Professional Documents

Culture Documents

FMECA Training Course Outline

Uploaded by

Inara Kollery0 ratings0% found this document useful (0 votes)

6 views2 pagesThis document outlines the Failure Mode, Effects and Criticality Analysis (FMECA) course, which teaches a systematic process for identifying potential failure modes in a system and assessing their effects and criticality. The course covers the history and purpose of FMECA, the FMECA process overview, and how to perform FMECAs at the system, subsystem and component level. It also details the 7 steps of the FMECA development methodology, which involves performing an FMEA, determining severity of effects, assigning failure probabilities, calculating and plotting criticality, implementing risk mitigation actions, and maintability analysis.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines the Failure Mode, Effects and Criticality Analysis (FMECA) course, which teaches a systematic process for identifying potential failure modes in a system and assessing their effects and criticality. The course covers the history and purpose of FMECA, the FMECA process overview, and how to perform FMECAs at the system, subsystem and component level. It also details the 7 steps of the FMECA development methodology, which involves performing an FMEA, determining severity of effects, assigning failure probabilities, calculating and plotting criticality, implementing risk mitigation actions, and maintability analysis.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views2 pagesFMECA Training Course Outline

Uploaded by

Inara KolleryThis document outlines the Failure Mode, Effects and Criticality Analysis (FMECA) course, which teaches a systematic process for identifying potential failure modes in a system and assessing their effects and criticality. The course covers the history and purpose of FMECA, the FMECA process overview, and how to perform FMECAs at the system, subsystem and component level. It also details the 7 steps of the FMECA development methodology, which involves performing an FMEA, determining severity of effects, assigning failure probabilities, calculating and plotting criticality, implementing risk mitigation actions, and maintability analysis.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Quality-One International

Failure Mode, Effects and Criticality Analysis (FMECA) Course Outline

History and Purpose of FMECA

FMECA Process Overview

FMECA in the Product Development Process

System / Subsystem / Component FMECA

Team Structure and Rules for Efficiency

Link between FMEA and FMECA

o Functions

o Failure Modes

o Causes

o Effects

FMECA Development Methodology

o Step 1: Perform FMEA

Functions / Failure Modes / Effects of Failure / Severity

Severity Ranking Guidelines

Review Actions for High Severity

o Step 2: Determine Severity for Effects for FMECA

o Step 3: Assign Effects Probabilities

o FMECA Workshop: Steps 1-3

o Step 4: Establish Probabilities

Failure Mode

Individual Components

Data source for Failure Rate data (Lambda)

o Step 5: Calculate and Plot Criticality

o FMECA Workshop: Steps 4-5

o Step 6: Design Feedback and Risk Mitigation

Mitigation actions directed at Highest Severity and Probability

combinations

o Step 7: Maintainability Analysis

1333 Anderson Clawson MI 48017

Phone: 248.280.4800 Fax: 248.280.4804

www.quality-one.com

Quality-One International

Reliability-based Selection of Components

Develop Spare Parts List

o FMECA Workshop: Steps 6-7

Design Review Integration of Risks

o Test Plan Development / Design Verification Plan and Report (DVP&R)

o Revisit Rankings After Action Completion

1333 Anderson Clawson MI 48017

Phone: 248.280.4800 Fax: 248.280.4804

www.quality-one.com

You might also like

- Advanced PFMEADocument22 pagesAdvanced PFMEAHassan KhanNo ratings yet

- FMEA Failure Modes & Effects AnalysisDocument32 pagesFMEA Failure Modes & Effects AnalysisSherif Eltoukhi100% (7)

- FMEADocument20 pagesFMEARonillo PormonNo ratings yet

- Process FmeaDocument8 pagesProcess Fmeaanirudha samalNo ratings yet

- Guidelines for Hazard Evaluation ProceduresFrom EverandGuidelines for Hazard Evaluation ProceduresRating: 5 out of 5 stars5/5 (4)

- FmeaDocument24 pagesFmeaanon-630122100% (4)

- Failure Mode and Effects Analysis (Design) : Importance in NPD ProcessDocument12 pagesFailure Mode and Effects Analysis (Design) : Importance in NPD Processsushant3240No ratings yet

- Improving Product Reliability and Software Quality: Strategies, Tools, Process and ImplementationFrom EverandImproving Product Reliability and Software Quality: Strategies, Tools, Process and ImplementationNo ratings yet

