Professional Documents

Culture Documents

Sejmste1 19

Uploaded by

hal9000_mark1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sejmste1 19

Uploaded by

hal9000_mark1Copyright:

Available Formats

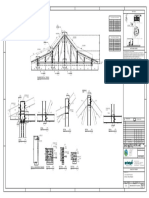

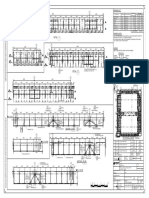

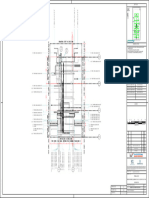

TABLE OF SEALED EXPANSION JOINT INFORMATION

pan form )

STRIP SEAL

Usual)

4" JOINT 5" JOINT

MANUFACTURER STEEL SECTION 2

Seal Joint Seal Joint

-0" (

Type Opening 3 Type Opening 3

-6" ~ CG (

2'

3

D.S. Brown Type SSCM2 A2R-400 1 4" A2R-XTRA 2"

3

Watson Bowman Acme Type R SE-400 1 4" SE-500 2"

1'

REDUCED LONGITUDINAL DESIGN NOTES:

Typ)

6"

MOVEMENT RANGE Joints installed on a skew have

Break Toe of rail, 1 Remove all burrs which will be in contact with seal

reduced ability to accommodate

point 7 curb or parapet

(

kind is m ade by TxDOT for any purpose whatsoever. TxDOT assum es no responsibility for the conversion

longitudinal movement. Use table prior to making splice.

Cut and shop SKEW JOINT SIZE

. No warranty of any

vulcanize seal values to determine the correct

(deg) 4" 5" 2

joint size for skewed installations. Shape of steel section shown is typical. Variations

when skew Miter and

1 For other skews over 25 degrees, in sections must be approved by the Engineer.

exceeds 35° shop weld 0 4.0" 5.0"

~

calculate reduced movement range

of this standard to other form ats or for incorrect results or dam ages resulting from its use.

15 4.0" 5.0" 3 These openings are also the recommended minimum

by multiplying joint size by cosine

(skew). installation openings.

30 3.5" 4.3"

~

2

~

Steel section Steel section 2

45 2.8" 3.5" 4 Reduce for sidewalk or parapet heights less than 6".

5

Texas Engineering Practice Act"

Other conditions affecting the joint profile should

Skew angle

be noted elsewhere.

Weld top 6 Move transverse bars that are in conflict with SEJ

and back.

SHOWING SKEWS WITH SHOWING SKEWS WITHOUT SHOWING WITHOUT SKEWS 1

studs, in either the bridge slab or approach slab,

8 Grind top

SLAB BREAKBACKS SLAB BREAKBACKS AND SLAB BREAKBACKS Type R Type SSCM2 to rest at the junction of the studs.

smooth

7 See Span details for location of break point.

PLANS OF END CONDITIONS

8 Align shipping angle perpendicular to joint.

1 1

FABRICATION NOTES:

Bevel Bevel Temporarily shop assemble corresponding sections of sealed

Median barrier Median barrier SEJ continuous

The use of this standard is governed by the "

Sidewalk

expansion joints (SEJ), check for fit, and match mark for shipment.

under barrier

not anchored to slab anchored to slab Rail Secure corresponding sections together for shipment with shipping

Cast or install barrier

angle. Do not use erection bolts.

after joint system

The seal must be continuous and included in the price bid for sealed

installation SEJ continuous

expansion joint.

under barrier WELD LIMITS WELD LIMITS REAR VIEW

Ship steel sections in convenient lengths of 10'-0" Min and 24'-0" Max

Traffic side unless necessary for staged construction or widenings. One shop

Cast median after

End SEJ See See

FIELD SPLICE DETAIL splice is permitted in each shipping length provided no piece is less

joint system

at toe of than 2'-0" long and sufficient studs are added to limit the stud to shop

"Upturn "Upturn installation

barrier splice distance to 2" Min and 4" Max.

Detail" Detail"

Weld studs in accordance with AWS D1.1.

