Professional Documents

Culture Documents

Final Assignment 2 Chafik

Uploaded by

Saheed A BusuraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Final Assignment 2 Chafik

Uploaded by

Saheed A BusuraCopyright:

Available Formats

Design/Analysis of Experiments STAT615 Section: 02 Fall 2020

Name: BUSURA Saheed Adekunle ID: Assignment 2 (13/11/2020)

202090119

Problem 1: A metal is used to make components for jet turbine aircraft engines. Cracking is a potentially serious problem

in the final part because it can lead to non-recoverable failure. A test is run at the parts producer to determine the effect of

four factors on cracks. The four factors are pouring temperature(A), titanium content (B), heat treatment method (C), and

amount of grain refiner used (D). Two replicates of a 24 design are run, and the length of crack (in mm ×10-2) induced in a

sample coupon subjected to a standard test is measured. The data are shown in Prob1_Ass2.mtw.

(a) [2 points]Estimate the factor effects.

Answer: Based on the Minitab results attached, all factors with P-Values > 0.0500 are not significant. These

include all higher terms interactions with the exception of ABC, AC, AD, & A, B, C, D single effect factors

Coded Coefficients

Model Summary

S R-sq R-sq(adj) R-sq(pred)

0.284885 99.77% 99.56% 99.09%

Analysis of Variance

Source DF Adj SS Adj MS

Model 15 570.948 38.063

Linear 4 333.496 83.374

Pour Temperature 1 72.909 72.909

Titanium Content 1 126.461 126.461

Heat Treat Method 1 103.464 103.464

Grain Refiner 1 30.662 30.662

2-Way Interactions 6 158.609 26.435

Pour Temperature*Titanium Content 1 29.927 29.927

Pour Temperature*Heat Treat Method 1 128.496 128.496

Pour Temperature*Grain Refiner 1 0.047 0.047

Titanium Content*Heat Treat Method 1 0.074 0.074

Titanium Content*Grain Refiner 1 0.018 0.018

Heat Treat Method*Grain Refiner 1 0.047 0.047

3-Way Interactions 4 78.841 19.710

Pour Temperature*Titanium Content*Heat Treat Method 1 78.751 78.751

Pour Temperature*Titanium Content*Grain Refiner 1 0.077 0.077

BUSURA Saheed Adekunle ID: 202090119 STAT 615 DOE Page 1

Pour Temperature*Heat Treat Method*Grain Refiner 1 0.003 0.003

Titanium Content*Heat Treat Method*Grain Refiner 1 0.010 0.010

4-Way Interactions 1 0.002 0.002

Pour Temperature*Titanium Content*Heat Treat Method*Grain Refiner 1 0.002 0.002

Error 16 1.299 0.081

Total 31 572.246

Source F-Value P-Value

Model 468.99 0.000

Linear 1027.28 0.000

Pour Temperature 898.34 0.000

Titanium Content 1558.17 0.000

Heat Treat Method 1274.82 0.000

Grain Refiner 377.80 0.000

2-Way Interactions 325.71 0.000

Pour Temperature*Titanium Content 368.74 0.000

Pour Temperature*Heat Treat Method 1583.26 0.000

Pour Temperature*Grain Refiner 0.58 0.459

Titanium Content*Heat Treat Method 0.91 0.355

Titanium Content*Grain Refiner 0.22 0.645

Heat Treat Method*Grain Refiner 0.58 0.456

3-Way Interactions 242.86 0.000

Pour Temperature*Titanium Content*Heat Treat Method 970.33 0.000

Pour Temperature*Titanium Content*Grain Refiner 0.95 0.345

Pour Temperature*Heat Treat Method*Grain Refiner 0.04 0.852

Titanium Content*Heat Treat Method*Grain Refiner 0.13 0.728

4-Way Interactions 0.02 0.890

Pour Temperature*Titanium Content*Heat Treat Method*Grain Refiner 0.02 0.890

BUSURA Saheed Adekunle ID: 202090119 STAT 615 DOE Page 2

Error

Total

Regression Equation in Un-coded Units

Crack Length = 11.9881 + 1.5094 Pour Temperature + 1.9879 Titanium Content

- 1.7981 Heat Treat Method + 0.9789 Grain Refiner + 0.9671 Pour Temperature*Titanium Content

- 2.0039 Pour Temperature*Heat Treat Method + 0.0383 Pour Temperature*Grain Refiner

+ 0.0480 Titanium Content*Heat Treat Method + 0.0236 Titanium Content*Grain Refiner

- 0.0384 Heat Treat Method*Grain Refiner + 1.5688 Pour Temperature*Titanium Content*Heat Treat Method

+ 0.0490 Pour Temperature*Titanium Content*Grain Refiner+ 0.0096 Pour Temperature*Heat Treat Method*Grain