- 10 Steps To Conduct A DFMEADocument5 pages10 Steps To Conduct A DFMEAkirthi83No ratings yet

- Problem Solving and Analysis Tools Failure Modes and Effects Analysis - FmeaDocument7 pagesProblem Solving and Analysis Tools Failure Modes and Effects Analysis - FmeaAhmed M. HashimNo ratings yet

- FMEA Failure Modes Effects Analysis PDFDocument32 pagesFMEA Failure Modes Effects Analysis PDFVILLANUEVA_DANIEL2064100% (1)

- Quality Core ToolsDocument14 pagesQuality Core Toolsالعاب الاطفال- jeux enfantsNo ratings yet

- Fmeca ProcedureDocument11 pagesFmeca Procedurewarigiyatno100% (1)

- Fig 4.8 OEE: 4.5 Failure Mode and Effect Analysis (Fmea)Document17 pagesFig 4.8 OEE: 4.5 Failure Mode and Effect Analysis (Fmea)Gowtham D'Night FoxNo ratings yet

- FMEA2002Document22 pagesFMEA2002deleep6132No ratings yet

- 203 LSS Gbo - FmeaDocument47 pages203 LSS Gbo - FmeaRocker byNo ratings yet

- RCM3: Risk-Based Reliability Centered MaintenanceFrom EverandRCM3: Risk-Based Reliability Centered MaintenanceRating: 1 out of 5 stars1/5 (1)

- Microsoft Word - Fire Fighting Manual - Copy 1Document84 pagesMicrosoft Word - Fire Fighting Manual - Copy 1Inara Kollery100% (1)

- 7 FmeaDocument25 pages7 Fmeaprx4177No ratings yet

- Structured Software Testing: The Discipline of DiscoveringFrom EverandStructured Software Testing: The Discipline of DiscoveringNo ratings yet

- Assembly Resolutiona.438Document4 pagesAssembly Resolutiona.438Inara KolleryNo ratings yet

- FMEA ProcessDocument7 pagesFMEA ProcessRANJITHNo ratings yet

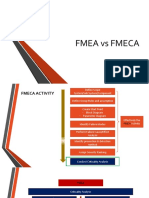

- FMEA Vs FMECADocument10 pagesFMEA Vs FMECAAndika Haris NugrohoNo ratings yet

- Failure Mode & Effects Analysis (FMEA) - A3 SizeDocument1 pageFailure Mode & Effects Analysis (FMEA) - A3 SizeRavi KiranNo ratings yet

- TQM Unit 4 FMEA Lecture 6Document17 pagesTQM Unit 4 FMEA Lecture 6tamilselvansambathNo ratings yet

- FMEA DeckDocument20 pagesFMEA Deckgogisetty100% (1)

- Development and Implementation of A High Energy Piping ProgramDocument25 pagesDevelopment and Implementation of A High Energy Piping ProgramKurt CobainNo ratings yet

- FMEADocument4 pagesFMEABERNARDO MALACARANo ratings yet

- 20bba0194 TQM Da 1 FmeaDocument9 pages20bba0194 TQM Da 1 Fmeavani sureshNo ratings yet

- Apparel Quality Management FmeaDocument12 pagesApparel Quality Management FmeaSakshi SinghNo ratings yet

- Failure Mode & Effect Analysis: Haroon ChughtaiDocument16 pagesFailure Mode & Effect Analysis: Haroon ChughtaiOwaisNo ratings yet

- Guide To Risk ManagementDocument9 pagesGuide To Risk ManagementelevendotNo ratings yet

- Failure Mode and Effect Analysis: Apparel Quality ManagementDocument30 pagesFailure Mode and Effect Analysis: Apparel Quality ManagementShagun SinhaNo ratings yet

- FmeaDocument6 pagesFmeaUmerNo ratings yet

- (International Journal of Quality and Reliability Management) Failure Mode and Effects AnalysisDocument19 pages(International Journal of Quality and Reliability Management) Failure Mode and Effects AnalysisLuis Gustavo PachecoNo ratings yet

- Mistake Proofing Training Course OutlineDocument2 pagesMistake Proofing Training Course OutlineRajkumar PrajapatiNo ratings yet

- Final MELCOR Gap Analysis Report 050304Document73 pagesFinal MELCOR Gap Analysis Report 050304romancoolNo ratings yet

