Professional Documents

Culture Documents

Ares Wps

Uploaded by

Kadry Nabil Hegazy0 ratings0% found this document useful (0 votes)

36 views16 pagesWp pqr

Original Title

Ares wps

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWp pqr

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

36 views16 pagesAres Wps

Uploaded by

Kadry Nabil HegazyWp pqr

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 16

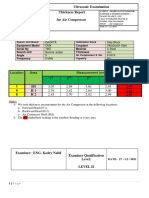

snl ARESC(

MANUFACTURING & INDUSTRIAL PROJECTS

From: Welding Engineer

To: Quality Control Manager 7 |

ject: [WPS's & POR’s For Approval

[2/24/2016

Welding Procedures Book .

WPS's & PQR's For PROJECT: SCC-SUEZ PLANT PRODUCTION LINE # 2

EZ PLANT PRODUCTION LINE #2

Tn WELDING

wren [re ose: “rue re

[ |

ARE M45 arent | pros tor | eros | sut-ri sMAW

"one

ZI

Lo dure Specification —

|. uillReseg a ies

a Applicable Code ASME iK

Dato

(Joints ( W403)

Doin Design As stan

Sacking (Ys) by SMa (7010) x

[sre ne S

1c Gouging: (Ye) SE

[oouging Matod: Area and grigor

FRLROBBeve angie a =

P= 45 mm

FRo= 05-9 tn

205208 35288 =

(Base Metal (QW-403) [Post Weld Heat Treatment (aw-aa7y aa

|rrsse0ed to Unease [Temceratre Range: NI

waited: Gree 10-70 Filet: 38 Hime Range NA

)Masmiom pss henness 31/2" (es) Heating Rate NA

fPpe Da. Range OD-Al___Cther: Weld from other sitet possbie_|Cootng hate wa

Filler Metal (QWicaoay [Gas (aw-406)

| Type SeCompostion — Few Rate (may

| Spec SAF-no 817 sricses ‘None Nene

JAWS NO. (Cassy Fraseuia [raiieg Nove None

fe j re ae

Have 1 Gs Cup size None None

[ter oi: ‘sor: [Electrical Characteristics (QW-408)_

Filer Meta produc farm: NA [Electrode & polarty See om

[fvickness weld metal quae lamer & Vet Range ‘See bow

| rove Ute 70mm Heat np (mm) NA

fat 3mm [Tngsten elecroe Sze and Type or (STAN): None

(er Tada Name ary Mode of Metal Transts for (GMAW) None

eauences: See above drowng eco | Wie feed Speed Rango None

In rw rata twa ‘Technique (QW-410)

trode - Flu (ass) Frawemt2 Stig a weove Bead Sg

A, ppoctpe. Fis hate or singe pass Muoete

[Fx Trade Name oy Muti or single electrode single

Icorsutin inser NA lorctten NA

| Position ( Qw-405) Conact te to won citnce: —~33.mm

[Poston ctorove 76 Ireenrg None

[Neting Pccmasion: None ett re nercass caning: 8 grinder and wre bush

Postion o tet aeaar Mets of Back Gouging: se arana gander

Preheat (QW-406) cas Cvp size None

[Preheat Temp.nin. 80°C (Closed to aut amber Nore

Iterpass Tempmax, 250°C Use ormenai rocess: Nese

Preheat Maiterance Yes Joters: Tea fier metal es ger manufacture recommendatons

Fil Matas Curent

No.of | process fat Range | *¥2*ag@ Travel Speed

ey ities Cass | Oa, Flux eee Crvmin

7 SAW EM aam —] —F7 Re mT OAT

| Fw AW} emi2 | 4mm | Frad 30-33, 30-40

|. cap A] eMt2 | 4mm | FTA . 20-33 30-40

At gers back gunn by ae aan der

8 RT ne |S OT CES ET |

foe fm:

‘ . Prepared) 1By Welding Ena | a at ‘Quality Mar

[ame Zo eae Coane ea

| signature ST eS

ate SOE =

. Welding Procedure Specification [Edition No. 3

Doway

ica care 4

interpass Temp 2 aa Rag

PWHT (QWa07) i x ae

Temperature °C) none > Coing Rates (Ce) sone |

Tone = iter Rowe Emaar

eating Rate (CF) Sone =

GAS (QW=408 1

PROCEDURE Date: 2acz009

QUALIFICATION

RECORD PORNOARE TH

ACCORDING To ASME CODE

SECTION 1 [Projeet:

Bene 7 fe Dues = ]

