Professional Documents

Culture Documents

Mitsubishi Diesel Engine Technical Information: Mitsubishi Heavy Industries, LTD

Uploaded by

Moniru islamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mitsubishi Diesel Engine Technical Information: Mitsubishi Heavy Industries, LTD

Uploaded by

Moniru islamCopyright:

Available Formats

ITEM NO.

T54-0020-E (1/4)

MITSUBISHI DIESEL ENGINE

TECHNICAL INFORMATION DATE June, 1988

Limiting requirements for fuel oils for Mitsubishi diesel engines

1. Mitsubishi high-speed diesel engines have the ability to burn a wide range of fuel oils.

Distillate fuel are the preferred fuels for use in all Mitsubishi engines.

JIS K-2204 TYPE1, TYPE2, TYPE3

ASTM, D975 No.1-D, No.2-D

BS2869 CLASS-A1, CLASS-A2

DIN51601 DIESEL-FUEL

ISO8217 DMX-CLASS

2. In selecting a fuel oil, consult Table 1 – “Limiting Requirements for Diesel Fuel Oils.”

3. Refer to Table 2 for effects of fuel properties on engine performance

4. For other fuel oils, refer to a separate MITSUBISHI DIESEL ENGINE TECHNICAL INFORMATION.

1st Edition : Jun. 1988 Engine Engineering Department

2nd Edition : Dec.1998 Large Engine Design Section

Revision

3rd Edition : Oct.1999 Approved by Checked by Drawn by

4th Edition : Jan. 2002

MITSUBISHI HEAVY INDUSTRIES, LTD.

GENERAL MACHINERY & SPECIAL VEHICLE HEADQUATERS

ITEM NO. T54-0020-E (2/4)

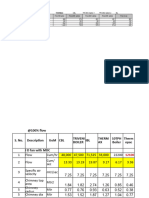

Table 1 Limiting Requirements for Fuel Oils for Mitsubishi High-Speed Diesel Engines

Property Recommended Limit Service Limit Remarks

JIS K 2204, 2205

Diesel fuel: 50°C,

Flash point By Legal By Legal min.

Furnace oil: 60°C,

min.

Initial boiling 170°C, min. 170°C, min.

Distillation point JIS K 2254

temperatures

90% point 330°C to 380°C 330°C to 380°C

6°C below the lowest 6°C below the lowest

Pour point ambient temperature, ambient temperature,

min. min. JIS K 2269

Cloud point Below the lowest Below the lowest

ambient temperature ambient temperature

Carbon residue on 10% residuum 0.4% by weight, max. 1.0% by weight, max. JIS K 2270

Cetane number 45, min. 45, min.

Cetane index 45, min. 45, min. JIS K 2280-1996

2.0 cSt, min. (60°C) 2.0 cSt, min. (60°C)

Kinematic viscosity 8.0 cSt, max. (50°C) 8.0 cSt, max. (50°C)

10.5 cSt, max. (40°C) 10.5 cSt, max. (40°C)

16.0 cSt, max. (30°C) 16.0 cSt, max. (30°C)

JIS K 2541

0.05% by weight, max.

Sulfur 0.2% by weight, max. 1.0% by weight, max. which is average of

diesel fuel is preferred.

Water and sediment 0.1% by volume, max. 0.1% by volume, max. JIS K 2275

Ash 0.03% by weight 0.03% by weight JIS K 2272

Copper strip corrosion at 100°C, ASTM No.3

3 hr No. 3, max. No. 3, max. JIS K 2513:

Discoloration No.3

Gravity, at 15°C 0.83 to 0.87 0.80 to 0.87

Fed 791 B

250°C∼Carbonization 250℃ × 24Hr

volume, 75% max. 250°C∼Carbonization

Coking volume, 85% max. 230℃ × 24H

230℃∼Evaporation

volume, 55% max.

180℃∼Non tarring 180℃ × 48Hr

Aroma (HPLC) 38% by volume, max. 38% by volume, max. JIS K 2536

Total Aroma Volume

Asphaltene 0.1% by weight, max. 0.1% by weight, max.

