Professional Documents

Culture Documents

19ME307 Rapid Product Development

Uploaded by

sahilCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

19ME307 Rapid Product Development

Uploaded by

sahilCopyright:

Available Formats

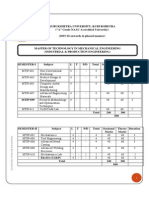

Pandit Deendayal Petroleum University School of Technology

19ME307T Rapid Product Development

Teaching Scheme Examination Scheme

Total

Theory Practical

L T P C Hrs/Week Marks

MS ES IA LW LE/Viva

3 - - 3 3 25 50 25 -- -- 100

COURSE OBJECTIVES

To gain knowledge of Product Development

To gain an insight Rapid Prototyping technologies

To gain the knowledge of pre and post processing techniques during rapid product development

To gain the knowledge of Rapid Tooling, use of Reverse Engineering for product development

UNIT 1 Introduction: 13 Hrs.

CAD-CAM and its integration, Rapid Prototyping (RP) Defined, Product development and its relationship.

AM process chain: Conceptualization, CAD, conversion to STL, Transfer to AM, STL file manipulation, Machine

setup, build , removal and clean up, post processing. Classification of AM processes: Liquid polymer system,

discrete particle system, molten material systems, solid sheet system. Process chain for Rapid Prototyping,

Reverse Engineering and CAD model, Digitizing Techniques: Mechanical Contact, Optical Non-contact, Data

interface STL interface, data generation, Manipulation, Open files, Repair of STL files, Alternative RP interfaces.

UNIT 2 Part orientation and support generation: 10 Hrs.

Factors affecting part orientation, support structure design, Automatic support structure generation. Model

Slicing and Contour Data organization: Model slicing and skin contour determination, Identification of

external and internal contours, Contour data organization, Direct and adaptive slicing: Identification of peak

features, Adaptive layer thickness determination, Skin contour computation, Tool path generation

UNIT 3 Part Building and Post Processing 10 Hrs.

Recoating, parameters affecting part building time, part quality. Part removal, finishing, curing. Other issues:

Shrinkage, Swelling, Curl and distortion, Surface Deviation and accuracy, Build Style Decisions

UNIT 4 Rapid Tooling and Future Directions 12 Hrs.

Rapid Tooling and Manufacturing: Classification of RT Routes, RP of Patterns, Indirect RT: Indirect method for

Soft and Bridge Tooling, Indirect method, Direct RT: Direct RT method for Soft and Bridge Tooling, Direct

method for Production Tooling, Future Directions of AM: Introduction, new types of products and

employment.

Max. 45 Hrs.

COURSE OUTCOMES

On completion of the course, student will be able to

CO1 - Comprehend various types of rapid prototyping/3D printing techniques

CO2 - Error estimation in STL files/tessellation algorithms

CO3 - Examine the important factors affecting the final product accuracy and precision

CO4 - Comprehend the product development cycle, RT processes and reverse engineering solutions

CO5 - Evaluate the efficacy of the data processing techniques for 3D model reconstruction

CO6 - Understand the working principles of various 3D printing machines

TEXT/REFERENCE BOOKS

1. Jacobs, PF (Ed), Rapid Prototyping and Manufacturing, Society of Manuf. Engrs.

2. Chua C. K. and L. K. Fai, Rapid Prototyping: Principles and Applications in Manufacturing.

3. Gibson, I. (Ed.), Software Solutions for Rapid Prototyping, Professional Engineering Publications, UK

END SEMESTER EXAMINATION QUESTION PAPER PATTERN

Max. Marks: 100 Exam Duration: 3 Hrs

Part A/Question: 5 Questions ( 8 Marks each) 40 Marks

Part B/Question: 5 Questions ( 12 Marks each) 60 Marks

You might also like

- Up and Running with Autodesk Inventor Simulation 2011: A Step-by-Step Guide to Engineering Design SolutionsFrom EverandUp and Running with Autodesk Inventor Simulation 2011: A Step-by-Step Guide to Engineering Design SolutionsNo ratings yet

- Machine Learning and Data Science in the Power Generation Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Power Generation Industry: Best Practices, Tools, and Case StudiesPatrick BangertNo ratings yet

- Additive Manufacturing Processes and ApplicationsDocument3 pagesAdditive Manufacturing Processes and ApplicationsNishant MayekarNo ratings yet

- Mee6015 Additive-Manufacturing-Technology Eth 1.0 40 Mee6015Document3 pagesMee6015 Additive-Manufacturing-Technology Eth 1.0 40 Mee6015manoj smNo ratings yet

