Professional Documents

Culture Documents

Igebsts1 17

Uploaded by

hal9000_mark1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Igebsts1 17

Uploaded by

hal9000_mark1Copyright:

Available Formats

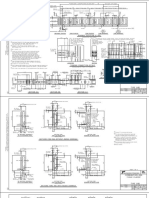

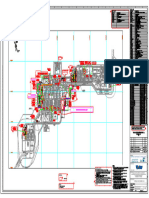

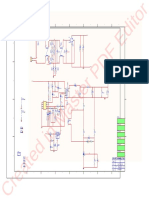

3" � Interior bent

1

1

1 C

L Inverted-T bent

� Girder dowels &

nominal � bearings 2

� Girder dowels &

Skew girder end 1

1' nominal � bearings 2

-0

"

3"

3"

1'

-0

kind is m ade by TxDOT for any purpose whatsoever. TxDOT assum es no responsibility for the conversion

Girder angle

"

� Girders

. No warranty of any

1-

'0" 1'

-0

Girder angle "

1 Girder angle

Girder angle

1 Dowel at doweled girder end [labeled (D) on Bridge

� Girders

of this standard to other form ats or for incorrect results or dam ages resulting from its use.

Layout]. Required for outside girder only or as

Girder angle 1'-0" ~ Parallel

shown on substructure details.

Face of stem to girder (Typ)

2 For purposes of computing bearing seat elevations,

nominal centerline of bearing must be defined as

Texas Engineering Practice Act"

shown. The actual center of bearing pad may vary

from this line.

3 For transition bents with backwall, girder and

Face of elastomeric bearings must receive the same

3" 3" abut bkwl treatment as shown for abutments.

� Girder dowels & 2 4 When angle exceeds 0°, one or both girders ends must

nominal � bearings

be skewed to maintain the clearance between girder

ends as shown in view.

3 5 See Table of Bearing Pad Dimensions for bearing size.

AT INVERTED-T BENT W/SKEW AT CONVENTIONAL INTERIOR BENT W/SKEW AT ABUTMENT W/SKEW

Girder end skew angles in Table not applicable for

The use of this standard is governed by the "

this situation. Table reflects girder conflicts of

� Interior bent this type on radial bents only.

� Inverted-T bent � Girder dowels & 2

nominal � bearings

� Girder dowels &

1'-0"

� Girder dowels & 2 nominal � bearings 2

1 1

nominal � bearings

3"

Face of stem Face of abut bkwl

DISCLAIM ER:

GENERAL NOTES:

These details accommodate skew angles up to 60°.

3" 3" 3" 3" Shop drawings for approval are required.

� Girders � Girders A bearing layout which identifies location and

1 1 orientation of all bearings must be developed by the

1'-0" 1'-0" 1'-0" 1'-0" bearing fabricator. Permanently mark each bearing in

1 accordance with the bearing layout. A copy of the

bearing layout is to be provided to the Engineer.

Cost of furnishing and installing elastomeric

bearings, including beveled and embedded steel plates,

must be included in unit price bid for "Prestressed

AT INVERTED-T BENT AT CONVENTIONAL INTERIOR BENT AT ABUTMENT 3 Concrete Girders".

GIRDER END DETAILS

Top edge of girder

Skew girder ends

.

3"

2"

Skew girder ends when

Top edge of girder Top edge of girder

distance between top

1

flanges is less than

3"

� Girders 3"

� Bent

HL93 LOADING SHEET 1 OF 3

Bisector of angle

between girders

Bridge

Division

Standard

ELASTOMERIC BEARING

AND GIRDER END DETAILS

� Bent PRESTR CONCRETE I-GIRDERS

� Bent 4

� Girder

� Girder

� Girder IGEB

FILE: igebsts1-17.dgn DN: AEE CK: JMH DW: JTR CK: TxDOT

Skew girder ends

� Girder

5 C TxDOT August 2017 CONT SECT JOB HIGHWAY

3"

REVISIONS

DATE:

FILE:

GIRDER CONFLICT DETAILS DIST COUNTY SHEET NO.