Impurities 5.0 mg/liter, max. 5.0 mg/liter, max. JIS B 9931

Including fuel pipe line

Application of Generator Prime-use Standby-use

Coutinuous-use

MITSUBISHI HEAVY INDUSTRIES, LTD.

GENERAL MACHINERY & SPECIAL VEHICLE HEADQUATERS

ITEM NO. T54-0020-E (3/4)

Table 2 Discussion of Fuel Properties

Has no effect on engine performance. It is, however, important in connection with

Flash point legal requirements and safety precautions involved in fuel handling and storage,

and is normally specified to meet fire regulations.

Fuel volatility requirements depend on engine design and size, nature of speed

and load variations, and on starting and atmospheric conditions. More volatile

fuels are best for engines in services involving rapidly varying loads and speeds.

Distillation

Low end-point fuels tend to give better fuel economy where their properties are

needed for complete combustion, and definitely will produce less smoke, odor,

deposits, dilution, and wear. Importance of end point increases with engine speed.

Determines the lowest atmospheric temperature at which fuel can be pumped

through the injection system. Fuel filters may clog with wax when operating near

Pour point

the pour point. The required pour point depends, therefore, on the minimum

expected operating temperature.

Is the temperature at which wax becomes visible and is generally above the pour

Cloud point point of fuel. It should be below the lowest atmospheric temperature at which the

engine will be operated so the filter will not be clogged with wax formation.

Gives a measure of the carbon depositing tendencies of fuel when heated in a

Carbon residue bulb under prescribed conditions. While not directly correlating with engine

deposits, this property is considered an approximation.

Is a measure of the ignition quality of fuel and influences both startability and

acceleration under load. The requirements depend on engine size and design,

Cetane number nature of speed and load variations, and on starting and atmospheric conditions.

For high altitude operation or cold weather starting, a higher cetane number may

be required.

Is the absolute viscosity divided by the density of the fluid at the temperature of

viscosity measurement. For some engines, it is advantageous to specify a

Kinematic viscosity minimum viscosity because of power loss due to injection pump and nozzle

leakage. Maximum viscosity, on the other hand, is limited by considerations

involved in engine design and size, and the characteristics of injection system.

Sulfur content has a marked effect on wear of pistons, rings, valves, and cylinder

liners. Wear is less serious under constant load and high-temperature operation.

This wear is promoted by corrosive effects of the hydrogen sulfide in the fuel and

sulfur dioxide or sulfur trioxide formed during combustion which combine with

Sulfur water vapor to form acids. High sulfur fuels tend to increase engine deposits and

require more frequent oil changes. High-additive lube oils are thought by many to

be desirable with high-sulfur fuels. Selection of the best lube oil for engines

burning high-sulfur fuels is dependent on the design of the individual engine and

its operating conditions.

Are factors relating to fuel filter life and to wear of injection equipment and

Water and sediment engine parts. Freezing of an emulsion of water and oil will prevent fuel flow to

the injection system.

MITSUBISHI HEAVY INDUSTRIES, LTD.

GENERAL MACHINERY & SPECIAL VEHICLE HEADQUATERS

ITEM NO. T54-0020-E (4/4)

Fuel contains ash-forming materials in the form of abrasive solids or soluble

metallic soaps. Solids will cause wear of injection equipment, pistons, rings and

Ash

liners, and also increase engine deposits. Ash from soluble soaps will also

contribute to engine deposits and wear.

Corrosion tendency is a measure of possible reaction with copper, brass, or

bronze parts of the fuel system. This specification gives no indication of corrosion

Corrosion

of steel parts of the engine which may occur from use of high-sulfur fuels with

low engine temperatures.

Vanadium and sodium contents have an effect on corrosion of exhaust valves

exposed to high temperature exhaust gases during operation. This corrosion can

Vanadium and

cause poor valve seating and promote fouling of turbocharger. Diesel fuel oils and

sodium

burner oils do not contain much vanadium and sodium contents, and no limiting

requirements of these contents are specified for diesel fuels and burner oils.