WpsNo.: Welding Process (E3) > reaw tat

[Fipe i Caso

[eis

| Tone Et Se

wos I

{ TECHNIQUE (QW-410y

Travel Speed (Cavin) > See Row | Sige Or Magi Feerodes ~~ -

ing OF Werve Bead gd ee Tota ‘rnin ont ang

ei Taz [ Reta OF pack a =

“Malt Pass Or Single Pan gar Side) rere

—— ak

Fai Coupon ier ear Carat “heres ]

No" | Wed tyes | Proves L eta rie [ame Yt [pera

i 1 | pee | aie es voce | ae Jes af

7 t

aang fare el dene |i verr [ow Ts |

Fe ree +

[ees ee 12m acer | 20 {

ee FAR EET | Timm ‘DGEP

iz { [ws z

Specimen | wists Area Type of Falare & Location

mma) mmz(ia2)

eae PROCEDURE

Ly QUALIFICATION

aad ‘i RECORD

ea aa | ACCORDING TO ASME CODE

SECTION IX

Revo: 7 [Rev Date: aeszom Sheet

Wps No.: | Welding Process (Es) + pcaw Clint: 5 |

[pes ae in

By

a Ren ‘Type and Figure No Result

Side Bend I(face 1) scceptpie Side Bend ice 2 ccrtapte

‘Side Bend 2(ro0t 1) scape Side Bend roe) seccopupte

Toughness Test (QW -1 70)

Specimen

Noreh | Notch | Test Temp,

No | tocatin | type foe)

WA NA NA NA

Fillet-Weld Tests(QW-180))

[ Hardiness Test = None

[Other Tests None

Welder’ Name & Stamp, asm Stamp no : 65

‘Test conducted by (Laboratory Test No.): FACULTY OF ENGINEERING -CalRO UN:

econ thatthe statement ts record are correct and tet the test welds were prepared wee and

‘tested in accordance with the requirements of Section IX ofthe ASME Code

| : : Approved

Sign Sa

Date

Tilton : 15777 2002

Procedure Qualification Record | PQ RNo.: aki -11

(P.Q.R) WPS No: ARE «1

According to ASME code sec.IX

Rev. Noo. Date: 2171172006 Sheet No.172

Welding Process: SMAW. Type: Manual By: Alily Sayed Alify

JOINTS (QW-402)

Joint Design: Single-V Groove

‘Test Coupon Dimension: (Length=350mm & Width=410mm ) A,

Backing: (No ) ——__—.

Back gouging: (No )

Meno L

i 4

ea a

Ro 5 mm

A 603d Ro

BASE METAL (QW-403) ITION (QW-405)

P-No: I Group No: | Position of grove: 2G.

Spec. SA-S16 GR.60 Welding Progression : N/A.

Or Position of fillet: N/A

Chem. Analysis & Mech, Prop.: None

Test Coupon Thickness:22.5 mm

‘Test Coupon Dia.: Plate

Other: None

FILLER METAL (QW-404), POSTWELD HEAT TREAT(QW-407)

Spece: No (SFA) 3 range: NIA

AWS No. (Class) E-6010 & E7018,

E-No, 3and4

ANo,

Size of Filler

Thick of deposit Weld Metal

Blectrode-Flux (Class)

ISTICS (QW-409)

Current: DC Polarity: Electrode (EP)

Ampere Range: See below

Volt Range: See below

Flux ‘Trade Name: ‘Tungsten Electrode Size and Type: None

Consumable Insert Other: None

Other:

‘GASES (QW-408) PREHEAT (QW-406)

Percent Composition Preheat Temp. Min, sec

gts (mixture) Flow Rate Interpass Temp. Mas. 235°C

Shielding: None

Trailing: None Backing: None

TECHNIQUE (QW-410)

String or weave bead: Sting & Weave Orifice or gas cup size: None

Inival and tnterpass cleaning :By grinding and brushing Method of Back Gouging ‘None

Contact tube to work distanee None Travel Speed Range: None

Mulipte or single pass(per side): Multiple Oscillation :None

Multiple or single electrode: Multiple Peening: None

Others: None ;

Filler Metal Type ‘Average Travel

Waittayers | Process (“Gass Die] poturiy | Am | Yom | Statin

i SMAW [Eat | 2.5mm | — DC-EN 3 = 5

” E7018 be-r ti & ho

e i a x

5 1% Fa 20

* 1% Fa 250

oe ts a zo

Tiiion 137775

HARESCO Procedure Qualifiication Record | Pano.” aati

WPS No: Areseo3

(P.Q.R) Chet

iuameraeruni According to ASME code sec.IX | Pic:

