Professional Documents

Culture Documents

S PT Penetrant Testing Scheme en

Uploaded by

Kadry Nabil Hegazy0 ratings0% found this document useful (0 votes)

10 views1 pageOriginal Title

s Pt Penetrant Testing Scheme En

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views1 pageS PT Penetrant Testing Scheme en

Uploaded by

Kadry Nabil HegazyCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

PENETRANT TESTING

EN ISO 3452

RED / WHITE IN DAYLIGHT FLUORESCENT WITH UV RADIATION

MR®- PRE-CLEANER

Mechanical or chemical preparation and pre-cleaning: Clean the surface to be tested (free of

rust, scale, oil, grease, etc.). Defects must be open to the surface.

Pre-cleaning

DRYING

MR®- PENETRANT RED MR®- PENETRANT FLUORESCENT

Water washable and / or solvent Water washable and / or solvent

removable penetrant removable penetrant

Penetration time: between 5 and 60 minutes Penetration time: between 5 and 60 minutes

Application: spraying, brushing, pouring, Application: spraying, brushing, pouring,

dipping dipping

Penetrant

INTERMEDIATE CLEANING

• Removal of excess penetrant with a clean, lint-free cloth

• Removal by rinsing, dipping, wiping with water and/or

with solvent (e.g. MR® 79, MR® 85, MR® 88)

Cleaning

CHECKING THE INTERMEDIATE CLEANING FOR RESIDUES OF THE PENETRANT

DAYLIGHT ≥ 350 LX UV RADIATION ≥ 100 µW/CM² AND < 100 LX

DRYING

MR®- DRY DEVELOPER or

MR®- WET DEVELOPER

MR®- WET DEVELOPER

solvent-based or water-based

solvent-based or water-based

Development DRYING

OBSERVE DEVELOPMENT PROCESS (duration 10 to 30 minutes)

DAILY LIGHT UV RADIATION

Daylight or artificial light Illuminance on the Irradiation on the test surface 1000 to 5000

test surface min. 500 lx µW/cm² darkened room max. 20 lx

Inspection LOGGING, IF NECESSARY POST-CLEANING AND PROTECTIVE MEASURES

MR Chemie GmbH | Nordstr. 61-63 | 59427 Unna (Germany) | www.mr-chemie.de

Tel.: +49 (0)2303 95151-0 | Fax: +49 (0)2303 95151-10 | e-mail: post@mr-chemie.de

You might also like

- Analisys and application of dry cleaning materials on unvarnished pain surfacesFrom EverandAnalisys and application of dry cleaning materials on unvarnished pain surfacesNo ratings yet

- Penetrant Testing: DIN EN ISO 3452-1Document2 pagesPenetrant Testing: DIN EN ISO 3452-1Kadry Nabil HegazyNo ratings yet

- Presentation On Non Descriptive TestingDocument36 pagesPresentation On Non Descriptive TestingBhargav BishuNo ratings yet

- 3M Sample Collection Brochure-MinDocument1 page3M Sample Collection Brochure-MinJoanesKrisdiantoNo ratings yet

- PT NDT MethodDocument34 pagesPT NDT MethodAshish ParmarNo ratings yet

- PT - Class-1Document29 pagesPT - Class-1Sameer MohammadNo ratings yet

- TRIFU Disinfection - EnGDocument10 pagesTRIFU Disinfection - EnGDenis RembrantNo ratings yet

- Chromaline UDC-HV Users Guide PDFDocument2 pagesChromaline UDC-HV Users Guide PDFGeras Lopez100% (1)

- Luxaprime 1000 Alkyd Anti-Corrosive PrimerDocument2 pagesLuxaprime 1000 Alkyd Anti-Corrosive PrimerGurdeep Sungh AroraNo ratings yet

- 3471 NovirucleanDocument2 pages3471 NovirucleanM Fajri SaputraNo ratings yet

- Convenient and Versatile Degreasing Wipes Impregnated With Lotoxane® FastDocument2 pagesConvenient and Versatile Degreasing Wipes Impregnated With Lotoxane® FastEurotech Tra TranNo ratings yet

- Luxaprime1300 Alkyd Zinc Chromate PrimerDocument2 pagesLuxaprime1300 Alkyd Zinc Chromate PrimerGurdeep Sungh AroraNo ratings yet

- Wound ManagementDocument25 pagesWound ManagementAlwin RaisNo ratings yet

- Kimtech Aviation MRO/OEM Wipes: 20 Wiping SolutionsDocument3 pagesKimtech Aviation MRO/OEM Wipes: 20 Wiping SolutionsBeverly RamosNo ratings yet

