Professional Documents

Culture Documents

Dimensions Table Elastometric Bearing

Uploaded by

DMROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dimensions Table Elastometric Bearing

Uploaded by

DMRCopyright:

Available Formats

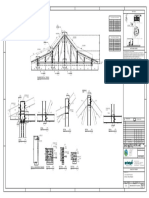

ELASTOMETRIC BEARING

DIMENSIONS TABLE

7

BEARING TWO

n ONE BEARING

Mi TYPE BEAM BEARINGS

" TYPE

• 4 L W L W

-7

1' 4XB20 8" 21" 8" 10"

XB20-"N"

C 5XB20 8" 21" 8" 10"

L Bent, Face of Abutment Backwall or Inverted Tee Stem

4XB28 8" 21" 8" 10"

C

L Bearing and C

L Bearing Pads XB28-"N"

5XB28 8" 21" 8" 10"

1

4XB34 8" 21" 8" 12"

XB34-"N"

kind is m ade by TxDOT for any purpose whatsoever. TxDOT assum es no responsibility for the conversion

1 L 2

C

L Bearing Pad L/ 5XB34 8" 21" 8" 12"

. No warranty of any

4XB40 8" 21" 8" 12"

C

L Beam 2

L/ XB40-"N"

Laminated 8 5XB40 8" 21" 8" 12"

of this standard to other form ats or for incorrect results or dam ages resulting from its use.

Elastomeric C

L Bearing Pad

Bearing

W/

1 Dowel at doweled beam end [labeled (D) on Bridge Layout]. Required

2

W

Texas Engineering Practice Act"

L Laminated for outside girder only or as shown on substructure details.

Elastomeric

W/

W

Bearing 2 Measured alongCL of Bearing.

2

3

W/

Maximum and minimum layer thicknesses shown are for elastomer only,

2

Skew Angle on tapered layers.

4 Indicate BEARING TYPE on all pads. For tapered pads, locate

BEARING TYPE on the high side. Include the value of "N" (amount

2 3"

L/ ) of taper in „" increments) in this mark.

yp

(T Examples: N=0, (for 0" taper)

Face of Cap

2 N=1, (for „" taper)

L/ " N=2, (for ‚" taper)

-0

1'

The use of this standard is governed by the "

yp) (etc.)

(T Fabricated pad top surface slope must not vary from plan beam slope

by more than 0.0625" IN/IN.

ELASTOMERIC BEARING PLACEMENT DIAGRAMS Length

5 Locate Permanent Mark here.

Place one bearing at forward station beam end.

Place two bearings at back station beam end.

6 Provide 2" Dia Hole only at locations required. See substructure

details for location.

7 Minimum dimension required for the bearings shown on this standard.

8 4XB beams = 1'-2" along CL Bearing (Typ).

Length

1 2" Dia Hole for 5XB beams = 1'-8" along CL Bearing (Typ).

Dowel. Located

in one-pad beam

DISCLAIM ER:

L/2 L/2

at ends only, where

Se

g applicable. 6 5

in h

ear gt

B n

Le C

W/2

L Brg

Width

GENERAL NOTES:

C Set beams on elastomeric bearings of the dimensions shown. Center

L Beam

C

W/2

bearings as near nominal L bearing as possible within limits shown.

C

L Pad

•

Constant thickness bearings may be used for moderate beam slopes

Be

up to 0.008 ft/ft.

Be

2

am

‚ "

For skewed supports, Bearings beveled for beam slope may not

TOP

am

5 provide uniform contact. However, predicted contact is considered

Elastomer Thickness

Ty

am

Ty

within allowable tolerances.

e

pe

PLAN

gl

Be

‚ " 6 Req'd at ‚ "

pe

Shop drawings for approval are required.

An

4X

A bearing layout which identifies location and orientation of all

INTERIOR

5X

bearings must be developed by the bearing fabricator. Permanently

B

B

mark each bearing in accordance with the bearing layout. Provide

=

=

copy of the bearing layout to the Engineer.

