Professional Documents

Culture Documents

Pilani Campus: Birla Institute of Technology and Science, Pilani AUGS/ AGSR Division

Uploaded by

HIMANSHU JAINOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pilani Campus: Birla Institute of Technology and Science, Pilani AUGS/ AGSR Division

Uploaded by

HIMANSHU JAINCopyright:

Available Formats

BIRLA INSTITUTE OF TECHNOLOGY AND SCIENCE, PILANI

Pilani Campus

AUGS/ AGSR Division

August 26, 2021

FIRST SEMESTER 2021-2022

Course Handout (Part II)

In addition to the part I (General Handout for all courses appended to the timetable), this portion gives further

specific details regarding the course.

Course No.: ME F315

Course Title: Advanced Manufacturing Process

Instructor-in-Charge: Radha Raman Mishra

Instructor (Lecture/Tutorial): Radha Raman Mishra

Instructors (Practical): Rishi Kumar (RS), Shrikanta Pawar (RS), Shailendra Tripathi (RS), and

T Lachana Dora (RS)

1. Course Description

Unconventional manufacturing processes and analysis, micro-manufacturing technologies, introduction to

computer-aided manufacturing, CNC machines, CNC Part programming, additive manufacturing, modelling

and simulation of manufacturing processes, surface technologies, related laboratory exercise and fabrication

project.

2. Scope and Objective of the Course

The present course introduces theoretical and analytical knowledge about unconventional manufacturing

processes and basic approach for modelling and simulation of the manufacturing processes. Moreover, it

enables learners to understand the fundamentals and working principles of micro manufacturing techniques,

additive manufacturing, CAM, and surface technologies.

3. Text Books

• S. Kalpakjian and S. R. Schmid, “Manufactuirng Engineering and Technology,” Pearson Education,

2001, New Delhi (T1)

• A. Ghosh and A. K. Mallik, “Manufacturing Science”, 2nd ed., Affiliated East-West Press, New

Delhi, 2010. (T2)

4. Reference Books

• G. F. Benedict, “Non Traditional Manufacturing Processes”, CRC Press, 2019. (R1)

• V. K. Jain, “Advanced Machining Processes”, 2nd ed., Allied Publisher Bombay, 2010. (R2)

• V. K. Jain (Editor), “Micromanufacturing Processes”, 1st ed., CRC Press, 2012. (R3)

• M. Groover and E. Zimmers, “CAD/CAM: Computer-Aided Design and Manufacturing”, 1st ed.,

Pearson Education, 2003, New Delhi (R4)

• I. Gibson, D. W. Rosen and B. Stucker, “Additive manufacturing technologies: rapid prototyping to

direct digital manufacturing”, Springer, 2010. (R5)

_

Please do not print unless necessary

BIRLA INSTITUTE OF TECHNOLOGY AND SCIENCE, PILANI

Pilani Campus

AUGS/ AGSR Division

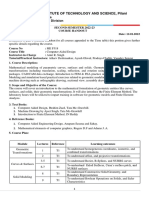

5. Course Plan

Module No. Lecture Session Reference Learning outcomes

M1: Unconventional L (1-5): Introduction, needs, applications, T1, T2, To understand the basic

Manufacturing advantages, and disadvantages. Principles, R1 and R2 concepts, working

processes and working and analysis of unconventional principles and learn

analysis Machining, unconventional forming, analyses of

unconventional welding, and unconventional

unconventional casting processes manufacturing processes

M2: Micro- L (6-10): Introduction, fundamentals and R3 To get acquainted with

manufacturing working principles: micro/nano finishing, various micro-

technologies micro-welding, micro-forming, and micro- manufacturing

molding technologies technologies

M3: Additive L (11-15): Introduction, needs and T1 and R5 To understand principles

manufacturing applications; fundamental principles and and working of Additive

working of additive manufacturing Manufacturing

processes processes

M4: Emerging L (16-22): 4D, 5D and 6D Printing, Class To get acquainted with

material processing microwave energy-based manufacturing, Notes recent technological

and manufacturing nanomanufacturing, bio-inspired developments in

technologies manufacturing manufacturing processes

M5: Computer- L (23-25): Introduction, CNC machines, T1and R4 To learn fundamentals,