- Ranjit 22Document26 pagesRanjit 22Tvarit PatelNo ratings yet

- Disifin Med FlyerDocument2 pagesDisifin Med FlyerdisifinNo ratings yet

- Carbohydrate SearchDocument3 pagesCarbohydrate SearchwjbersabaNo ratings yet

- Luxaprime1400 Alkyd Zinc Phosphate PrimerDocument2 pagesLuxaprime1400 Alkyd Zinc Phosphate PrimerGurdeep Sungh AroraNo ratings yet

- Can You Spot The Difference? Liquid Penetrant Examination/Testing 2013 ASME V Article 6 Vs ISO 3452-1: 2013Document1 pageCan You Spot The Difference? Liquid Penetrant Examination/Testing 2013 ASME V Article 6 Vs ISO 3452-1: 2013Clayton CalvertNo ratings yet

- Non Destructive Testing - Dye Penetrant InspectionDocument6 pagesNon Destructive Testing - Dye Penetrant InspectionKevin ThomasNo ratings yet

- Product Overviewcoeic90001016 PDFDocument4 pagesProduct Overviewcoeic90001016 PDFAFRIANSYAHNo ratings yet

- Braun Product Overviewcoeic90001016Document4 pagesBraun Product Overviewcoeic90001016muhjaerNo ratings yet

- Oil Spill Dispersant Osd 9000 SupergreenDocument4 pagesOil Spill Dispersant Osd 9000 SupergreenWandaNo ratings yet

- Liquid or Dye Penetrant InspectionDocument43 pagesLiquid or Dye Penetrant InspectionTrinadh Venkata Kumar NillaNo ratings yet

- Karcher 0.011-330.0 - PI - en - INTDocument2 pagesKarcher 0.011-330.0 - PI - en - INTurosgalovicNo ratings yet

- Aviation Catalog 2016 PDFDocument17 pagesAviation Catalog 2016 PDFMurat aktaşNo ratings yet

- Renoclean Bio Rig WashDocument2 pagesRenoclean Bio Rig WashMuh yusup100% (1)

- Doctor Brochure Stylage Bi Soft 2018Document36 pagesDoctor Brochure Stylage Bi Soft 2018薛凯No ratings yet

- Fiche Diphoterine enDocument2 pagesFiche Diphoterine enpeksNo ratings yet

- TermoRens ASIA Presentation (ENGLISH)Document48 pagesTermoRens ASIA Presentation (ENGLISH)asaiNo ratings yet

- Water-Washable Visible Penetrant: Product Data SheetDocument3 pagesWater-Washable Visible Penetrant: Product Data SheetShashi VindranNo ratings yet

- PT Day 1.0Document39 pagesPT Day 1.0farshid KarpasandNo ratings yet

- j6) Autocareenamel 3087Document2 pagesj6) Autocareenamel 3087vinodNo ratings yet

- 4012 WI58 DP Test Procedure - Rev.0Document4 pages4012 WI58 DP Test Procedure - Rev.0sachinpsawantNo ratings yet

- Product Data Sheet: Transuniprene Finish 2.53Document2 pagesProduct Data Sheet: Transuniprene Finish 2.53Sachin NambiarNo ratings yet

- Surfasafe Disinfectant Detergent For Surfaces and Equipment Fqy PDFDocument2 pagesSurfasafe Disinfectant Detergent For Surfaces and Equipment Fqy PDFAlaa FasialNo ratings yet

- Ext-Cm-1081 FT - Surfa Safe SHDocument2 pagesExt-Cm-1081 FT - Surfa Safe SHJessika VargasNo ratings yet

- Hydris Hydris™: Disinfectant CleanerDocument1 pageHydris Hydris™: Disinfectant Cleanernikors65No ratings yet

- Infektocide BR 502Document1 pageInfektocide BR 502satya ranjanNo ratings yet

- Materials: Non-Porous Magnetic-Particle Inspection Porosity Fatigue CracksDocument3 pagesMaterials: Non-Porous Magnetic-Particle Inspection Porosity Fatigue CracksArfanAliNo ratings yet

- ProCepT 4M8-TriX PDFDocument4 pagesProCepT 4M8-TriX PDFfishvalNo ratings yet

- DrySanDuoSellSheet PDFDocument2 pagesDrySanDuoSellSheet PDFSarah Jane BroñolaNo ratings yet

- Nippon Road Line Paint TDSDocument2 pagesNippon Road Line Paint TDSfaridanurro100% (1)

- ZP 14a Pds July17Document3 pagesZP 14a Pds July17aravindanNo ratings yet

- Intensiv Catalogue 2017-1Document92 pagesIntensiv Catalogue 2017-1GabriellaMariaNo ratings yet

- LPTDocument58 pagesLPTShrikant MojeNo ratings yet

- Intensiv Swiss Dental ProductsDocument92 pagesIntensiv Swiss Dental ProductsMohamed yusufNo ratings yet