5'

•

6'

Place 0.105" thick steel laminates Cost of furnishing and installing elastomeric bearings is to be

-0

2 parallel to the bottom surface of

-0

Face of Abut Cap or Inverted Tee included in unit price bid for "Prestressed Concrete X-Beams".

"

the pad, except the top laminate(s)

"

Corbel or Interior Bent Cap Details are drawn showing right forward skew. See Bridge Layout

2 may be sloped to satisfy maximum for actual direction.

Face of Abut Bkwl or Inverted

BOTT

and minimum thickness criteria for These details are applicable for skews up to 30 degrees only.

Tee Stem orCL Interior Bent 3

tapered elastomeric top layers.

… " Max

Edges of Bearing Seat Build-up

C Brg (Typ) Bevel to match Beam Slope

are perpendicular to L 2 ƒ"

4 HL93 LOADING

BEARING SEAT DIMENSIONS

Bridge

All beam types

Used when shown on Abutment and/or Bent details. Division

Pad Taper in inches (= N„ ")

Standard

3

ELASTOMERIC

" Min

Length = L

BEARING DETAILS

‰

PRESTR CONC X-BEAMS

ELEVATION

(50 DUROMETER)

XBEB

FILE: xbstde07.dgn DN: JMH CK: AM DW: JTR CK: JMH

ELASTOMERIC BEARING SECTION

C TxDOT June 2011 CONT SECT JOB HIGHWAY

REVISIONS

DATE:

The use of Polyisoprene (natural rubber), for the

FILE:

manufacture of bearing pads, is not permitted. DIST COUNTY SHEET NO.

You might also like

- Instant Assessments for Data Tracking, Grade 1: MathFrom EverandInstant Assessments for Data Tracking, Grade 1: MathRating: 4 out of 5 stars4/5 (1)

- TA2899-Progress Design 20220131Document3 pagesTA2899-Progress Design 20220131Back To SumateraNo ratings yet

- MRS-DWG-DD-ST-01-SL-5004 - R0 - Detail - Steel Truss-3Document1 pageMRS-DWG-DD-ST-01-SL-5004 - R0 - Detail - Steel Truss-3arman gauNo ratings yet

- 2nd flr.planDocument1 page2nd flr.planManjunatha A.RNo ratings yet

- Sejmste1 19Document1 pageSejmste1 19hal9000_mark1No ratings yet

- #Isomap-Arnaud Velten 2007Document1 page#Isomap-Arnaud Velten 2007Etherikal Commander100% (2)

- Ad-90.0-E-02054-Pdf Small Power & LightingDocument1 pageAd-90.0-E-02054-Pdf Small Power & LightingmcaslamNo ratings yet

- Line Ex-Mh3 Legend:: Otak InternationalDocument1 pageLine Ex-Mh3 Legend:: Otak InternationalnaveenNo ratings yet

- بلان الدور الارضي 1-ModelDocument1 pageبلان الدور الارضي 1-ModelShrook Nasr AbdElKarimNo ratings yet

- 9m Ev Electrical LV SchematicDocument1 page9m Ev Electrical LV SchematicShankar NaiduNo ratings yet

- Working Drawings: Key PlanDocument1 pageWorking Drawings: Key PlanSharanyaNo ratings yet

- Cipageran Peta CitraDocument1 pageCipageran Peta Citrarullybandung100% (1)

- Hoja 1Document1 pageHoja 1Juan Carlos SoriaNo ratings yet

- Iitp LT Acoustics 204 SeatingDocument1 pageIitp LT Acoustics 204 Seatingsumant giriNo ratings yet

- Iitp - LT - Acoustics - 156 SeatingDocument1 pageIitp - LT - Acoustics - 156 Seatingsumant giriNo ratings yet

- MRS, FlorenceDocument1 pageMRS, Florencemagoobe reaganNo ratings yet

- G6 G5 G3 G2 G1 G5' G7 G4: 1 Elephant Holding Ground Floor Level Load MapDocument1 pageG6 G5 G3 G2 G1 G5' G7 G4: 1 Elephant Holding Ground Floor Level Load MaphemanthsridharaNo ratings yet

- Ec2-02a Second Floor Auxiliary LayoutDocument1 pageEc2-02a Second Floor Auxiliary LayoutSEDFREY DELA CRUZNo ratings yet