Aided CNC Part programming systems, working and

Manufacturing part programing of CNC

M6: Modelling and L (26-28): Introduction, need, different Class To learn molecular

simulation approaches of modeling, atomistic Notes dynamics approach and

modeling, exposure to LAMMPS exposure to atomistic

software, simulation of basic material simulations of material

systems systems

M7: Surface L (29-31): Basics of tribology, lubrication, T1 and T2 To get acquainted with

technologies wear, cost of friction and wear fundamentals of surface

behavior of materials

Please do not print unless necessary

BIRLA INSTITUTE OF TECHNOLOGY AND SCIENCE, PILANI

Pilani Campus

AUGS/ AGSR Division

6. Evaluation Scheme

Components Duration Weightage Date Remarks

(minutes) (%)

Mid Semester Test 90 25 Will be announced by AUGSD-AGSRD CB/OB

Assignments/Projects/ - 20 To be announced in the class CB/OB

Seminars/Quiz

Practical - 20 To be announced in the class CB/OB

Comprehensive 180 35 Will be announced by AUGSD-AGSRD CB/OB

Examination

7. Chamber Consultation Hour

To be announced in the first class.

8. Notices

All notices regarding the course will be sent through the email/Nalanda/Google classroom.

9. Make-up Policy

Make-up will be granted ONLY in genuine cases with PRIOR permission as per the institute rules.

Instructor-in-Charge

ME F315

Please do not print unless necessary

You might also like

- Digital Supply Chain For Dummies JDA SoftwareDocument77 pagesDigital Supply Chain For Dummies JDA SoftwareVedavathy TC100% (6)

- Customer Returns in ERP - Advanced Returns Management: PurposeDocument5 pagesCustomer Returns in ERP - Advanced Returns Management: PurposecliffyeungNo ratings yet

- Schedule Q - Quality RequirementsDocument73 pagesSchedule Q - Quality RequirementsFirdaus Nasir93% (14)

- Category ManagementDocument12 pagesCategory ManagementMisliSlaluAdaNo ratings yet

- Setting up a cosmetics business in AbujaDocument12 pagesSetting up a cosmetics business in Abujafirst materials100% (1)

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- Gantt Chart: Plant Pals Operations and Training Plan (Mohammad Ali Chehade)Document5 pagesGantt Chart: Plant Pals Operations and Training Plan (Mohammad Ali Chehade)Moe Ali ChehadeNo ratings yet

- Birla Institute of Technology & Science, Pilani: Course HandoutDocument4 pagesBirla Institute of Technology & Science, Pilani: Course HandoutAniruth ApparNo ratings yet

- Social Media Management PortfolioDocument21 pagesSocial Media Management PortfolioSiti FatimahNo ratings yet

- Developing Enterprise ArchitectsDocument12 pagesDeveloping Enterprise ArchitectskikinjoNo ratings yet

- Sap Plant MaintenanceDocument10 pagesSap Plant Maintenancemahesh_rai44No ratings yet

- Business Plan Guide QuestionsDocument7 pagesBusiness Plan Guide QuestionsTyria BanksNo ratings yet

- It Ops Devops Productivity Report 2013Document39 pagesIt Ops Devops Productivity Report 2013gabrielfalcone100% (1)

- Pilani Campus: Birla Institute of Technology and Science, Pilani AUGS/ AGSR DivisionDocument3 pagesPilani Campus: Birla Institute of Technology and Science, Pilani AUGS/ AGSR DivisionSIDDHARTH JAINNo ratings yet

- SyllabusDocument3 pagesSyllabusDishank UpadhyayNo ratings yet

- Gujarat Technological University: Page 1 of 3Document3 pagesGujarat Technological University: Page 1 of 3ashish patelNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document3 pagesGujarat Technological University: W.E.F. AY 2018-19Divyeshkumar MorabiyaNo ratings yet

- PEC-IVDocument6 pagesPEC-IV3111hruthvikNo ratings yet

- Syllabus AMTDocument2 pagesSyllabus AMTSyed Farooq PatilNo ratings yet

- Department of Mechanical Engineering 17-7-2015Document44 pagesDepartment of Mechanical Engineering 17-7-2015Manu K VasudevanNo ratings yet

