Professional Documents

Culture Documents

GFA Series PDF

Uploaded by

RahulOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GFA Series PDF

Uploaded by

RahulCopyright:

Available Formats

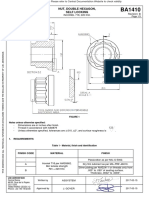

GFA-S series

CNC Tilting Rotary Table DIMENSIONAL DRAWINGS

203 30

40 Unit : mm

20

33

19

30

58

154.2

GFA-101S GFA-125S 32

GFA-101S

GF-101S 52 19

GFA-170S GFA-210S

321

Ø30

230

426

24.5

12H7

19

30 50 5030

G F A- 1 2 5 S 20

88

105

Ø30

Worktable diameter Ø100, Ø125, Ø170, Ø210.

4

40 60

100

Exclusive patented dual pneumatic piston braking

-17° + - 187

system. 196 125 109 68 80

Ø100

+1

Super pneumatic for Enlarged the high precision cross roller bearing.

07

°

135 70

multiple clamp force Transmitted by dual lead worm with high efficiency and

226

231

230

Table size

135

135

full depth gear teeth.

new evolution model 18h7

105 105

7

20

136.5

187 312.5

Five axes 499.5

Worm gear transmission

Upgraded high precision

cross roller bearings. GFA-125S

GF-125P 7.2 153 145

125 124 116 116

25

SPECIFICATIONS

116

116

39

70

327.6

40

315

100 100 324

310

32 28

25

70

39

75

Ø30H7

MODEL

19

32

100

12H7

10080

70 25

63 63

20

Unit GFA-101S GFA-125S GFA-170S GFA-210S

120

80

12H7 Ø30H7

115

Worktable diameter mm / inch Ø100 / Ø3.94 Ø125 / Ø4.92 Ø170 / Ø6.69 Ø210 / Ø8.27 20 25

50

50 50

50

20

Center bore diameter mm / inch Ø30H7 / Ø1.18H7 Ø30H7 / Ø1.18H7 Ø40H7 / Ø1.57H7 Ø65H7 / Ø2.56H7 20

-30

o

Ø25 86 85 19.5

26 73 85 20

Ø125

Height of table (horizontal) mm / inch 205 / 8.07 224.5 / 8.84 260 / 10.24 280 / 11.02 +40

°

Ø125

+1

0°

64.5

20

Height of center (vertical) mm / inch 135 / 5.31 160 / 6.30 190 / 7.48 210 / 8.27

o

-12

160 70

279

282

270

270

Width of T-slot mm / inch 12H7 / 0.47H7 12H7 / 0.47H7 12H7 / 0.47H7 12H7 / 0.47H7

160

25

5

Width of guide block mm / inch 18 / 0.71 18 / 0.71 18 / 0.71 18 / 0.71 18h7 18h7 232.5 230139.5175

30

7

7

120 115

120 115 535.1

pneumatic pneumatic pneumatic pneumatic 526.2

Clamping method /pressure Mpa / psi 0.55 ~ 0.7 / 0.55 ~ 0.7 / 0.55 ~ 0.7 / 0.55 ~ 0.7 /

GF-170P/H

GFA-170S

160.2 125 116

79.8 ~ 101.5 79.8 ~ 101.5 79.8 ~ 101.5 79.8 ~ 101.5 40

145 124 116

Servo motor spec refer to page 53 40

116

39

39 25

116

70 75

25

328.4

32

337

R T R T R T R T

100 100 344

344

70 25

25 100 100 25

Transmission ratio 32 Ø40H7

28

1:75 1:120 1:90 1:90 1:90 1:90 1:90 1:120 12H770

125 125

Ø40H7

20

Max. table speed min 33.3 16.6 44.4 44.4 33.3 22.2 33.3 22.2

-1

150

142.5

12H7

20

20 40

20 100 100

In Horizontal kg / lb 35 / 77 50 / 110 75 / 165 100 / 220 100 100

125 125

Allowable o

40 20 120 123 28

120.5

Ø170 123 28

-30+30° +1

loading capacity In Tilting 20 Ø169.576

0°

o

-12

kg / lb 20 / 44 35 / 77 50 / 110 70 / 154

298 70

(0~90°)