- 2016 Ce A1 101 PDFDocument1 page2016 Ce A1 101 PDFjatinNo ratings yet

- BBQ Chicken Nustar KFSS A1Document1 pageBBQ Chicken Nustar KFSS A1agflamesengineering.salesNo ratings yet

- DD13 Engine Harness PDFDocument2 pagesDD13 Engine Harness PDFalejandro calixtoNo ratings yet

- DD13 Engine Harness PDFDocument2 pagesDD13 Engine Harness PDFalejandro sanchezNo ratings yet

- Part2 - Addendum 1 - Conti - Alignment of Line 10Document15 pagesPart2 - Addendum 1 - Conti - Alignment of Line 10handsomekashNo ratings yet

- Porto AlegreDocument1 pagePorto AlegreMonica GoulartNo ratings yet

- GN-300-002Document1 pageGN-300-002Xavier LeeNo ratings yet

- Elementos de Curvas: Universidad Catolica Santo Toribio de Mogrovejo Municipalidad Distrital de ArequipaDocument1 pageElementos de Curvas: Universidad Catolica Santo Toribio de Mogrovejo Municipalidad Distrital de ArequipaJhosut GonzalesNo ratings yet

- Main WalletDocument1 pageMain Walletshaan.parmar07No ratings yet

- Lllllleeeee: O F FEDocument54 pagesLllllleeeee: O F FEthe next miamiNo ratings yet

- 100136C-051-DD-1841-1013 - 1 (Shop Drawing) - 005-005Document1 page100136C-051-DD-1841-1013 - 1 (Shop Drawing) - 005-005Tamil Arasu SNo ratings yet

- Claudare Stree T: Not For ConstructionDocument1 pageClaudare Stree T: Not For Constructionfehmeen zehraNo ratings yet

- Master Plan of Dairy Farm: Ans AssociatesDocument9 pagesMaster Plan of Dairy Farm: Ans AssociatesIrfan MunirNo ratings yet

- Tilal Mall and Hotel Sharjah, UAE: Detail 1Document22 pagesTilal Mall and Hotel Sharjah, UAE: Detail 1Michael Camit Eso100% (1)

- Amolik 97 Site Map - 7827005000Document1 pageAmolik 97 Site Map - 7827005000dsgbookmyflats1No ratings yet

- Iitp - LT - Acoustics - 303 SeatingDocument1 pageIitp - LT - Acoustics - 303 Seatingsumant giriNo ratings yet

- 072744C-RA1-DW-CH-31018-0-01 - 2 Change Joint W.catDocument1 page072744C-RA1-DW-CH-31018-0-01 - 2 Change Joint W.catLocus Jhun MichaelNo ratings yet

- 072744C-RA1-DW-CH-31004-0-01 - 3change Joint NumberDocument3 pages072744C-RA1-DW-CH-31004-0-01 - 3change Joint NumberLocus Jhun MichaelNo ratings yet

- Electoral Maps - BegaDocument1 pageElectoral Maps - BegaBen SmythNo ratings yet

- 2016 Ce A1 104 PDFDocument1 page2016 Ce A1 104 PDFjatinNo ratings yet

- VO Back Flow AD Ref 4-1Document15 pagesVO Back Flow AD Ref 4-1wiwitoke3No ratings yet

- Bbstde 08Document1 pageBbstde 08hal9000_mark1No ratings yet

- Planta 04 Sin ColorDocument1 pagePlanta 04 Sin ColorDIEGO FERNANDO GARCIA CARMONANo ratings yet

- RD To plt26 Distance Reqd.: General Notes Technip Energies NTS Steel Pipe Rack (Pr-Pta-02A)Document1 pageRD To plt26 Distance Reqd.: General Notes Technip Energies NTS Steel Pipe Rack (Pr-Pta-02A)Tamil Arasu SNo ratings yet

- Shelby Views A & C US Copy Shop Pattern 36x118inDocument1 pageShelby Views A & C US Copy Shop Pattern 36x118inTatiana Codorniz100% (1)

