Professional Documents

Culture Documents

Adhesive-Bonded Anchors and Dowels

Uploaded by

Rubianne Dela TorreCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adhesive-Bonded Anchors and Dowels

Uploaded by

Rubianne Dela TorreCopyright:

Available Formats

SECTION 416

INSTALLING ADHESIVE-BONDED ANCHORS AND DOWELS

FOR STRUCTURAL APPLICATIONS

416-1 Description.

Prepare and install adhesive bonded anchors and dowels in hardened concrete as

indicated in the Contract plans, as directed by the Engineer, and in accordance with the

manufacturer’s instructions and this Section.

Anchors and dowels in this Section are intended for use in structural applications

where designated on the Contract plans.

416-2 Materials.

Use adhesive bonding material systems which meet the requirements of

Section 937, and are included on the Qualified Products List. For applications involving

installation of traffic railing barrier reinforcement and anchor bolts to existing bridge

decks and approach slabs, use only Type HSHV adhesives.

416-2.1 Storage of Materials: Store materials delivered to the job-site in the

original unopened containers within an appropriate facility capable of maintaining

storage conditions consistent with the manufacturer’s recommendations.

416-3 Equipment.

Ensure that the equipment used to install adhesive-bonded anchors and dowels is

in conformance with the recommendations of the manufacturer.

416-4 Preparing of Concrete Members.

Ensure that concrete members receiving adhesive-bonded anchors or dowels are

structurally sound and free of cracks in the vicinity of the anchor or dowel to be installed.

Unless other equipment is recommended by the adhesive manufacturer, drill holes to the

diameter required by the manufacturer, but as a minimum, not less than 105% of the

diameter including deformations, nor more than 150% of the nominal diameter of the

steel bar anchor or dowel, using a rotary hammer drill and bit.

Use a metal detector specifically designed for locating steel in concrete to avoid

conflicts with existing steel reinforcement whenever placement tolerances and edge

clearances permit. Perform core drilling to clear existing steel reinforcement only when

approved by the Engineer. Dry the drilled holes completely prior to cleaning and

installing the anchors or dowels.

Clean and prepare drilled holes in accordance with the manufacturer’s

recommendations, but as a minimum, use oil-free compressed air to remove loose

particles from drilling, brush inside surface to free loose particles trapped in pores, then

use compressed air again to remove the remaining loose particles. Use a non-metallic

bristle brush and avoid over-brushing to prevent polishing the inside surface of the drilled

hole.

416-5 Installing of Anchors or Dowels.

Remove all debris, oils, and any other deleterious material from the anchors and

dowels to avoid contamination of the adhesive bonding material. Install anchors or

dowels in accordance with the details shown on the plans and the manufacturer’s

instructions, with particular attention to requirements and/or limitations due to anchor

position, dampness, ambient temperature, and curing.

Use adequate quantities of the adhesive bonding material to fill the drilled hole to

within 1/4 inch of the concrete surface measured after placement of the steel bar or

anchor. For horizontal and inclined installations, provide temporary supports to maintain

the anchors or dowels in the center of the drilled holes until the adhesive bonding

material has cured.

416-6 Testing of Anchors or Dowels.

Field test installed anchors and dowels for traffic railing barrier applications using

Type HSHV adhesives. The Engineer may also require testing of installed anchors and

dowels for other applications.

416-6.1 Field Testing: Provide an Independent Testing Agency to perform field

testing of the installed anchors and dowels under the direction of a Professional Engineer

registered in the State of Florida. Submit test reports for each LOT signed and sealed by

the Professional Engineer. Perform restrained static tension tests to prevent damage to the

surrounding concrete. A restrained test is defined as a test conducted in accordance with

ASTM E-488 except that the test equipment support clearance requirements of

ASTM E-488 do not apply. The reaction base shall be approximately equal to the drilled

hole diameter for the anchor to preclude concrete or masonry failure, but allow bond

failure. Displacement measurement for field testing is not required. Test individual

anchors and dowels by proof loading in tension to 85% of the Specified Bond Strength in

Section 937, based on the nominal anchor or dowel diameter and embedment depth, but

not more than 90% of the yield strength of the anchor or dowel, unless otherwise shown

in the Contract Documents.

Divide the anchors and dowels into LOTs for testing and acceptance. Each

LOT must contain a maximum of 100 anchors or dowels, of the same diameter,

embedment length and Adhesive Bonding Material System. Randomly select four of the

anchors and dowels in each LOT for testing, except if there are three or less in the LOT,

in which case, test all anchors, unless otherwise directed by the Engineer. If three

consecutive LOTs have no failing tests, sample the next three LOTs at a 2% rate and if

these LOTs have no failing tests, sample at a rate of 1% for the remaining LOTs unless

there is a failure; however, regardless of LOT size, sample at least one dowel per LOT.