70

340

322

340

190

190

25

Allowable unblancing

WxL Nm /ft. lbs. 24 / 17.69 24 / 17.69 40 / 29.5 62 / 45.7 18h7 305 225

7

work moment 150 15018h7 267 659.4 206

7

142.5 142.5 597.75

F N / lbs 4000 / 897.60 4000 / 897.60 7000 / 1570.8 14000 / 3141.6 GFA-210SPB

GF-211P/ +30°

156 125

40 116

425.4

25

7.2 153 125

116

0°

Allowable load

39

75

-12

32

116

(when table FxL Nm /ft. lbs. 200 / 147.4 140 / 103.2 300 / 221 400 / 294.7 70 25

344345

125100228.4

25

251

Ø40H7

40

337

clamped)

25

12H7

20

39

70

100 100

25 100

32 28

165

218

FxL Nm /ft. lbs. 250 / 184.25 300 / 221.1 400 / 294.7 600 / 442 20

70 40

Ø65H7

142.5

125

12H7 125 125

40 130 180 28

40

Ø210100

100

Allowable loading inertia ( W.D kg.m 0.044 0.1 0.28 0.55

2 20

)

2

8 65 125 125

225 80

131 123 28

375

375

Resolution deg. 0.001 0.001 0.001 0.001

o

-30 Ø210

Indexing accuracy sec 40" 60" 40" 60" 20" 60" 20" 50"

+1

25

25

5

20

70

o

18h7 18h7 185 330 283

7

Repeatability sec 6" 8" 6" 8" 6" 8" 6" 8"

7

162 150 741.4

360

340

162 150

1125

210

Tilting angle range deg. +17 ~ -107 -30 ~ +120 -30 ~ +120 -30 ~ +120

Net weight (servo motor excluded) kg / lb 90 / 198 120 / 264 180 / 396 230 / 490.6 18h7 277 206

27

142.5 142.5 607.75

Allowable cutting torque Nm /ft. lbs. 85 / 62.65 85 /62.65 200 / 147.4 250 / 184.25

Note: R: Rotary Axis T: Tilt Axis

Note: 1. The length of servo guard may vary with servo motor type. (the metal sheet dimensions shown above are based on Fanuc motor)

-1

2. Allowable wheel torque at table speed of 1 min .

3. According to application engineering, optical encoder is recommended for tilting axis.

35 Tilting Rotary Table 36

You might also like

- Inno UEFA - Trompete 2Document1 pageInno UEFA - Trompete 2renatocomeairisNo ratings yet

- Tico Tico No Fuba LyricsDocument2 pagesTico Tico No Fuba LyricsAlaide NunesNo ratings yet

- Key document insightsDocument2 pagesKey document insightsPiotr AvramNo ratings yet

- Baldia Sub DivisionDocument1 pageBaldia Sub DivisionZahid AliNo ratings yet

- Fue Por M-PianoDocument3 pagesFue Por M-PianoToja AmyNo ratings yet

- Fondations - Persan-Fondation m1 m2Document1 pageFondations - Persan-Fondation m1 m2Soulanges YannickNo ratings yet

- 007_-_Bond..._James_Bond-Trombone_1Document1 page007_-_Bond..._James_Bond-Trombone_1Gabriel QuezadaNo ratings yet

- STP-Ph1-JWWF-XXX-LD-002 - PLUMBING GENERAL NOTES, LEGEND, SYMBOLS & ABBREVIATIONS SHEET 02 OF 02Document1 pageSTP-Ph1-JWWF-XXX-LD-002 - PLUMBING GENERAL NOTES, LEGEND, SYMBOLS & ABBREVIATIONS SHEET 02 OF 02Mohamed MousaNo ratings yet