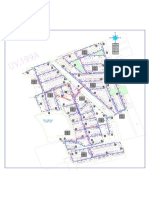

Length TABLE OF MINIMUM SUBSTRUCTURE DIMENSIONS 14 TABLE OF BEARING PAD DIMENSIONS

for Dowel

� 2" H ole

Abutments Int Bents Inv-T Bents

B"

Bearing Girder End Pad Clip

12 12 Girder Bent Girder Pad Size

"

"A" Type Skew Angle Dimensions

Type Face of Bkwl Overall Corbel

Type Type Range Lgth x Wdth

to Face of Cap Cap Width Width 13 "A" "B"

� 2" Hole 1

Diam eter

Tx28 thru Tx54 1'-9" 3'-6" 1'-10 2" G-1-"N" 0° thru 21° 8" x 21" --- ---

W idth

for Dowel 9

Tx62 & Tx70 2'-0" 4'-0" 2'-1

1 Tx28,Tx34, 1 1

2" G-2-"N" 21°+ thru 30° 8" x 21" 1 2" 2 2"

ABUTMENTS, Tx40,Tx46

1 1

INVERTED-T & Tx54 G-3-"N" 30°+ thru 45° 9" x 21" 4 2" 4 2"

L Girder

� Girder

AND G-4-"N" 45°+ thru 60° 15" Dia --- ---

& pad

& pad

TRANSITION

BENTS G-5-"N" 0° thru 21° 9" x 21" --- ---

B"

C

WITH Tx62 G-6-"N" 21°+ thru 30° 9" x 21" 1

1 1

2" 2 2"

"A"

"

12 BACKWALLS &

12 G-7-"N" 30°+ thru 45° 10" x 21" 4

1 1

2" 4 2"

4"

TOP

Tx70

1

1 1

G-8-"N" 45°+ thru 60° 10" x 21" 7 4" 4 4"

kind is m ade by TxDOT for any purpose whatsoever. TxDOT assum es no responsibility for the conversion

8 )

Elastom er thickness

N "

10

. No warranty of any

PLANS --- --- --- --- ---

Tx28,Tx34,

4"

CONVENTIONAL Tx40,Tx46 --- --- --- --- ---

INTERIOR

=

d at

INTERIOR

(

& Tx54

G-1-"N" 0° thru 60° 8" x 21" --- ---

BENTS

of this standard to other form ats or for incorrect results or dam ages resulting from its use.

Pad taper in inches

6 req'

Place 0.105" thick steel laminates Tx62 & Tx70 G-5-"N" 0° thru 60° 9" x 21" --- ---

parallel to the bottom surface of G-1-"N" 0° thru 18° 8" x 21" --- ---

CONVENTIONAL

the pad, except the top laminate(s)

INTERIOR Tx28,Tx34, G-2-"N" 18°+ thru 30° 8" x 21" 1

1 1

may be sloped to satisfy maximum 2" 2 2"

BENTS Tx40,Tx46

and minimum thickness criteria for G-9-"N" 30°+ thru 45° 8" x 21" 3" 3"

Texas Engineering Practice Act"

WITH & Tx54

BOTT

tapered elastomeric top layers.

4"

1

SKEWED G-10-"N" 45°+ thru 60° 9" x 21" 6" 3 2"

1

11 GIRDER

G-5-"N" 0° thru 18° 9" x 21" --- ---

ENDS

8" M ax

4"

Bevel to match girder slope, Tx62

(GIRDER G-5-"N" 18°+ thru 30° 9" x 21" --- ---

3

5 percent Max 15 &

13 CONFLICTS) 1 1

2

Tx70 G-11-"N" 30°+ thru 45° 9" x 21" 1 2" 1 2"

1

3

Face of cap 16 3

1 2"

G-12-"N" 45°+ thru 60° 9" x 21" 3" 1 4"

M

in

6

7

11 Nominal � brg 2 2 For purposes of computing bearing seat elevations, nominal centerline of

C

L Pad & C

L girder

bearing must be defined as shown. The actual center of bearing pad may

Length or Diameter 16" M in

The use of this standard is governed by the "

vary from this line.

9

6

"

3" for inverted-T.

3

7 Place centerline pad as near nominal centerline bearing as possible between

ELEVATION

3

limits shown.

"

8 Girder end skew angle is equal to 90° minus the girder angle except at some

conflicting girders.

LAMINATED Face of inverted-T

stem or face of bkwl 9

ELASTOMERIC BEARING PAD Provide 2" dia hole only at locations required. See Substructure details

for location.

(50 DUROMETER)

10 See Table of Bearing Pad Dimensions for dimensions.

Girder end

1

"

skew angle 8

M

11 Maximum and minimum layer thicknesses shown are for elastomer only, on

DISCLAIM ER:

in

tapered layers.

12 Locate Permanent Mark here.

ROUND BEARINGS FOR

SKEWED GIRDER ENDS AT FACE OF 13 Indicate BEARING TYPE on all pads. For tapered pads, locate BEARING TYPE

on the high side. The Fabricator must include the value of "N" (amount of

INVERTED-T STEM OR FACE OF BKWL

1

C taper in 8" increments) in this mark.