For every failed field test, perform two additional field tests on adjacent untested anchors

or dowels within the LOT. Continue additional field tests until no more test failures

occur, or all anchors and dowels within the LOT are tested. For the next LOT after a

failed LOT, the sampling rate must be 4% but not less than one dowel per LOT and

conform to the sampling rate procedure above including rate reductions as appropriate.

416-6.2 Removal & Replacement of Failed Test Specimens: Remove all

anchors and dowels that fail the field test, without damage to the surrounding concrete.

Redrill holes to remove adhesive bonding material residue and clean in accordance with

416-4. Reinstall new anchors and dowels in accordance with 416-5. Do not reuse the

failed anchors and dowels unless approved by the Engineer. Assign reinstalled anchors

into new LOTs only containing reinstalled anchors or dowels of the same diameter,

embedment length and adhesive bonding material system, and field test in accordance

with 416-6.1.

416-7 Acceptance.

The Engineer will base acceptance of adhesive-bonded anchors and dowels on

determining that the material requirements of Section 937, the installation and testing

requirements of this Section, and the placement requirements of the plans have been met.

416-8 Basis of Payment.

The work specified in this Section will not be paid for directly, but will be

considered as incidental work.

You might also like

- Storage Tank Inspection API 650Document27 pagesStorage Tank Inspection API 650Pandu Damay Putra92% (12)

- Specification For FRP TankDocument10 pagesSpecification For FRP TankKyaw Kyaw Aung75% (4)

- Astm D2466Document6 pagesAstm D2466Hernando Andrés Ramírez Gil0% (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Specification For Prefabricated Vertical DrainsDocument7 pagesSpecification For Prefabricated Vertical DrainsRecep Caner Akyılmaz100% (2)

- Wps PQR GuideDocument40 pagesWps PQR GuideBalakumar100% (10)

- RTR Piping SystemDocument8 pagesRTR Piping Systemsajeed7674075% (4)

- Waha Oil Company: Specification For Factory Applied Internal Coating of Pipe Spools, and FittingsDocument12 pagesWaha Oil Company: Specification For Factory Applied Internal Coating of Pipe Spools, and FittingsRobert LiraNo ratings yet

- Prestressing Works SpecsDocument30 pagesPrestressing Works SpecsVladimir Simeunovic100% (1)

- 03 3800 Post-Tensioned ConcreteDocument8 pages03 3800 Post-Tensioned ConcreteCarlos SYNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Tugas CH 7 - Amelia Zulaikha PDocument3 pagesTugas CH 7 - Amelia Zulaikha Pamelia zulaikha100% (1)

- Field Welding of RailDocument4 pagesField Welding of Raildurandm10No ratings yet

- Continuously Reinforced Concrete PavementDocument7 pagesContinuously Reinforced Concrete PavementtanujpadhyNo ratings yet

- Specification For FRP DuctDocument6 pagesSpecification For FRP DuctAli HassanNo ratings yet

- Exhibit B-28 PipingDocument7 pagesExhibit B-28 Pipingsethu1091No ratings yet

- Tube Fitting Technical SpecificationDocument4 pagesTube Fitting Technical Specificationksivakumar09100% (2)

- Rock BoltDocument5 pagesRock BoltMuhammad Noufal AchyarNo ratings yet

- Attachment2 TempTieback AnchorsDocument4 pagesAttachment2 TempTieback Anchorsalex_g00dyNo ratings yet

- Critical Installation ElementsDocument10 pagesCritical Installation ElementsmishikhanNo ratings yet

- Installation, Testing & Flushing of Firefighting Piping SystemDocument5 pagesInstallation, Testing & Flushing of Firefighting Piping SystemJoy MalakNo ratings yet

- Illinois Tollway Authority Materials SpecDocument5 pagesIllinois Tollway Authority Materials SpecBella ZakariaNo ratings yet

- Method of StatementDocument23 pagesMethod of StatementChad SoribelloNo ratings yet

- Duct For Corrosive Fumes ExhaustDocument8 pagesDuct For Corrosive Fumes ExhaustTS WongNo ratings yet

- Swagelok Fittings SpecificationsDocument3 pagesSwagelok Fittings SpecificationsSam Chong Ks100% (1)

- Anticorrosion Reinforcement SpecsDocument5 pagesAnticorrosion Reinforcement SpecsNishan Lulu Muhamed JaleelNo ratings yet