MITSUBISHI HEAVY INDUSTRIES, LTD.

GENERAL MACHINERY & SPECIAL VEHICLE HEADQUATERS

You might also like

- L-TSE Turbine OilDocument3 pagesL-TSE Turbine OilYoong TanNo ratings yet

- Marine Fuel3Document2 pagesMarine Fuel3Finito TheEndNo ratings yet

- Technical Reference Guide for Oil Purification SeparatorDocument5 pagesTechnical Reference Guide for Oil Purification SeparatorninatenaNo ratings yet

- Turbine Oil - SpecDocument2 pagesTurbine Oil - SpecEid EeidNo ratings yet

- Skikda Training CDU (Goal Content)Document26 pagesSkikda Training CDU (Goal Content)Mohamed OuichaouiNo ratings yet

- TGSB(M) Turbine OilDocument3 pagesTGSB(M) Turbine OilQuy NguyenNo ratings yet

- GEK28143a - Hydrocarbon LO RecommendationsDocument10 pagesGEK28143a - Hydrocarbon LO RecommendationssyedNo ratings yet

- Rigid 10k DatasheetDocument2 pagesRigid 10k DatasheetAna Maria RodrigoNo ratings yet

- alloy20DataSheet PDFDocument2 pagesalloy20DataSheet PDFichrakNo ratings yet

- Operator Training-Eng (Compatibility Mode)Document31 pagesOperator Training-Eng (Compatibility Mode)jendriko100% (1)

- Alloy 718 high strength nickel-base superalloy properties applicationsDocument2 pagesAlloy 718 high strength nickel-base superalloy properties applicationsOnder TemelNo ratings yet

- 1Document3 pages1Catalina CuzminNo ratings yet

- QALCO Syntholube GX 220Document1 pageQALCO Syntholube GX 220Deepak JoyNo ratings yet

- ReportFFFF PDFDocument2 pagesReportFFFF PDFحسن دشتيNo ratings yet

- Oil Analysis Charge and Cleaning: Item Unit Test Method LimitDocument1 pageOil Analysis Charge and Cleaning: Item Unit Test Method LimitJose Yebra DeaunaNo ratings yet

- DuraplateDocument4 pagesDuraplatelovaldes62No ratings yet

- Boiler Chimny - 29.12.23Document18 pagesBoiler Chimny - 29.12.23Rajendra GautamNo ratings yet

- D2 JP54 Spec PDFDocument3 pagesD2 JP54 Spec PDFcesarjabbour1No ratings yet

- Hytherm S NewDocument2 pagesHytherm S NewOliver OliverNo ratings yet

- Biodiesel Fuel and How To HandlingDocument35 pagesBiodiesel Fuel and How To Handlingandistwn99No ratings yet

- B20 Biodiesel Fuel and Technical Requirements PDFDocument35 pagesB20 Biodiesel Fuel and Technical Requirements PDFandistwn99No ratings yet

- Pertamina Biodiesel Technical Requirements PDFDocument35 pagesPertamina Biodiesel Technical Requirements PDFandistwn99No ratings yet

- Seriola K 3120Document2 pagesSeriola K 3120WWTP SerafoodNo ratings yet

- Gas Turbine GEK28143a PDFDocument10 pagesGas Turbine GEK28143a PDFSunario YapNo ratings yet

- Separator Sizing SheetDocument8 pagesSeparator Sizing SheetCahyoNo ratings yet

- Deutz Power SystemsDocument4 pagesDeutz Power SystemsRudiNo ratings yet

- Technical Data Sheet Rigid 4000Document2 pagesTechnical Data Sheet Rigid 4000dikimanNo ratings yet

- Motor Maintenance: General InspectionDocument3 pagesMotor Maintenance: General InspectionWaskito AjiNo ratings yet

- Heat Transfer Oil - Total Seriola K 3120 SpecDocument3 pagesHeat Transfer Oil - Total Seriola K 3120 SpecQuang VũNo ratings yet