Butt weld all shop and field splices and grind smooth areas in

contact with seal. Make all necessary field splice joint preparations

Toe of sidewalk,

in the shop.

rail or median

Paint the entire steel section with System II or IV primer in

WITH OPEN DECK JOINT AT SIDEWALK barrier

DISCLAIM ER:

accordance with Item 446, "Feild Cleaning and Painting Steel", unless

BELOW MEDIAN BARRIER AT MEDIAN BARRIER BEHIND BRIDGE RAIL AT RAISED MEDIAN

2"

required to galvanize when shown in the plans. Provide galvanizing

in accordance with Item 445, "Galvanizing". Provide paints in

7"

accordance with Item 446.2. Prepare steel and apply paint in

4 accordance with Item 446.4.7.3 and 446.4.7.4.

Shop drawings for the fabrication of sealed expansion joints will

Rail See Cope as required

not require the Engineer's approval if fabrication is in accordance

1 "Upturn to provide 1" Min

End 1 2" with the details shown on this standard.

See See Detail" clear cover. Stud

SEJ "Upturn "Upturn location may require

CONSTRUCTION NOTES:

Detail" Detail" adjustment

Secure the sealed expansion joint in position and place to the

proper grade and alignment by welding braces to adjacent reinforcing

60°

1

steel, to prestressed beam stirrups, or to anchors cast in concrete

End 1 2"

diaphragms. Include cost of temporary bracing in the price bid for

SEJ sealed expansion joint.

WITH OPEN DECK JOINT Remove shipping angle immediately after each joint half is secured

ADJACENT TO MEDIAN BARRIER AT CONCRETE BRIDGE RAIL AT SIDEWALK AT STEEL POST BRIDGE RAIL 2" in place. Grind smooth, and touch up with organic zinc-rich paint.

Miter and

Clean and prepare seal cavity for seal installation as per the

shop weld 1

Manufacturer's installation procedures.

5

Slab thickness

TYPICAL SECTIONS

Slab thickness

1

5" UPTURN DETAIL GENERAL NOTES:

less than 7 1

4" 7 4" and greater Provide sealed expansion joints in the size and at locations shown

on the plans.

Steel section 2 Determined by

Minimum slab and overhang thickness required for the use of

joint opening SEJ-M is 6

1

Conforms to slab 2".

See table for joint Steel

surface (Typ) Shipping angle

opening at 70° F section 2 See table for joint

opening at 70°F L 2 x 2 x 316

Top of

5 Conforms to spaced at 4'-0"

8" Dia x 0'-6" concrete Bridge

slab surface C-C Max 8

stud anchors at Division

6" C.C. Max (Typ) 5 Standard

6 8" Dia x 0'-6"

4" M ax

(alternate location) stud anchors at

(Ty

6" C.C. Max

SEALED EXPANSION JOINT

8

6 1

"

8

p)

(alternate location)

3

5

TYPE M

8"

1

8

5

1

4" WITHOUT OVERLAY

Typ)

8"

7

(Typ)

5

1

(T 6" 7

(

y 16"

p SHOWING D.S. BROWN (Ty SSCM2)

)

(Typ)

(All joints are similar.) (Studs are not shown for clarity.)

Bend studs as shown when depth of CIP concrete SEJ-M

1

is less than 7 4" at joint location FILE: sejmste1-19.dgn DN: TxDOT CK: TxDOT DW: JTR CK: JMH

SHIPPING ANGLE

C TxDOT April 2019 CONT SECT JOB HIGHWAY

SECTION THRU WATSON BOWMAN SECTION THRU D.S. BROWN An alternate method of securing joint sections may REVISIONS

DATE:

FILE:

be used if approved by the Bridge Division.

ACME (SE-400 OR SE-500) JOINTS (A2R-400 OR A2R-XTRA) JOINTS DIST COUNTY SHEET NO.

Erection bolts are not allowed.

