Professional Documents

Culture Documents

p95-1672 Routing - IsM NBI

Uploaded by

Diego LiraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

p95-1672 Routing - IsM NBI

Uploaded by

Diego LiraCopyright:

Available Formats

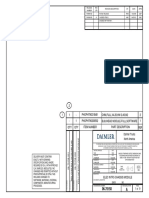

Routing - Eng Harness ISM P95-1672 A 01

GENERAL NOTES

1) USE ON NBI B-CAB WITH CUMMINS ISM SERIES ENGINE

EQUIPPED WITH CM875 CONTROLLER. TO FAN CLUTCH SOLENOID VALVE ( J05 )

! CAUTION

2) SEE SHEET 2 FOR MATERIAL LIST

40 WAY IP FIREWALL CONNECTOR ( P09 )

3 USE AS REFERENCE FOR ROUTING TOGETHER OF:

- P92-2461-X OR P92-2518-X - ENGINE HARNESS

- P92-2016 - CHARGE GROUND HARNESS 3

- P92-1952-XXXX - TRAILER POWER HARNESS

- K246-729-XY-ZZZZ - ALTERNATOR HARNESS

4 FOR P92-2461-2 OR P92-2518-2.

5) SUPERSEDES P95-1665 HARNESS ROUTING FOR PROD X

SERV INCORRECT CORRECT

6 ALSO REF FOR A / C LINES - SEE F95-1025 INSTALL POWER CABLES WITH THE TERMINAL ORIENTED

AS SHOWN. FAILURE TO PROPERLY INSTALL COMPONENT

7 APPLY REFLEXWRAP HEAT SHIELD TO ENGINE HARNESS MAY RESULT IN SHORT CIRCUIT OR EQUIPMENT DAMAGE.

ALTERNATOR GROUND BREAKOUT AND ALTERNATOR HARNESS

PER R414-1212 AND R026-198-98 SECTION 17.7

DETAIL A

TO WATER VALVE ( J60 ) TO FIREWALL GROUND

TO EXHAUST TEMPERATURE ( J33+P01 ) TO ETHER START

SOLENOID ( J37+P11 )

TO CHASSIS HARNESS ( J34 )

4

TO TRANSMISSION HARNESS ( J43 )

TO COOLING MODULE HARNESS ( J02 ). ENGINE GROUNDS,

ROUTE AS REQUIRED TO RH OR LH SEE DETAIL A

SIDE FOR SPECIFIC COOLING MODULE.

LOCATE YELLOW INDEX TAPE AT

THE TOP LH CORNER OF ENGINE.

SEE DETAIL D

TO MULTI-FUNCTION ENGINE

BODY BUILDER CONNECTOR

4

TO ALTERNATOR

GROUND ( GND_A ) STARTER GROUND

J1939 TERMINATING

7 RESISTOR ( J23+P27 ) STARTER SOLENOID ( J22 )

DETAIL B

ENG ECM OEM CONNECTOR ( J19 )

TO ENGINE ECM POWER PORT ( J3 )

TO STARTER INTERRUPT ( J12+P05 )

SEE DETAILS A, B & C

TO TORQUE CONVERTER

LOCKUP SIGNAL ( J03+P33 ) FAN OUT GND LUGS TO

ALLOW PROPER CONTACT. ALWAYS ROUTE AND TIE J1939 WIRING TO

OUTSIDE OF BUNDLE. DO NOT PLACE TIES

TO AMBIENT AIR TO AMMETER ( J32+P03 ) OVER CONNECTOR LATCHES. CONNECTOR LATCHES

4 TEMPERATURE

SENSOR ( P17+J38 )

DETAIL C MUST NOT BE SECURED AGAINST ANY OTHER

TO POWER FUSE HARNESS ( P60 ) BUNDLE OR OBJECT WHICH MAY DEPRESS THE

LATCH AND ALLOW THE CONNECTOR TO UNSEAT.

FOR FIREWALL MOUNTED CIRCUIT BREAKERS,

ROUTE THIS THESE BREAKOUTS WITH DETAIL D

MAIN HARNESS TRUNK TO FIREWALL.

