Professional Documents

Culture Documents

Controlador de Flama SIEMENS

Uploaded by

Alejandro VeraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Controlador de Flama SIEMENS

Uploaded by

Alejandro VeraCopyright:

Available Formats

Presentation example PME7... Presentation example LME7...

PME71.402...

Program module for burner control LME71.000

User Documentation

Application: - 1-stage, direct or pilot ignited forced draft burners

- E.g. for burners to EN 676

The PME7… and this User Documentation are intended for use by OEMs which

integrate the LME7... with PME7... in their products.

Note!

This documentation is only valid together with LME7... Basic Documentation

(P7105)!

Software Version V02.00 Building Technologies Division

Infrastructure & Cities Sector

CC1A7105.4en

26.09.2014

Contents

1 Supplementary documentation ....................................................................3

2 Warning notes ................................................................................................4

3 Typographical conventions ..........................................................................4

4 Program sequence PME71.402... ..................................................................5

5 List of phase display .....................................................................................6

6 Fuel trains (examples) ....................................................................................7

6.1 Gas direct ignition (G), 1-stage ........................................................................7

6.2 Gas pilot ignition 1 (Gp1/1), 1-stage ................................................................7

7 Input gas pressure switch-min .....................................................................7

8 Time table and settings .................................................................................8

9 Inputs and outputs / internal connection diagram .....................................9

10 Parameter list (AZL2...) ................................................................................10

11 Error code list...............................................................................................13

12 Legend ..........................................................................................................14

13 List of figures ...............................................................................................15

2/15

Building Technologies Division User Documentation PME41.402... CC1A7105.4en

Infrastructure & Cities Sector Contents 26.09.2014

1 Supplementary documentation

Product type Type of documentation Documentation number

LME… Environmental Product Declaration E7105

PME… Environmental Product Declaration E7105.1

LME7... Data Sheet N7105

LME... Product Range Overview Q7010

LME7 Basic Documentation P7105

3/15

Building Technologies Division User Documentation PME71.402... CC1A7105.4en

Infrastructure & Cities Sector 1 Supplementary documentation 26.09.2014

2 Warning notes

Warning!

The safety, warning and technical notes given in the Basic Documentation

on the LME7... (P7105) apply fully to the present document also!

To avoid injury to persons, damage to property or the environment, the following

warning notes must be observed!

The LME7... are safety devices! Do not open, interfere with or modify the unit.

Siemens does not assume responsibility for damage resulting from unauthorized

interference!

3 Typographical conventions

Safety notes

This User Documentation contains notes which must be observed to ensure your

personal safety and to protect the product and the connected equipment.

The instructions and notes are highlighted by warning triangles or a hand symbol and

are presented as follows, depending on the hazard level:

Warning means that death, severe personal injury or substantial

damage to property can occur if adequate precautionary

measures are not taken

Note draws your attention to important information on the

product, on product handling, or to a special part of the

documentation

Qualified personnel Only qualified staff are allowed to install and operate the equipment. Qualified staff in

the context of the safety-related notes contained in this document are persons who are

authorized to commission, ground and tag devices, systems and electrical circuits in

compliance with established safety practices and standards.

Correct use Note the following:

The device may only be used on the applications described in the technical

documentation and only in connection with devices or components from other suppliers

that have been approved or recommended by Siemens.

The product can only function correctly and safely if shipped, stored, set up and

installed correctly, and operated and maintained as specified.

4/15

Building Technologies Division User Documentation PME41.402... CC1A7105.4en

Infrastructure & Cities Sector 2 Warning notes 26.09.2014

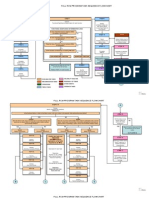

4 Program sequence PME71.402...

For fuel trains G and Gp1/1

Figure 1: Program sequence

5/15

Building Technologies Division User Documentation PME71.402... CC1A7105.4en

Infrastructure & Cities Sector 4 Program sequence PME71.402... 26.09.2014

5 List of phase display

Phase number of display LED Function

7-segment AZL2...