- Yann Tiersen - 8 MMDocument4 pagesYann Tiersen - 8 MMdyamboNo ratings yet

- Expozitie: Gspublisherversion 0.0.100.100Document1 pageExpozitie: Gspublisherversion 0.0.100.100Florin ChirilaNo ratings yet

- Smooth Criminal 최종-Solo - ViolinDocument4 pagesSmooth Criminal 최종-Solo - Violin변재현No ratings yet

- Hit The Road Jack: (Soprano Recorder)Document1 pageHit The Road Jack: (Soprano Recorder)ubs rcNo ratings yet

- OceansDocument2 pagesOceansJordan AugustoNo ratings yet

- Decision Making Process VisualizedDocument2 pagesDecision Making Process VisualizedPablo Mena VilchesNo ratings yet

- In Sight GuitarDocument1 pageIn Sight GuitarCelso KrauseNo ratings yet

- Dona Nobis Pacem - GuitarDocument1 pageDona Nobis Pacem - Guitardarklord285No ratings yet

- Hino Do CorinthiansDocument2 pagesHino Do CorinthiansJuja TeixeiraNo ratings yet

- 04 - Crocodile Rock - 1st Clarinet in BBDocument1 page04 - Crocodile Rock - 1st Clarinet in BBsargirisNo ratings yet

- Unit Jam Tonyx Trumpet in BB 2Document2 pagesUnit Jam Tonyx Trumpet in BB 2Hector LauraNo ratings yet

- Star Wars Imperial March Sheet Music SummaryDocument2 pagesStar Wars Imperial March Sheet Music SummaryHannah Gill100% (1)

- Alex Imperial March - Darth VaderDocument2 pagesAlex Imperial March - Darth VaderHannahNo ratings yet

- Sample - Pipe Support - 4Document5 pagesSample - Pipe Support - 4sridharNo ratings yet

- Capuzzi Concerto BajoDocument3 pagesCapuzzi Concerto BajoZhaid PinedaNo ratings yet

- Espera - Bombardino BBDocument1 pageEspera - Bombardino BBSolano MusicNo ratings yet

- ADAGIO CANTABILE - BB - Clarinet - I - IIDocument1 pageADAGIO CANTABILE - BB - Clarinet - I - IIjorge farquezNo ratings yet

- Colorbars-Elliott Smith PianoDocument3 pagesColorbars-Elliott Smith PianoStefan Simanton100% (1)

- Tarantella Del '600 FinitaDocument3 pagesTarantella Del '600 FinitadarioNo ratings yet

- MozartDocument4 pagesMozartMaricaNo ratings yet

- Impromptu Op. 90 No. 2 Eb Major - SchubertDocument12 pagesImpromptu Op. 90 No. 2 Eb Major - SchubertCami MarsiglioneNo ratings yet

- Cat Dcs Sis Controller PDFDocument2 pagesCat Dcs Sis Controller PDFjuanNo ratings yet

- Palladio-Violins IIDocument2 pagesPalladio-Violins IIFrancesca FasolinoNo ratings yet

- Opus Dustin OHalloran HauschkaDocument4 pagesOpus Dustin OHalloran HauschkaHollyNo ratings yet

- 2 - Trio Sib PDFDocument2 pages2 - Trio Sib PDFPaula Ferrara RibesNo ratings yet

- 2 - Trio Sib 2 PDFDocument2 pages2 - Trio Sib 2 PDFPaula Ferrara RibesNo ratings yet

- Thousand YearsDocument2 pagesThousand YearsestherNo ratings yet

- Hit The Road JackDocument3 pagesHit The Road JackfranzaNo ratings yet

- In The MoodAlto Sax SoloDocument2 pagesIn The MoodAlto Sax SolomikyNo ratings yet