L Interior bent,

Examples: N=0, (for 0" taper)

face of inverted-T

1

stem or face of bkwl N=1, (for 8" taper)

1 1 1 1

2" N=2, (for 4" taper)

1

6

Mi 7 M 2"

n in (etc.)

6

Nominal � brg 2 C

L Interior bent,

1

9" Face of cap Fabricated pad top surface slope must not vary from plan girder slope by

1 2"

7

M

face of inverted-T more than 0.0625" IN/IN.

3"

in

Ab ut stem or face of bkwl

C

L Brg pad s C

L Brg pad C

L Brg pad 7 Length or Dia

Inv-T

2" Min 14 Substructure dimensions must satisfy the minimums provided to accommodate

Face of cap Nominal � brg 2 Face of cap 9 L Pad & C

C L girder Nominal � brg 2 the elastomeric bearings shown on this standard.

" (Typ)

15 See sheet 3 of 3 for beveled plate use when slopes exceed 5 percent.

3

"

A

b 16 If girder end is skewed for a girder conflict at an interior bent and a

u

In ts beveled sole plate is required, use bearing type for abutments at this

v

7 - 7 location. Location of bearing centerline is to be set as for abutments

T

in this case.

Equal

Equal

C

L Interior bent

HL93 LOADING SHEET 2 OF 3

Bridge

Division

Standard

1

"

1" Girder end M 7

Girder end Girder end ELASTOMERIC BEARING

1

7 in M

"

skew angle 8 skew angle 8 skew angle 8

Min

in 7

AND GIRDER END DETAILS

9" 3" 9" 3" Varies with girder 9" 3"

PRESTR CONCRETE I-GIRDERS

Int bents Int bents end skew angle Int bents

SKEWED GIRDER ENDS SKEWED GIRDER ENDS

AT INT BENTS, FACE OF AT CONVENTIONAL IGEB

INVERTED-T STEM OR FACE OF BKWL INTERIOR BENTS 16 FILE: igebsts1-17.dgn DN: AEE CK: JMH DW: JTR CK: TxDOT

C TxDOT August 2017 CONT SECT JOB HIGHWAY

(NO GIRDER DOWELS)

REVISIONS

DATE:

FILE:

BEARING PAD PLACEMENT DIAGRAMS DIST COUNTY SHEET NO.

4" 4" 4" 4" 4" 4"

1 1 1

1 2" 1 2" 1 2" 1

1 1

Embedded plate, 2" thick

Embedded plate, 2" thick Embedded plate, 2" thick

Pad L + 3" Pad L + 3" 1'-6"

4"

4"

3

Beveled plate

3

Beveled plate

�

1

�

1

2" Dia studs 2" Dia studs

Beveled plate

Bearing pad

3

3

" 4"

4

Nominal Nominal

2"

� bearing � bearing

4"

C 3

4"

3

" (Typ) L 4" Dia screws

kind is m ade by TxDOT for any purpose whatsoever. TxDOT assum es no responsibility for the conversion

-7"

-0"

-0"

1

3

and caps

-6

. No warranty of any

-4

-1

1'

2'

2'

2'

3 4"

3 4"

2'

2'

Bearing

pad

of this standard to other form ats or for incorrect results or dam ages resulting from its use.

Bearing pad

Edge of

Edge of

girder

girder

� Girder and plates � Girder and plates

Texas Engineering Practice Act"

�

3

4" Dia

& slotted hole

screws and 17 17

1

1 caps 1 4 2" x 2"

4 2" x 2" Nominal 4 2" x 2"

Slotted hole 18

Slotted hole 18 � bearing Slotted hole 18

NORMAL GIRDER END SKEWED GIRDER END SKEWED GIRDER END

RECTANGULAR BEARING PAD CLIPPED RECTANGULAR BEARING PAD 15" DIA BEARING PAD

PLAN VIEW OF SOLE PLATE DETAILS

The use of this standard is governed by the "

Length

3" SOLE PLATE NOTES:

Bevelt

o matchgi

rdersl

ope Provide constant thickness elastomeric bearings with beveled and

Bevelto match

Typ

gi

rders lope 13

embedded steel sole plates in accordance with these details when

90° 16"

the girder slope exceeds 5 percent or if otherwise required in the

Surface against plans. Provide for all girders in the span.