- Gujarat Technological University: Mechanical (Cad/Cam) (08) / Mechanical (Machine Design) (09) SUBJECT CODE: 2740801Document3 pagesGujarat Technological University: Mechanical (Cad/Cam) (08) / Mechanical (Machine Design) (09) SUBJECT CODE: 2740801Ravi ParikhNo ratings yet

- MEE2016 Rapid-Manufacturing-Technologies ETH 1 AC40Document2 pagesMEE2016 Rapid-Manufacturing-Technologies ETH 1 AC40HarishVenkatesanNo ratings yet

- BTech Mechanical - 2020-24 ADMDocument4 pagesBTech Mechanical - 2020-24 ADMKanu SharmaNo ratings yet

- 2nd Sem PDM SyllabusDocument11 pages2nd Sem PDM SyllabusVinay AlagundiNo ratings yet

- List of Exercises: Computer Integrated Manufacturing & Technology Driven PracticesDocument1 pageList of Exercises: Computer Integrated Manufacturing & Technology Driven Practicesnavneetkpatil8409No ratings yet

- Mechsyll 8Document18 pagesMechsyll 8Anonymous SLKWYHBoNo ratings yet

- M.tech Mechanical Engg. (I &P)Document44 pagesM.tech Mechanical Engg. (I &P)Upender DhullNo ratings yet

- SyllabusDocument3 pagesSyllabusDishank UpadhyayNo ratings yet

- RPTDocument4 pagesRPTSARAN PRASANTHNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document3 pagesGujarat Technological University: W.E.F. AY 2018-19Divyeshkumar MorabiyaNo ratings yet

- FALLSEM2020-21 MEE3501 ETH VL2020210100431 Reference Material I 14-Jul-2020 SyllabusDocument3 pagesFALLSEM2020-21 MEE3501 ETH VL2020210100431 Reference Material I 14-Jul-2020 SyllabusJawa freakNo ratings yet

- Gujarat Technological University Mechanical (Cad/Cam) (08) : Computer Aided Process Planning 2720813 Semester: IiDocument3 pagesGujarat Technological University Mechanical (Cad/Cam) (08) : Computer Aided Process Planning 2720813 Semester: IiGeorge CamachoNo ratings yet

- CIM Course PlanDocument8 pagesCIM Course PlanKamal Vijay Ram R SNo ratings yet

- MTech Machine Design PDFDocument41 pagesMTech Machine Design PDFswapnilNo ratings yet

- Syllabus AMTDocument2 pagesSyllabus AMTSyed Farooq PatilNo ratings yet

- 6th Sem SyllabusDocument16 pages6th Sem SyllabusSOUMIK DASNo ratings yet

- If Fifth Semester Syllabus DiplomaDocument39 pagesIf Fifth Semester Syllabus Diplomakals100% (4)

- Manufacturing Processes UTA026Document9 pagesManufacturing Processes UTA026Tania CENo ratings yet

- Shri G. S. Institute of Technology and ScienceDocument32 pagesShri G. S. Institute of Technology and Scienceabhaymvyas1144No ratings yet

- Selected Engineering ProblemsDocument6 pagesSelected Engineering ProblemsDiscord YtNo ratings yet

- Mee3502 - Design-Process-Planning-And-Management - Eth - 1.0 - 62 - Mee3502 - 58 AcpDocument3 pagesMee3502 - Design-Process-Planning-And-Management - Eth - 1.0 - 62 - Mee3502 - 58 AcpwewewewNo ratings yet

- Btech Cse Curriculum N Syllabus 2015 RMPDocument99 pagesBtech Cse Curriculum N Syllabus 2015 RMPSRM e-LearningNo ratings yet

- DR - Siby John Punjab Technical University Dean (Academics) Ladowali Road, JALANDHAR - 144001Document8 pagesDR - Siby John Punjab Technical University Dean (Academics) Ladowali Road, JALANDHAR - 144001Surjeet MarwahNo ratings yet

- MSBTE 5th Semester Final Year Syllabus/Curriculum For Computer Engineering GroupDocument44 pagesMSBTE 5th Semester Final Year Syllabus/Curriculum For Computer Engineering GroupSanjay Dudani64% (11)

- ECE279 - Zero - Lecture - 2023 - UpdatedDocument31 pagesECE279 - Zero - Lecture - 2023 - Updatedkofineg493No ratings yet

- Operation Research NotesDocument98 pagesOperation Research Notessagar kadam100% (2)

- Topic 1: Overview of CAD/CAM SystemsDocument3 pagesTopic 1: Overview of CAD/CAM SystemsKelvin Ting S BNo ratings yet