Rev Noo Rev Due 1/2 72007 Sheet Noe

Welding Process: SAW Type: Machine By: AMiy Sayed ANT

TENSILE TEST (QW-150)

Specimen No. | Wah um Thiekness mam UIs Kym Failure Position]

i 188 345 27 Parent meta

2 185 339 Re Parant metal

GUIDED-BEND TEST(QW-160)

Bead Type Rew Bend ype Reul

Side Bend Acceptable Side Bend Acceptable

Side Bend-3 Acceptable Side Benda ‘Acceptable

TOUGHNESS TEST (QW-170) : N/A

Spesinea No. [Nach Location Noch Type [TS TempC [Impact — | Tat Eipanton” [Dag nag

Value [stew — Pion Pata

WA WA NA Wa NA [NA [NAT Nin_[ NA

FILLET WELD TEST (QW-180) : None

Result Satisfactory: Yes) Not) Penetration into parent metd: Yes) No)

Macro Results

Other 1 : None

Type of Test Results

Welder’s Name: Sayed Bayomy Stamp No.: 01

‘Test conducted by: Faculty of Engineering-Cai

Laboratory test no. 1-2

Univ.

We certify that the statements in this record are correct and that the test welds were prepared

welded and tested in accordance with the requirements of Section IX of the ASME Code.

Sign. Welding Eng, aaa

Date: Pea

QUALIFIED WELDER'S LIST bare aaan6

ESCO FOR PROJECT: SCC - SUEZ PLANT =a 7

ciadeall@AR mece

(.cconner0 se ower | sear

== Soa __ Feet Jom) mee Pom] | ee ee] me | Pr

“T[ose| amen wonwan ATSEDA frcoownan| Paw, tenvoe |e] sone [wa] oom [a [er ma] Ww osteornee] tw

2 [#85 | MAMOUD SAVED ARMED ABDELAL reateoema ra ressae ] [ree] wa] eer [wa axa] wa | SS [errors

2 [217 | _ IBRAHIM ESMAT ABDEL FATTAH "Teen Tesewoisea] Plat Pine 920 6 | sone | wa oceP NA | wa] wa] win [wartosemecs| &

[= [728 HASSAN RABIA HASSAN Teowsa] Pow. aa mm [we | SR [om [= [wa] mm [entoocmcocl ey | ur Poe

Fropared By Welain RS axel

Sigur: “ef

PRF.02.01

2 HARESCO WELDER PERFORMANCE QUALIFICATION (WP

vasorenmeesneorna | gm ASMEM JAWS DLA O EN Cootma

L WELDER |

Welder Name MAHMOUD SAYED AHMED ABDELAL

Welder ID 156 E

Position 3G. -

Certificate Date 14/12/2015 .

Process: FCAW ‘Type: Semi-Auto. Progroscion: UP

TEST DESCRIPTION ]

WPS No. ARE-02 Rev. 0 MM Test coupon §—[] Production weld

TESTING CONDITIONS AND QUALIFICATION LIMITS.

Welding Variables ‘Actual Valve Range of Qvaiiation

Backing Wire Win & Wino asking

[Base Metal Specification ‘SA516 Gr 60

1 Group Number. to Noigh na

Mm P- Number. PNe1wPNDI pm Seante Ne A

mm Plate Plate , 25mm Pate , Pipesaa

Pipe diameter

Filer metal or eoctrode Speciation) Raw 7m

Filler metal or electrode classification(s) ent F Nos

Filer metal F-Number(s) Fes Tie

Filer ypetSold'metal or Fax cored ponder) Faces Fax coed

Deposit tickness for each process em Tie be Woe

Position qualified x6 EW Pato ade O)

F for pipe = 27

nor gas backing zy WA

Transtar mode Serr Seay & bar

[Direct or remote visual contrat WA WA

[Automate are votage contol (STAW) WA wa

[Automati joint wracking Wa Wa

[Consumabies inserts (GTAW) WA WA

[Single or muttple pass per side Tae Sa

RESULTS

[Mcval Examination —[ ACCEPTED [UT Ropon No. —[ —WPGT-0S [Macro teat for fusion WA

[Transverse root and face bend test NA [Longitudinal root and face bend test NA

Side bend test WA [Filet weldtracture test WA [Macro etching NAL

[Mechanical Test Repot_| WA [Other Tesis: [None WA

Date:

hte san ng a er vow a ve

_Jand tested in accordance with the Code requirements.