- Hallelujah PianoDocument2 pagesHallelujah PianojuandavidpianistaNo ratings yet

- A7K Final Assembly X01: Torque Conversion TableDocument3 pagesA7K Final Assembly X01: Torque Conversion TableJULIO CESAR GASPAR SANCHEZNo ratings yet

- Hummel Sonata ViolaDocument8 pagesHummel Sonata Violaana valeroNo ratings yet

- Windows of The World - 006 Flugelhorn 2Document2 pagesWindows of The World - 006 Flugelhorn 2Dumel OliveiraNo ratings yet

- Sonata in C Major Sheet MusicDocument2 pagesSonata in C Major Sheet MusicShahrul RedhwanNo ratings yet

- Sion Ciudad - COMPLETODocument3 pagesSion Ciudad - COMPLETOSamuel TayaNo ratings yet

- 9 Acf 0 DDocument1 page9 Acf 0 DAdam ThatcherNo ratings yet

- Baryton Trio in D Major: Hob - XI:31Document3 pagesBaryton Trio in D Major: Hob - XI:31Paloma Anahy Ramirez FloresNo ratings yet

- A B H I J: Lap. T Kolam Lapangan FutsalDocument1 pageA B H I J: Lap. T Kolam Lapangan FutsalTreisnaning WidasgantriNo ratings yet

- Battle Cry Solo by Ryan KisorDocument2 pagesBattle Cry Solo by Ryan KisorTobias WeberNo ratings yet

- Battle Cry PDFDocument2 pagesBattle Cry PDFTobias WeberNo ratings yet

- Atlas Copco SCOOPTRAM ST1020 Diagrams & DrawingsDocument117 pagesAtlas Copco SCOOPTRAM ST1020 Diagrams & DrawingsMacarena Benavides CastañedaNo ratings yet

- 2020 PowerBass CatalogDocument56 pages2020 PowerBass CatalogJhonne TJ (TJ)No ratings yet

- BWV - 1034 - Allegro BassDocument2 pagesBWV - 1034 - Allegro BassgianNo ratings yet

- RV 281-Violín - 3Document2 pagesRV 281-Violín - 3Juan sebastian CantorNo ratings yet

- DPL Usb Fpga Schematic v6Document6 pagesDPL Usb Fpga Schematic v6Manuel Alejandro TellezNo ratings yet

- Сияй easy PDFDocument2 pagesСияй easy PDFFreckledNo ratings yet

- Disney Song Medley 오보에 2: When You Wish Upon a Star-Mickey Mouse March-Beauty and the BeastDocument2 pagesDisney Song Medley 오보에 2: When You Wish Upon a Star-Mickey Mouse March-Beauty and the Beast백진선No ratings yet

- Disney Song Medley Violin III: When You Wish Upon A Star-Mickey Mouse March-Beauty and The BeastDocument2 pagesDisney Song Medley Violin III: When You Wish Upon A Star-Mickey Mouse March-Beauty and The Beast백진선No ratings yet

- EG Blues-Percussion PDFDocument5 pagesEG Blues-Percussion PDFFlorin StanescuNo ratings yet

- Mozart Symphony No.21 - Violin 1Document7 pagesMozart Symphony No.21 - Violin 1Thomas CoseyNo ratings yet

- Sugar Maroon 5Document5 pagesSugar Maroon 5David MoránNo ratings yet

- Introduction To MatlabDocument45 pagesIntroduction To MatlabSivaraman ChidambaramNo ratings yet

- Eng Pcdmis 2022.1 CMM ManualDocument453 pagesEng Pcdmis 2022.1 CMM ManualRahulNo ratings yet

- ITNC 530 Cycle ProgammingDocument527 pagesITNC 530 Cycle ProgammingRahulNo ratings yet

- ITNC 530 Cycle ProgammingDocument527 pagesITNC 530 Cycle ProgammingRahulNo ratings yet

