1 17Document3 pagesIgebsts1 17hal9000_mark1No ratings yet

- Ready to Go Guided Reading: Synthesize, Grades 5 - 6From EverandReady to Go Guided Reading: Synthesize, Grades 5 - 6No ratings yet

- Os 2Document1 pageOs 2Doru DoruNo ratings yet

- Os 1Document1 pageOs 1Doru DoruNo ratings yet

- Tokim-Panompoana: AmpifitiaDocument4 pagesTokim-Panompoana: AmpifitiaHosea RandNo ratings yet

- Mz-04-00001-00-05-Ar-Aed-Dg-011011 (03) - Mzfw-Overall First Floor PlanDocument1 pageMz-04-00001-00-05-Ar-Aed-Dg-011011 (03) - Mzfw-Overall First Floor PlanAMR ABDALHNo ratings yet

- Pop-44860-006 Rev2 0Document2 pagesPop-44860-006 Rev2 0edward blancoNo ratings yet

- InteliLite AMF25 Wiring - MCCBSCTRL ModelDocument1 pageInteliLite AMF25 Wiring - MCCBSCTRL Modelsoufienne b.yahmed0% (1)

- DM Architectural Set 14.12.2023Document22 pagesDM Architectural Set 14.12.2023VinodNo ratings yet

- PartionDocument24 pagesPartionAhmad KhaanuNo ratings yet

- ASCEDesign Hazards ReportDocument3 pagesASCEDesign Hazards ReportRonnie1478No ratings yet

- Rebar 2Document1 pageRebar 2Ronnie1478No ratings yet

- Nystrom Expansion Joint System CatalogDocument48 pagesNystrom Expansion Joint System CatalogRonnie1478No ratings yet

- Csidetail User Csidetail: Client Project Designed NADocument1 pageCsidetail User Csidetail: Client Project Designed NARonnie1478No ratings yet

- Concrete Beam Rebar TableDocument1 pageConcrete Beam Rebar TableRonnie1478No ratings yet

- Pages From ASCE 7-05 Minimum Design Loads For Buildings and Other StrucDocument3 pagesPages From ASCE 7-05 Minimum Design Loads For Buildings and Other StrucRonnie1478No ratings yet

- Retaining WallDocument1 pageRetaining WallRonnie1478No ratings yet

- Rebar 5Document1 pageRebar 5Ronnie1478No ratings yet

- Topic15 2 PerformanceBasedEngineeringNotesDocument100 pagesTopic15 2 PerformanceBasedEngineeringNotestrabajosicNo ratings yet

- 2020 AISI Profile BookDocument28 pages2020 AISI Profile BookRonnie1478No ratings yet

- Nystrom EJS SFG-400-2400 SHPDRDocument1 pageNystrom EJS SFG-400-2400 SHPDRRonnie1478No ratings yet

- Aashto08 PDFDocument218 pagesAashto08 PDFJunior VeraNo ratings yet

- 2020 AISI Profile BookDocument28 pages2020 AISI Profile BookRonnie1478No ratings yet

- 04 - Concrete and Sustainable DevelopmentDocument8 pages04 - Concrete and Sustainable DevelopmentFahid AslamNo ratings yet

- DEWALT Technical Manual PDFDocument388 pagesDEWALT Technical Manual PDFRonnie1478100% (1)

- Powers Design Assist Real-Time Anchor Design Software V2.0 Free Download atDocument16 pagesPowers Design Assist Real-Time Anchor Design Software V2.0 Free Download atRonnie1478No ratings yet

- Lesson4 CustomComponents Precast PDFDocument28 pagesLesson4 CustomComponents Precast PDFKadutrisampaNo ratings yet

- Lewis Sign Technical PlanDocument1 pageLewis Sign Technical PlanRonnie1478No ratings yet

- Pole and Pier FoundationDocument38 pagesPole and Pier FoundationNalaka SanthajeewaNo ratings yet

- Krishtalevich AlexeyDocument128 pagesKrishtalevich AlexeyKiran Kumar KondapalliNo ratings yet

- Design of Reinforced Concrete Deep Beams PDFDocument5 pagesDesign of Reinforced Concrete Deep Beams PDFRonnie1478No ratings yet

- ETABS Tutorial: Analyzing and Designing a G+10 BuildingDocument81 pagesETABS Tutorial: Analyzing and Designing a G+10 BuildingJwanro Hawramy0% (1)

- Lewis Sign TechDocument1 pageLewis Sign TechRonnie1478No ratings yet

- Geotechnical Design Manual: Technical Services Branch Geo-Environmental SectionDocument95 pagesGeotechnical Design Manual: Technical Services Branch Geo-Environmental SectionRonnie1478No ratings yet