- RPTDocument4 pagesRPTSARAN PRASANTHNo ratings yet

- CNC LAB MANUAL GUIDEDocument34 pagesCNC LAB MANUAL GUIDEಪವರ್ ಆನಂದ್No ratings yet

- MECH Lab ManualDocument64 pagesMECH Lab ManualDiksha PadiyarNo ratings yet

- WP Sem 2Document4 pagesWP Sem 2Ansh DhankharNo ratings yet

- IV B.Tech CAD/CAM Lab ManualDocument127 pagesIV B.Tech CAD/CAM Lab ManualSantosh SantuNo ratings yet

- 2.me 8462-Mt-II Lab ManualDocument48 pages2.me 8462-Mt-II Lab ManualMURALI KRISHNAN RNo ratings yet

- DesignDocument45 pagesDesignedris farahNo ratings yet

- Unconventional Machining Processes: Subject Code: A70359 Regulations: R15-JNTUH Class: IV Year B. Tech MECH I SemDocument16 pagesUnconventional Machining Processes: Subject Code: A70359 Regulations: R15-JNTUH Class: IV Year B. Tech MECH I Sem312817116012 Ganesh RamNo ratings yet

- Course OverviewDocument14 pagesCourse OverviewVinayaka G PNo ratings yet

- PGDocument34 pagesPGarunmec1992No ratings yet

- Basic EngineeringDocument48 pagesBasic Engineeringalexrodenn659No ratings yet

- Mechatronics Handout BITSDocument3 pagesMechatronics Handout BITSmusarraf172No ratings yet

- R19M.Tech - CAD CAMSyllabusDocument50 pagesR19M.Tech - CAD CAMSyllabusSYED ABU NADALNo ratings yet

- Maulana Abul Kalam Azad University of Technology, West BengalDocument32 pagesMaulana Abul Kalam Azad University of Technology, West BengalarindamckbtNo ratings yet

- Anna University 2019Document140 pagesAnna University 2019Arun KarthickNo ratings yet

- R19ITDocument372 pagesR19IT20071a1290No ratings yet

- 18ME653 - Syllabus - CO - PODocument4 pages18ME653 - Syllabus - CO - PORameshkumarNo ratings yet

- Additive Manufacturing Processes and ApplicationsDocument3 pagesAdditive Manufacturing Processes and ApplicationsNishant MayekarNo ratings yet

- Production Drawing Practice Lab ManualDocument52 pagesProduction Drawing Practice Lab ManualoutlanderNo ratings yet

- CIM Course PlanDocument8 pagesCIM Course PlanKamal Vijay Ram R SNo ratings yet

- 19ME307 Rapid Product DevelopmentDocument2 pages19ME307 Rapid Product DevelopmentsahilNo ratings yet

- Department of Collegiate and Technical EducationDocument16 pagesDepartment of Collegiate and Technical Educationnageshbanagar57No ratings yet

- Cad Cam SyllabusDocument4 pagesCad Cam SyllabuskrishrathoreNo ratings yet

- 5.syllabus Copy and Brief On PrerequisitesDocument3 pages5.syllabus Copy and Brief On PrerequisitesSreedhar MNo ratings yet

- 20 P 19 Curriculum CO Semester VIDocument6 pages20 P 19 Curriculum CO Semester VISachin JadhavNo ratings yet

- VIIIth Semester Scheme and SyllabusDocument21 pagesVIIIth Semester Scheme and SyllabusJitesh DewanganNo ratings yet

- Page No. 1 of 2Document2 pagesPage No. 1 of 2Harshit ShahNo ratings yet

- M. Tech Machine Design EngineeringDocument73 pagesM. Tech Machine Design Engineeringsaurabh salviNo ratings yet

- 11.NUMPY Lab File (R20)Document105 pages11.NUMPY Lab File (R20)Mohammed Ahmed100% (1)

- 2 IPE 3 and 4 Sem Scheme and Syllabus Academic Year 2020-2021 PDFDocument46 pages2 IPE 3 and 4 Sem Scheme and Syllabus Academic Year 2020-2021 PDFSanjay SanjuNo ratings yet