TO BATTERY BOX HARNESS ( P56 )

TO A / C COMPRESSOR TO BATTERY BOX

CLUTCH ( J17 ) HARNESS ( P54 )

STANDARD ENGINE HARNESS BREAKOUTS

FRAME GROUND ( REF R414-558 )

P92-2461-1 AND -2

OR P92-2518-1 AND -2

Routing - Eng Harness ISM P95-1672 A 02

8 9 10

ORIENT ALTERNATOR LUG CONNECTORS

7

OUTBOARD, AWAY FROM EGR PIPING

5 9 10

( F85-1013 ) REF FOR

FILL / VENT LINE

- SEE V95-1023

SEE DETAIL E

1 9 10 DETAIL E

RB ROTATED VIEW

12

7

6 9 10 SEE DETAIL F

COWL MTD AIR CLNR

ENGN MTD AIR CLNR

( D11-1024 ) REF FOR

DISCH / FUEL LINE - SEE

R414-1094 / R414-1128

2 9 10 6

REF REF 12 K167-308-120 MOLDING-EDGE TRIM

DETAIL F 9 10

3 9 10 REF REF 11 K231-363-172 STRAP - HEAVY DUTY TIE ITEM 12 NOT SHOWN

FOR CLARITY

9 9 10 T255R0H1R STRAP - CABLE TIE

1 9 10 ENGINE MTD AIR CLNR 9 9 9 HDM250H1R HEAVY DUTY TIE MOUNT

1 1 8 K299-723 BRACKET-90 DEG STANDOFF

6

1 1 7 K299-3 BRACKET-90 DEG STANDOFF

2 9 10 COWL MTD AIR CLNR

1 1 6 K275-2422 BRACKET - STANDOFF

4 9 10

REF REF 5 K275-1446 BRACKET - STANDOFF

1 1 4 K275-187 BRACKET - HEATER PIPE

1 1 3 K317-184 BRACKET - 90 DEG STANDOFF

2 1 2 K028-2491-12 BRACKET - 90 DEG STANDOFF

1 2 1 K028-867 BRACKET - 90 DEG STANDOFF

You might also like

- Harness KenworthDocument17 pagesHarness KenworthNembot AmedeNo ratings yet

- Flood Lamps P94-1401 - 01: General NotesDocument4 pagesFlood Lamps P94-1401 - 01: General NotesGonzalo GalvezNo ratings yet

- Diagram - System, Sleeper HVAC P94-1478 A 01Document8 pagesDiagram - System, Sleeper HVAC P94-1478 A 01Gonzalo GalvezNo ratings yet

- Controller, w/CAT 3406E or C10/C12 w/ADEM III P94-1189 A 01: Usage NoteDocument3 pagesController, w/CAT 3406E or C10/C12 w/ADEM III P94-1189 A 01: Usage NoteGonzalo GalvezNo ratings yet

- P94-1591 Diagrama Eléctrico KWDocument3 pagesP94-1591 Diagrama Eléctrico KWOswaldoNo ratings yet

- P94 1389Document2 pagesP94 1389JoseGarzaNo ratings yet

- P94-1298 Diagrama Electrico CAT C15Document6 pagesP94-1298 Diagrama Electrico CAT C15pedro luisNo ratings yet

- p92-2805 Harness - IP BC 2007 NAMUX 2Document18 pagesp92-2805 Harness - IP BC 2007 NAMUX 2Diego LiraNo ratings yet

- Rtlo 20918B AsDocument36 pagesRtlo 20918B AsVolcambus SacNo ratings yet

- RTX-14710C Caja EatonDocument36 pagesRTX-14710C Caja EatonCarlos Chavez100% (1)

- BODY CONTROL MODULES - Saturn Vue Green Line 2008 - SYSTEM WIRING DIAGRAMSDocument2 pagesBODY CONTROL MODULES - Saturn Vue Green Line 2008 - SYSTEM WIRING DIAGRAMSFredyNo ratings yet

- Diag - Instrumentation P94-1585 A 01: Prod Serv XDocument8 pagesDiag - Instrumentation P94-1585 A 01: Prod Serv XElmer Tintaya MamaniNo ratings yet

- P94-1932 Luces Led InteriorDocument9 pagesP94-1932 Luces Led InteriorGonzalo GalvezNo ratings yet

- P92-2941 Temp CajaDocument3 pagesP92-2941 Temp Cajacarlos ramosNo ratings yet

- Eaton Rto 15715 Transmission Illustrated Parts List en UsDocument44 pagesEaton Rto 15715 Transmission Illustrated Parts List en UsCrystian PerezNo ratings yet