- Ves 5145 R3Document10 pagesVes 5145 R3danikakaNo ratings yet

- Educational Bulletin No 2Document2 pagesEducational Bulletin No 2nagc12No ratings yet

- 2 Specification For GRP PipingDocument4 pages2 Specification For GRP Pipinggc_panchaNo ratings yet

- Specifications For Supplying and Driving Steel Pipe Piles: 1.0 DescriptionDocument8 pagesSpecifications For Supplying and Driving Steel Pipe Piles: 1.0 DescriptionMuhammad Idham SyafarNo ratings yet

- Boiler License Exam GuideDocument45 pagesBoiler License Exam Guidemen100% (1)

- Shop Welding InspectionDocument4 pagesShop Welding InspectionIndra Nath MishraNo ratings yet

- Section 461 Multirotational Bearings 461-1 DescriptionDocument3 pagesSection 461 Multirotational Bearings 461-1 Descriptionl_aguilar_mNo ratings yet

- Specification For Duct and Grouting Systems For Post-Tensioned TendonsDocument4 pagesSpecification For Duct and Grouting Systems For Post-Tensioned TendonsAli KNo ratings yet

- Specification For Subsea Flange FittingDocument16 pagesSpecification For Subsea Flange FittingMuzammil Makandar100% (1)

- AASHTO Pot BearingsDocument4 pagesAASHTO Pot BearingsJithesh.k.sNo ratings yet

- Micro Pile SpecificationsDocument3 pagesMicro Pile SpecificationsAnonymous 5VwQ0KC3No ratings yet

- Annexure 2A - Prestressing - VOLUME 5-69-84Document16 pagesAnnexure 2A - Prestressing - VOLUME 5-69-84ManukantShrotriyaNo ratings yet

- How To INSTALL Anchors in Accordance With BS 8539Document4 pagesHow To INSTALL Anchors in Accordance With BS 8539hanyaNo ratings yet

- Installation Guide For Precast Concrete Access ChambersDocument11 pagesInstallation Guide For Precast Concrete Access Chamberseomar0572No ratings yet

- Specifications For Wick DrainsDocument7 pagesSpecifications For Wick DrainsAnirudh SharmaNo ratings yet

- Rockwool FS GuideDocument1 pageRockwool FS GuidedasdaNo ratings yet

- Educational Bulletin No 1Document2 pagesEducational Bulletin No 1sandeep5No ratings yet

- Ductwork SystemsDocument28 pagesDuctwork SystemsSurekanth ManikkavasagamNo ratings yet

- DuctDocument10 pagesDuctromasokyNo ratings yet

- Mini-Pile SpecificationsDocument3 pagesMini-Pile SpecificationsthescubataterNo ratings yet

- Wsdot 6-03.3Document3 pagesWsdot 6-03.3Dave MulvihillNo ratings yet

- Sec612 - Post-Tensioning of Concrete UnitsDocument11 pagesSec612 - Post-Tensioning of Concrete UnitsAmr Adel HameedNo ratings yet

- Section - 15140 Supports&AnchorsDocument11 pagesSection - 15140 Supports&AnchorsNana DelgadoNo ratings yet

- Clarifications and Exceptions of Api 675, Third EditionDocument3 pagesClarifications and Exceptions of Api 675, Third EditionFathan KarimanNo ratings yet

- SpecificationDocument26 pagesSpecificationdanhielitNo ratings yet

- 44AC9100-000-V.02-0106-A4 - Rev B - GENERAL SPECIFICATION FOR EXPANDED TUBE TO TUBE SHEET JOINTDocument6 pages44AC9100-000-V.02-0106-A4 - Rev B - GENERAL SPECIFICATION FOR EXPANDED TUBE TO TUBE SHEET JOINTAvinash ShuklaNo ratings yet

- Joints For Concrete Pipe, Manholes, and Precast Box Sections Using Preformed Flexible Joint SealantsDocument4 pagesJoints For Concrete Pipe, Manholes, and Precast Box Sections Using Preformed Flexible Joint SealantsRenish Regi100% (1)

- HVAC Dampers Installation Method StatementDocument3 pagesHVAC Dampers Installation Method StatementDong VanraNo ratings yet

- Specification Soil NailingDocument7 pagesSpecification Soil NailingAmir JiggyNo ratings yet

- OPSS 942 Nov09Document26 pagesOPSS 942 Nov09Ashok Kumar MuthuswamyNo ratings yet