- 17502-Drawing Template PDFDocument6 pages17502-Drawing Template PDFveerash100No ratings yet

- 2016 SP CD Soils and Foundations 2 Slide PDFDocument60 pages2016 SP CD Soils and Foundations 2 Slide PDFRonnie1478No ratings yet

- TABLE R301.7 Allowable Deflection of Structural MembersDocument2 pagesTABLE R301.7 Allowable Deflection of Structural MembersovunctezerNo ratings yet

- Diseño de Conexiones PCIDocument102 pagesDiseño de Conexiones PCIj-balderasNo ratings yet

- Foundation Design Field Investigation RequirementsDocument20 pagesFoundation Design Field Investigation RequirementsJack TaylorNo ratings yet

- CTS Separation PolicyDocument7 pagesCTS Separation PolicyshaannivasNo ratings yet

- Nick & Sammy - Baby You Love Me (Bass Tab)Document6 pagesNick & Sammy - Baby You Love Me (Bass Tab)Martin MalenfantNo ratings yet

- P3am 7642 enDocument205 pagesP3am 7642 enAmine SEMRANINo ratings yet

- PE Week QuizDocument2 pagesPE Week QuizMarvin RetutalNo ratings yet

- Corporate Finance I - Lecture 7bDocument20 pagesCorporate Finance I - Lecture 7bSandra BempongNo ratings yet

- 2pat Fit - Module Week 1-8Document21 pages2pat Fit - Module Week 1-8Xxx100% (1)

- Module 9 PresentationDocument28 pagesModule 9 PresentationJerico CastilloNo ratings yet

- Shot List TemplateDocument2 pagesShot List Templateapi-525636391No ratings yet

- WK 4 Exam 2 Key ConceptsDocument24 pagesWK 4 Exam 2 Key ConceptsKrystel LahomNo ratings yet

- Barack ObamaDocument40 pagesBarack ObamaTimothy100% (2)

- Malbog Sulfuric Hot SpringDocument2 pagesMalbog Sulfuric Hot SpringMark-Christopher Roi Pelobello MontemayorNo ratings yet

- Wound Healing PhasesDocument27 pagesWound Healing PhasesAnil BasnetNo ratings yet

- PaliLossy PDFDocument408 pagesPaliLossy PDFtemp100% (2)

- WEG-WEMOB-totem-10008242920-guia-de-instalacao-ptDocument2 pagesWEG-WEMOB-totem-10008242920-guia-de-instalacao-ptalexcampos172No ratings yet

- Prabuddha Bharata June10Document58 pagesPrabuddha Bharata June10talk2ankitNo ratings yet

- John's Recommendation LetterDocument1 pageJohn's Recommendation LetterJohn StanleyNo ratings yet

- Picasso's Blue Period - WikipediaDocument24 pagesPicasso's Blue Period - WikipediaDinesh RajputNo ratings yet

- Ticket 3586662689Document2 pagesTicket 3586662689dev dNo ratings yet

- Tall Buildings Case Studies of John Hancock Centre and Sears TowerDocument75 pagesTall Buildings Case Studies of John Hancock Centre and Sears TowerShanikAromgottilNo ratings yet

- DLP Pe - 1 & 2Document1 pageDLP Pe - 1 & 2Dn AngelNo ratings yet

- The Norwegian Oil Experience:: Helge RyggvikDocument58 pagesThe Norwegian Oil Experience:: Helge RyggvikhiyeonNo ratings yet

- List of Students with Registration DetailsDocument69 pagesList of Students with Registration Detailsharshasg92No ratings yet

- PSMB Certified Trainer Curriculum StructureDocument19 pagesPSMB Certified Trainer Curriculum StructureFlankerSparrowNo ratings yet

- Mis11e ch03Document42 pagesMis11e ch03Vasudha RaoNo ratings yet

- Electronic Media. 2nd Edition PDFDocument319 pagesElectronic Media. 2nd Edition PDFAwobamise Ayodeji Olalekan100% (1)

- Qurratul Aynayn Translation AnalysisDocument15 pagesQurratul Aynayn Translation AnalysisAbdullah YusufNo ratings yet

- Preprints201701 0112 v1Document17 pagesPreprints201701 0112 v1vikasNo ratings yet

- Kami Export - Year 11 Spring Break RevisionDocument90 pagesKami Export - Year 11 Spring Break Revisionbkhmnrq4d6No ratings yet

- Describing LearnersDocument29 pagesDescribing LearnersSongül Kafa67% (3)

- Step by Step Automation Using Zerodha Api Python VersionDocument156 pagesStep by Step Automation Using Zerodha Api Python VersionRasel more100% (1)