8"

90° embedded plate 1

On the shop drawings, dimension sole plates to the nearest 16" based

1

17 Cut beveled and embedded plates to match on required thickness at centerline of bearing and slope of girder.

girder end skew. Adjust location of screw Thickness tolerance variation from the approved shop drawings is 116"+/-,

and stud as shown when necessary. except variation from a plane parallel to the theoretical top surface

� Brg 1" at

1

� Brg can not exceed 16" total. Bearing surface tolerances listed in

18 Slotted hole is required at doweled girder

See HOLE

Item 424 apply to embedded and beveled plates.

DETAIL end locations.

Steel plate must conform to ASTM A36, A572 Gr 50, or A709 Gr 36

or Gr 50. Hot dip galvanize both the embedded plate and beveled sole

DISCLAIM ER:

� 16"

13 plate after fabrication. Seal weld caps to embedded plate before

Dia holes,

countersunk, for 1 716" Bottom of galvanizing.

3 beveled When determining if relocation of screw holes and studs are necessary

4" dia screws

plate for skewed girder ends, minimum clearance from screw or stud centerline

to plate edge is 1.25".

SECTION HOLE DETAIL Tap threads in the embedded plate only. Drill and tap prior to

galvanizing.

3

4" Dia screws must be electroplated, socket flat head countersunk cap

screws conforming to ASTM F835. Electroplating must conform to

BEVELED PLATE DETAILS ASTM B633, SC 2, Type I. Provide screws long enough to maintain a

3

4"

minimum embedment into the embedded plate and galvanized cap. Provide

galvanized steel caps (16 ga Min) with a nominal 1" inside diameter and

1

deep enough to accommodate the screws, but not less than 2" deep or

deeper than 1".

Screw Spacing 3" 3" 2" 6" 6" 2"

Install beveled sole plates prior to shipping girders. Installed screw

heads must not protrude below the bottom of the beveled plate.

� Girder and plates

& slotted hole 18

1

4 2" x 2" Nominal 3 1

4" Dia screws and caps, 2" Dia x 2"

Slotted hole 18 � bearing

four required headed studs,

six required HL93 LOADING SHEET 3 OF 3

Level Bridge

brg seat Division

Standard

Embedded

2"

1

plate, 2" thick

ELASTOMERIC BEARING

Level AND GIRDER END DETAILS

brg seat

~ ~ PRESTR CONCRETE I-GIRDERS

Bearing pad Beveled Bearing pad

plate

IGEB

FILE: igebsts1-17.dgn DN: AEE CK: JMH DW: JTR CK: TxDOT

SIDE ELEVATION END ELEVATION

C TxDOT August 2017 CONT SECT JOB HIGHWAY

Showing normal girder end. REVISIONS

DATE:

FILE:

GIRDER DETAILS DIST COUNTY SHEET NO.

You might also like

- Bjork Oh So Quiet PDFDocument7 pagesBjork Oh So Quiet PDFkv792No ratings yet

- Asme A112.6.7-2001 PDFDocument16 pagesAsme A112.6.7-2001 PDFAmer AmeryNo ratings yet

- Design of ManholeDocument8 pagesDesign of ManholeCristian Bajado100% (2)

- Instant Assessments for Data Tracking, Grade 1: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNo ratings yet

- Untitled Extract Pages1Document1 pageUntitled Extract Pages1Moz KamalNo ratings yet

- Refrigeration and Air-Conditioning by C P Arora 3 EdDocument962 pagesRefrigeration and Air-Conditioning by C P Arora 3 EdDivyank Kumar75% (8)

- Diagrama Electrico 242BDocument4 pagesDiagrama Electrico 242Barmando_l_08100% (2)

- Bonding CompositesDocument12 pagesBonding CompositesAbyss Dweller100% (1)

- Competency Based Learning MaterialDocument75 pagesCompetency Based Learning MaterialCherry Gavanzo87% (23)

- 811 Brochure GrisgoldDocument20 pages811 Brochure GrisgoldEmerson RuizNo ratings yet

- Design Calculation C-Tech Basin Zone 4&5Document18 pagesDesign Calculation C-Tech Basin Zone 4&5navneet3bawaNo ratings yet

- Jubilee PreviewDocument1 pageJubilee PreviewAnonymous TKW6N0KSH0% (2)

- Centrifugal Pump Piping Design LayoutDocument21 pagesCentrifugal Pump Piping Design LayoutKavin KumarNo ratings yet

- Edited EIM - Module Grade 11Document7 pagesEdited EIM - Module Grade 11Julius MendozaNo ratings yet

- Grout Volume CalculationDocument3 pagesGrout Volume CalculationGEOLOGICSNo ratings yet