- Modelos de Cajas y Velociades FullerDocument2 pagesModelos de Cajas y Velociades Fullerj_hernandez_chNo ratings yet

- Harness - Instr Panel B-Cab P92-4319 C 01: CompanyDocument18 pagesHarness - Instr Panel B-Cab P92-4319 C 01: Companyraymond rizaNo ratings yet

- Suggested Installation Connection PointsDocument12 pagesSuggested Installation Connection Pointsgustavoqr27No ratings yet

- Codigos de FallaDocument9 pagesCodigos de FallaJohn MkCito KINo ratings yet

- Cascadia PrtPak 09AUG13Document44 pagesCascadia PrtPak 09AUG13Raul LunaNo ratings yet

- Ecf9 Nh3 ManualDocument20 pagesEcf9 Nh3 Manualgonza100% (1)

- Fdocuments - in Manual Installation Cummins 67l Paccar PX 6 Fitting 4 Jic 18 NPTDocument17 pagesFdocuments - in Manual Installation Cummins 67l Paccar PX 6 Fitting 4 Jic 18 NPTManuelNo ratings yet

- Harness - T800 Fieldtest Aftertrtmnt P92-3026 - 01: DWG SizeDocument3 pagesHarness - T800 Fieldtest Aftertrtmnt P92-3026 - 01: DWG SizeElmer Tintaya MamaniNo ratings yet

- 23 IS 300 / 200 (LHD) : Horn Front W Iper and W Asher Power SourceDocument1 page23 IS 300 / 200 (LHD) : Horn Front W Iper and W Asher Power SourceVishal Vishal VishalNo ratings yet

- MeritorDocument104 pagesMeritorDANIELNo ratings yet

- Harness - Tail Lamp K068-6997 A 01Document1 pageHarness - Tail Lamp K068-6997 A 01Daniel RobichaudNo ratings yet

- Engineering Installation Bulletin: Belt Drive SystemDocument7 pagesEngineering Installation Bulletin: Belt Drive Systemmxnoxn100% (1)

- Series 60 Engine Sensor Harness: Available in Some ApplicationsDocument1 pageSeries 60 Engine Sensor Harness: Available in Some ApplicationsDuy KhaNo ratings yet

- C7 On-Highway Engine Electrical System: Nph1-Up Lbm1-Up SAP3956-UP Wax1-UpDocument2 pagesC7 On-Highway Engine Electrical System: Nph1-Up Lbm1-Up SAP3956-UP Wax1-UpOswaldo Andrade100% (1)

- Harn - Allison 4th Gen Ext P92-3017 - 01: DWG SizeDocument1 pageHarn - Allison 4th Gen Ext P92-3017 - 01: DWG SizeMohanad MHPSNo ratings yet

- Kenworth Dash Layout: CoversheetDocument6 pagesKenworth Dash Layout: CoversheetHORACIONo ratings yet

- Diag - Wiper & Washer P94-1860 - 01: A Division ofDocument2 pagesDiag - Wiper & Washer P94-1860 - 01: A Division ofGonzalo GalvezNo ratings yet

- Fuller 18-Speed Transmissions PDFDocument2 pagesFuller 18-Speed Transmissions PDFWILMAR ANDRES MONTOYA MAYANo ratings yet

- Harn - Allison 4th Gen, Dash P92-3018 - 01: VAR Option Omit Connectors Omit WiresDocument3 pagesHarn - Allison 4th Gen, Dash P92-3018 - 01: VAR Option Omit Connectors Omit WiresMohanad MHPSNo ratings yet

- Diagrama CollageDocument14 pagesDiagrama CollageJuan del AngelNo ratings yet

- MBE - MBE4000 (2007 & Newer) .MBE4000 EPA07Document10 pagesMBE - MBE4000 (2007 & Newer) .MBE4000 EPA07Alfonso Robles RubioNo ratings yet

- P94 1170 PDFDocument4 pagesP94 1170 PDFeduardonemoNo ratings yet

- HINO 300 SERIES - Body Mounting ManualDocument169 pagesHINO 300 SERIES - Body Mounting ManualAndrew AwadNo ratings yet

- Paccar - PX-8 CM2150 (2007-09)Document11 pagesPaccar - PX-8 CM2150 (2007-09)solucionesdiesel2022No ratings yet