LOC LOC OFF Lockout phase

Standby

OFF OFF OFF Standby, waiting for heat request

P08 Ph08 OFF Power ON/test phase (e.g. detector test)

Startup

P21 Ph21 Yellow Safety valve ON, air pressure switch in no-load position

Test if POC closed

(timeout/lockout after 5 seconds)

P22 Ph22 Yellow Part 1: Fan motor ON

Part 2: Specified time air pressure switch

Message (timeout), stabilization air pressure switch

P30 Ph30 Yellow Part 1: Prepurge time without extraneous light test

Part 2: Prepurging with extraneous light test (2.1 seconds)

P38 Ph38 Yellow flashing Preignition time

P40 Ph40 Yellow flashing Postignition time

P42 Ph42 Green Flame detection

P44 Ph44 Green Interval: End of safety time and fuel valve 1 ON

P50 Ph50 Green Part 1: Interval: Fuel valve 1 ON and pilot valve OFF

Part 2: Flame-out response time

Operation

oP1 oP:P1 Green Operation

Shutdown

P10 Ph10 OFF Home run

P74 Ph74 Yellow Postpurge time

Safety shutdown phases

P01 Ph01 Yellow / red Under voltage / over voltage

P02 Ph02 Yellow Safety shutdown (e.g. open safety loop)

Lockout

P04 Ph04 Green / red Extraneous light in standby

P90 Ph90 Yellow Gas pressure switch-min open

safety shutdown and start prevention

6/15

Building Technologies Division User Documentation PME41.402... CC1A7105.4en

Infrastructure & Cities Sector 5 List of phase display 26.09.2014

6 Fuel trains (examples)

6.1 Gas direct ignition (G), 1-stage

Program G Gas direct 1-stage

LME71.000... V1

X7-01 X7-04

SV

Dbr2

Figure 2: Fuel train gas direct ignition (G), 1-stage

6.2 Gas pilot ignition 1 (Gp1/1), 1-stage

Program Gp1/1 Gas pilot 1-stage

LME71.000... V1

X7-01 X7-04

SV

PV

Figure 3: Fuel train gas pilot ignition 1 (Gp1/1), 1-stage

7 Input gas pressure switch-min

Behavior in the event gas If gas pressure switch-min fails, safety shutdown is triggered and startup prevented

pressure switch-min fails until gas pressure switch-min closes again. During start prevention, the yellow LED is lit

(terminal X5-01 pin 2 and 3) and the safety circuit is active. Burner control operates in phase 90.

7/15

Building Technologies Division User Documentation PME71.402... CC1A7105.4en

Infrastructure & Cities Sector 6 Fuel trains (examples) 26.09.2014

8 Time table and settings

Type Times in seconds

t1 t3 t3n t4 t8 t9 t10

TSA t22

PME71.402... tw P225 P226 P257 P230 P234 P231 P224 1) 2) 3)

max. approx.

min. min. approx. min. min. approx. approx.

Requirements 2.5 3 30 3 2.5 3 15 3 15 --- --- --- ---

Factory setting --- t3n+0.45 29.106+2.1 3.087 2.205+0.3 3.234 19.404 2.646 13.818 t9+1 --- --- ---

Max. 2.5 14 1237+2.1 37.485 13.23+0.3 74.97 1237 74.97 13.818 --- 1 0.45 0.45

Min. --- --- 0+2.1 1.029 0+0.3 3.234 0 0 0 --- 0.3 0.3 ---

Step size --- --- 4.851 0.147 0.147 0.294 4.851 0.294 0.294 --- --- --- ---

Function parameter Parameter number Factory setting

Repetition in the event of loss of flame during operation 240 0

0 = none

1 = none

2 = 1 x repetition

Continuous pilot (during operation) 247 0

0: OFF

1: ON

Legend

tw Waiting time

TSA Safety time

t1 Prepurge time

t3 Preignition time

t3n Postignition time parameter 257 +0.3 seconds

t4 Interval: End of safety time - fuel valve 1 ON

t8 Postpurge time

t9 Interval: Fuel valve 1 ON and pilot valve OFF

t10 Specified time air pressure switch message (timeout)

t22 2nd safety time

1) Reaction time to a change of signal by the air pressure switch contact (opens) and flame-out response time in the event of loss of flame