Refiner

+ 0.0178 Titanium Content*Heat Treat Method*Grain Refiner

+ 0.0071 Pour Temperature*Titanium Content*Heat Treat Method*Grain Refiner

Alias Structure

Factor Name

A Pour Temperature

B Titanium Content

C Heat Treat Method

D Grain Refiner

ALIASES: I, A, B, C, D, AB, AC, AD, BC, BD, CD, ABC, ABD, ACD, BCD, ABCD

Analysis of Variance

Source DF Seq SS Contribution Adj SS

Model 8 570.744 99.74% 570.744

Linear 4 333.496 58.28% 333.496

Pour Temperature 1 72.909 12.74% 72.909

Titanium Content 1 126.461 22.10% 126.461

Heat Treat Method 1 103.464 18.08% 103.464

Grain Refiner 1 30.662 5.36% 30.662

2-Way Interactions 3 158.497 27.70% 158.497

Pour Temperature*Titanium Content 1 29.927 5.23% 29.927

Pour Temperature*Heat Treat Method 1 128.496 22.45% 128.496

Titanium Content*Heat Treat Method 1 0.074 0.01% 0.074

3-Way Interactions 1 78.751 13.76% 78.751

Pour Temperature*Titanium Content*Heat Treat Method 1 78.751 13.76% 78.751

Error 23 1.502 0.26% 1.502

BUSURA Saheed Adekunle ID: 202090119 STAT 615 DOE Page 3

Lack-of-Fit 7 0.203 0.04% 0.203

Pure Error 16 1.299 0.23% 1.299

Total 31 572.246 100.00%

Source Adj MS F-Value P-Value

Model 71.343 1092.46 0.000

Linear 83.374 1276.68 0.000

Pour Temperature 72.909 1116.43 0.000

Titanium Content 126.461 1936.46 0.000

Heat Treat Method 103.464 1584.32 0.000

Grain Refiner 30.662 469.52 0.000

2-Way Interactions 52.832 809.01 0.000

Pour Temperature*Titanium Content 29.927 458.26 0.000

Pour Temperature*Heat Treat Method 128.496 1967.63 0.000

Titanium Content*Heat Treat Method 0.074 1.13 0.299

3-Way Interactions 78.751 1205.90 0.000

Pour Temperature*Titanium Content*Heat Treat Method 78.751 1205.90 0.000

Error 0.065

Lack-of-Fit 0.029 0.36 0.913

Pure Error 0.081

Total

Regression Equation in Un-coded Units

Crack Length = 11.9881 + 1.5094 Pour Temperature + 1.9879 Titanium Content - 1.7981 Heat Treat Method

+ 0.9789 Grain Refiner + 0.9671 Pour Temperature*Titanium Content

- 2.0039 Pour Temperature*Heat Treat Method

+ 0.0480 Titanium Content*Heat Treat Method+ 1.5687 Pour Temperature*Titanium Content*Heat Treat

Method

Alias Structure

BUSURA Saheed Adekunle ID: 202090119 STAT 615 DOE Page 4

Factor Name

A Pour Temperature

B Titanium Content

C Heat Treat Method

D Grain Refiner

ALIASES: I , A, B, C, D, AB, AC, BC, ABC

[3 points]

(b) Write two regression models for predicting crack length, one for each level of the heat treatment method

variable. What differences, if any, do you notice in these two equations?

Regression Equations

Heat

Treat

Method

-1 Crack = 13.786 + 1.509 Pour Temperature + 1.988 Titanium Content + 0.979 Grain Refiner

Length

1 Crack = 10.190 + 1.509 Pour Temperature + 1.988 Titanium Content + 0.979 Grain Refiner

Length

Answer: The two equation differs in terms of their constant terms i.e. at lower level of heat treatment (-1),

Bo=13.785 while at higher level (+1), its value is 10.190

[2 points]

(c) Generate appropriate response surface contour plots for the two regression models in part (b). Describe.

BUSURA Saheed Adekunle ID: 202090119 STAT 615 DOE Page 5

Answer: By holding Grain refiner constant (with contribution of 5%), the 2 plots are unequal and is safer to operate

at lower level of heat treatment method

[2 points]

(d) What set of conditions would you recommend for factors A, B and D if you use heat treatment method

C=+?

Answer: I will recommend low level of A(-),B(-) and D(+)

[3 points]

(e) Suppose that only 16 runs could be made on a single day, so each replicate was treated as block. Analyze

the experiment and draw conclusions.

Answer: Based on the Minitab output, all main effects are significant including all two factors interactions with

the exception of Titanium concentration-Heat treatment Method that has P-Value greater than 0.0500

Coded Coefficients

Term Effect Coef SE Coef 95% CI

Constant 12.0103 0.0684 (11.8486, 12.1720)

Pour Temperature 3.0436 1.5218 0.0684 (1.3601, 1.6835)

Titanium Content 4.0421 2.0211 0.0684 (1.8594, 2.1828)

Heat Treat Method -3.4244 -1.7122 0.0684 (-1.8739, -1.5505)

Grain Refiner 1.9649 0.9824 0.0684 (0.8207, 1.1441)

Pour Temperature*Titanium Content 1.9886 0.9943 0.0684 (0.8326, 1.1560)

Pour Temperature*Heat Treat Method -3.8469 -1.9234 0.0684 (-2.0851, -1.7617)

Titanium Content*Heat Treat Method 0.1831 0.0916 0.0684 (-0.0701, 0.2533)

Pour Temperature*Titanium Content*Heat Treat Method 3.0861 1.5431 0.0684 (1.3814, 1.7048)