- Falla Data CanDocument4 pagesFalla Data CanGrupo Alber SACNo ratings yet

- P92-2410 SantiDocument5 pagesP92-2410 Santicarlos ramosNo ratings yet

- P27-1147 - A B C D: Exploded ViewDocument4 pagesP27-1147 - A B C D: Exploded ViewAndrew WilliamsNo ratings yet

- EPA07 10 GHG14 DDEC VI 10 Electronics and Troubleshooting Manual (DDC-SVC-MAN-0084)Document36 pagesEPA07 10 GHG14 DDEC VI 10 Electronics and Troubleshooting Manual (DDC-SVC-MAN-0084)E. CastilloNo ratings yet

- Usage:: TolerancesDocument39 pagesUsage:: TolerancesMANUEL VICTORNo ratings yet

- Codigos de Falla CumminsDocument3 pagesCodigos de Falla CumminsCrecencio Sanches50% (2)

- MBE - MBE900 (2007 & Newer) .MBE900 EPA07 PDFDocument11 pagesMBE - MBE900 (2007 & Newer) .MBE900 EPA07 PDFAlfonso Robles Rubio100% (1)

- Continental Cm2220 Mpc5566 Cummins EngineDocument4 pagesContinental Cm2220 Mpc5566 Cummins EngineRomeo HinogNo ratings yet

- Diagram - Engine, 2010 PX-6, PX-8 P94-6099 A 01: CompanyDocument11 pagesDiagram - Engine, 2010 PX-6, PX-8 P94-6099 A 01: CompanyMaríaNo ratings yet

- BHM SeñalesDocument9 pagesBHM Señalesbrayam100% (1)

- Conectores y Numeros de Par TDocument42 pagesConectores y Numeros de Par TJonathan Francisco Perez Ayala100% (1)

- Diagrama Electrico 3126 9szDocument2 pagesDiagrama Electrico 3126 9szLuis EcheverriamendezNo ratings yet

- Rto 16910B DM3Document43 pagesRto 16910B DM3Juan PerezNo ratings yet

- S08337b PDFDocument121 pagesS08337b PDFJhony KizeNo ratings yet

- Eatonroadranger RTLO-14610BDocument48 pagesEatonroadranger RTLO-14610BSalvador CrespoNo ratings yet

- BERGSTROM Manual Instalación KenworthDocument39 pagesBERGSTROM Manual Instalación KenworthCarlos AnticonaNo ratings yet

- Bendix ABS - EC-80.Dual Rear Axle Control (6S-6M)Document7 pagesBendix ABS - EC-80.Dual Rear Axle Control (6S-6M)nenadNo ratings yet

- M2 106 Circuito Neumatico CompletoDocument6 pagesM2 106 Circuito Neumatico CompletoBernardo OlivaNo ratings yet

- P94-1918 ArrancadorDocument5 pagesP94-1918 ArrancadorGonzalo GalvezNo ratings yet

- A/V & Navigation (5) SD969-5Document1 pageA/V & Navigation (5) SD969-5Dhashana MoorthyNo ratings yet

- Reference List of Drawings: SwitchboardsDocument96 pagesReference List of Drawings: SwitchboardsDINESH CHATAPNo ratings yet

- DT466 530 (2000-2003) Diagnostic Manual (EGES215) PDFDocument358 pagesDT466 530 (2000-2003) Diagnostic Manual (EGES215) PDFDiego Lira100% (1)

- p94-1634 Diagram - Headlamps W DRL PDFDocument2 pagesp94-1634 Diagram - Headlamps W DRL PDFDiego LiraNo ratings yet

- Trsm0980en-Us 0516Document169 pagesTrsm0980en-Us 0516Anonymous PYaGnlamNo ratings yet

- Denominación Fallas ThomasDocument60 pagesDenominación Fallas ThomasDaniel Alex SánchezNo ratings yet

- MX (EPA10) Engine Wiring PDFDocument7 pagesMX (EPA10) Engine Wiring PDFDiego Lira100% (1)

- Chelsea 630 Parts ManualDocument12 pagesChelsea 630 Parts ManualL GNo ratings yet

- P92-4998 Harness Aftertreatment PDFDocument4 pagesP92-4998 Harness Aftertreatment PDFDiego LiraNo ratings yet