- Window SchedulesDocument1 pageWindow SchedulesdenisNo ratings yet

- Ir - CTCR - STR - La - M2 - 1004 - Initial Vertical Pile Load TestDocument1 pageIr - CTCR - STR - La - M2 - 1004 - Initial Vertical Pile Load TestCTC RLY (Photos)No ratings yet

- 42 Sawantmaitreyee DD&ARDDocument5 pages42 Sawantmaitreyee DD&ARDArchana ChavanNo ratings yet

- T5 B2 LayoutDocument1 pageT5 B2 Layoutsatyam.pulkam7490No ratings yet

- Limite de Frentes de TrabajosDocument1 pageLimite de Frentes de TrabajosJohann Nick Flores AparicioNo ratings yet

- Dr. Suresh DrawingsDocument1 pageDr. Suresh DrawingsMohammed AliNo ratings yet

- Eamco DMJ RS SD 001Document1 pageEamco DMJ RS SD 001libin513No ratings yet

- SCBD Golf Studio & Dining - Layout Plan v32Document1 pageSCBD Golf Studio & Dining - Layout Plan v32Giovanni MikeNo ratings yet

- Ad 90.0 e 02061 PDF Earthing Details B 4Document1 pageAd 90.0 e 02061 PDF Earthing Details B 4mcaslamNo ratings yet

- 2016 Ce A1 102 PDFDocument1 page2016 Ce A1 102 PDFjatinNo ratings yet

- RONDOS ZonabajaDocument1 pageRONDOS Zonabaja2018111073No ratings yet

- 2016 Ce A1 016 PDFDocument1 page2016 Ce A1 016 PDFjatinNo ratings yet

- Desague (1) - Planta GeneralDocument1 pageDesague (1) - Planta Generalkristian MéndezNo ratings yet

- Siteplan 2Document1 pageSiteplan 2muhammadulil abrorNo ratings yet

- Siteplan 1Document1 pageSiteplan 1muhammadulil abrorNo ratings yet

- 65391-Jacked-Cooling-R0 2Document12 pages65391-Jacked-Cooling-R0 2ramesh_madkatte1082No ratings yet

- 07-Rajasthani Ghat kDocument1 page07-Rajasthani Ghat kVinod Kumar GaurNo ratings yet

- Seismic Behavior of Ground Rested Rectangular RC Tank Considering Fluid-Structure-Soil InteractionDocument16 pagesSeismic Behavior of Ground Rested Rectangular RC Tank Considering Fluid-Structure-Soil InteractionDMRNo ratings yet

- Paleta RALDocument5 pagesPaleta RALFilipe José Andrade PereiraNo ratings yet

- 5706.westergaard Added Mass (PLAXIS V20Update1)Document9 pages5706.westergaard Added Mass (PLAXIS V20Update1)DMRNo ratings yet

- Thomas Mendez Strut and Tie Design What They Didnt Teach You in Scho PDFDocument49 pagesThomas Mendez Strut and Tie Design What They Didnt Teach You in Scho PDFDMRNo ratings yet

- P307 PDFDocument2 pagesP307 PDFXtremozeroNo ratings yet

- Pov Nori Apr2007Document31 pagesPov Nori Apr2007DMRNo ratings yet

- Timber Connections PDFDocument76 pagesTimber Connections PDFمهندس يحيى ابن وابري100% (2)

- Dimensions Table Elastometric BearingDocument1 pageDimensions Table Elastometric BearingDMRNo ratings yet

- 2010 Presentation 1 Misunderstood For SeaooDocument1 page2010 Presentation 1 Misunderstood For SeaooDMRNo ratings yet

- Design of Pile Cap - Strut and Tie MethodDocument7 pagesDesign of Pile Cap - Strut and Tie MethodHong VeasnaNo ratings yet

- Guide To Tower CranesDocument10 pagesGuide To Tower CranesArisNo ratings yet

- Frequently Misunderstood Ibc/asce 7 Structural ProvisionsDocument43 pagesFrequently Misunderstood Ibc/asce 7 Structural ProvisionsabhinavNo ratings yet