Term T-Value P-Value VIF

Constant 175.63 0.000

Pour Temperature 22.25 0.000 1.00

Titanium Content 29.55 0.000 1.00

Heat Treat Method -25.04 0.000 1.00

Grain Refiner 14.37 0.000 1.00

BUSURA Saheed Adekunle ID: 202090119 STAT 615 DOE Page 6

Pour Temperature*Titanium Content 14.54 0.000 1.00

Pour Temperature*Heat Treat Method -28.13 0.000 1.00

Titanium Content*Heat Treat Method 1.34 0.222 1.00

Pour Temperature*Titanium Content*Heat Treat Method 22.56 0.000 1.00

Model Summary

S R-sq R-sq(adj) PRESS R-sq(pred) AICc BIC

0.273542 99.81% 99.60% 2.73647 99.02% 54.70 18.42

Analysis of Variance

Source DF Seq SS Contribution Adj SS

Model 8 278.001 99.81% 278.001

Linear 4 164.758 59.15% 164.758

Pour Temperature 1 37.055 13.30% 37.055

Titanium Content 1 65.355 23.46% 65.355

Heat Treat Method 1 46.905 16.84% 46.905

Grain Refiner 1 15.443 5.54% 15.443

2-Way Interactions 3 75.146 26.98% 75.146

Pour Temperature*Titanium Content 1 15.819 5.68% 15.819

Pour Temperature*Heat Treat Method 1 59.194 21.25% 59.194

Titanium Content*Heat Treat Method 1 0.134 0.05% 0.134

3-Way Interactions 1 38.097 13.68% 38.097

Pour Temperature*Titanium Content*Heat Treat Method 1 38.097 13.68% 38.097

Error 7 0.524 0.19% 0.524

Total 15 278.525 100.00%

Source Adj MS F-Value P-Value

Model 34.7501 464.42 0.000

Linear 41.1895 550.48 0.000

Pour Temperature 37.0546 495.21 0.000

Titanium Content 65.3551 873.44 0.000

Heat Treat Method 46.9054 626.86 0.000

Grain Refiner 15.4429 206.39 0.000

2-Way Interactions 25.0488 334.76 0.000

Pour Temperature*Titanium Content 15.8185 211.41 0.000

Pour Temperature*Heat Treat Method 59.1938 791.09 0.000

Titanium Content*Heat Treat Method 0.1341 1.79 0.222

BUSURA Saheed Adekunle ID: 202090119 STAT 615 DOE Page 7

3-Way Interactions 38.0967 509.14 0.000

Pour Temperature*Titanium Content*Heat Treat Method 38.0967 509.14 0.000

Error 0.0748

Total

Regression Equation in Un-coded Units

Crack Length = 12.0103 + 1.5218 Pour Temperature + 2.0211 Titanium Content - 1.7122 Heat Treat Method

+ 0.9824 Grain Refiner + 0.9943 Pour Temperature*Titanium Content

- 1.9234 Pour Temperature*Heat Treat Method + 0.0916 Titanium Content*Heat Treat Method

+ 1.5431 Pour Temperature*Titanium Content*Heat Treat Method

Alias Structure

Factor Name

A Pour Temperature

B Titanium Content

C Heat Treat Method

D Grain Refiner

Aliases: I, A, B, C, D, AB, AC, BC, ABC,

BUSURA Saheed Adekunle ID: 202090119 STAT 615 DOE Page 8

Problem 2: An electrical engineer tests the efficiency of the heat radiator. Four factors were selected, and two replicates

of a completely randomized experiment were run. The results are shown in Prob2._Ass2.xls

a) Analyze the effects of the 4 factors on the efficiency of the heat radiator. Use α =0.05 .

[2 points]

From the attached Minitab, all treatments combinations or single effect treatments with P-value.0.0500 are not

significant The heat radiator is only affected with those treatment combinations with P-value <0.05.

The data satisfy normality assumption, homogeneity, and independent. This can be seen in the attached plots. A

further confirmation can be seen in the residual plots and the probability plots.