2) Reaction time to a change of signal by the inputs (e.g. pressure switch-min)

3) Flame detection time

8/15

Building Technologies Division User Documentation PME71.402... CC1A7105.4en

Infrastructure & Cities Sector 8 Time table and settings 26.09.2014

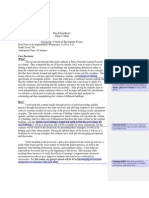

9 Inputs and outputs / internal connection diagram BCI

X65 X66 X76 X56

Note!

*) If POC not used,

Not used

Not used

Not used

wire link Dbr1 must be connected!

GND

BCI

7105d41e/0914

K2/1

K1

Output alarm

03K15

X2-03

N L

NT

05K30

X3-04

LME71.000...

03K57

X6-03

+

Feedback input POC

03K34

X7-01

04K22

X2-02

K2/2

A

direct ignition

Output pilot valve PV

K4

Dbr2 for

µC

03K105

X2-01

04K77

X7-04

K7

03K66

04K01

X4-02

X5-03

K5

/reset

02K02

X3-02

FSV2

X10-05

05K37

03K54

X5-01

LED

FSV1

X10-06

02K43

X9-04

03K30

Coding

Plug marking

Figure 4: Inputs and outputs / internal connection diagram

9/15

Building Technologies Division User Documentation PME71.402... CC1A7105.4en

Infrastructure & Cities Sector 9 Inputs and outputs / internal connection diagram 26.09.2014

10 Parameter list (AZL2...)

Parameter- Parameter Edit Value range Password level

Password level

number Min. Max. Resolution Factory setting reading from

writing from level

level

000 Internal parameter

41 Heating engineer's password (4 characters) Edit xxxx xxxx --- --- --- OEM

42 OEM's password (5 characters) Edit xxxxx xxxxx --- --- --- OEM

60 Backup/restore Edit --- --- --- --- --- SO

100 General

102 Identification date Read only --- --- --- --- Info ---

103 Identification number Read only 0 9999 1 0 Info ---

113 Burner identification Edit x xxxxxxxx 1 --- Info SO

140 Mode display of display and operating unit AZL2... 1 4 1 1 SO SO

1 = standard (program phase)

2 = flame 1 (QRA.../ION) Edit

3 = flame 2 (QRB.../QRC...) not used

4 = active power (power value)