- PGDocument34 pagesPGarunmec1992No ratings yet

- CSE320 Lecture0Document35 pagesCSE320 Lecture0aditya.raj60104No ratings yet

- Course Structure 1Document1 pageCourse Structure 1Savan PatelNo ratings yet

- PEC-IVDocument6 pagesPEC-IV3111hruthvikNo ratings yet

- Me403.01 - Production and Operations Management - Lab ManualDocument32 pagesMe403.01 - Production and Operations Management - Lab ManualTUSHAR VALANo ratings yet

- Final M.E. Production EnggDocument18 pagesFinal M.E. Production EnggsatishNo ratings yet

- MA505-N-C Modern Manufacturing ProcessesDocument3 pagesMA505-N-C Modern Manufacturing Processeshrana287No ratings yet

- 0 LectureDocument17 pages0 LectureGunjan MudgalNo ratings yet

- Birla Institute of Technology & Science, Pilani: Course HandoutDocument4 pagesBirla Institute of Technology & Science, Pilani: Course HandoutAniruth ApparNo ratings yet

- Title of SubjectDocument2 pagesTitle of Subjectloki654321No ratings yet

- Rapid Prototyping Notes by Shashidhar 2Document132 pagesRapid Prototyping Notes by Shashidhar 2sharma devarajuNo ratings yet

- CSE320 Lecture0 (1)Document36 pagesCSE320 Lecture0 (1)akku.gautam23No ratings yet

- CSE II - II SyllabusDocument16 pagesCSE II - II SyllabusBabu GiriNo ratings yet

- Sem 2Document11 pagesSem 2jtsrinivasdownNo ratings yet

- Gujarat Technological University: SUBJECT NAME: Computer Aided Manufacturing SUBJECT CODE: 2171903 BE Semester VIIDocument4 pagesGujarat Technological University: SUBJECT NAME: Computer Aided Manufacturing SUBJECT CODE: 2171903 BE Semester VIIKrupal VithlaniNo ratings yet

- Additive Manufacturing Additive Manufacturing Technology Additive ManufacturingDocument19 pagesAdditive Manufacturing Additive Manufacturing Technology Additive Manufacturingvarun.119No ratings yet

- ZERO Lecture CSE316 Jan - April 2024Document39 pagesZERO Lecture CSE316 Jan - April 2024what90642No ratings yet

- Additive MFG SyllabusDocument2 pagesAdditive MFG SyllabusDr.V.Sivakumar /KIOT-SALEM KIOTNo ratings yet

- Application of CAD/CAE & Rapid Prototyping Technology in Medical FieldDocument5 pagesApplication of CAD/CAE & Rapid Prototyping Technology in Medical FieldRizwanNo ratings yet

- Course Syllabus: Cebu Technological University Ctu-Main CampusDocument5 pagesCourse Syllabus: Cebu Technological University Ctu-Main CampusRicson BondadNo ratings yet

- A Review of AdditiveManufacturingDocument11 pagesA Review of AdditiveManufacturingMüslüm KOÇNo ratings yet

- 5.syllabus Copy and Brief On PrerequisitesDocument3 pages5.syllabus Copy and Brief On PrerequisitesSreedhar MNo ratings yet

- Introduction To Rapid Prototyping: Unit 4Document26 pagesIntroduction To Rapid Prototyping: Unit 4Joeb DsouzaNo ratings yet

- 8 - 2 B - Tech Cse (Ai & DS) (33 Pages)Document33 pages8 - 2 B - Tech Cse (Ai & DS) (33 Pages)RitikaNo ratings yet

- ME403 Production & Operation Management SyllabusDocument6 pagesME403 Production & Operation Management SyllabusGajanan Shankarrao PatangeNo ratings yet

- ECE279 Zero LectureDocument16 pagesECE279 Zero Lecturecaptain.pool7No ratings yet

- Tool Design and Concurrent Engineering Through Six Rapid Tooling Construction Methods Using Rapid Prototype ModelsDocument7 pagesTool Design and Concurrent Engineering Through Six Rapid Tooling Construction Methods Using Rapid Prototype ModelsDiscord YtNo ratings yet

- Product Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesFrom EverandProduct Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesRating: 4 out of 5 stars4/5 (4)

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- 60 Minutes-60 Questions: Mathematics TestDocument15 pages60 Minutes-60 Questions: Mathematics TestJihyun YeonNo ratings yet

- Animals Adaptation LessonDocument6 pagesAnimals Adaptation LessonPascal Bou NajemNo ratings yet

- GynecologyDocument24 pagesGynecologylovelots1234No ratings yet

- Wound Care, Dressing and BandagingDocument11 pagesWound Care, Dressing and BandagingJessica Febrina Wuisan100% (1)