- 3 ConcreteWorksDocument19 pages3 ConcreteWorksMuhammad AgungNo ratings yet

- Method Statement For InstallationDocument5 pagesMethod Statement For Installationsamsul maarifNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Heterogeneity in Macroeconomics: Macroeconomic Theory II (ECO-504) - Spring 2018Document5 pagesHeterogeneity in Macroeconomics: Macroeconomic Theory II (ECO-504) - Spring 2018Gabriel RoblesNo ratings yet

- D&D 5.0 - Aventura (Nível 7) O Refúgio Perdido Do ArquimagoDocument30 pagesD&D 5.0 - Aventura (Nível 7) O Refúgio Perdido Do ArquimagoMurilo TeixeiraNo ratings yet

- 4.7 Composite FunctionsDocument4 pages4.7 Composite Functionskaziba stephenNo ratings yet

- Tell Me When To Do Something Electional AstrologyDocument3 pagesTell Me When To Do Something Electional AstrologyAycan ÖzenbaşNo ratings yet

- Optimal Portfolio Strategy To Control Maximum DrawdownDocument35 pagesOptimal Portfolio Strategy To Control Maximum DrawdownLoulou DePanamNo ratings yet

- Paper 1 (Answer All Questions) : Saraswati Vidya NiketanDocument3 pagesPaper 1 (Answer All Questions) : Saraswati Vidya Niketanyuvita prasadNo ratings yet

- IKEA - Global Sourcing Challenge - Case Analysis - SuryarajanS - EPGPKC06077Document2 pagesIKEA - Global Sourcing Challenge - Case Analysis - SuryarajanS - EPGPKC06077surya rajanNo ratings yet

- Questions - Product Portfolio AnalysisDocument3 pagesQuestions - Product Portfolio Analysismarija88No ratings yet

- Solutions To Text Problems: Chapter 6: Quick QuizzesDocument60 pagesSolutions To Text Problems: Chapter 6: Quick QuizzesThư PhạmNo ratings yet

- SIrena As of Feb 11Document50 pagesSIrena As of Feb 11Paula AlmeydaNo ratings yet

- Airline Codes 1Document8 pagesAirline Codes 1B. Young100% (1)

- The Wedge PatternDocument56 pagesThe Wedge PatternMohaNo ratings yet

- Unox xvc704Document3 pagesUnox xvc704Automatist DanGONo ratings yet

- Site Diary Work TemplateDocument15 pagesSite Diary Work Templateblaqhaqar0% (1)

- MIL-B-81934 2C Bearings, Self LubricatingDocument5 pagesMIL-B-81934 2C Bearings, Self LubricatingthomasNo ratings yet

- Does Financial Behavior Mediate The Relationship BDocument7 pagesDoes Financial Behavior Mediate The Relationship BIrma HarrietNo ratings yet

- Writing Task 1 Line GraphDocument3 pagesWriting Task 1 Line GraphThanh ThảoNo ratings yet

- Winter ExamDocument4 pagesWinter ExamJuhee SeoNo ratings yet

- Cost Acc. Final-CollierDocument15 pagesCost Acc. Final-CollierKathya SilvaNo ratings yet

- 2023 04 29 Annual ReportDocument1 page2023 04 29 Annual ReportbiancamantohNo ratings yet

- Ahsanullah University of Science and Technology: AssignmentDocument7 pagesAhsanullah University of Science and Technology: AssignmentSudip TalukdarNo ratings yet

- Brokerage Statement - XXXX6691 - 202112Document6 pagesBrokerage Statement - XXXX6691 - 202112mikeNo ratings yet

- Communication SkillsDocument14 pagesCommunication SkillsZakia AkramNo ratings yet

- Transunion Cibil ReportDocument39 pagesTransunion Cibil ReportSHREYAS KHANOLKARNo ratings yet

- Pakistan Stock Exchange Limited: List of Trading Right Entitlement (Tre) Certificate HoldersDocument36 pagesPakistan Stock Exchange Limited: List of Trading Right Entitlement (Tre) Certificate HoldersWaqas AkramNo ratings yet

- 945B PGL ALY & DUNG DoxcDocument24 pages945B PGL ALY & DUNG DoxcBri AnNo ratings yet

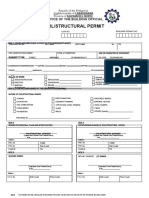

- Civil/Structural Permit: Office of The Building OfficialDocument1 pageCivil/Structural Permit: Office of The Building OfficialEngineer LeeNo ratings yet

- Grade 12 English The Lost SpringDocument5 pagesGrade 12 English The Lost SpringReshma AnsariNo ratings yet

- l88 Bus Time TableDocument18 pagesl88 Bus Time Tablesharat7No ratings yet