164 Number of startups resettable Resettable 0 999999 1 0 Info Info

166 Total number of startups Read only 0 999999 1 0 Info ---

170.00 Switching cycles relay contact K12 Read only 0 999999 1 0 Info ---

170.01 Switching cycles relay contact K11 Read only 0 999999 1 0 Info ---

170.02 Switching cycles relay contact K2 Read only 0 999999 1 0 Info ---

170.03 Switching cycles relay contact K1 Read only 0 999999 1 0 Info ---

171 Max. switching cycles relay Read only 0 999999 1 0 Info ---

10/15

Building Technologies Division User Documentation PME71.402... CC1A7105.4en

Infrastructure & Cities Sector 10 Parameter list (AZL2...) 26.09.2014

Parameter Parameter Edit Value range Password level

Password level

number Min. Max. Resolution Factory setting reading from

writing from level

level

200 Burner control

224 Specified time air pressure switch Edit 0s 13.818 s 0.294 s 13.818 s SO OEM

225 Prepurge time -2.1 seconds Edit 0s 1237 s 4.851 s 29.106 s SO OEM

226 Preignition time Edit 1.029 s 37.485 s 0.147 s 3.087 s SO OEM

230 Interval: End of safety time - fuel valve 1 ON Edit 3.234 s 74.97 s 0.294 s 3.234 s SO OEM

231 Interval: Fuel valve 1 ON - pilot valve OFF Edit 0s 74.97 s 0.294 s 2.646 s SO OEM

234 Postpurge time Edit 0s 1237 s 4.851 s 19.404 s SO OEM

240 Repetition in the event of loss of flame during Edit 0 2 1 0 SO OEM

operation

0: None

1: None

2: 1 x repetition

247 Continuous pilot (during operation) Edit 0 1 1 0 SO OEM

0: OFF

1: ON

257 Postignition time -0.3 seconds Edit 0s 13.23 s 0.147 s 2.205 s SO OEM

11/15

Building Technologies Division User Documentation PME71.402... CC1A7105.4en

Infrastructure & Cities Sector 10 Parameter list (AZL2...) 26.09.2014

Parameter Parameter Edit Value range Password level

Password level

number Min. Max. Resolution Factory setting reading from

writing from level

level

700 Error history

701 Current error: Read only --- Service ---

00: Error code 2 255 1

01: Startup meter reading 0 999999 1

02: HMI phase --- --- ---

03: Power value 0% 100% 1

702 Error history former 1: Read only --- Service ---

00: Error code 2 255 1

01: Startup meter reading 0 999999 1

02: HMI phase --- --- ---

03: Power value 0% 100% 1

•

•

•

711 Error history former 10: --- Service ---

00: Error code 2 255 1

01: Startup meter reading Read only 0 999999 1

02: HMI phase --- --- ---

03: Power value 0% 100% 1

900 Process data

936 Normalized speed Read only 0% 100% 0.01% --- Service ---

951 Mains voltage Read only 0V LME71.000A1: 175 V 1V --- Service ---

LME71.000A2: 350 V

954 Flame intensity Read only 0% 100% 1% --- Service ---

12/15

Building Technologies Division User Documentation PME71.402... CC1A7105.4en

Infrastructure & Cities Sector 10 Parameter list (AZL2...) 26.09.2014

11 Error code list

Error code

Clear text Possible cause

AZL2... 7-segment

- Faulty or soiled fuel valves

No establishment of flame at the end - Faulty or soiled flame detector

Loc: 2 Loc 2 - Poor adjustment of burner, no fuel

of safety time

- Faulty ignition equipment

Air pressure faulty (air pressure switch Air pressure switch faulty

welded in no-load position, decrease - Loss of air pressure signal after specified time

Loc: 3 Loc 3

to specified time (air pressure switch - Air pressure switch has welded in no-load

flame-on response time) position

Loc: 4 Loc 4 Extraneous light Extraneous light during burner startup

Time supervision air pressure switch

Air pressure faulty, air pressure switch

Loc: 5 Loc 5 - Air pressure switch has welded in working

welded in working position

position

Too many losses of flame during operation

(limitation of repetitions)

Loc: 7 Loc 7 Loss of flame - Faulty or soiled fuel valves

- Faulty or soiled flame detector

- Poor adjustment of burner

Error not relatable (application), Wiring error or internal error, output contacts,

Loc: 10 Loc 10

internal error other faults

Loc: 14 Loc 14 POC error Error valve closure control POC

- Gas pressure switch-max open

Loc: 22 Loc 22 Safety loop open

- Safety limit thermostat cut out

Loc: 138 Loc 138 Restore process successful Restore process successful

Loc: 139 Loc 139 No program module detected No program module plugged in

Loc: 167 Loc 167 Manual locking Manual locking

Loc: 206 Loc 206 AZL2... incompatible Use the latest version

Error in compatibility program module - Program sequence of program module does not

rSt Er1 rSt Er1

to basic unit during restore process match the basic unit

Error in compatibility program module - Hardware of basic unit does not match the

rSt Er2 rSt Er2

to basic unit during restore process program module

- Program module faulty

rSt Er3 rSt Er3 Error during restore process - Program module removed during restore

process

Fault of compatibility program module Program sequence of program module does not

bAC Er3 bAC Er3

to basic unit during backup process match the basic unit

- Error in data content of program module

Err PrC Err PrC Fault of program module

- No program module fitted

13/15

Building Technologies Division User Documentation PME71.402... CC1A7105.4en

Infrastructure & Cities Sector 11 Error code list 26.09.2014

12 Legend

AL Alarm device

Dbr... Wire link

Lockout reset button (info button)