- 3406 Performance Specification PDFDocument2 pages3406 Performance Specification PDFaliNo ratings yet

- Extracted Pages From A001064 - 12EDocument4 pagesExtracted Pages From A001064 - 12EAwais8888No ratings yet

- Continental Engines Comparison A65 A75 Though A85Document1 pageContinental Engines Comparison A65 A75 Though A85AIRCRAFTSNo ratings yet

- Transformer Oil Specifications: BY Central Insulating Oil Testing LaboratoryDocument17 pagesTransformer Oil Specifications: BY Central Insulating Oil Testing LaboratoryRonak ThakkarNo ratings yet

- Iqcm Annex 1 Product SpecsDocument19 pagesIqcm Annex 1 Product Specssonn1729No ratings yet

- Heavy - Duty - Engine - Oils - SAE 40 PDFDocument2 pagesHeavy - Duty - Engine - Oils - SAE 40 PDFCorina StanculescuNo ratings yet

- Aditya Tech Diary PDFDocument155 pagesAditya Tech Diary PDFSiddhant SatpathyNo ratings yet

- L-QB 300 Heat Transfer OilDocument3 pagesL-QB 300 Heat Transfer OilYoong TanNo ratings yet

- 8017 - 3 - Transformer Oil - Tech Spec PDFDocument2 pages8017 - 3 - Transformer Oil - Tech Spec PDFlostkinNo ratings yet

- GT Class TKGTPSDocument84 pagesGT Class TKGTPSGnanaseharan Arunachalam100% (1)

- FC234 High Temperature Fuel and Oil HoseDocument1 pageFC234 High Temperature Fuel and Oil HoseHotnCrispy CrispyNo ratings yet

- TI 618-1 PERT Pipe Material Properties: EDITION 0516 PAGE 1/1Document1 pageTI 618-1 PERT Pipe Material Properties: EDITION 0516 PAGE 1/1abdelkader benabdallahNo ratings yet

- 7th International İstanbul Bunker Conference Chris Fisher PDFDocument39 pages7th International İstanbul Bunker Conference Chris Fisher PDFBatul KhuzemaNo ratings yet

- Quality Control of Products in Petroleum RefiningDocument29 pagesQuality Control of Products in Petroleum RefiningAdrian RodriguezNo ratings yet

- Exp 3 - Carbon Residue TestDocument15 pagesExp 3 - Carbon Residue TestMark Cortez92% (12)

- Quality Tyre Derieved Fuel: National Tyre Pyrolysis CorporationDocument6 pagesQuality Tyre Derieved Fuel: National Tyre Pyrolysis CorporationratneshNo ratings yet

- Hopelex Af 3100Document2 pagesHopelex Af 3100FarizNo ratings yet

- Presentation Transformer OilDocument44 pagesPresentation Transformer Oilravi_bagga2000100% (3)

- DATA SHEET BLOWER FRAIJANES - URAI-33-Blower-Data-SheetDocument2 pagesDATA SHEET BLOWER FRAIJANES - URAI-33-Blower-Data-SheetOscar SteigerNo ratings yet

- Thermal Conversion ProcessesDocument24 pagesThermal Conversion ProcessesAl JawadNo ratings yet

- PUSH 400CTL K38热平衡表Document1 pagePUSH 400CTL K38热平衡表周庆卓No ratings yet

- English & Arab DescriptionDocument15 pagesEnglish & Arab DescriptionRacem LoukilNo ratings yet

- Biodiesel Standards & PropertiesDocument6 pagesBiodiesel Standards & PropertiesMarta Lopez BerralNo ratings yet

- Shearer Volume1 Book 2-FinalDocument125 pagesShearer Volume1 Book 2-FinalSatyanarayanarao ChitluriNo ratings yet

- Thermal performances for one boilerDocument1 pageThermal performances for one boilerJosé Pedro MagalhãesNo ratings yet

- Thermic Fluid Heater Data Sheet - Rev 0Document10 pagesThermic Fluid Heater Data Sheet - Rev 0Dhamotharan ChinnaduraiNo ratings yet