Coded Coefficients

Term Effect Coef SE Coef 95% CI T-Value P-Value VIF

Constant 82.469 0.445 (81.525, 83.413) 185.22 0.000

A -8.562 -4.281 0.445 (-5.225, -3.337) -9.62 0.000 1.00

B -1.813 -0.906 0.445 (-1.850, 0.038) -2.04 0.059 1.00

C -3.312 -1.656 0.445 (-2.600, -0.712) -3.72 0.002 1.00

D 4.438 2.219 0.445 (1.275, 3.163) 4.98 0.000 1.00

A*B 4.687 2.344 0.445 (1.400, 3.288) 5.26 0.000 1.00

A*C 1.188 0.594 0.445 (-0.350, 1.538) 1.33 0.201 1.00

A*D -2.812 -1.406 0.445 (-2.350, -0.462) -3.16 0.006 1.00

B*C -1.062 -0.531 0.445 (-1.475, 0.413) -1.19 0.250 1.00

B*D 0.437 0.219 0.445 (-0.725, 1.163) 0.49 0.630 1.00

C*D 2.188 1.094 0.445 (0.150, 2.038) 2.46 0.026 1.00

A*B*C -4.563 -2.281 0.445 (-3.225, -1.337) -5.12 0.000 1.00

A*B*D 4.187 2.094 0.445 (1.150, 3.038) 4.70 0.000 1.00

A*C*D -1.563 -0.781 0.445 (-1.725, 0.163) -1.75 0.098 1.00

B*C*D -0.312 -0.156 0.445 (-1.100, 0.788) -0.35 0.730 1.00

A*B*C*D 1.937 0.969 0.445 (0.025, 1.913) 2.18 0.045 1.00

Analysis of Variance

Source DF Seq SS Contribution Adj SS Adj MS F-Value P-Value

Model 15 1514.47 93.72% 1514.47 100.965 15.92 0.000

Linear 4 858.12 53.10% 858.12 214.531 33.82 0.000

A 1 586.53 36.30% 586.53 586.531 92.46 0.000

B 1 26.28 1.63% 26.28 26.281 4.14 0.059

BUSURA Saheed Adekunle ID: 202090119 STAT 615 DOE Page 9

C 1 87.78 5.43% 87.78 87.781 13.84 0.002

D 1 157.53 9.75% 157.53 157.531 24.83 0.000

2-Way Interactions 6 299.19 18.51% 299.19 49.865 7.86 0.000

A*B 1 175.78 10.88% 175.78 175.781 27.71 0.000

A*C 1 11.28 0.70% 11.28 11.281 1.78 0.201

A*D 1 63.28 3.92% 63.28 63.281 9.98 0.006

B*C 1 9.03 0.56% 9.03 9.031 1.42 0.250

B*D 1 1.53 0.09% 1.53 1.531 0.24 0.630

C*D 1 38.28 2.37% 38.28 38.281 6.03 0.026

3-Way Interactions 4 327.12 20.24% 327.13 81.781 12.89 0.000

A*B*C 1 166.53 10.31% 166.53 166.531 26.25 0.000

A*B*D 1 140.28 8.68% 140.28 140.281 22.11 0.000

A*C*D 1 19.53 1.21% 19.53 19.531 3.08 0.098

B*C*D 1 0.78 0.05% 0.78 0.781 0.12 0.730

4-Way Interactions 1 30.03 1.86% 30.03 30.031 4.73 0.045

A*B*C*D 1 30.03 1.86% 30.03 30.031 4.73 0.045

Error 16 101.50 6.28% 101.50 6.344

Total 31 1615.97 100.00%

Regression Equation in Un-coded Units

Response = 82.469 - 4.281 A - 0.906 B - 1.656 C + 2.219 D + 2.344 A*B + 0.594 A*C 1.406 A*D - 0.531 B*C + 0.219 B*D + 1.094 C*D

- 2.281 A*B*C + 2.094 A*B*D - 0.781 A*C*D - 0.156 B*C*D + 0.969 A*B*C*D

Alias Structure

Factor Name

A A

B B

C C

D D

Aliases: I, A, B, C, D, AB, AC, AD, BC, BD, CD, ABC,ABD, ACD, BCD,ABCD

Analysis of Variance

Source DF Seq SS Contribution Adj SS Adj MS F-Value P-Value

Model 12 1464.12 90.60% 1464.12 122.010 15.27 0.000

Linear 4 858.12 53.10% 858.12 214.531 26.84 0.000

A 1 586.53 36.30% 586.53 586.531 73.39 0.000

B 1 26.28 1.63% 26.28 26.281 3.29 0.086

C 1 87.78 5.43% 87.78 87.781 10.98 0.004

BUSURA Saheed Adekunle ID: 202090119 STAT 615 DOE Page 10

D 1 157.53 9.75% 157.53 157.531 19.71 0.000

2-Way Interactions 6 299.19 18.51% 299.19 49.865 6.24 0.001

A*B 1 175.78 10.88% 175.78 175.781 22.00 0.000

A*C 1 11.28 0.70% 11.28 11.281 1.41 0.249

A*D 1 63.28 3.92% 63.28 63.281 7.92 0.011

B*C 1 9.03 0.56% 9.03 9.031 1.13 0.301

B*D 1 1.53 0.09% 1.53 1.531 0.19 0.667

C*D 1 38.28 2.37% 38.28 38.281 4.79 0.041

3-Way Interactions 2 306.81 18.99% 306.81 153.406 19.20 0.000

A*B*C 1 166.53 10.31% 166.53 166.531 20.84 0.000

A*B*D 1 140.28 8.68% 140.28 140.281 17.55 0.000

Error 19 151.84 9.40% 151.84 7.992

Lack-of-Fit 3 50.34 3.12% 50.34 16.781 2.65 0.085

Pure Error 16 101.50 6.28% 101.50 6.344

Total 31 1615.97 100.00%

Regression Equation in Un-coded Units

Response = 82.469 - 4.281 A - 0.906 B - 1.656 C + 2.219 D + 2.344 A*B + 0.594 A*C - 1.406 A*D

- 0.531 B*C + 0.219 B*D + 1.094 C*D - 2.281 A*B*C + 2.094 A*B*D

[3 points]

b) Consider the data from the second replicate. Construct a design of two blocks of eight observations each

with ABCD confounded. Analyze the data. Compare your findings to a)

The effect of B, D, AB, AC, AD, BC, BD, CD are not significant since they all have p-value >0.0500 while that

of AB IS SLIGHTLY significant. All other effects are significant. This is not the same as the result obtained in

BUSURA Saheed Adekunle ID: 202090119 STAT 615 DOE Page 11

(a) to a large extent Since only B, AC, BC, BD, and CD are not significant in (a) While D, AB and AD are

significant with other single factor effect too. Comparison of the residual and probability plots reveal this.