- Hindusthan College of Engineering and Technology: (An Autonomous Institution, Affiliated To Anna University, Chennai)Document16 pagesHindusthan College of Engineering and Technology: (An Autonomous Institution, Affiliated To Anna University, Chennai)kumareshNo ratings yet

- Workshop Lab Manual 2019-20Document61 pagesWorkshop Lab Manual 2019-20Vivek ReddyNo ratings yet

- Shivaji University Mechanical Engineering Course DocumentsDocument71 pagesShivaji University Mechanical Engineering Course DocumentsNilesh Vijay SabnisNo ratings yet

- Gujarat Technological University: Page 1 of 3Document3 pagesGujarat Technological University: Page 1 of 3AkashNo ratings yet

- R19 Cse (Iot)Document368 pagesR19 Cse (Iot)pushpa lathaNo ratings yet

- Shri G. S. Institute of Technology and ScienceDocument32 pagesShri G. S. Institute of Technology and Scienceabhaymvyas1144No ratings yet

- Mee6015 Additive-Manufacturing-Technology Eth 1.0 40 Mee6015Document3 pagesMee6015 Additive-Manufacturing-Technology Eth 1.0 40 Mee6015manoj smNo ratings yet

- B - Tech Syllabus PDFDocument31 pagesB - Tech Syllabus PDFkaran5singh-12No ratings yet

- Cam 25062016 030053amDocument4 pagesCam 25062016 030053amRemi KwetchaNo ratings yet

- Government Polytechnic Mechanical Engineering Students Measure Connecting RodDocument22 pagesGovernment Polytechnic Mechanical Engineering Students Measure Connecting RodAsaduddin pattewaleNo ratings yet

- Additive Manufacturing Additive Manufacturing Technology Additive ManufacturingDocument19 pagesAdditive Manufacturing Additive Manufacturing Technology Additive Manufacturingvarun.119No ratings yet

- 5.professional PracticesDocument9 pages5.professional PracticesShivanad HosurNo ratings yet

- MTech CimDocument114 pagesMTech CimGangadhar TallaNo ratings yet

- Gujarat Technological University Mechanical (Cad/Cam) (08) : SUBJECT CODE: 2710807Document2 pagesGujarat Technological University Mechanical (Cad/Cam) (08) : SUBJECT CODE: 2710807ganeshNo ratings yet

- Gujarat Technological University: SUBJECT NAME: Computer Aided Manufacturing SUBJECT CODE: 2171903 BE Semester VIIDocument4 pagesGujarat Technological University: SUBJECT NAME: Computer Aided Manufacturing SUBJECT CODE: 2171903 BE Semester VIIKrupal VithlaniNo ratings yet

- AMP - Lecture Class - 3 Oct 2023Document28 pagesAMP - Lecture Class - 3 Oct 2023Aryan SonthaliaNo ratings yet

- R20 CseDocument196 pagesR20 Csesandeep_siriNo ratings yet

- Bms Syllabus PDFDocument58 pagesBms Syllabus PDFAshley Jovian CorreaNo ratings yet

- IIT Delhi Placement BrochureDocument7 pagesIIT Delhi Placement BrochureAnmol SinhaNo ratings yet

- Gujarat Technological University: Mechanical (Cad/Cam) (08) / Mechanical (Machine Design) (09) SUBJECT CODE: 2740801Document3 pagesGujarat Technological University: Mechanical (Cad/Cam) (08) / Mechanical (Machine Design) (09) SUBJECT CODE: 2740801Ravi ParikhNo ratings yet

- System Lifecycle Management: Engineering Digitalization (Engineering 4.0)From EverandSystem Lifecycle Management: Engineering Digitalization (Engineering 4.0)No ratings yet

- Aulail Desigm: Laeleayas B.C&Ni& Bet Liglsy Mlcbauica TuguuingDocument13 pagesAulail Desigm: Laeleayas B.C&Ni& Bet Liglsy Mlcbauica TuguuingHIMANSHU JAINNo ratings yet

- Comprehensive Exam Seating Arrangement 14 Nov 2022Document33 pagesComprehensive Exam Seating Arrangement 14 Nov 2022HIMANSHU JAINNo ratings yet