/reset (EK1)

EK2 Remote lockout reset button

FSV Flame signal amplifier

ION Ionization probe

K... Relay contact

LED 3-color signal lamp

LP Air pressure switch

LR Load controller

LR-OPEN Load controller OPEN position

LR-CLOSED Load controller CLOSED position

M Fan motor

NT Power supply unit

Pmax Pressure switch-max

Pmin Pressure switch-min

POC Valve closure control (proof of closure)

PV Pilot valve

QRA... Flame sensor

R Control thermostat or pressurestat

SK Safety Loop

SV Safety valve

V1 Fuel valve

Z Ignition transformer

Input/output signal 1 (ON)

Input/output signal 2 (OFF)

Permissible input signal 1 (ON) or 0 (OFF)

14/15

Building Technologies Division User Documentation PME71.402... CC1A7105.4en

Infrastructure & Cities Sector 12 Legend 26.09.2014

13 List of figures

Figure 1: Program sequence ........................................................................................... 5

Figure 2: Fuel train gas direct ignition (G), 1-stage ......................................................... 7

Figure 3: Fuel train gas pilot ignition 1 (Gp1/1), 1-stage ................................................. 7

Figure 4: Inputs and outputs / internal connection diagram ............................................. 9

Siemens AG Infrastructure & Cities Sector Building Technologies Division © 2014 Siemens AG Infrastructure & Cities Sector

Berliner Ring 23 Building Technologies Division

D-76437 Rastatt Subject to change!

Tel. +49 7222 598 279

Fax +49 7222 598 269

www.siemens.com

15/15

Building Technologies Division User Documentation PME71.402... CC1A7105.4en

Infrastructure & Cities Sector 13 List of figures 26.09.2014

You might also like

- Yfm350s Yfm350s Yfm350s Yfm350s Yfm350: (5yt1) (5yt2) (5yt3) (5yt1) (5yt1)Document75 pagesYfm350s Yfm350s Yfm350s Yfm350s Yfm350: (5yt1) (5yt2) (5yt3) (5yt1) (5yt1)David Castro GasteluNo ratings yet

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- 3512B B 1014bkW 1360bhp 1600rpmDocument6 pages3512B B 1014bkW 1360bhp 1600rpmMILADNo ratings yet

- Modified Full RCM Program ProcessDocument4 pagesModified Full RCM Program ProcessNenad Deusic100% (1)

- Talal Asad On TortureDocument30 pagesTalal Asad On TortureClara Gonzalez CragnolinoNo ratings yet

- Tenses For SpeakingDocument34 pagesTenses For Speakingdsekulic_1100% (1)

- Cubes - Lightweight Python OLAP FrameworkDocument103 pagesCubes - Lightweight Python OLAP FrameworkStefan Urbanek100% (1)

- Rexroth Indradrive Drive Controllers Power Sections Hcs04: Instruction ManualDocument76 pagesRexroth Indradrive Drive Controllers Power Sections Hcs04: Instruction Manualeduardoduboc100% (1)

- WinCC Professional V13 EnUS en-USDocument8,314 pagesWinCC Professional V13 EnUS en-USHildemaro CarrasquelNo ratings yet

- PN Bacnet Link Operating Instructions en-USDocument96 pagesPN Bacnet Link Operating Instructions en-USIng Capriel CaprielNo ratings yet

- A5E43455517 6 76 - MANUAL - SITOP Manager - en USDocument252 pagesA5E43455517 6 76 - MANUAL - SITOP Manager - en USdasdNo ratings yet

- 828D PLC FCT Man 0721 en-USDocument356 pages828D PLC FCT Man 0721 en-USHernan MaynaNo ratings yet

- PME73.840 Oct 2014 A7105.28enDocument22 pagesPME73.840 Oct 2014 A7105.28enAangels PorrasNo ratings yet