- Eng Pcdmis 2022.1 CMM ManualDocument453 pagesEng Pcdmis 2022.1 CMM ManualRahulNo ratings yet

- SurveyDocument2 pagesSurveyRahulNo ratings yet

- Avl DocDocument38 pagesAvl DocRahulNo ratings yet

- Models - Chem.drug Release PDFDocument28 pagesModels - Chem.drug Release PDFRahulNo ratings yet

- Solving Ordinary Differential Equations With MatlabDocument22 pagesSolving Ordinary Differential Equations With MatlabMario ZamoraNo ratings yet

- Scientific Method: Hypothetico-Deductive ScienceDocument1 pageScientific Method: Hypothetico-Deductive ScienceRahulNo ratings yet

- ANSYS Tutorial: ContactDocument74 pagesANSYS Tutorial: Contacthailfreedom100% (1)

- TB Ansys Maxwell Magnetic Field Formulation PDFDocument3 pagesTB Ansys Maxwell Magnetic Field Formulation PDFRahulNo ratings yet

- WsDocument1 pageWsRahulNo ratings yet

- 002.hydro-Magnetic Mixed Convection Flow in A Lid-Driven Cavity With Wavy Bottom SurfaceDocument12 pages002.hydro-Magnetic Mixed Convection Flow in A Lid-Driven Cavity With Wavy Bottom SurfaceRahulNo ratings yet

- Halbach Array Electric MachinesDocument8 pagesHalbach Array Electric MachinesalexsurenderNo ratings yet

- Beam DeflectionDocument16 pagesBeam DeflectionPrashant MavaleNo ratings yet

- Fluid Structure Interaction Turek Benchmark Problem ResultsDocument12 pagesFluid Structure Interaction Turek Benchmark Problem ResultsRahulNo ratings yet

- Student Landing GearDocument1 pageStudent Landing GearRahulNo ratings yet

- AN INTRODUCTION TO HYDRODYNAMICSDocument109 pagesAN INTRODUCTION TO HYDRODYNAMICSVipul KumarNo ratings yet

- OpenFOAM-3.0.1 Programmer's GuideDocument100 pagesOpenFOAM-3.0.1 Programmer's GuideCendhyLiestyariniNo ratings yet

- Git Cheat SheetDocument1 pageGit Cheat Sheetkzelda100% (1)

- Assignment Register Form For Intern AE TUD v3 ProtectedDocument1 pageAssignment Register Form For Intern AE TUD v3 ProtectedRahulNo ratings yet

- Jianan PartDocument69 pagesJianan PartRahul0% (1)

- Exploring Openfoam Source Code: There and Back AgainDocument72 pagesExploring Openfoam Source Code: There and Back AgainSantiago Márquez DamiánNo ratings yet

- Rankine HugoniotDocument21 pagesRankine HugoniotSaurabh KhandelwalNo ratings yet

- Comparison of Pressure and VelocityDocument7 pagesComparison of Pressure and VelocityRahulNo ratings yet

- HowTo Navigate OpenFoam MB PDFDocument72 pagesHowTo Navigate OpenFoam MB PDFRahulNo ratings yet

- Aerospace Engineers AIAA 2010 531Document15 pagesAerospace Engineers AIAA 2010 531RahulNo ratings yet

- Video Content EFMDocument8 pagesVideo Content EFMviggi657No ratings yet

- Configurando CMC FACDocument14 pagesConfigurando CMC FACDante ChutorianscyNo ratings yet

- No. Hotel Address City Star Number of Room Room Allocation PIC Phone EmailDocument27 pagesNo. Hotel Address City Star Number of Room Room Allocation PIC Phone Emailali71usmanNo ratings yet

- Vertical Turbine Pumps Engineering Data: Effective April 1, 2003Document11 pagesVertical Turbine Pumps Engineering Data: Effective April 1, 2003Israel CastilloNo ratings yet