Aliases: I, Block 1 – ABCD, A, B, C, D, AB, AC, AD, BC, BD, ABC, ABD

Coded Coefficients

Term Effect Coef SE Coef 95% CI T-Value P-Value VIF

Constant 82.188 0.717 (79.905, 84.470) 114.60 0.000

Blocks

1 -0.813 0.717 (-3.095, 1.470) -1.13 0.340 1.00

A -8.125 -4.063 0.717 (-6.345, -1.780) -5.66 0.011 1.00

B -1.875 -0.938 0.717 (-3.220, 1.345) -1.31 0.282 1.00

C -4.625 -2.313 0.717 (-4.595, -0.030) -3.22 0.048 1.00

D 2.875 1.438 0.717 (-0.845, 3.720) 2.00 0.139 1.00

A*B 3.625 1.813 0.717 (-0.470, 4.095) 2.53 0.086 1.00

A*C 0.875 0.438 0.717 (-1.845, 2.720) 0.61 0.585 1.00

A*D -0.625 -0.312 0.717 (-2.595, 1.970) -0.44 0.692 1.00

B*C 0.125 0.063 0.717 (-2.220, 2.345) 0.09 0.936 1.00

B*D 1.125 0.562 0.717 (-1.720, 2.845) 0.78 0.490 1.00

A*B*C -4.375 -2.188 0.717 (-4.470, 0.095) -3.05 0.055 1.00

A*B*D 4.625 2.313 0.717 (0.030, 4.595) 3.22 0.048 1.00

Model Summary

S R-sq R-sq(adj) PRESS R-sq(pred) AICc BIC

2.86865 96.24% 81.20% 702.222 0.00% 500.35 91.16

Analysis of Variance

Source DF Seq SS Contribution Adj SS Adj MS F-Value P-Value

Model 12 631.750 96.24% 631.750 52.646 6.40 0.076

Blocks 1 10.563 1.61% 10.562 10.562 1.28 0.340

Linear 4 396.750 60.44% 396.750 99.188 12.05 0.034

A 1 264.063 40.23% 264.063 264.063 32.09 0.011

B 1 14.063 2.14% 14.062 14.062 1.71 0.282

C 1 85.563 13.03% 85.562 85.562 10.40 0.048

D 1 33.063 5.04% 33.063 33.063 4.02 0.139

2-Way Interactions 5 62.313 9.49% 62.313 12.463 1.51 0.389

A*B 1 52.563 8.01% 52.563 52.563 6.39 0.086

A*C 1 3.063 0.47% 3.063 3.063 0.37 0.585

A*D 1 1.562 0.24% 1.563 1.563 0.19 0.692

B*C 1 0.063 0.01% 0.063 0.063 0.01 0.936

B*D 1 5.062 0.77% 5.062 5.062 0.62 0.490

3-Way Interactions 2 162.125 24.70% 162.125 81.063 9.85 0.048

A*B*C 1 76.563 11.66% 76.563 76.563 9.30 0.055

A*B*D 1 85.563 13.03% 85.563 85.563 10.40 0.048

Error 3 24.687 3.76% 24.687 8.229

Total 15 656.438 100.00%

Regression Equation in Uncoded Units

Response = 82.188 - 4.063 A - 0.938 B - 2.313 C + 1.438 D + 1.813 A*B + 0.438 A*C - 0.312 A*D

+ 0.063 B*C + 0.562 B*D - 2.188 A*B*C + 2.313 A*B*D

Equation averaged over blocks.

Alias Structure

Factor Name

A A

B B

BUSURA Saheed Adekunle ID: 202090119 STAT 615 DOE Page 12

C C

D D

Aliases : I, Block 1 – ABCD, A, B, C, D, AB, AC, AD, BC, BD, ABC, ABD

BUSURA Saheed Adekunle ID: 202090119 STAT 615 DOE Page 13

c) Consider the data from the first replicate. Suppose we want to use the 24 −1 fractional factorial

[3 points]

design with I=ABCD instead. Set up the design and select the responses for the runs from the full

factorial data. Analyze the data and draw conclusions. Compare your findings with those from full

factorial in a) and the confounded in b).

Answer: Only A, C, ABD and BCD are not significant with other main effects and other

interactions significant with their confounding terms. See Aliases: I+ABCD, A+BCD, D + ABC,

AB + CD, AD +BC for this

Coded Coefficients

Term Effect Coef SE Coef 95% CI T-Value P-Value VIF

Constant 85.000 0.500 (82.849, 87.151) 170.00 0.000

A -1.000 -0.500 0.500 (-2.651, 1.651) -1.00 0.423 1.00

B 4.000 2.000 0.500 (-0.151, 4.151) 4.00 0.057 1.00

D -12.000 -6.000 0.500 (-8.151, -3.849) -12.00 0.007 1.00

A*B -5.000 -2.500 0.500 (-4.651, -0.349) -5.00 0.038 1.00

A*D 6.000 3.000 0.500 (0.849, 5.151) 6.00 0.027 1.00

Analysis of Variance

Source DF Seq SS Contribution Adj SS Adj MS F-Value P-Value

Model 5 444.000 99.11% 444.000 88.800 44.40 0.022

Linear 3 322.000 71.87% 322.000 107.333 53.67 0.018

A 1 2.000 0.45% 2.000 2.000 1.00 0.423

B 1 32.000 7.14% 32.000 32.000 16.00 0.057

D 1 288.000 64.29% 288.000 288.000 144.00 0.007

2-Way Interactions 2 122.000 27.23% 122.000 61.000 30.50 0.032

A*B 1 50.000 11.16% 50.000 50.000 25.00 0.038

A*D 1 72.000 16.07% 72.000 72.000 36.00 0.027

Error 2 4.000 0.89% 4.000 2.000

Total 7 448.000 100.00%

Regression Equation in Uncoded Units

Response = 85.000 - 0.500 A + 2.000 B - 6.000 D - 2.500 A*B + 3.000 A*D

Alias Structure

Factor Name

A A

B B

BUSURA Saheed Adekunle ID: 202090119 STAT 615 DOE Page 14

C C

D D

Aliases: I+ABCD, A+BCD, D + ABC, AB + CD, AD +BC

BUSURA Saheed Adekunle ID: 202090119 STAT 615 DOE Page 15

BUSURA Saheed Adekunle ID: 202090119 STAT 615 DOE Page 16

You might also like

- VRM-Fill Data Only in Yellow Cells: Total Feed (MT) Clinker (MT) Gypsum (MT) Slag (MT)Document2 pagesVRM-Fill Data Only in Yellow Cells: Total Feed (MT) Clinker (MT) Gypsum (MT) Slag (MT)Sahadeb Manna100% (1)