- Design of Trestle "TF1" and Beams AboveDocument8 pagesDesign of Trestle "TF1" and Beams AbovePartha Gangopadhyay100% (3)

- BG-QA-CL-304 - 10-13 Check List For HVACDocument5 pagesBG-QA-CL-304 - 10-13 Check List For HVACYousaf Richu100% (1)

- Multi Phase Flow BookDocument153 pagesMulti Phase Flow Bookagnotts09100% (2)

- (SILVA) Response of Standard Caltrans Pile-To-pile Cap Connections Under Simulated Seismic LoadsDocument375 pages(SILVA) Response of Standard Caltrans Pile-To-pile Cap Connections Under Simulated Seismic Loadshal9000_mark1No ratings yet

- Usp12 - 20160725 - Circuit Diagram of CTG 550 80PDocument1 pageUsp12 - 20160725 - Circuit Diagram of CTG 550 80PLeonelDrozdNo ratings yet

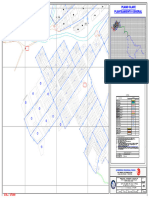

- PLANO CATASTRAL DEL PROYECTO-catasDocument1 pagePLANO CATASTRAL DEL PROYECTO-catasLeoncio RuizNo ratings yet

- Roadway Elevation of Rail: Pilaster Bent Pilaster BentDocument3 pagesRoadway Elevation of Rail: Pilaster Bent Pilaster BentgetnetNo ratings yet

- 11Document1 page11FabianoNo ratings yet

- TP4-SD-PH5-ME-PO-3605& 3711 To 3715 Rev-01-LINE-49Document1 pageTP4-SD-PH5-ME-PO-3605& 3711 To 3715 Rev-01-LINE-49Husen ZahranNo ratings yet

- Slow Blues in A (Quick Change)Document1 pageSlow Blues in A (Quick Change)LordPoseidonNo ratings yet

- Cco-U551-070743-090000-0003 R1Document1 pageCco-U551-070743-090000-0003 R1gregorio martinezNo ratings yet

- MDA800.PRO Schematic - DSP BoardDocument1 pageMDA800.PRO Schematic - DSP BoardSergey VissarionovNo ratings yet

- Temp Site FacilityDocument1 pageTemp Site FacilityImperialNo ratings yet

- Plano San Luis Gonzaga (Lotizacion y Manzaneo) Actual-ModelDocument1 pagePlano San Luis Gonzaga (Lotizacion y Manzaneo) Actual-ModelSAUL CHAVEZNo ratings yet

- 4.2 Plano de RedesDocument1 page4.2 Plano de Redeslucianocastillocolonna3No ratings yet

- Arquitectura Tipo BDocument1 pageArquitectura Tipo BMercy Carmen Pantoja RublosNo ratings yet

- BM1 X 973.941 Y 1068.308: Jl. Prabu RangkasariDocument1 pageBM1 X 973.941 Y 1068.308: Jl. Prabu Rangkasaripp banjaratmaNo ratings yet

- Untitled Extract Pages3Document1 pageUntitled Extract Pages3Moz KamalNo ratings yet

- BARANDocument1 pageBARANANS OFFICIALNo ratings yet

- Os 1Document1 pageOs 1Doru DoruNo ratings yet

- Os 2Document1 pageOs 2Doru DoruNo ratings yet

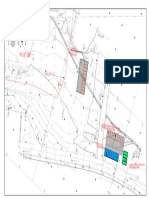

- Key Plan: LegendDocument1 pageKey Plan: LegendJoel MontoyaNo ratings yet

- Nte GR D: E-Bel2-56.2-3Document1 pageNte GR D: E-Bel2-56.2-3Prashant SanapNo ratings yet

- The Vintage New 02-09-11Document1 pageThe Vintage New 02-09-11kickerilloNo ratings yet

- Overall Plan 02-09-11Document1 pageOverall Plan 02-09-11kickerilloNo ratings yet

- Enlace Cable Peru - Entel-ModelDocument1 pageEnlace Cable Peru - Entel-ModelHubert Reynaldo Chang EscalanteNo ratings yet

- MA29Document1 pageMA29Kwun Hok ChongNo ratings yet

- Ubic - Loc 3DDocument1 pageUbic - Loc 3DRolan Yañez ParionaNo ratings yet

- Bingo LibrasDocument13 pagesBingo LibrasVanessa CarvalhoNo ratings yet

- He Lifted MeDocument2 pagesHe Lifted MexneuznwaodblynasrrNo ratings yet

- Urdu Notes - 2024Document71 pagesUrdu Notes - 2024MuqadusNo ratings yet

- Grieg Mountain KingDocument2 pagesGrieg Mountain KingManuel RuizNo ratings yet

- 03 12000 48000441 Boc Inf DRG 000011 - 02Document1 page03 12000 48000441 Boc Inf DRG 000011 - 02Yasir Nisar SyedNo ratings yet