- BITS Pilani Supply Chain Management Course DetailsDocument3 pagesBITS Pilani Supply Chain Management Course DetailsHIMANSHU JAINNo ratings yet

- Amp 1 Amp 2 Amp2 MergedDocument44 pagesAmp 1 Amp 2 Amp2 MergedHIMANSHU JAINNo ratings yet

- ME F341 Course Handout Provides DetailsDocument5 pagesME F341 Course Handout Provides DetailsHIMANSHU JAINNo ratings yet

- Bits F416 1808Document4 pagesBits F416 1808HIMANSHU JAINNo ratings yet

- BITS Pilani CAD Course OverviewDocument3 pagesBITS Pilani CAD Course OverviewHIMANSHU JAINNo ratings yet

- BIT ENERGY MANAGEMENT COURSE HANDOUTDocument3 pagesBIT ENERGY MANAGEMENT COURSE HANDOUTHIMANSHU JAINNo ratings yet

- This Study Resource Was: Juliet S. Punongbayan BA3102 International Business and TradeDocument2 pagesThis Study Resource Was: Juliet S. Punongbayan BA3102 International Business and TradeAllyza RenoballesNo ratings yet

- Hardox Hitemp Can Take The HeatDocument2 pagesHardox Hitemp Can Take The HeatFrançois CarlierNo ratings yet

- Fundamental of Process Safety Management System (PSM)Document41 pagesFundamental of Process Safety Management System (PSM)Basaci AbdelghaffarNo ratings yet

- THURGA Tutorial 5Document5 pagesTHURGA Tutorial 5thurgakannanNo ratings yet

- Pre - Interrogation Assessment: Awareness Evaluation Purchase Delight Sales FunnelDocument2 pagesPre - Interrogation Assessment: Awareness Evaluation Purchase Delight Sales FunnelRuchi AgarwallNo ratings yet

- IJLRA - 2015 - Bottani - Improving Logistics Efficiency of Industrial Districts - A Framework and Case Study in The Food SectorDocument25 pagesIJLRA - 2015 - Bottani - Improving Logistics Efficiency of Industrial Districts - A Framework and Case Study in The Food SectorAdrian SerranoNo ratings yet

- SK 1010Document33 pagesSK 1010ABRALYN HOO WENG YAN MoeNo ratings yet

- Full-Mold CastingDocument2 pagesFull-Mold CastingclubmailusNo ratings yet

- PM2 - Life CycleDocument15 pagesPM2 - Life CycleAbdul WadoodNo ratings yet

- Vanish and AirWick Consumer Buying Journeys by Reckitt BenckiserDocument5 pagesVanish and AirWick Consumer Buying Journeys by Reckitt BenckiserGarimaBhandariNo ratings yet

- Evolving Digital ConsumerDocument50 pagesEvolving Digital Consumerphanminhhao0711No ratings yet

- T1. Tutorial Questions/ DiscussionDocument2 pagesT1. Tutorial Questions/ DiscussionnikhilNo ratings yet

- Brand Management Mock Exam Paper Semester Vi Type: MCQDocument5 pagesBrand Management Mock Exam Paper Semester Vi Type: MCQOmkar KhutwadNo ratings yet

- Digital Marketing Summer Internship Report on WebinarWallDocument29 pagesDigital Marketing Summer Internship Report on WebinarWallSargam SrivastavaNo ratings yet

- QUESTIONNAIRESDocument8 pagesQUESTIONNAIRESRya May BanagbanagNo ratings yet

- Marketing Management: Hindustan Uniliver LimitedDocument19 pagesMarketing Management: Hindustan Uniliver LimitedomdNo ratings yet

- MSDS Primer S1301-M Parte ADocument2 pagesMSDS Primer S1301-M Parte AMichael Betetta AbadNo ratings yet

- Changes in Company's Management Accounting Systems: Case Study On Activity - Based Costing Implementation and Operation in Medium-Sized Production CompanyDocument27 pagesChanges in Company's Management Accounting Systems: Case Study On Activity - Based Costing Implementation and Operation in Medium-Sized Production CompanyLilian BrodescoNo ratings yet

- Coal WashingDocument32 pagesCoal WashingYagnesh ChainyNo ratings yet