Centted By: al wCO7

Fav. OF

PRF-02-01

i ARESCO

WELDER PERFORMANCE QUALIFICATION (WPQ)

mm ASME jaws put O EN Corn

WELDER.

TESTING CONDITIONS AND QUALIFICATION LIMITS

Welder Name HASSAN RABIA HASSAN

Welder ID 728

Position : 3G

Centticate Date: Monday, December 14, 2015

Process: SMAW Type: MANUAL Progression uP

Test Place : ‘Aresco-Tebbin

TEST DESCRIPTION

WPS No, ARESCO.01 Rev: 4 HM Test coupon] Production wekd

wot ginthioden,, ie

We cSt edp\pan gordo correct and hat the et coupons were prepared, webde,

“Ssc(Zo hb edited I 6c8Grdatteg withthe requirements of ASME Code See IX.

Woling varies ‘etal Value Range of Qualification

fBackang Witet Wiha Witt

[Base Metal mlm Specification Tasiea @

Group Number, Piestibeagie

mm P- Number. Po 19PNot ea

mm Phite Pate, 16mm aie ara ape sae

Co ___ Pipe diameter

[Filter metal or electrode specifation(s) a 3]

Fiter meta or electrode clasaifieaton(a) Tawoac Toe Troaar Te

Fier metal F-Numbers) FRoa uF Ne Fre eae wanbectig

Fier ype(Sonarmeta or Fux coredipowder Wa WA

Depenit richness for each process ism by 7018 a lobe ela Not

FA orf

Position qualified a FW Pie) and ee aT

Florpipe =? 7

linen gas backing Wa NA

Franster mode wa wa

Direct or remote waual coir wa WA

[Automatic arc vokage control (@TAW) wa WA

[automat joint vacking wa WA

[Consumables insert (GTAW) Wa WA

Single or muliple pass per side Tat Sige & Ma

RESULTS

jeual Examination | ACCEPTED [UT Repo No. | WPOT-02 [Macro test for fusion WA

[Trancverse root and ace bendtest WA |Longitucnal root ana face bend test WA

ide bend test NWA [Filet weld-racture Test A |Maco etching WA

[Mechancal Test Report] WA —_]Other Tests: [None WA

Jes Bes

Certified by:

Rev. 01

PRF.02.01

AARESCO

WELDING OPERATOR PERFORMANCE QUALIFICATION (WOPQ)

mm ASMEIK =jawso11 o (CooTHer

with the Code requirements

WELDING OPERATOR

Welder Name IBRAHIM ESSMAT ABDEL FATTAH

Wilder 10 27

Position 16

Cerificate Date raraia01s

Process: SAW ‘Type: Machine Progression: «NIA

TEST DESCRIPTION

WPS No. Rev.: 0 Bil Testcoupon [2] Production weld

TESTING CONDITIONS AND QUALIFICATION LIMITS

Welding Vaiabios nawal Vale ange of Qulfcaton

Backing F oe

Base Metal Specification

1 Goup Number.

mm P-Number Noto PN!

mm Pi fae 2500

1 _ Pipe diameter

Filer meta or eecrode specricaton(s) maw

Filer meta or electrode classifcaton(s) eva Fo

Fiter metal F Number(s) Frog Fo

Fier ype(Sobarmetal or Fix coredipowden, Tawa Sear

[Deposit thickness for each process 7 Taobe waded

Position qualified s Fao ar pea)

linen gas backing WA

[rraneter mods a

Direct or remote visual contol NA ry

[Automatic are votage contol (STAN) ean One Dies

[Automatic joint racking wax ft

[Consumables inserts (GTAW) = WA

Etecrial Cheracterscs (GTAW) x

Single oF multiple pass per side a

TEST RESULTS

[isa Exammaton | ACCEPTED [OT Report No. [WPaT.03 _Wacro est forfusion

Fransverse rootandTace bend test [| __NA ___|Longitudinal roct and face bend test