You might also like

- EX1200-Electrical Circuit Diagram (Cummins Engine Specification)Document1 pageEX1200-Electrical Circuit Diagram (Cummins Engine Specification)Norman CoetzeeNo ratings yet

- DD13 Engine Harness PDFDocument2 pagesDD13 Engine Harness PDFalejandro sanchezNo ratings yet

- GENERATOR DATA - CaterpillarDocument8 pagesGENERATOR DATA - Caterpillarschraz4575100% (2)

- DD13 Engine Harness PDFDocument2 pagesDD13 Engine Harness PDFalejandro calixtoNo ratings yet

- Instant Assessments for Data Tracking, Grade 2: MathFrom EverandInstant Assessments for Data Tracking, Grade 2: MathNo ratings yet

- TRAIN Briefing - Revised Personal Income Tax RatesDocument73 pagesTRAIN Briefing - Revised Personal Income Tax RatesElizaFaithEcleoNo ratings yet

- Apollo Experience Report Lunar Module Landing Gear SubsystemDocument60 pagesApollo Experience Report Lunar Module Landing Gear SubsystemBob Andrepont100% (3)

- Amazon removes restricted supplement listing multiple timesDocument12 pagesAmazon removes restricted supplement listing multiple timesMasood Ur RehmanNo ratings yet

- 250 KVA Genset Wiring PDFDocument1 page250 KVA Genset Wiring PDFSZANo ratings yet

- FCPP Fiberglass Coated ConcreteDocument20 pagesFCPP Fiberglass Coated ConcretemahdiNo ratings yet

- Chandler V MillerDocument2 pagesChandler V MillerJay Cezar100% (1)

- (SILVA) Response of Standard Caltrans Pile-To-pile Cap Connections Under Simulated Seismic LoadsDocument375 pages(SILVA) Response of Standard Caltrans Pile-To-pile Cap Connections Under Simulated Seismic Loadshal9000_mark1No ratings yet

- Fire Water NetworkDocument1 pageFire Water NetworkKhuda BukshNo ratings yet

- Case Digest Basic Legal Ethics Subject FERDINAND A. CRUZ, Petitioner, vs. ALBERTO MINA, Et - Al., Respondents (G.R. No. 154207, 27 April 2007)Document3 pagesCase Digest Basic Legal Ethics Subject FERDINAND A. CRUZ, Petitioner, vs. ALBERTO MINA, Et - Al., Respondents (G.R. No. 154207, 27 April 2007)Grandeur P. G. GuerreroNo ratings yet

- BBQ Chicken Nustar KFSS A1Document1 pageBBQ Chicken Nustar KFSS A1agflamesengineering.salesNo ratings yet

- Circuit Diagrams: MAIN PWB CIRCUIT DIAGRAM (AV-29B316/B) (1/4) (2/4) SHEET1Document4 pagesCircuit Diagrams: MAIN PWB CIRCUIT DIAGRAM (AV-29B316/B) (1/4) (2/4) SHEET1Fede DiNo ratings yet

- Proposal 1Document4 pagesProposal 1Mahmoud FarahatNo ratings yet

- Dimensions Table Elastometric BearingDocument1 pageDimensions Table Elastometric BearingDMRNo ratings yet

- 42 Sawantmaitreyee DD&ARDDocument5 pages42 Sawantmaitreyee DD&ARDArchana ChavanNo ratings yet

- Irrigation Control Cable LayoutDocument4 pagesIrrigation Control Cable Layoutalivesince1091No ratings yet

- Air 1Document1 pageAir 1saipNo ratings yet

- Hwy 49 Roadwork2Document1 pageHwy 49 Roadwork2The UnionNo ratings yet

- Stilt Plan: Column Number Column SizeDocument1 pageStilt Plan: Column Number Column SizeRHUTI NAIKNo ratings yet

- 4355-Aa-Dc-22i10pr0900i - Checkprint For SquadDocument1 page4355-Aa-Dc-22i10pr0900i - Checkprint For Squadamit bagchiNo ratings yet

- FF Service Si-006 Vs Si-029-R1Document12 pagesFF Service Si-006 Vs Si-029-R1Chilo InNo ratings yet

- mcc2 PDFDocument1 pagemcc2 PDFSravyaSree100% (2)