- 9AMP TechBulletin 2016Document2 pages9AMP TechBulletin 2016keila bernalliNo ratings yet

- Corona Essentioal Supplies GKMINDADocument6 pagesCorona Essentioal Supplies GKMINDANityanand ChaudharyNo ratings yet

- Enzymes For PowderDocument6 pagesEnzymes For PowderoszagyanNo ratings yet

- Product Data Sheet: Transpoxy Finish 4.60Document2 pagesProduct Data Sheet: Transpoxy Finish 4.60Sachin NambiarNo ratings yet

- Detrox, DisinfectantDocument67 pagesDetrox, Disinfectantsumiya mashadiNo ratings yet

- Dye Penetrant ProcedureDocument2 pagesDye Penetrant ProcedureunikmyquestarNo ratings yet

- Peroxide Multi Surface Cleaner & Disinfectant TDSDocument2 pagesPeroxide Multi Surface Cleaner & Disinfectant TDSJinto JoseNo ratings yet

- Whisper V: Product DescriptionDocument2 pagesWhisper V: Product Descriptiondian sintawatiNo ratings yet

- Stoving Thinner Data SheetDocument3 pagesStoving Thinner Data SheetNaveen ChaudharyNo ratings yet

- Nanoprotech Full CatalogueDocument50 pagesNanoprotech Full CatalogueManish KumarNo ratings yet

- Mara Cure HY: Field of ApplicationDocument3 pagesMara Cure HY: Field of ApplicationAnonymous 9q5GEfm8INo ratings yet

- Nova CrossDocument2 pagesNova CrossFloorkitNo ratings yet

- DPI (Dye Penetrant Inspection) : Main PurposedDocument9 pagesDPI (Dye Penetrant Inspection) : Main PurposedAgung Prastyo WibowoNo ratings yet

- Egy Final Report No. 1 TersaDocument22 pagesEgy Final Report No. 1 TersaKadry Nabil HegazyNo ratings yet

- SyncScan 3Document5 pagesSyncScan 3Kadry Nabil HegazyNo ratings yet

- Ares WpsDocument16 pagesAres WpsKadry Nabil HegazyNo ratings yet

- WPW Issue4 Apr 2022 WEBDocument12 pagesWPW Issue4 Apr 2022 WEBKadry Nabil HegazyNo ratings yet

- Ultrasonic Flaw DetectorDocument4 pagesUltrasonic Flaw DetectorEhab Attia SelimNo ratings yet

- PHOTOS Mall of EgyptDocument2 pagesPHOTOS Mall of EgyptKadry Nabil HegazyNo ratings yet

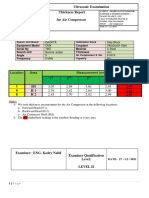

- Air Comp 4 Inspection Report Mall of EgyptDocument4 pagesAir Comp 4 Inspection Report Mall of EgyptKadry Nabil HegazyNo ratings yet

- Auditing Welds Under ASME IX PDFDocument21 pagesAuditing Welds Under ASME IX PDFkbldamNo ratings yet

- mr-85 en PiDocument1 pagemr-85 en PiKadry Nabil HegazyNo ratings yet

- WPW Issue5 May 2022 WEB PDFDocument12 pagesWPW Issue5 May 2022 WEB PDFKadry Nabil HegazyNo ratings yet

- End Year Policy 2022Document7 pagesEnd Year Policy 2022Kadry Nabil HegazyNo ratings yet

- Brochure Aug22Document3 pagesBrochure Aug22Kadry Nabil HegazyNo ratings yet

- PAUT RequestDocument1 pagePAUT RequestKadry Nabil HegazyNo ratings yet

- PHOTOS Air Comp 3 Mall of EgyptDocument2 pagesPHOTOS Air Comp 3 Mall of EgyptKadry Nabil HegazyNo ratings yet

- 6 Sigma Green Belt OutlineDocument6 pages6 Sigma Green Belt OutlineKadry Nabil HegazyNo ratings yet

- Air Comp 5 Thickness Report Mall of EgyptDocument1 pageAir Comp 5 Thickness Report Mall of EgyptKadry Nabil HegazyNo ratings yet

- FULLTEXT01Document12 pagesFULLTEXT01Kadry Nabil HegazyNo ratings yet

- Penetrant Testing: Product InformationDocument1 pagePenetrant Testing: Product InformationKadry Nabil HegazyNo ratings yet

- 001 General Piping Arrangement Area - 3 (3 of 6) Rev. 2Document1 page001 General Piping Arrangement Area - 3 (3 of 6) Rev. 2Kadry Nabil HegazyNo ratings yet