- LFS1 A7782en March 2018Document51 pagesLFS1 A7782en March 2018Jarvy AgudeloNo ratings yet

- s71500 Et200mp System Manual en-US en-USDocument435 pagess71500 Et200mp System Manual en-US en-USabo.omar.elmasry.900No ratings yet

- Manual SIRIUS Overload Relay 3RU 3RB en-USDocument200 pagesManual SIRIUS Overload Relay 3RU 3RB en-USArunava BasakNo ratings yet

- Scalance - x1011 Commisioning ManualDocument86 pagesScalance - x1011 Commisioning Manualdbhzj76hz9No ratings yet

- Et200eco PN CM 8xio-Link Diq8x24vdc m12l Manual Manual en-US en-USDocument83 pagesEt200eco PN CM 8xio-Link Diq8x24vdc m12l Manual Manual en-US en-USPen TranNo ratings yet

- 3 Om650Document45 pages3 Om650Raul CallejasNo ratings yet

- Cpci Ea221 o I de en UsDocument40 pagesCpci Ea221 o I de en UsX'mix ĐreamerNo ratings yet

- A5e35857004-Agen Multi Oi En-UsDocument350 pagesA5e35857004-Agen Multi Oi En-UsAmir KalčoNo ratings yet

- PN Bacnet Link Operating Instructions En-En en-USDocument93 pagesPN Bacnet Link Operating Instructions En-En en-USOscar Enrique Serrano PerezNo ratings yet

- Manual Inversor SINAMICS G120CDocument316 pagesManual Inversor SINAMICS G120CMichaelNo ratings yet

- Manual 3RP25 Time Relay en-US PDFDocument90 pagesManual 3RP25 Time Relay en-US PDFZulfiqar ZaidiNo ratings yet

- PAC 3120 Ja 3220Document160 pagesPAC 3120 Ja 3220YAR SOLUTIONSNo ratings yet

- P7il81b en UsDocument572 pagesP7il81b en UsHugo DiazNo ratings yet

- Et200 SP Spha Ex System Manual en-US en-USDocument146 pagesEt200 SP Spha Ex System Manual en-US en-USFaizal AfzalNo ratings yet

- Sentron Pac 3100 Manuaali Englanti PDFDocument150 pagesSentron Pac 3100 Manuaali Englanti PDFtungskhaNo ratings yet

- Manual BW500 BW500L en-USDocument204 pagesManual BW500 BW500L en-USAdilson SouzaNo ratings yet

- Sentron Pac3100Document152 pagesSentron Pac3100Alirio Rodrigo MartinezNo ratings yet

- Industrial Controls Switching Devices SIRIUS 3RT Contactors/contactor AssembliesDocument568 pagesIndustrial Controls Switching Devices SIRIUS 3RT Contactors/contactor AssembliesNIKINo ratings yet

- Et200sp Cpu1512sp 1 PN Manual en-US en-USDocument38 pagesEt200sp Cpu1512sp 1 PN Manual en-US en-USanthonyNo ratings yet

- Et200sp Cpu1510sp 1 PN Manual en-US en-USDocument38 pagesEt200sp Cpu1510sp 1 PN Manual en-US en-USzakariareal623No ratings yet

- A5E33329501-AGen LUT400 OI en-USDocument331 pagesA5E33329501-AGen LUT400 OI en-USbrancokyoNo ratings yet

- SIPLUS HCS300I en en-USDocument132 pagesSIPLUS HCS300I en en-USJorge LoeraNo ratings yet

- BA BoxPC627 EngDocument196 pagesBA BoxPC627 EngEren akarsuNo ratings yet

- s71500 Cpu150xs Manual en-US en-USDocument196 pagess71500 Cpu150xs Manual en-US en-UScarlosoriNo ratings yet

- SENTRON Molded Case Circuit Breakers 3VL en USDocument360 pagesSENTRON Molded Case Circuit Breakers 3VL en USnishantpsbNo ratings yet