- H2 Liquefaction - Cryogenic V14 - HYSYS (Aspentech)Document9 pagesH2 Liquefaction - Cryogenic V14 - HYSYS (Aspentech)Ian MannNo ratings yet

- Data Sheet Indirect Fired Heater NapkjsDocument12 pagesData Sheet Indirect Fired Heater Napkjsahmad santosoNo ratings yet

- SB15 - Le Gia Han - 31211023234 - Assignment 2Document9 pagesSB15 - Le Gia Han - 31211023234 - Assignment 2Gia Hân LêNo ratings yet

- Presentation For Sugar Mill Energy ReportDocument17 pagesPresentation For Sugar Mill Energy ReportTrinathBanikNo ratings yet

- Raw Mill Heat Balance Without WHR: Sn. Parameters Units ValuesDocument3 pagesRaw Mill Heat Balance Without WHR: Sn. Parameters Units ValuesRamachandrarao MaddaliNo ratings yet

- China Shandong Ruyi Sahiwal of Pakistan 2×660MW Coal-Fired Power Station Project 1 Boiler, Set To Start The Debugger StepsDocument32 pagesChina Shandong Ruyi Sahiwal of Pakistan 2×660MW Coal-Fired Power Station Project 1 Boiler, Set To Start The Debugger StepsJawad HussainNo ratings yet

- Effectiveness - NTU CurvesDocument31 pagesEffectiveness - NTU CurvesLoken Rizal0% (1)

- Seriola K 3120Document2 pagesSeriola K 3120WWTP SerafoodNo ratings yet

- Quality CertificateDocument2 pagesQuality CertificateErick Benito TorralvaNo ratings yet

- Material Test Certificate: M/s Alstom Projects India LimitedDocument1 pageMaterial Test Certificate: M/s Alstom Projects India LimitedDeepak HoleNo ratings yet

- Citrullus Seed DetailDocument9 pagesCitrullus Seed Detailthai avvaiNo ratings yet

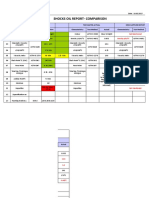

- Shocks Oil - Comparison ReportDocument2 pagesShocks Oil - Comparison ReportRaja Sekaran SajjaNo ratings yet

- Nominal Composition Standard Inventory Specifications: Click Here To View The 718 Product Page On Our WebsiteDocument2 pagesNominal Composition Standard Inventory Specifications: Click Here To View The 718 Product Page On Our WebsiteOnder TemelNo ratings yet

- Eliott 152-20-065 - Proposal Rev 0Document18 pagesEliott 152-20-065 - Proposal Rev 0Racem Loukil0% (1)

- Mitsubishi Diesel Engine Technical Information: Mitsubishi Heavy Industries, LTDDocument4 pagesMitsubishi Diesel Engine Technical Information: Mitsubishi Heavy Industries, LTDMoniru islamNo ratings yet

- Heat Exchanger AnalysisDocument39 pagesHeat Exchanger Analysisingegnere12340% (1)

- Cuptor 600kgDocument84 pagesCuptor 600kgIon CristinaNo ratings yet

- Heat Transfer Oil - Total Seriola K 3120 SpecDocument3 pagesHeat Transfer Oil - Total Seriola K 3120 SpecQuang VũNo ratings yet

- Timetal: Ti - 6 A L - 2 S N - 4 Z r-2 M oDocument2 pagesTimetal: Ti - 6 A L - 2 S N - 4 Z r-2 M oCataNo ratings yet

- Biomass (Rice Straw) Fired BoilerDocument9 pagesBiomass (Rice Straw) Fired BoilerSnehashis MaityNo ratings yet

- Characteristics Units Result Test Method: Southern Pars 1 CondensateDocument14 pagesCharacteristics Units Result Test Method: Southern Pars 1 CondensatemohammadhadiNo ratings yet

- 03 HRR Flame Height Burning Duration Calculations Sup1 SiDocument5 pages03 HRR Flame Height Burning Duration Calculations Sup1 Sisohail parachaNo ratings yet

- Brosur Taland ThermallDocument4 pagesBrosur Taland ThermallFebry ChristoperNo ratings yet

- M. Muhammad, N. Shamsaei, Additively Manufactured Haynes 230 by Laser Powder Directed Energy DepositionDocument13 pagesM. Muhammad, N. Shamsaei, Additively Manufactured Haynes 230 by Laser Powder Directed Energy Depositiondpicc8No ratings yet

- AGA 5 Calculation Spreadsheet - Imperial Units of Measure: Molar Mass Mole Fraction (X) Molar Mass XDocument21 pagesAGA 5 Calculation Spreadsheet - Imperial Units of Measure: Molar Mass Mole Fraction (X) Molar Mass XHafizh Prashantyo100% (1)

- Chapter - 3 Experimentation & Results and DiscussonDocument17 pagesChapter - 3 Experimentation & Results and Discussonthalla rajenderNo ratings yet

- PWHT ProcedureDocument10 pagesPWHT ProcedureSang Nguyen QuangNo ratings yet

- Daphne Bright Quench M-SDocument2 pagesDaphne Bright Quench M-SSuprastowo Bin SarinoNo ratings yet