- Mares Nemo Dive Computer ManualDocument77 pagesMares Nemo Dive Computer Manualjohn@moron.it100% (1)

- HP Compaq 6910p Compal LA-3261p UMA Rev 1A SchematicDocument55 pagesHP Compaq 6910p Compal LA-3261p UMA Rev 1A Schematicbbbbbb1987No ratings yet

- Queuing TheoryDocument25 pagesQueuing TheoryVishal Kapoor100% (1)

- Datasheet Uni M QNB NS enDocument2 pagesDatasheet Uni M QNB NS enLinh dươngNo ratings yet

- AW169 Executive and Private Transport Brochure - Gen2020Document8 pagesAW169 Executive and Private Transport Brochure - Gen2020Lavern P. SipinNo ratings yet

- Free SEO Audit TemplateDocument3 pagesFree SEO Audit Templatepassivejournal74No ratings yet

- Nut, Double Hexagon, Self Locking: Page 1/3Document3 pagesNut, Double Hexagon, Self Locking: Page 1/3Renato WatanabeNo ratings yet

- Configuration Andtuning GPFS For Digital Media EnvironmentsDocument272 pagesConfiguration Andtuning GPFS For Digital Media EnvironmentsascrivnerNo ratings yet

- Triaxial Accelerometer With Integral Magnet (A0643TX)Document2 pagesTriaxial Accelerometer With Integral Magnet (A0643TX)ORAMAYNo ratings yet

- LAC 1 Session GuideDocument1 pageLAC 1 Session GuideCherry CarlosNo ratings yet

- IRJET Online Student PortalDocument6 pagesIRJET Online Student PortalEmmanuel FerolinoNo ratings yet

- Work Order HDPE PipeDocument33 pagesWork Order HDPE PipeANKURNo ratings yet

- Registered Contractor List PPADBDocument3 pagesRegistered Contractor List PPADBGaone Lydia SetlhodiNo ratings yet

- Sunny Brochure 16 Pages 23102018 PDFDocument8 pagesSunny Brochure 16 Pages 23102018 PDFSunilNo ratings yet

- A General Contingency Theory of ManagementDocument16 pagesA General Contingency Theory of ManagementlucasNo ratings yet

- 7 Figure Template BookDocument5 pages7 Figure Template Bookmattia89No ratings yet

- DCMotorsDocument19 pagesDCMotorsAndrew BuckleyNo ratings yet

- Histograms Answers MMEDocument5 pagesHistograms Answers MMEEffNo ratings yet

- Accessing Web Services Using Ibm Db2 For I HTTP Udfs and UdtfsDocument48 pagesAccessing Web Services Using Ibm Db2 For I HTTP Udfs and UdtfsJames MorrisonNo ratings yet

- Installation Manual: Tankless Gas Water HeaterDocument26 pagesInstallation Manual: Tankless Gas Water HeateralanNo ratings yet

- CC - B302mel3-Bwp05-C-Dwg-3013-01-A2-Code 2Document2 pagesCC - B302mel3-Bwp05-C-Dwg-3013-01-A2-Code 2vt9984No ratings yet

- SSIGL-2 Site Identification and Prioritization Ver-6Document106 pagesSSIGL-2 Site Identification and Prioritization Ver-6Amiira AbdumalikNo ratings yet

- Airbus Techdata AC A321 0322Document434 pagesAirbus Techdata AC A321 0322Mario AntonioNo ratings yet

- Dcit 7.0 NotesDocument4 pagesDcit 7.0 NotesErick GitahiNo ratings yet

- AI-Powered Search v14Document398 pagesAI-Powered Search v14NikhilNo ratings yet

- Power BI Vs Excel 1694801413Document1 pagePower BI Vs Excel 1694801413LifeNo ratings yet

- Zerust Flange Savers - WebDocument2 pagesZerust Flange Savers - WebFederico MoranNo ratings yet