- Siemens SITRANS FUP1010 Man A5E02951522rAC 2013 01 PDFDocument218 pagesSiemens SITRANS FUP1010 Man A5E02951522rAC 2013 01 PDFrcorintoNo ratings yet

- BA SIMOCRANE CenSOR 0418 enDocument194 pagesBA SIMOCRANE CenSOR 0418 enBobNo ratings yet

- Siemens SITRANS FCT070 ManualDocument84 pagesSiemens SITRANS FCT070 ManualWaleed MohamedNo ratings yet

- Maxum II Airless and Airbath Reference Manual 2017 en-USDocument100 pagesMaxum II Airless and Airbath Reference Manual 2017 en-USchias04No ratings yet

- Simocode ProDocument400 pagesSimocode Prowerleyr.gNo ratings yet

- Industrial Controls Motor Management and Control Devices Simocode ProDocument400 pagesIndustrial Controls Motor Management and Control Devices Simocode Profranck stanleyNo ratings yet

- CFCBDocument136 pagesCFCBProteccion MedicionNo ratings yet

- Industrial Controls Safety Engineering SIRIUS 3SK1 Safety Relays and 3RQ1 Positively-Driven Coupling RelaysDocument230 pagesIndustrial Controls Safety Engineering SIRIUS 3SK1 Safety Relays and 3RQ1 Positively-Driven Coupling RelaysMetalprint ProjetosNo ratings yet

- Manual SIWAREX WT231 enDocument169 pagesManual SIWAREX WT231 enRinaldy ManaluNo ratings yet

- Manaual Transmisor SitransDocument330 pagesManaual Transmisor SitransAbel LopezNo ratings yet

- Ba Scalance-Xc-200 76Document166 pagesBa Scalance-Xc-200 76brunobcgNo ratings yet

- Sentron Pac3100 Manual en 03 en-USDocument172 pagesSentron Pac3100 Manual en 03 en-USthangna87No ratings yet

- V90 PN 1FL6 Getting Started 0818 en-USDocument152 pagesV90 PN 1FL6 Getting Started 0818 en-USMilan KanriNo ratings yet

- Ba Sinec-Pni 76Document47 pagesBa Sinec-Pni 76Victor Ignacio Alabi MontoyaNo ratings yet

- MAN - L1V30604052B-01 - PT - PT-BR - S-Medidor 2Document94 pagesMAN - L1V30604052B-01 - PT - PT-BR - S-Medidor 2Deltec DeltecNo ratings yet

- 840Dsl ONE PortLists Prod Info 0722 en-USDocument28 pages840Dsl ONE PortLists Prod Info 0722 en-USalejocmedNo ratings yet

- Readme Wincc Comfort Advanced v13 Enus PDFDocument62 pagesReadme Wincc Comfort Advanced v13 Enus PDFRafaelNo ratings yet

- ET200S - Fail-Safe ModulesDocument208 pagesET200S - Fail-Safe ModulesTetsusaiga100% (1)

- Ipc427e Operating Instructions en en-US PDFDocument164 pagesIpc427e Operating Instructions en en-US PDFglaucoNo ratings yet

- 3WA 92310000002-04 en en-USDocument528 pages3WA 92310000002-04 en en-USOvidiu VranceanuNo ratings yet

- Manual 3wa 02 2023 enDocument576 pagesManual 3wa 02 2023 ennagaselvamNo ratings yet

- Ipc847d Operating Instructions en-USDocument250 pagesIpc847d Operating Instructions en-UShassNo ratings yet

- A5E39789214-ABen FC410 FCS400 OI en-USDocument160 pagesA5E39789214-ABen FC410 FCS400 OI en-USpetrisor jocuriNo ratings yet

- ReadMe STEP7 WinCC V15 enUS PDFDocument112 pagesReadMe STEP7 WinCC V15 enUS PDFsrajuNo ratings yet

- Manual SIRIUS Overload Relay 3RU 3RB en-USDocument210 pagesManual SIRIUS Overload Relay 3RU 3RB en-USfindepyorsov74No ratings yet