- Dr. Suresh DrawingsDocument1 pageDr. Suresh DrawingsMohammed AliNo ratings yet

- Line Ex-Mh3 Legend:: Otak InternationalDocument1 pageLine Ex-Mh3 Legend:: Otak InternationalnaveenNo ratings yet

- Working Drawings: Key PlanDocument1 pageWorking Drawings: Key PlanSharanyaNo ratings yet

- Thrusters Fresh Cooling Water SystemDocument1 pageThrusters Fresh Cooling Water SystemAndreas SofianidisNo ratings yet

- MRS-DWG-DD-ST-01-SL-5004 - R0 - Detail - Steel Truss-3Document1 pageMRS-DWG-DD-ST-01-SL-5004 - R0 - Detail - Steel Truss-3arman gauNo ratings yet

- Pipe Sleeve Size ScheduleDocument2 pagesPipe Sleeve Size Scheduleppha hahajajshjNo ratings yet

- Ad-90.0-E-02054-Pdf Small Power & LightingDocument1 pageAd-90.0-E-02054-Pdf Small Power & LightingmcaslamNo ratings yet

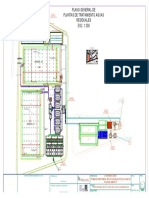

- Plano General de Plantas de Tratamiento-Planta de Tratamiento GeneralDocument1 pagePlano General de Plantas de Tratamiento-Planta de Tratamiento GeneralarmandoteranbNo ratings yet

- PRTAPU (2)Document1 pagePRTAPU (2)Shivam VermaNo ratings yet

- 65391-Jacked-Cooling-R0 2Document12 pages65391-Jacked-Cooling-R0 2ramesh_madkatte1082No ratings yet

- Power Layout Circuit-R1 (SF)Document1 pagePower Layout Circuit-R1 (SF)Electrical PCBL TeamNo ratings yet

- Power Layout Circuit-R1 (3F)Document1 pagePower Layout Circuit-R1 (3F)Electrical PCBL TeamNo ratings yet

- 3 2 PDFDocument2 pages3 2 PDFhernando ramosNo ratings yet

- 9035 Erction DWG (Demirsan)Document1 page9035 Erction DWG (Demirsan)ghulamNo ratings yet

- Span Arrangementpackage-59 - P3L2 PDFDocument23 pagesSpan Arrangementpackage-59 - P3L2 PDFJ. Kumar Infraprojects LtdNo ratings yet

- Floor Plan - Em-Schematic RiserDocument1 pageFloor Plan - Em-Schematic Riserisyed1948No ratings yet

- 1801-FR02-42-R-XD-00009 - C1 - General Arrangement - S42PD530A Scale Inhibitor - SubseaDocument1 page1801-FR02-42-R-XD-00009 - C1 - General Arrangement - S42PD530A Scale Inhibitor - SubseaNam DHNo ratings yet

- Offshore Supply Vessel: ProfileDocument1 pageOffshore Supply Vessel: ProfileAswin Sathian100% (1)

- Os00002 T Bw31.za3.um02&ez18453 R03-SHT1Document1 pageOs00002 T Bw31.za3.um02&ez18453 R03-SHT1Gopalakrishnan DhandapaniNo ratings yet

- Gutter Detail XX: West Elevation 1:100 South Elevation 1:100Document1 pageGutter Detail XX: West Elevation 1:100 South Elevation 1:100tngaraNo ratings yet

- Gas Option 2 210504Document1 pageGas Option 2 210504Md ShahinNo ratings yet

- Jazz Cl00botm PDFDocument1 pageJazz Cl00botm PDFchaz brandon serunjojiNo ratings yet

- P8 Fisico PDFDocument2 pagesP8 Fisico PDFazul mesaNo ratings yet

- VN1801-RHD-00-XX-DR-E-1002-P2 Main Single Line DiagramDocument1 pageVN1801-RHD-00-XX-DR-E-1002-P2 Main Single Line DiagramKao SophearakNo ratings yet