- 001 General Piping Arrangement Area - 4 (4 of 6) Rev. 2Document1 page001 General Piping Arrangement Area - 4 (4 of 6) Rev. 2Kadry Nabil HegazyNo ratings yet

- 001 General Piping Arrangement Area - 2 (2 of 6) Rev. 2Document1 page001 General Piping Arrangement Area - 2 (2 of 6) Rev. 2Kadry Nabil HegazyNo ratings yet

- Coefficient of FrictionDocument4 pagesCoefficient of Frictionjsmargate100% (1)

- Jotafloor Damp BondDocument4 pagesJotafloor Damp BondMohamed FarhanNo ratings yet

- Advanced Construction TechnologyDocument55 pagesAdvanced Construction Technologyanandhisana100% (1)

- CHEM 1031 Final Exam Study GuideDocument43 pagesCHEM 1031 Final Exam Study GuidePranava MalluNo ratings yet

- Hess's Law Lab CalculatorDocument1 pageHess's Law Lab Calculatortyrantking8No ratings yet

- Basf Masteremaco S 488 TdsDocument3 pagesBasf Masteremaco S 488 TdsArindamBhattacharjee100% (2)

- 04 ExtrusionDocument57 pages04 Extrusion9811923100% (1)

- Old Quiz Electron ConfigurationDocument6 pagesOld Quiz Electron ConfigurationtinaNo ratings yet

- Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-Strength Low-Alloy With Improved Formability, and Ultra-High StrengthDocument9 pagesSteel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-Strength Low-Alloy With Improved Formability, and Ultra-High StrengthlinamariamonroyginetNo ratings yet

- Acrylic Sheets Roofing: Group Members: Priyal Mittal Anuj Nandanwar Shubham Parekh Sanket PanditDocument18 pagesAcrylic Sheets Roofing: Group Members: Priyal Mittal Anuj Nandanwar Shubham Parekh Sanket PanditPriya ManeNo ratings yet

- 02 - Mass Balances With Notes PDFDocument17 pages02 - Mass Balances With Notes PDFPrasad VhatkarNo ratings yet

- Identification of AlcoholsDocument26 pagesIdentification of Alcoholspupu_wowNo ratings yet

- 3 Methods of Food PreservationDocument5 pages3 Methods of Food Preservationpainx7No ratings yet

- As Week 3 Q2Document5 pagesAs Week 3 Q2Elaine MagpatagNo ratings yet

- Air Quality in Europe - 2015 ReportDocument64 pagesAir Quality in Europe - 2015 ReportLuis Antonio Ibáñez GuerreroNo ratings yet

- Sri Chaitanya Techno School - India: Techno & C-Batch Performance Test Syllabus For New Students (State & CBSE)Document1 pageSri Chaitanya Techno School - India: Techno & C-Batch Performance Test Syllabus For New Students (State & CBSE)Prasad ChowdaryNo ratings yet

- Ethanol Aspen Data BaseDocument36 pagesEthanol Aspen Data BaseGustavo CestariNo ratings yet

- Vdocuments - MX A Report On Organizational Study at Carborundum Universal LTD Cumi NalukettuDocument78 pagesVdocuments - MX A Report On Organizational Study at Carborundum Universal LTD Cumi NaluketturishiganeshNo ratings yet

- Protein Crystallization ThesisDocument5 pagesProtein Crystallization ThesisHelpOnWritingAPaperSingapore100% (2)

- Effect of Carbon To Nitrogen Ratio On Biogas ProductionDocument10 pagesEffect of Carbon To Nitrogen Ratio On Biogas ProductionLTE002100% (1)

- RAC 3,7 Feb 17Document30 pagesRAC 3,7 Feb 17MSaqibKhanNo ratings yet

- Answered ProblemsDocument38 pagesAnswered ProblemsNida Bagoyboy NatichoNo ratings yet

- EngDocument666 pagesEngOvidijus VyšniauskasNo ratings yet

- Group V Cations-ClassB AnionsDocument4 pagesGroup V Cations-ClassB AnionsApril Mergelle LapuzNo ratings yet

- 11 Otbb MSDSDocument7 pages11 Otbb MSDSAnubhav SewdaNo ratings yet

- SkimmingDocument16 pagesSkimmingluis mosqueraNo ratings yet

- Basics of SemiconductorsDocument4 pagesBasics of Semiconductorsde8737No ratings yet

- John Deere Mangueiras PDFDocument43 pagesJohn Deere Mangueiras PDFAmanda Rezende100% (1)

- Powder Coating As A Corrosion Protection MethodDocument12 pagesPowder Coating As A Corrosion Protection Methodchemikas8389No ratings yet

- Mini Project 1Document16 pagesMini Project 1SadikAhmedNo ratings yet