- Data Sheet Tcg2032 DeutzDocument3 pagesData Sheet Tcg2032 DeutzMaximiliano SanchezNo ratings yet

- Nptel Chemical Engineering Petroleum Refinery Engineering9Document6 pagesNptel Chemical Engineering Petroleum Refinery Engineering9Ahmed Mohamed KhalilNo ratings yet

- Deactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and ModelingFrom EverandDeactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and ModelingNo ratings yet

- T07sonota Jishukanri03 EngDocument108 pagesT07sonota Jishukanri03 EngMoniru islamNo ratings yet

- Mitsubishi Diesel Engine Technical Information: Quality of Water Used As Engine CoolantDocument3 pagesMitsubishi Diesel Engine Technical Information: Quality of Water Used As Engine CoolantMoniru islamNo ratings yet

- Mitsubishi Diesel Engine Technical Information: Management Standard For Engine Lubricating OilsDocument4 pagesMitsubishi Diesel Engine Technical Information: Management Standard For Engine Lubricating OilsMoniru islamNo ratings yet

- Operation & Maintenance Manual: Issued: March 2021 Pub. No. 29A01-00120 Revision: 1Document123 pagesOperation & Maintenance Manual: Issued: March 2021 Pub. No. 29A01-00120 Revision: 1Falgon IslamNo ratings yet

- Mitsubishi Diesel Engine Technical Information: Coolant AdditivesDocument3 pagesMitsubishi Diesel Engine Technical Information: Coolant AdditivesMoniru islamNo ratings yet

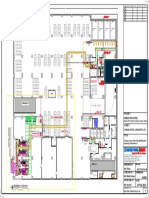

- Car lift installation design documentDocument1 pageCar lift installation design documentMoniru islamNo ratings yet

- SCB-175 D-C1 - P1Document1 pageSCB-175 D-C1 - P1Moniru islamNo ratings yet

- As Built Drawing of Front PageDocument1 pageAs Built Drawing of Front PageMoniru islamNo ratings yet

- Mitsubishi Diesel Engine Starting AidsDocument4 pagesMitsubishi Diesel Engine Starting AidsMoniru islamNo ratings yet

- Hydac User ManualDocument2 pagesHydac User ManualMoniru islamNo ratings yet

- Solution 1: Temperature Inlet: Approx 37°Document4 pagesSolution 1: Temperature Inlet: Approx 37°Moniru islamNo ratings yet

- SCB-175 D-C1 - P2Document1 pageSCB-175 D-C1 - P2Moniru islamNo ratings yet

- Cooling TowerDocument8 pagesCooling TowerMoniru islamNo ratings yet

- Plate Heat ExchangerDocument4 pagesPlate Heat ExchangerMoniru islamNo ratings yet

- Installation RecomendationsDocument5 pagesInstallation RecomendationsMoniru islamNo ratings yet

- Sun Coolrng T /ryer. Urd., Fart.: U'Hruusl"Ue1Nfi 'Ilu F$A Tyl'Ll? ?Document2 pagesSun Coolrng T /ryer. Urd., Fart.: U'Hruusl"Ue1Nfi 'Ilu F$A Tyl'Ll? ?Moniru islamNo ratings yet

- Technical Data: Pump NameDocument4 pagesTechnical Data: Pump NameMoniru islamNo ratings yet

- Gcm01-Mu-Gb-12 2 (Ac02)Document33 pagesGcm01-Mu-Gb-12 2 (Ac02)saiful islamNo ratings yet

- HistoryDocument312 pagesHistoryFalgon IslamNo ratings yet

- Quality Control of Crude DrugsDocument17 pagesQuality Control of Crude Drugskamal devdaNo ratings yet

- research-group-1-DDDDocument18 pagesresearch-group-1-DDDCarlo Tiburcio CapunoNo ratings yet

- Template Develop Lab TrainingDocument2 pagesTemplate Develop Lab TrainingThusitha LakpriyaNo ratings yet