- Jazz Cl00top PDFDocument1 pageJazz Cl00top PDFchaz brandon serunjojiNo ratings yet

- Jazz Cl00top PDFDocument1 pageJazz Cl00top PDFchaz brandon serunjojiNo ratings yet

- Vietmobile - VN: Spell Mode:1X2 Hl1Cjazzmm Ver.A Silkscreen TopDocument1 pageVietmobile - VN: Spell Mode:1X2 Hl1Cjazzmm Ver.A Silkscreen Topchaz brandon serunjojiNo ratings yet

- Planta 04 Sin ColorDocument1 pagePlanta 04 Sin ColorDIEGO FERNANDO GARCIA CARMONANo ratings yet

- Council DWG-01Document1 pageCouncil DWG-01Janitha SandaruwanNo ratings yet

- 2016 Ce A1 102 PDFDocument1 page2016 Ce A1 102 PDFjatinNo ratings yet

- 2016 Ce A1 016 PDFDocument1 page2016 Ce A1 016 PDFjatinNo ratings yet

- Hold Fab: ONE - BEAM - 210B1Document1 pageHold Fab: ONE - BEAM - 210B1Raghu ramanNo ratings yet

- Elt - Villgio - 0505Document1 pageElt - Villgio - 0505Leandro JampietreNo ratings yet

- Wh-1088pe DrawingDocument1 pageWh-1088pe Drawingom sai quality developmentNo ratings yet

- X Ref - JF-P0015 - Oasis Cafe - 11052019 - A-2 TablesDocument1 pageX Ref - JF-P0015 - Oasis Cafe - 11052019 - A-2 TablesCOTA ESTUDIO DE ARQUITECTURANo ratings yet

- Ad-90.0-E-02108-Pdf Small Power Layout Ls&admin BLDNGDocument1 pageAd-90.0-E-02108-Pdf Small Power Layout Ls&admin BLDNGmcaslamNo ratings yet

- Bathroom B-17-Elev.2: Master Bathroom Plans & ElevationsDocument1 pageBathroom B-17-Elev.2: Master Bathroom Plans & ElevationsWinmentolMalisaNo ratings yet

- VH Ad 2 VHHH Aoc 4 (Typec)Document1 pageVH Ad 2 VHHH Aoc 4 (Typec)Loïc GIROUDNo ratings yet

- Tilal Mall and Hotel Sharjah, UAE: Detail 1Document22 pagesTilal Mall and Hotel Sharjah, UAE: Detail 1Michael Camit Eso100% (1)

- Detalles Constructivos para La Red de Agua PotableDocument4 pagesDetalles Constructivos para La Red de Agua PotableRoberto Cabrera MillerNo ratings yet

- Drp001-Puc-330000-P-Gad-005-5 (Y)Document1 pageDrp001-Puc-330000-P-Gad-005-5 (Y)John AlmasNo ratings yet

- Diagrama DataCenter - Yungay 8.11.2022Document1 pageDiagrama DataCenter - Yungay 8.11.2022Carmen RodriguezNo ratings yet

- DEEPSOIL User Manual v7 PDFDocument170 pagesDEEPSOIL User Manual v7 PDFsebastian gajardoNo ratings yet

- Bbstde 08Document1 pageBbstde 08hal9000_mark1No ratings yet

- Igebsts1 17Document3 pagesIgebsts1 17hal9000_mark1No ratings yet

- Aig55sts 17Document2 pagesAig55sts 17hal9000_mark1No ratings yet

- (PECKER) Seismic Analyses and Design of Foundation SSIDocument10 pages(PECKER) Seismic Analyses and Design of Foundation SSIhal9000_mark1No ratings yet

- (GOMEZ-NOVELL) Fault System-Based PSHA of A Moderate Seismicity Region - The Eastern Betics Shear ZoneDocument25 pages(GOMEZ-NOVELL) Fault System-Based PSHA of A Moderate Seismicity Region - The Eastern Betics Shear Zonehal9000_mark1No ratings yet