- PPGJ-PRO-CAL-192 Hot Oil Demand CalculationDocument24 pagesPPGJ-PRO-CAL-192 Hot Oil Demand CalculationTifano Khristiyanto100% (1)

- Pyro & Cooler Heat & Mass Balance Ed1Document2 pagesPyro & Cooler Heat & Mass Balance Ed1JCSNo ratings yet

- Certificates-50l O2 CylinderDocument6 pagesCertificates-50l O2 CylinderClaudia TiradoNo ratings yet

- Cement Kiln Pyro BalanceDocument40 pagesCement Kiln Pyro BalanceGanapathy SubramaniamNo ratings yet

- Application Note: Determination of Moisture in Plant TissueDocument3 pagesApplication Note: Determination of Moisture in Plant TissueLab kimia bahan bakarNo ratings yet

- L-QB 300 Heat Transfer OilDocument3 pagesL-QB 300 Heat Transfer OilYoong TanNo ratings yet

- Standard Heat Transfer Oil: Data SheetDocument3 pagesStandard Heat Transfer Oil: Data SheetHamid KharazmiNo ratings yet

- Page 3 Tsi MTC Plate (MTC - 249)Document2 pagesPage 3 Tsi MTC Plate (MTC - 249)trayojam.rilNo ratings yet

- Pyro Heat Balance 8000TPD @23.03.2023Document2 pagesPyro Heat Balance 8000TPD @23.03.2023harikrushnaNo ratings yet

- AISI 1015 Steel, Cold Drawn: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Low Carbon SteelDocument3 pagesAISI 1015 Steel, Cold Drawn: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Low Carbon SteelAleesha RehanNo ratings yet

- WNCC Shift Report Sched 20200711 A Day DailyDocument14 pagesWNCC Shift Report Sched 20200711 A Day DailyMahmoud HanafyNo ratings yet

- Maximizing Sinter Plant Heat Recovery PDFDocument11 pagesMaximizing Sinter Plant Heat Recovery PDFpinenamu100% (1)

- 1485 - EC2172-signedDocument4 pages1485 - EC2172-signedDeepak HoleNo ratings yet

- HexaneDocument3 pagesHexaneIan RidzuanNo ratings yet

- Technical Data Sheet Rigid 4000Document2 pagesTechnical Data Sheet Rigid 4000dikimanNo ratings yet

- 1299 - Ec0583Document5 pages1299 - Ec0583Deipak HoleNo ratings yet

- Development of 30Kg Crucible Furnace: BY Ore-Aruwaji Oluwaseyi 13/ENG06/027 Supervised by Engr. Dr. A. O. AdeoduDocument15 pagesDevelopment of 30Kg Crucible Furnace: BY Ore-Aruwaji Oluwaseyi 13/ENG06/027 Supervised by Engr. Dr. A. O. AdeoduVictor ImehNo ratings yet

- Balance de Materia 1Document12 pagesBalance de Materia 1diego veyzagaNo ratings yet

- Silber BDocument1 pageSilber BstatisticssalesNo ratings yet

- Heat TreatmentDocument2 pagesHeat TreatmentAnonymous VRspXsmNo ratings yet

- Lampiran 2 OkeDocument18 pagesLampiran 2 OkeJenie FakhriNo ratings yet

- Crue Distillation Process (1) .EditedDocument16 pagesCrue Distillation Process (1) .EditedEdunjobi TundeNo ratings yet

- Therminol 72Document4 pagesTherminol 72Coent TjoroNo ratings yet

- TDC En24Document2 pagesTDC En24Lionell LogeshNo ratings yet

- Experiment No: 01 Experiment Name: Determination of GPM, Heating Value & Wobbe Number of Chattak Gas ObjectiveDocument4 pagesExperiment No: 01 Experiment Name: Determination of GPM, Heating Value & Wobbe Number of Chattak Gas ObjectiveShimu AnwarNo ratings yet

- Boiling Point Distribution of Crude Oils Based On TBP and Astm D-86 Distillation DataDocument17 pagesBoiling Point Distribution of Crude Oils Based On TBP and Astm D-86 Distillation DataFAH MANNo ratings yet

- Dryer EBDocument4 pagesDryer EBOmprakaash MokideNo ratings yet

- Thermal Ceramics Kaolite 2500 LI Insulation CastablesDocument3 pagesThermal Ceramics Kaolite 2500 LI Insulation Castablesjoel cisnerosNo ratings yet

- 304Document2 pages304julianmorantesNo ratings yet

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesFrom EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Project 1 PDFDocument1 pageProject 1 PDFSaheed A BusuraNo ratings yet

- Exercise SolutionDocument5 pagesExercise SolutionSaheed A BusuraNo ratings yet

- Enzymes 3Document47 pagesEnzymes 3Saheed A BusuraNo ratings yet

- Adsorption 1Document9 pagesAdsorption 1Saheed A BusuraNo ratings yet

- 2018 Andrology Registration FormDocument1 page2018 Andrology Registration FormSaheed A BusuraNo ratings yet

- DOE ProjectDocument16 pagesDOE ProjectSaheed A BusuraNo ratings yet

- 14.12final Report STAT 615 ModifiedDocument19 pages14.12final Report STAT 615 ModifiedSaheed A BusuraNo ratings yet

- Project 1 PDFDocument1 pageProject 1 PDFSaheed A BusuraNo ratings yet

- Curriculum Vitae: Ogunjimi Taiwo Jeremiah Professional ObjectivesDocument2 pagesCurriculum Vitae: Ogunjimi Taiwo Jeremiah Professional ObjectivesSaheed A BusuraNo ratings yet