- Kenworth P92 4319 B Cab Wiring Diagram PDFDocument18 pagesKenworth P92 4319 B Cab Wiring Diagram PDFJessica Noriega Sanguino100% (3)

- P92-4039 Harness - MX 2010 EngineDocument4 pagesP92-4039 Harness - MX 2010 EngineDiego Lira100% (1)

- p92-4440 Harness - Chassis Load CNTR CumminsDocument4 pagesp92-4440 Harness - Chassis Load CNTR CumminsDiego Lira100% (1)

- p92-4441 Harness - Chassis Load CNTR MXDocument4 pagesp92-4441 Harness - Chassis Load CNTR MXDiego Lira100% (1)

- p92-3838 Harness - Front Chassis CumminsDocument11 pagesp92-3838 Harness - Front Chassis CumminsDiego LiraNo ratings yet

- p92-4266 Harness - Tail Lamp, RussiaDocument1 pagep92-4266 Harness - Tail Lamp, RussiaDiego LiraNo ratings yet

- p92-2805 Harness - IP BC 2007 NAMUX 2Document18 pagesp92-2805 Harness - IP BC 2007 NAMUX 2Diego LiraNo ratings yet

- p92-3922 Harness - IP BC 2010 NAMUX 3Document18 pagesp92-3922 Harness - IP BC 2010 NAMUX 3Diego LiraNo ratings yet

- Eaton - Gen 3 (Auto & UltraShift) .10 Speed With Push Button (AutoShift)Document5 pagesEaton - Gen 3 (Auto & UltraShift) .10 Speed With Push Button (AutoShift)Diego LiraNo ratings yet

- P27-1040 Switch - Eaton PNsDocument3 pagesP27-1040 Switch - Eaton PNsDiego LiraNo ratings yet

- Refrigerant Compressor - Remove and Install: Cerrar SIS Pantalla AnteriorDocument7 pagesRefrigerant Compressor - Remove and Install: Cerrar SIS Pantalla AnteriorDiego LiraNo ratings yet

- T600, T800, & C500Document20 pagesT600, T800, & C500antonio95% (22)

- 936Document2 pages936Diego LiraNo ratings yet

- KM815020 Pre 2001 PD Box Serive Manual - B-CabsDocument6 pagesKM815020 Pre 2001 PD Box Serive Manual - B-CabsDiego Lira100% (3)

- Eaton - Gen 3 (Auto & UltraShift) .18 Speed With Analog Shifter (AutoShift)Document5 pagesEaton - Gen 3 (Auto & UltraShift) .18 Speed With Analog Shifter (AutoShift)Diego LiraNo ratings yet

- Eaton - Gen 3 (Auto & UltraShift) .18 Speed With Push Button (AutoShift)Document5 pagesEaton - Gen 3 (Auto & UltraShift) .18 Speed With Push Button (AutoShift)Diego LiraNo ratings yet

- Eaton - Gen 3 (Auto & UltraShift) .13 Speed With Analog Shifter (UltraShift)Document5 pagesEaton - Gen 3 (Auto & UltraShift) .13 Speed With Analog Shifter (UltraShift)Diego LiraNo ratings yet

- Eaton - Gen 3 (Auto & UltraShift) .13 Speed With Push Button (UltraShift)Document5 pagesEaton - Gen 3 (Auto & UltraShift) .13 Speed With Push Button (UltraShift)Diego LiraNo ratings yet

- Eaton - Gen 3 (Auto & UltraShift) .18 Speed With Analog Shifter (AutoShift)Document5 pagesEaton - Gen 3 (Auto & UltraShift) .18 Speed With Analog Shifter (AutoShift)Diego LiraNo ratings yet

- Eaton - Gen 2 (AutoShift) .10 Speed (AutoShift)Document5 pagesEaton - Gen 2 (AutoShift) .10 Speed (AutoShift)Diego LiraNo ratings yet

- Eaton - Gen 3 (Auto & UltraShift) .13 Speed With Push Button (UltraShift)Document5 pagesEaton - Gen 3 (Auto & UltraShift) .13 Speed With Push Button (UltraShift)Diego LiraNo ratings yet

- Eaton - Gen 2 (AutoShift) .10 Speed (AutoShift)Document5 pagesEaton - Gen 2 (AutoShift) .10 Speed (AutoShift)Diego LiraNo ratings yet