- 07-H-501 - Diagrama de Sistema Hvac - 1 - Hvac System Diagram Rev.5 MarkupDocument1 page07-H-501 - Diagrama de Sistema Hvac - 1 - Hvac System Diagram Rev.5 MarkupSami DominguezNo ratings yet

- Rev 1. Revelstoke PDFDocument2 pagesRev 1. Revelstoke PDFLevi Leonardo Abayon JuniorNo ratings yet

- Tom Jobim: IntroduçãoDocument2 pagesTom Jobim: IntroduçãoPiano EducatoNo ratings yet

- Tarapoto BC ImprimirDocument1 pageTarapoto BC ImprimirROSSANANo ratings yet

- A B C D E: Planta Estructural Ne 3.80M ESCALA 1:40Document1 pageA B C D E: Planta Estructural Ne 3.80M ESCALA 1:40jpenalozaicNo ratings yet

- Mysteriss ConcertDocument3 pagesMysteriss Concertjspacejam01No ratings yet

- S7 Monthly As - Built 01-02-24Document9 pagesS7 Monthly As - Built 01-02-24Domie Neil Bucag SalasNo ratings yet

- San Francisco Bikeway Network Map: LegendDocument1 pageSan Francisco Bikeway Network Map: LegendfrazNo ratings yet

- Sector 03: Consultor Ubicación Proyecto: PlanoDocument1 pageSector 03: Consultor Ubicación Proyecto: PlanoeeeNo ratings yet

- ZTE - 3 - AC - 00059 - 0 ABD FSUN03D01 DMS18800 KEMANTREN AREA (1) MALANG RW13-Layout1Document1 pageZTE - 3 - AC - 00059 - 0 ABD FSUN03D01 DMS18800 KEMANTREN AREA (1) MALANG RW13-Layout1fajar prasetyoNo ratings yet

- XT2129-X - Moto g30 (Capri+) - SB - SchematicsDocument4 pagesXT2129-X - Moto g30 (Capri+) - SB - SchematicsFelipe de san anicetoNo ratings yet

- Exercicios para Flauta Doce ContraltoDocument34 pagesExercicios para Flauta Doce Contraltoclara piaoNo ratings yet

- 03 120000 4800000522 Amt Elv DRG 100003Document1 page03 120000 4800000522 Amt Elv DRG 100003Mosab DowaNo ratings yet

- AS-BUILT Pipe PlanPart-1Document1 pageAS-BUILT Pipe PlanPart-1Rodel MarataNo ratings yet

- Acoustic B450 B600H PDFDocument10 pagesAcoustic B450 B600H PDFgerardo20086854No ratings yet

- Limite de Frentes de TrabajosDocument1 pageLimite de Frentes de TrabajosJohann Nick Flores AparicioNo ratings yet

- Detail & Pot Rigit Pavement-Alur C - R3Document3 pagesDetail & Pot Rigit Pavement-Alur C - R3godek5No ratings yet

- Braamfontein CampusDocument1 pageBraamfontein CampusThabiso MathobelaNo ratings yet

- Untitled Extract Pages2Document1 pageUntitled Extract Pages2Moz KamalNo ratings yet

- SEPF 1850 13 PPL 0102 - Rev.T1Document1 pageSEPF 1850 13 PPL 0102 - Rev.T1Bimal DeyNo ratings yet

- YuyttjDocument7 pagesYuyttjyeider pinedaNo ratings yet

- SCZ439 ModelDocument1 pageSCZ439 ModelRussell Sanguino FloresNo ratings yet

- Mazurka in D Major KK Anh. Ia1 Frdric ChopinDocument1 pageMazurka in D Major KK Anh. Ia1 Frdric ChopinHong Anh LuongNo ratings yet

- Third Floor Isometric Sewer Line Layout Plan: For PermitDocument1 pageThird Floor Isometric Sewer Line Layout Plan: For PermitChristine Joyce RoseteNo ratings yet

- Priti NartanDocument37 pagesPriti NartanDeepak BhosaleNo ratings yet

- DEEPSOIL User Manual v7 PDFDocument170 pagesDEEPSOIL User Manual v7 PDFsebastian gajardoNo ratings yet