- Graduate Programs Information and Admission Deadlines 2020 2021Document1 pageGraduate Programs Information and Admission Deadlines 2020 2021Saheed A BusuraNo ratings yet

- Course Information 2 PDFDocument1 pageCourse Information 2 PDFSaheed A BusuraNo ratings yet

- Enzymes 2Document12 pagesEnzymes 2Saheed A BusuraNo ratings yet

- Sec6 Steepest AscentDocument13 pagesSec6 Steepest AscentSaheed A BusuraNo ratings yet

- T 2 F D N: HE Actorial EsigDocument33 pagesT 2 F D N: HE Actorial EsigSaheed A BusuraNo ratings yet

- T 2 F D N: HE Actorial EsigDocument33 pagesT 2 F D N: HE Actorial EsigSaheed A BusuraNo ratings yet

- Transition Iron TempDocument9 pagesTransition Iron TempSaheed A BusuraNo ratings yet

- MosdicDocument1 pageMosdicSaheed A BusuraNo ratings yet

- CamScanner 12-13-2020 12.04.04Document3 pagesCamScanner 12-13-2020 12.04.04Saheed A BusuraNo ratings yet

- MainDocument7 pagesMainsanty071No ratings yet

- Assignment 1 (Descriptive Analysis)Document4 pagesAssignment 1 (Descriptive Analysis)Anum SolehahNo ratings yet

- S5 Math (The Binomial Distribution)Document5 pagesS5 Math (The Binomial Distribution)Mwesigwa HannahNo ratings yet

- How To Perform A Two-Way (Within-Between) ANOVA in SPSSDocument12 pagesHow To Perform A Two-Way (Within-Between) ANOVA in SPSSIndraAzaNo ratings yet

- Lecture 6-Measure of Central Tendency-ExampleDocument36 pagesLecture 6-Measure of Central Tendency-ExampleamirhazieqNo ratings yet

- Conf IntDocument1 pageConf IntAnastasia SusciucNo ratings yet

- AP Questions Chapter 4Document8 pagesAP Questions Chapter 4JT GreenbergNo ratings yet

- Terapi Musik Klasik Beethoven Terhadap Penatalaksanaan Cemas Pada PersalinanDocument7 pagesTerapi Musik Klasik Beethoven Terhadap Penatalaksanaan Cemas Pada PersalinanPutu FinaNo ratings yet

- Cluster Analysis - Ward's MethodDocument6 pagesCluster Analysis - Ward's Methodraghu_sbNo ratings yet

- Data ManagementDocument7 pagesData ManagementJhan Ray Gomez BarrilNo ratings yet

- Factor AnalysisDocument36 pagesFactor AnalysisNakul Garg100% (1)

- Statistics FinalReviewDocument8 pagesStatistics FinalReviewWolf's RainNo ratings yet

- Oup TransitionDocument4 pagesOup TransitionBjorn AbuboNo ratings yet

- Mba ZC417 Ec-3m First Sem 2018-2019Document6 pagesMba ZC417 Ec-3m First Sem 2018-2019shiintuNo ratings yet

- Paired and Independent Samples T TestDocument34 pagesPaired and Independent Samples T TestMcjohnden LorenNo ratings yet

- Package Lcda' - (Buecker, 2022)Document19 pagesPackage Lcda' - (Buecker, 2022)Diego ArsNo ratings yet

- Syllabus of Stats BU and MUDocument2 pagesSyllabus of Stats BU and MURajendra KumarNo ratings yet

- Course Syllabus On EconometricsDocument2 pagesCourse Syllabus On EconometricsFrance MoNo ratings yet

- Principal Component and Factor AnalysisDocument43 pagesPrincipal Component and Factor AnalysisstanduppstoreNo ratings yet

- Regression Analysis AssignmentDocument8 pagesRegression Analysis Assignmentضیاء گل مروتNo ratings yet

- Lilliefors Van Soest's Test of NormalityDocument10 pagesLilliefors Van Soest's Test of Normalitydimitri_deliyianniNo ratings yet

- Psychological Assessment PDFDocument234 pagesPsychological Assessment PDFMawi BadNo ratings yet

- Researc H DesignDocument18 pagesResearc H DesignTj NovalNo ratings yet

- Descriptive Statistical MeasuresDocument63 pagesDescriptive Statistical MeasuresKUA JIEN BINNo ratings yet

- The Wartegg Zeichen Test: A Literature Overview and A Meta-Analysis of Reliability and ValidityDocument15 pagesThe Wartegg Zeichen Test: A Literature Overview and A Meta-Analysis of Reliability and ValidityYahyaMaulanaIbrahimNo ratings yet

- Parametric Test: DR - Dr.Siswanto, MSCDocument34 pagesParametric Test: DR - Dr.Siswanto, MSCadindapramitrapsNo ratings yet

- Statistics Lab Report 2Document20 pagesStatistics Lab Report 2Arbeen ZNo ratings yet

- Applied Statistics Lab Manual No. 3 MinitabDocument11 pagesApplied Statistics Lab Manual No. 3 MinitabJOHN JUSTIN DELA CRUZNo ratings yet

- Contoh Uji Validitas Dan Reliabulitas Dengan Excell Dan SPSSDocument8 pagesContoh Uji Validitas Dan Reliabulitas Dengan Excell Dan SPSSLiana LimbongNo ratings yet