- (SILVA) Response of The Coronado Bay Bridge Pile-To-Pile Cap Connections Under Simulated Seismic LoadsDocument362 pages(SILVA) Response of The Coronado Bay Bridge Pile-To-Pile Cap Connections Under Simulated Seismic Loadshal9000_mark1No ratings yet

- (AISC) Steel Span LengthDocument10 pages(AISC) Steel Span Lengthhal9000_mark1No ratings yet

- 14wcee HV PDFDocument10 pages14wcee HV PDFDamsiarNo ratings yet

- (GINER) Structural Analysis of Earthquake Archaelogical Effects - Baelo Claudia ExamplesDocument130 pages(GINER) Structural Analysis of Earthquake Archaelogical Effects - Baelo Claudia Exampleshal9000_mark1No ratings yet

- Kinematic SSI Effects on Foundation Input MotionsDocument226 pagesKinematic SSI Effects on Foundation Input Motionshal9000_mark1No ratings yet

- (KIKUCHI) An Analytical Hysteresis Model For Elastomeric Seismic Isolation BearingsDocument17 pages(KIKUCHI) An Analytical Hysteresis Model For Elastomeric Seismic Isolation Bearingshal9000_mark1No ratings yet

- (SILVA) Fuentes Históricas y Geológicas de Los Terremotos Antiguos en La Península IbéricaDocument22 pages(SILVA) Fuentes Históricas y Geológicas de Los Terremotos Antiguos en La Península Ibéricahal9000_mark1No ratings yet

- (KELLY) The Role of Damping in Seismic IsolationDocument22 pages(KELLY) The Role of Damping in Seismic Isolationhal9000_mark1No ratings yet

- (JRC) Field Manual For Post-Earthquake Damage and Safety Assessment and Short Term Countermeasures (AeDES)Document100 pages(JRC) Field Manual For Post-Earthquake Damage and Safety Assessment and Short Term Countermeasures (AeDES)hal9000_mark1No ratings yet

- (ABRAHAMSON) Why Do Modern Probabilistic Seismic-Hazard Analyses Often Lead To Increased Hazard EstimatesDocument11 pages(ABRAHAMSON) Why Do Modern Probabilistic Seismic-Hazard Analyses Often Lead To Increased Hazard Estimateshal9000_mark1No ratings yet

- (KIKUCHI) Simulation Analysis For The Ultimate Behavior of Full-Scale Lead-Rubber Seismic Isolation BearingsDocument10 pages(KIKUCHI) Simulation Analysis For The Ultimate Behavior of Full-Scale Lead-Rubber Seismic Isolation Bearingshal9000_mark1No ratings yet

- (EADS) Assessment of The Probability of Collapse of Buildings During EarthquakesDocument12 pages(EADS) Assessment of The Probability of Collapse of Buildings During Earthquakeshal9000_mark1No ratings yet

- (FURINGHETTI) Investigation of The Consequences of Mounting Laying Defects For Curved Surface Slider Devices Under General Seismic Input PDFDocument21 pages(FURINGHETTI) Investigation of The Consequences of Mounting Laying Defects For Curved Surface Slider Devices Under General Seismic Input PDFhal9000_mark1No ratings yet

- (KELLY) Dynamic and Failure Characterisitcs of Bridgestone Isolation BearingsDocument81 pages(KELLY) Dynamic and Failure Characterisitcs of Bridgestone Isolation Bearingshal9000_mark1No ratings yet

- Abrahamson 2006Document17 pagesAbrahamson 2006Francolt41No ratings yet

- Bazurro and Cornell Disaggregation of Seismic HazardDocument20 pagesBazurro and Cornell Disaggregation of Seismic HazardKarim AljawhariNo ratings yet

- Adapting Earthquake Actions in EurocodeDocument17 pagesAdapting Earthquake Actions in EurocodeChee Soon LeeNo ratings yet

- (CZOP) Fluid-Structure Simulation of A Valve System Used in Hydraulic DampersDocument9 pages(CZOP) Fluid-Structure Simulation of A Valve System Used in Hydraulic Dampershal9000_mark1No ratings yet