- Automatic Water Level PDFDocument9 pagesAutomatic Water Level PDFStarliam WilliamsNo ratings yet

- Avery ALX-924 ManualDocument18 pagesAvery ALX-924 ManualMike Farver100% (2)

- REG-DP Indications V16.1Document6 pagesREG-DP Indications V16.1Ioan MarcuNo ratings yet

- Electric Tool Parts List: Hitachi Power ToolsDocument4 pagesElectric Tool Parts List: Hitachi Power ToolsyoranvaneekelenNo ratings yet

- Hvrm15e SMDocument250 pagesHvrm15e SMpanasony1No ratings yet

- EM-II Lab ManualDocument53 pagesEM-II Lab Manualrv_andeNo ratings yet

- GROHE Specification Sheet 36451000Document3 pagesGROHE Specification Sheet 36451000Iftikhar AmjadNo ratings yet

- InventoryOverview HN (08.05.2023)Document15 pagesInventoryOverview HN (08.05.2023)Văn Thế NamNo ratings yet

- MAGNETISM & ElectromagnetismDocument47 pagesMAGNETISM & ElectromagnetismJames SarkerNo ratings yet

- Fisa Tehnica Seria AK - Valiadis GreeceDocument15 pagesFisa Tehnica Seria AK - Valiadis GreeceRemus GhincuNo ratings yet

- Spotface: Machined Faced Cast Forged Roughness Flatness Tolerances Counterbore BossDocument2 pagesSpotface: Machined Faced Cast Forged Roughness Flatness Tolerances Counterbore Bossmamasita25No ratings yet

- 2018-12-14 Battery-Box Pro 13.8 User Manual EN V4.0 PDFDocument23 pages2018-12-14 Battery-Box Pro 13.8 User Manual EN V4.0 PDFnevkatNo ratings yet

- Installation, Wiring, and Specifications: in This Chapter. - .Document47 pagesInstallation, Wiring, and Specifications: in This Chapter. - .Dani PrasetyoNo ratings yet

- 6.10 (Control Cables) - AnnotationsDocument18 pages6.10 (Control Cables) - AnnotationsAslam AwanNo ratings yet

- PlantPAx Process LibraryDocument54 pagesPlantPAx Process LibraryisraelalmaguerNo ratings yet

- Benelli Tornado 903 Workshop ManualDocument352 pagesBenelli Tornado 903 Workshop ManualGeorge Bisdikis100% (1)

- Parts Catalogue YSD4900Document33 pagesParts Catalogue YSD4900Willem van der BerghNo ratings yet

- SoleCity Data Sheet Led Light ColumnDocument4 pagesSoleCity Data Sheet Led Light ColumnMoustafa NabilNo ratings yet

- Ca235005en Uhs Ultra CopperDocument16 pagesCa235005en Uhs Ultra CopperMatthew JordanNo ratings yet

- QJ51AW12D2 - User's Manual SH (NA) - 080968-D (10.14)Document84 pagesQJ51AW12D2 - User's Manual SH (NA) - 080968-D (10.14)fajri asyukronNo ratings yet

- Panasonic SA-BTT785 PDFDocument50 pagesPanasonic SA-BTT785 PDFboroda2410100% (1)

- Genesis BroDocument4 pagesGenesis BrojmljNo ratings yet

- Timberland RanchDocument28 pagesTimberland Ranchrob_crowell_1No ratings yet

- Setup Manual: SC-F9300 Series Rev. BDocument68 pagesSetup Manual: SC-F9300 Series Rev. BChapi-Chape Chapi ChapeNo ratings yet

- d027 d029 Na Parts Catalog v1.14Document162 pagesd027 d029 Na Parts Catalog v1.14Joe BlackNo ratings yet

- AC - Stampede-2 UTVDocument2 pagesAC - Stampede-2 UTVSebastian Rentsch0% (1)

- Ms 881Document32 pagesMs 881Mlam MlamNo ratings yet

- Dxe PrtlistDocument31 pagesDxe PrtlistdevilsharmaNo ratings yet

- YZF-R15: Parts & AccessoriesDocument55 pagesYZF-R15: Parts & AccessoriesSiam HussainNo ratings yet

- Siecsa - Ecuador - SCADA + PLC Architecture CT (Rev.F)Document9 pagesSiecsa - Ecuador - SCADA + PLC Architecture CT (Rev.F)eduarodrigoNo ratings yet