- Bbstde 08Document1 pageBbstde 08hal9000_mark1No ratings yet

- Sejmste1 19Document1 pageSejmste1 19hal9000_mark1No ratings yet

- Aig55sts 17Document2 pagesAig55sts 17hal9000_mark1No ratings yet

- (PECKER) Seismic Analyses and Design of Foundation SSIDocument10 pages(PECKER) Seismic Analyses and Design of Foundation SSIhal9000_mark1No ratings yet

- (GOMEZ-NOVELL) Fault System-Based PSHA of A Moderate Seismicity Region - The Eastern Betics Shear ZoneDocument25 pages(GOMEZ-NOVELL) Fault System-Based PSHA of A Moderate Seismicity Region - The Eastern Betics Shear Zonehal9000_mark1No ratings yet

- (SILVA) Response of The Coronado Bay Bridge Pile-To-Pile Cap Connections Under Simulated Seismic LoadsDocument362 pages(SILVA) Response of The Coronado Bay Bridge Pile-To-Pile Cap Connections Under Simulated Seismic Loadshal9000_mark1No ratings yet

- (AISC) Steel Span LengthDocument10 pages(AISC) Steel Span Lengthhal9000_mark1No ratings yet

- 14wcee HV PDFDocument10 pages14wcee HV PDFDamsiarNo ratings yet

- (GINER) Structural Analysis of Earthquake Archaelogical Effects - Baelo Claudia ExamplesDocument130 pages(GINER) Structural Analysis of Earthquake Archaelogical Effects - Baelo Claudia Exampleshal9000_mark1No ratings yet

- Kinematic SSI Effects on Foundation Input MotionsDocument226 pagesKinematic SSI Effects on Foundation Input Motionshal9000_mark1No ratings yet

- (KIKUCHI) An Analytical Hysteresis Model For Elastomeric Seismic Isolation BearingsDocument17 pages(KIKUCHI) An Analytical Hysteresis Model For Elastomeric Seismic Isolation Bearingshal9000_mark1No ratings yet

- (SILVA) Fuentes Históricas y Geológicas de Los Terremotos Antiguos en La Península IbéricaDocument22 pages(SILVA) Fuentes Históricas y Geológicas de Los Terremotos Antiguos en La Península Ibéricahal9000_mark1No ratings yet

- (KELLY) The Role of Damping in Seismic IsolationDocument22 pages(KELLY) The Role of Damping in Seismic Isolationhal9000_mark1No ratings yet

- (JRC) Field Manual For Post-Earthquake Damage and Safety Assessment and Short Term Countermeasures (AeDES)Document100 pages(JRC) Field Manual For Post-Earthquake Damage and Safety Assessment and Short Term Countermeasures (AeDES)hal9000_mark1No ratings yet

- (ABRAHAMSON) Why Do Modern Probabilistic Seismic-Hazard Analyses Often Lead To Increased Hazard EstimatesDocument11 pages(ABRAHAMSON) Why Do Modern Probabilistic Seismic-Hazard Analyses Often Lead To Increased Hazard Estimateshal9000_mark1No ratings yet

- (KIKUCHI) Simulation Analysis For The Ultimate Behavior of Full-Scale Lead-Rubber Seismic Isolation BearingsDocument10 pages(KIKUCHI) Simulation Analysis For The Ultimate Behavior of Full-Scale Lead-Rubber Seismic Isolation Bearingshal9000_mark1No ratings yet

- (EADS) Assessment of The Probability of Collapse of Buildings During EarthquakesDocument12 pages(EADS) Assessment of The Probability of Collapse of Buildings During Earthquakeshal9000_mark1No ratings yet

- (FURINGHETTI) Investigation of The Consequences of Mounting Laying Defects For Curved Surface Slider Devices Under General Seismic Input PDFDocument21 pages(FURINGHETTI) Investigation of The Consequences of Mounting Laying Defects For Curved Surface Slider Devices Under General Seismic Input PDFhal9000_mark1No ratings yet

- (KELLY) Dynamic and Failure Characterisitcs of Bridgestone Isolation BearingsDocument81 pages(KELLY) Dynamic and Failure Characterisitcs of Bridgestone Isolation Bearingshal9000_mark1No ratings yet

- Abrahamson 2006Document17 pagesAbrahamson 2006Francolt41No ratings yet

- Bazurro and Cornell Disaggregation of Seismic HazardDocument20 pagesBazurro and Cornell Disaggregation of Seismic HazardKarim AljawhariNo ratings yet

- Adapting Earthquake Actions in EurocodeDocument17 pagesAdapting Earthquake Actions in EurocodeChee Soon LeeNo ratings yet