- (ABRAHAMSON) Probability and Uncertainty in Seismic Hazard AnalysisDocument5 pages(ABRAHAMSON) Probability and Uncertainty in Seismic Hazard Analysishal9000_mark1No ratings yet

- (DURFEE) Fluid Power System DynamicsDocument54 pages(DURFEE) Fluid Power System Dynamicshal9000_mark1No ratings yet

- Heating Phenomena at The Sliding Interface of Double Curved Surface Sliders and Resulting Effects On The Hysteretic BehaviorDocument7 pagesHeating Phenomena at The Sliding Interface of Double Curved Surface Sliders and Resulting Effects On The Hysteretic Behaviorhal9000_mark1No ratings yet

- (DWAIRI) Implememtation of Inelastic Displacement Patterns in Direct Displacement-Based Design of Continuous Bridge StructuresDocument32 pages(DWAIRI) Implememtation of Inelastic Displacement Patterns in Direct Displacement-Based Design of Continuous Bridge Structureshal9000_mark1No ratings yet

- B.Tech Digital Principles and System Design Exam Question BankDocument24 pagesB.Tech Digital Principles and System Design Exam Question Bankdigital1206No ratings yet

- Format Transmittal - TemplateDocument1 pageFormat Transmittal - TemplateavriamandaNo ratings yet

- Partial Full Volume of TankDocument8 pagesPartial Full Volume of TankBabita GuptaNo ratings yet

- Atlantic Revolutions: Ogé Insurrection Inspired Haitian IndependenceDocument18 pagesAtlantic Revolutions: Ogé Insurrection Inspired Haitian IndependenceNiara ChaneyNo ratings yet

- Elementos ElectrónicosDocument9 pagesElementos ElectrónicosKratt DeividNo ratings yet

- Manual Equus 810 070Document10 pagesManual Equus 810 070Juan Ramón100% (1)

- Laboratory Testing of Oilwell CementsDocument41 pagesLaboratory Testing of Oilwell Cementsbillel ameuriNo ratings yet

- Crim Cases MidtermsDocument76 pagesCrim Cases MidtermsCoreine Valledor-SarragaNo ratings yet

- 11 Core CompetenciesDocument11 pages11 Core CompetenciesrlinaoNo ratings yet

- Zara Marketing Mix Four PsDocument3 pagesZara Marketing Mix Four PsHaniyeh ShojaeiNo ratings yet

- 2D IconsDocument8 pages2D IconsJacky ManNo ratings yet

- Electrical Machine 7-26-2016Document94 pagesElectrical Machine 7-26-2016Engr. Raheel khanNo ratings yet

- Seasonal Work Brochure 05Document2 pagesSeasonal Work Brochure 05R-lau R-pizNo ratings yet

- Test IMO EnglezaDocument4 pagesTest IMO EnglezaCristina PopovNo ratings yet

- Schedule LIII Form No. 376 CommutationDocument3 pagesSchedule LIII Form No. 376 Commutationbkrawat2008No ratings yet

- Parent DC Promo Ui LogDocument193 pagesParent DC Promo Ui LogRachell SmithNo ratings yet

- Consideration PropDocument2 pagesConsideration PropQasim GorayaNo ratings yet

- ABB Surge Arrester POLIM-H SD - Data Sheet 1HC0075860 E02 ABDocument4 pagesABB Surge Arrester POLIM-H SD - Data Sheet 1HC0075860 E02 ABHan HuangNo ratings yet

- Trace Log 20131229152625Document3 pagesTrace Log 20131229152625Razvan PaleaNo ratings yet

- Genetic Modified FoodDocument16 pagesGenetic Modified FoodKishoNo ratings yet

- Sample Letter - P.D. 705 Vis-A-Vis R.A. 10951Document3 pagesSample Letter - P.D. 705 Vis-A-Vis R.A. 10951Pauline Mae AranetaNo ratings yet

- Get started with Power BI DesktopDocument34 pagesGet started with Power BI Desktopbhargavc7No ratings yet

- Mechanical Seminar ListDocument9 pagesMechanical Seminar ListalokbdasNo ratings yet