- Q.1 The Major Product Formed in The Following Reaction IsDocument10 pagesQ.1 The Major Product Formed in The Following Reaction IsDoom RefugeNo ratings yet

- Paragon Air FilterDocument8 pagesParagon Air FilterRandi WijayaNo ratings yet

- Application Worksheet Motorized Pulleys Fax: 910-794-9296: Standard Loading Conditions: Operating ConditionsDocument1 pageApplication Worksheet Motorized Pulleys Fax: 910-794-9296: Standard Loading Conditions: Operating Conditionsemrah nalbantNo ratings yet

- VSC 606Document51 pagesVSC 606aditikaNo ratings yet

- Lab Report GCDocument18 pagesLab Report GCMohamad Saiful Mohd RaffiahNo ratings yet

- Argentometry PPT TitrationDocument5 pagesArgentometry PPT TitrationSayan RoyNo ratings yet

- Lecture 18 - Isopropanol and Acetone From PropyleneDocument6 pagesLecture 18 - Isopropanol and Acetone From PropyleneRichardN55No ratings yet

- Wheat QC Training GuidelineDocument53 pagesWheat QC Training GuidelineMelikteNo ratings yet

- Is 12308-3 - 1987 - 1Document1 pageIs 12308-3 - 1987 - 1Svapnesh ParikhNo ratings yet

- Polymerisarion PMTDocument8 pagesPolymerisarion PMTChristine MoyoNo ratings yet

- Biogeochemical Cycles For APESDocument42 pagesBiogeochemical Cycles For APESjohnosborneNo ratings yet

- Alfagoma HidraulicaDocument37 pagesAlfagoma HidraulicaViniciusCamargosNo ratings yet

- Heterocyclic CompoundsDocument38 pagesHeterocyclic CompoundsMuhammad NaqiNo ratings yet

- Klubertemp HM 83 402Document2 pagesKlubertemp HM 83 402AlfredNo ratings yet

- Astm D3590 Nitrogeno Total en Aguas PDFDocument9 pagesAstm D3590 Nitrogeno Total en Aguas PDFAlvaro Pérez PérezNo ratings yet

- Ingen Laboratory Catalog Roth 2017 PDFDocument2,440 pagesIngen Laboratory Catalog Roth 2017 PDFComan GigiNo ratings yet

- Ryton® PPS - Corrosion-Resistant-CoatingsDocument9 pagesRyton® PPS - Corrosion-Resistant-CoatingsAhmed FathyNo ratings yet

- Rubber World Magazine 2020-12 DecDocument90 pagesRubber World Magazine 2020-12 DecGijoNo ratings yet

- Kaplan + UWorldDocument49 pagesKaplan + UWorldELIOMAR ROSA-RAMONNo ratings yet

- Polymers 14 04269Document22 pagesPolymers 14 04269Athlur Sai KiranNo ratings yet

- RADIOIMMUNOASSAYDocument4 pagesRADIOIMMUNOASSAYJansen MunioNo ratings yet

- Redox 1DPDocument57 pagesRedox 1DPIsadora ThibauNo ratings yet

- COSHH Risk Assessment for SIGMACOVER 620 BASE PaintDocument3 pagesCOSHH Risk Assessment for SIGMACOVER 620 BASE PaintKannan Sasidharan PillaiNo ratings yet

- 0 Material Safety Data Sheet: Giemsa Stain - Stock MSDSDocument6 pages0 Material Safety Data Sheet: Giemsa Stain - Stock MSDSA.N. MNo ratings yet

- Molluscicidal Potential of Mimosa pudica Stem Extract Against Achatina fulica (39 charactersDocument26 pagesMolluscicidal Potential of Mimosa pudica Stem Extract Against Achatina fulica (39 charactersChestelle TaporcoNo ratings yet

- Steel Sheets For Highly Productive Hot StampingDocument6 pagesSteel Sheets For Highly Productive Hot StampingWeston ChenNo ratings yet

- A Guide To Safe Use of Salon Hair ProductsDocument38 pagesA Guide To Safe Use of Salon Hair ProductsPaula Coxixo Taborda100% (1)