- cc1101 p25Document105 pagescc1101 p25fadfadfNo ratings yet

- Modifier Export Establishment 2Document22 pagesModifier Export Establishment 2Sanu PhilipNo ratings yet

- Grados: Rad Ia Ne SDocument4 pagesGrados: Rad Ia Ne SJean Pierre AHNo ratings yet

- Speed Control of BLDC Motor Using MicrocontrollerDocument16 pagesSpeed Control of BLDC Motor Using MicrocontrollerVõ Đức HuyNo ratings yet

- Computer Organization & Computer Organization & Computer Organization & Computer Organization & Assembly Languages Assembly LanguagesDocument119 pagesComputer Organization & Computer Organization & Computer Organization & Computer Organization & Assembly Languages Assembly LanguagesEdel Karlo Sibidal ZarasateNo ratings yet

- Steam Reforming - Approach To EquilibriumDocument39 pagesSteam Reforming - Approach To EquilibriumAlexReituNo ratings yet

- ICSE 2014 Pupil Analysis MathematicsDocument26 pagesICSE 2014 Pupil Analysis MathematicsRohit AgarwalNo ratings yet

- SAS Base Programming Practice Exam V9 QuestionsDocument24 pagesSAS Base Programming Practice Exam V9 QuestionssrinivasaraosomuNo ratings yet

- Fdfdedfd PDFDocument10 pagesFdfdedfd PDFRajeshKumarSahuNo ratings yet

- Mapeo ComputoDocument20 pagesMapeo ComputoGuillermo Santiago Robles RangelNo ratings yet

- Cre Technology ParallelingDocument6 pagesCre Technology ParallelingduaNo ratings yet

- Acceptance Criteria For Helical Foundation Systems and DevicesDocument21 pagesAcceptance Criteria For Helical Foundation Systems and DevicesJose FernandoNo ratings yet

- Chapter 1 Error MesurementDocument99 pagesChapter 1 Error MesurementMuhammad SyahmiNo ratings yet

- Calculation of Electrical Energy With SolarDocument4 pagesCalculation of Electrical Energy With Solarmohamed parvez100% (1)

- Article: Blood Pressure in Canadian Children and AdolescentsDocument9 pagesArticle: Blood Pressure in Canadian Children and AdolescentsMr. ShadenfreudeNo ratings yet

- Excel Data Exploration for Lemonade Stand SalesDocument11 pagesExcel Data Exploration for Lemonade Stand SalesArif Marias0% (2)

- Yilida Selection Report Version Number:YLD20170528Document2 pagesYilida Selection Report Version Number:YLD20170528ruloNo ratings yet

- Debugger c2000Document58 pagesDebugger c2000carver_uaNo ratings yet

- Seminar: Industrial ChimneysDocument12 pagesSeminar: Industrial Chimneysmanu_696No ratings yet

- Maths - Sample Paper1Document5 pagesMaths - Sample Paper1Arnav SudhindraNo ratings yet

- Final Assignment 2 ChafikDocument16 pagesFinal Assignment 2 ChafikSaheed A BusuraNo ratings yet

- Pareto Analysis v2.ppt 1Document7 pagesPareto Analysis v2.ppt 1prabu06051984No ratings yet

- Intervalos 2 ConstruccionDocument4 pagesIntervalos 2 ConstruccionEsteban AlbarralNo ratings yet

- SCI P292 SecureDocument222 pagesSCI P292 Secureg1g1ng100% (1)

- Money WiseDocument62 pagesMoney Wisejei liNo ratings yet

- Lab Report Chemistry Experiment 6 Group 1Document12 pagesLab Report Chemistry Experiment 6 Group 1NUR RABIAHTUL NAZILLA BINTI MAPATANG FS21110430No ratings yet

- Pipe Cleaning Systems Operating Waterblasting Equipment Safety GuideDocument1 pagePipe Cleaning Systems Operating Waterblasting Equipment Safety GuideЮрийNo ratings yet

- Marcom Opc ProductsDocument8 pagesMarcom Opc ProductsMARCOM SRLNo ratings yet

- Overcurrent Protection / 7SJ63Document38 pagesOvercurrent Protection / 7SJ63KnjigescribdNo ratings yet