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- Challenges and Approaches for Selecting, Assessing and Qualifying Commercial Industrial Digital Instrumentation and Control Equipment for Use in Nuclear Power Plant ApplicationsFrom EverandChallenges and Approaches for Selecting, Assessing and Qualifying Commercial Industrial Digital Instrumentation and Control Equipment for Use in Nuclear Power Plant ApplicationsNo ratings yet

- Asus VS247HVDocument92 pagesAsus VS247HVbawbawerert34No ratings yet

- Life Processes - Daily Home Assignment 01 - (Udaan 2024)Document3 pagesLife Processes - Daily Home Assignment 01 - (Udaan 2024)NadiaNo ratings yet

- Kinetics Body Work&Energy Impulse&MomentumDocument26 pagesKinetics Body Work&Energy Impulse&MomentumKano MolapisiNo ratings yet

- Nefax 671 691 Field ServiceDocument323 pagesNefax 671 691 Field Servicechuckt528No ratings yet

- Direct ContractingDocument1 pageDirect ContractingCharlie AdonaNo ratings yet

- Space Robotics: PreviewDocument21 pagesSpace Robotics: PreviewAnvit TiwariNo ratings yet

- Brdy Ya6c2n Spec enDocument2 pagesBrdy Ya6c2n Spec enDaniyal ParvezNo ratings yet

- DefenseDocument23 pagesDefenseCharles Gabriel Vinson CandelonNo ratings yet

- Ceratophyllum Demersum (Rigid Hornwort)Document15 pagesCeratophyllum Demersum (Rigid Hornwort)ador kumarNo ratings yet

- Design of FIR Filter Using Window Method: IPASJ International Journal of Electronics & Communication (IIJEC)Document5 pagesDesign of FIR Filter Using Window Method: IPASJ International Journal of Electronics & Communication (IIJEC)International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- The Wedding DayDocument2 pagesThe Wedding DayJomari Paulino PangilinanNo ratings yet

- Guias de Inspeccion Cheyenne IIDocument23 pagesGuias de Inspeccion Cheyenne IIesedgar100% (1)

- Mitac 8615 - Rev r01Document29 pagesMitac 8615 - Rev r01zokiNo ratings yet

- HRACM Assignment III - Infosys Case StudyDocument4 pagesHRACM Assignment III - Infosys Case Studysupriya sonkusareNo ratings yet

- Misc-Mock Thermodyamics TestDocument2 pagesMisc-Mock Thermodyamics TestGhenwa DimachkiNo ratings yet

- MKTG 2P52 - Case Study Number 1 - 1Document6 pagesMKTG 2P52 - Case Study Number 1 - 1Jeffrey O'LearyNo ratings yet

- Reinforced Concrete Design-Ii: Course Instructors: Prof. Dr. Asad-ur-Rehman Khan / Dr. Aslam Faqeer MohammadDocument20 pagesReinforced Concrete Design-Ii: Course Instructors: Prof. Dr. Asad-ur-Rehman Khan / Dr. Aslam Faqeer Mohammadzeeshan68No ratings yet

- Jaquet FT3000 ManualDocument48 pagesJaquet FT3000 Manualaden mngNo ratings yet

- Meghan Math Lesson Plan-2 FeedbackDocument7 pagesMeghan Math Lesson Plan-2 Feedbackapi-242877332No ratings yet

- General Studies New SyllabusDocument4 pagesGeneral Studies New SyllabusmykhaulujjhjNo ratings yet

- The Influence of The Integrated Marketing Communication On The Consumer Buying Behaviour PDFDocument5 pagesThe Influence of The Integrated Marketing Communication On The Consumer Buying Behaviour PDFPrimaGriseldaNo ratings yet

- HR Practice in AarongDocument20 pagesHR Practice in AarongRipon HossainNo ratings yet

- Bridge Design Manual - M23-50.03CompleteDocument1,302 pagesBridge Design Manual - M23-50.03CompleteJavier TalledoNo ratings yet