- Scope of WorkDocument2 pagesScope of WorkMadhu Sudhan ReddyNo ratings yet

- FMEA TrainingDocument49 pagesFMEA Trainingeidlberto casedoNo ratings yet

- Failure Mode and Effects Analysis (Fmea)Document11 pagesFailure Mode and Effects Analysis (Fmea)Chaudhary Hassan AliNo ratings yet

- Failure Mode and Effects Analysis - GoSkills Course SyllabusDocument3 pagesFailure Mode and Effects Analysis - GoSkills Course SyllabusIndra KurniawanNo ratings yet

- ANALYZEDocument6 pagesANALYZEpranitsadhuNo ratings yet

- Analyze Opportunity Part 1: Failure Modes Effect Analysis (FMEA)Document36 pagesAnalyze Opportunity Part 1: Failure Modes Effect Analysis (FMEA)Viswanathan SrkNo ratings yet

- Application of FMEA and FMECA To Subsea Drilling SystemDocument2 pagesApplication of FMEA and FMECA To Subsea Drilling SystemKhánh Tuyền Nguyễn ThịNo ratings yet

- EMT 480 Reliability & Failure AnalysisDocument38 pagesEMT 480 Reliability & Failure AnalysisK ULAGANATHANNo ratings yet

- FMEADocument46 pagesFMEAKathiresan NarayananNo ratings yet

- Performance Test ReportDocument44 pagesPerformance Test ReportDaniel TenkerNo ratings yet

- MainFEMA SKH PDFDocument46 pagesMainFEMA SKH PDFswapan kumar hazraNo ratings yet

- Analyze Opportunity Part 1: Failure Modes Effect Analysis (FMEA)Document36 pagesAnalyze Opportunity Part 1: Failure Modes Effect Analysis (FMEA)Viswanathan SrkNo ratings yet

- Innovative Approach To FMEA Facilitation: Govind RamuDocument34 pagesInnovative Approach To FMEA Facilitation: Govind Ramukskr_44No ratings yet

- 2.4 Failure Mode Effect AnalysisDocument6 pages2.4 Failure Mode Effect AnalysisDr.T. Pridhar ThiagarajanNo ratings yet

- Analyze Opportunity Part 1: Failure Modes Effect Analysis (FMEA)Document35 pagesAnalyze Opportunity Part 1: Failure Modes Effect Analysis (FMEA)Yuwaraj DandeNo ratings yet

- Topic: Failure Mode & Effect AnalysisDocument6 pagesTopic: Failure Mode & Effect AnalysisAbdullah AwanNo ratings yet

- TQM Fmea 3Document14 pagesTQM Fmea 3Hamza AminNo ratings yet

- Prem Kumar SDocument24 pagesPrem Kumar SPrem KumarNo ratings yet

- Failure Modes & Effects Analysis: Project Activities in Which The FMEA Is UsefulDocument10 pagesFailure Modes & Effects Analysis: Project Activities in Which The FMEA Is Usefulpajaro1111111No ratings yet

- RiskmanagementDocument18 pagesRiskmanagementAmirul 'Ariff Abdul ManafNo ratings yet

- 4-Edp 4 FmeaDocument20 pages4-Edp 4 FmeaRohith ReddyNo ratings yet

- FMEA Applications in Asset Integrity Management: Don OgwudeDocument33 pagesFMEA Applications in Asset Integrity Management: Don Ogwudeali moriNo ratings yet

- TOT FMEA Presentation 4th April 2024Document21 pagesTOT FMEA Presentation 4th April 2024aungmyokyaw300386No ratings yet

- Assignment 4Document13 pagesAssignment 4api-265324689No ratings yet

- BsidDocument2 pagesBsidInara KolleryNo ratings yet

- Eng Circular6Document1 pageEng Circular6Inara KolleryNo ratings yet

- Relationships 2.0Document19 pagesRelationships 2.0Inara KolleryNo ratings yet

- DGS Circular 16 of 2021Document5 pagesDGS Circular 16 of 2021Inara KolleryNo ratings yet

- Inara Time TableDocument2 pagesInara Time TableInara KolleryNo ratings yet

- STS Course Time TableDocument2 pagesSTS Course Time TableInara KolleryNo ratings yet

- VictDocument3 pagesVictInara KolleryNo ratings yet