- (CZOP) Fluid-Structure Simulation of A Valve System Used in Hydraulic DampersDocument9 pages(CZOP) Fluid-Structure Simulation of A Valve System Used in Hydraulic Dampershal9000_mark1No ratings yet

- (ABRAHAMSON) Probability and Uncertainty in Seismic Hazard AnalysisDocument5 pages(ABRAHAMSON) Probability and Uncertainty in Seismic Hazard Analysishal9000_mark1No ratings yet

- (DURFEE) Fluid Power System DynamicsDocument54 pages(DURFEE) Fluid Power System Dynamicshal9000_mark1No ratings yet

- Heating Phenomena at The Sliding Interface of Double Curved Surface Sliders and Resulting Effects On The Hysteretic BehaviorDocument7 pagesHeating Phenomena at The Sliding Interface of Double Curved Surface Sliders and Resulting Effects On The Hysteretic Behaviorhal9000_mark1No ratings yet

- (DWAIRI) Implememtation of Inelastic Displacement Patterns in Direct Displacement-Based Design of Continuous Bridge StructuresDocument32 pages(DWAIRI) Implememtation of Inelastic Displacement Patterns in Direct Displacement-Based Design of Continuous Bridge Structureshal9000_mark1No ratings yet

- Fatigue Crack Growth in The Heat Affected Zone of A Hydraulic Turbine Runner WeldDocument8 pagesFatigue Crack Growth in The Heat Affected Zone of A Hydraulic Turbine Runner WeldJuan Enrique GrassoNo ratings yet

- Ahu 3Document2 pagesAhu 3Thanhquy NguyenNo ratings yet

- Performance Improvement of The Vapour Compression Refrigeration Cycle by A Two-Phase Constant Area EjectorDocument12 pagesPerformance Improvement of The Vapour Compression Refrigeration Cycle by A Two-Phase Constant Area EjectornajeeullahNo ratings yet

- Toronto Sewer and Watermain Manual March2014Document218 pagesToronto Sewer and Watermain Manual March2014Obinna ObiefuleNo ratings yet

- SCHEMATIC SYSTEM CHILLER PLANT 3 (MERO) - ModelDocument1 pageSCHEMATIC SYSTEM CHILLER PLANT 3 (MERO) - ModelIlham HarisNo ratings yet

- Chapter 4 Ventilation PDFDocument6 pagesChapter 4 Ventilation PDFAbdelhameed Tarig AlemairyNo ratings yet

- Seismic Upgrade of Fault Crossing Water Pipelines Using Large Diameter Earthquake Resistant Ductile Iron PipeDocument12 pagesSeismic Upgrade of Fault Crossing Water Pipelines Using Large Diameter Earthquake Resistant Ductile Iron PipeponjoveNo ratings yet

- Synthesis and Analysing The Structural, Optical, Morphological, Photocatalytic and Magnetic Properties of TiO2and Doped (Ni and Cu) TiO2 Nanoparticles by Sol-Gel Technique PDFDocument12 pagesSynthesis and Analysing The Structural, Optical, Morphological, Photocatalytic and Magnetic Properties of TiO2and Doped (Ni and Cu) TiO2 Nanoparticles by Sol-Gel Technique PDFRahul MadanNo ratings yet

- Design of ConcreteDocument3 pagesDesign of Concretesachin balyanNo ratings yet

- Uflow Make Angle Seat ValveDocument3 pagesUflow Make Angle Seat ValveMurtaza BarwaniwalaNo ratings yet

- MDF U33vDocument2 pagesMDF U33vEslam HassanNo ratings yet

- End of Line Flame Arrester Model 310 8 InchDocument3 pagesEnd of Line Flame Arrester Model 310 8 InchfelixNo ratings yet

- Copper Clad SteelDocument4 pagesCopper Clad SteelJohn Noya VergaraNo ratings yet

- Einforced Oncrete Tairs: Structural System of StairsDocument7 pagesEinforced Oncrete Tairs: Structural System of StairsFahad AlbutiNo ratings yet

- Technical Data Sheet SIMONA Pvc-CawDocument2 pagesTechnical Data Sheet SIMONA Pvc-Cawstephen arkadiNo ratings yet

- Wire rope chart - 6x37 & 6x19, IWRC, EIPS rope specificationsDocument5 pagesWire rope chart - 6x37 & 6x19, IWRC, EIPS rope specificationsTarek HareedyNo ratings yet

- Design of Stairs 2 ACIDocument8 pagesDesign of Stairs 2 ACIKarim TammourNo ratings yet