- The Human BodyDocument17 pagesThe Human BodyRuthie MendozaNo ratings yet

- Vammika Sutta - Mahasi SayadawDocument108 pagesVammika Sutta - Mahasi SayadawtravelbootsNo ratings yet

- MTD Big Bore Engines 78 277cc 83 357cc 90 420cc Repair Manual PDFDocument136 pagesMTD Big Bore Engines 78 277cc 83 357cc 90 420cc Repair Manual PDFGiedrius MalinauskasNo ratings yet

- Question According VDA 6.3 Questionnaire 0 0: VDA - 6.3 - Report - Potential - Analysis - 2016 - V3 - Vollversion Seite 1 Von 1Document1 pageQuestion According VDA 6.3 Questionnaire 0 0: VDA - 6.3 - Report - Potential - Analysis - 2016 - V3 - Vollversion Seite 1 Von 1ssierroNo ratings yet

- SAE International StandardsAS5553 and AS5553A Counterfeit Electronic Parts Avoidance, Detection, Mitigation and Dispositio PDFDocument35 pagesSAE International StandardsAS5553 and AS5553A Counterfeit Electronic Parts Avoidance, Detection, Mitigation and Dispositio PDFAlejandroAcuñaMaureira100% (1)

- Revisiting The Irish Royal Sites: Susan A. JohnstonDocument7 pagesRevisiting The Irish Royal Sites: Susan A. JohnstonJacek RomanowNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document4 pagesGujarat Technological University: W.E.F. AY 2018-19Premal PatelNo ratings yet

- HP DeskJet Report POM 20150413Document5 pagesHP DeskJet Report POM 20150413Carolina DelgadoNo ratings yet

- 2.seismic Coefficient CalculationDocument14 pages2.seismic Coefficient CalculationVenkat PalliNo ratings yet

- The Mini Percutaneous Nephrolithotomy (Mini-PCNL) and Percutaneous Nephrolithotomy (PCNL) in Pediatric PatientsDocument4 pagesThe Mini Percutaneous Nephrolithotomy (Mini-PCNL) and Percutaneous Nephrolithotomy (PCNL) in Pediatric PatientsMarius DanilaNo ratings yet

- Berry phase in the simple harmonic oscillatorDocument14 pagesBerry phase in the simple harmonic oscillatora2618765No ratings yet

- Ic F3022SDocument36 pagesIc F3022SEfren.galNo ratings yet

- Heidegger and RhetoricDocument202 pagesHeidegger and RhetoricMagda AliNo ratings yet

- Syngo MR E11 OncoDocument64 pagesSyngo MR E11 OncoLuís GuerraNo ratings yet

- Viscous Fluid Flow Ch1-Preliminary Concepts: Kfupm ME 532-172Document40 pagesViscous Fluid Flow Ch1-Preliminary Concepts: Kfupm ME 532-172Majid KhanNo ratings yet

- Fact Sheet - Electrician (General)Document4 pagesFact Sheet - Electrician (General)Saravanan Rasaya100% (1)

- Plant LocationDocument40 pagesPlant LocationAvril PizzaNo ratings yet

- Statics: Vector Mechanics For EngineersDocument32 pagesStatics: Vector Mechanics For EngineersArdaNo ratings yet

- Carte Blanche: The New James Bond Novel by Jeffery DeaverDocument12 pagesCarte Blanche: The New James Bond Novel by Jeffery DeaverSimon and Schuster0% (1)

- OK - EndUserGuideHoseSafetyInstituteDocument8 pagesOK - EndUserGuideHoseSafetyInstituteSunil GhosalkarNo ratings yet

- #Healthy Food Recipes EasyDocument4 pages#Healthy Food Recipes EasyTHE NEXT GENNo ratings yet

- The Process, Church of The Final Judgment - ScripturesDocument132 pagesThe Process, Church of The Final Judgment - Scripturescirclesphere100% (2)

- Life-Science-Grade-12-April-2021-QP-and-memoDocument15 pagesLife-Science-Grade-12-April-2021-QP-and-memokhoza9312No ratings yet

- II PUC PHYSICS - Previously Appeared Questions and Answers For 2021 Exam by MANJUNATH BDocument52 pagesII PUC PHYSICS - Previously Appeared Questions and Answers For 2021 Exam by MANJUNATH BVishal Ramesh100% (1)

- Panasonic DMP BDT230PDocument87 pagesPanasonic DMP BDT230PaldoNo ratings yet

- IKM - Sample Size Calculation in Epid Study PDFDocument7 pagesIKM - Sample Size Calculation in Epid Study PDFcindyNo ratings yet