[560 bend test WA [Fillet weld-racture test Macro etching

Recharical Test Ropon | WA [owner Tesis [None

We certify that th —aaESeek: ct as the tost coupons wore prepared, welded,

e desta

PRF-02.01

il ARESCO WELDING OPERATOR PERFORMANCE QUALIFICATION (worq)

poees Mm ASMEIK Cawso1t O § Comer

LL WELDING OPERATOR

Wekser Name ‘AHMED MOAWAD ALI SEDA

Welder 1D 032

Position 16

Certificate Date rartano%e

Process: SAW Type: Machine Progression: NIA

TEST DESCRIPTION

WPS No. ARESCO-CS-AO1 Rev. o Hi Test coupon] Production weld

LL —_I

TESTING CONDITIONS AND QUALIFICATION LIMITS

Weting Varios Tati ake Range of Qualfeton

[Backing Nain “With Backing

ase Metal ll Spociicalon Team

1 Sroup umber. P No.3 tough No. F

EP Numder wos Phot Phe Sard Neat

mE Pato oe Paw Pao

_ Pipe diameter

[Filler metal or electrode specification(s) : ASa7 AST

[Filler metal or electrode classification(s) . EMIzK FNS

Filer metal F-Numbors) Fes Free

Filler type(Solidimetal or Flux cored/powder) " ‘Solid Wire

[Deposit tickness foreach process Tito be Woda

a F tor let

Position quaiod 6 ESTE

liner gas backing T — WA

Traneer mode WA

Dies or remote visual conrl NA

[Automatic are voltage contr (GTA) Died

[Automat ont racking Wir Wo

Consumables inserts (GTA)

Electrical Characterstics (GTAW) NA

[Single or multple pass per sida zs igo a

TEST RESULTS

[Wave Erarinaton —[ ACOEBTED [UT ReportNo | whOT G3 acta ortison [NA

[Transverse root and face bendtest | __WA__—[Uongitdinalroct and face bend test | Nik

ks end test NA [Filelwolrracure est | NA [Macro etching NA

[Mechanical TestRepot [WA [Other Tests - JN Wa,

—|

the tost coupons were prepared, welded,

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- SyncScan 3Document5 pagesSyncScan 3Kadry Nabil HegazyNo ratings yet

- WPW Issue5 May 2022 WEB PDFDocument12 pagesWPW Issue5 May 2022 WEB PDFKadry Nabil HegazyNo ratings yet

- Egy Final Report No. 1 TersaDocument22 pagesEgy Final Report No. 1 TersaKadry Nabil HegazyNo ratings yet

- PHOTOS Mall of EgyptDocument2 pagesPHOTOS Mall of EgyptKadry Nabil HegazyNo ratings yet

- WPW Issue4 Apr 2022 WEBDocument12 pagesWPW Issue4 Apr 2022 WEBKadry Nabil HegazyNo ratings yet

- End Year Policy 2022Document7 pagesEnd Year Policy 2022Kadry Nabil HegazyNo ratings yet

- PAUT RequestDocument1 pagePAUT RequestKadry Nabil HegazyNo ratings yet

- Air Comp 4 Inspection Report Mall of EgyptDocument4 pagesAir Comp 4 Inspection Report Mall of EgyptKadry Nabil HegazyNo ratings yet

- Brochure Aug22Document3 pagesBrochure Aug22Kadry Nabil HegazyNo ratings yet

- 6 Sigma Green Belt OutlineDocument6 pages6 Sigma Green Belt OutlineKadry Nabil HegazyNo ratings yet

- 001 General Piping Arrangement Area - 4 (4 of 6) Rev. 2Document1 page001 General Piping Arrangement Area - 4 (4 of 6) Rev. 2Kadry Nabil HegazyNo ratings yet

- Penetrant Testing: DIN EN ISO 3452-1Document2 pagesPenetrant Testing: DIN EN ISO 3452-1Kadry Nabil HegazyNo ratings yet

- PHOTOS Air Comp 3 Mall of EgyptDocument2 pagesPHOTOS Air Comp 3 Mall of EgyptKadry Nabil HegazyNo ratings yet

- Air Comp 5 Thickness Report Mall of EgyptDocument1 pageAir Comp 5 Thickness Report Mall of EgyptKadry Nabil HegazyNo ratings yet

- S PT Penetrant Testing Scheme enDocument1 pageS PT Penetrant Testing Scheme enKadry Nabil HegazyNo ratings yet

- FULLTEXT01Document12 pagesFULLTEXT01Kadry Nabil HegazyNo ratings yet

- 001 General Piping Arrangement Area - 3 (3 of 6) Rev. 2Document1 page001 General Piping Arrangement Area - 3 (3 of 6) Rev. 2Kadry Nabil HegazyNo ratings yet

- 001 General Piping Arrangement Area - 2 (2 of 6) Rev. 2Document1 page001 General Piping Arrangement Area - 2 (2 of 6) Rev. 2Kadry Nabil HegazyNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)