Professional Documents

Culture Documents

Precautions during ballasting/de-ballasting operations

Uploaded by

Anonymous 1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Precautions during ballasting/de-ballasting operations

Uploaded by

Anonymous 1Copyright:

Available Formats

Precautions during ballasting/ de-ballasting operations

a. Communication between deck officer and duty engineer should be left open and free

throughout.

b. Ensure manholes for ballast tanks are shut.

c. Check soundings of tank(s) being ballasted/ deballasted frequently to confirm that ballast

water is being filled/ removed to / from the right tank.

d. Check that air pipes float /flap are open and air is freely flowing in or out as the case may be.

e. When topping - off a tank, reduce the filling rate in order to prevent pressurizing the tank and

reduce air pockets.

f. Where circumstances allow, check the cargo hold where the air escape pipes are passing

through - in case of any leakage in those pipes or from any previous unnoticed damages on

hoppers or tank top to prevent cargo damage.

g. Stop the pump or open the valve of the next water ballast tank, when tank is reached desired

level. Do not overflow tanks through the air pipes. The air-pipes of the ballast tanks are not

of sufficient size to allow continuous pumping of water into the tank without dangerously

over-pressurising the tank.

h. Confirm that the valve of the completed tank is closed.

i. When de-ballasting with the main pumps, care must be taken not to let the pump run dry/lose

suction. Duty engineer to stand-by the pump and throttle discharge valve to get maximum

ballast out by the main pump.

j. When the main pump loses suction, change over to stripping with the eductor / bilge- ballast

pump.

k. Strip one tank at a time, and confirm that the valve is firmly/ tightly closed after stripping.

l. The ballasting / de-ballasting sequence to be strictly followed in concurrence with cargo

operations or during exchange of ballast at sea. In case ballasting/ de-ballasting falling

behind schedule, duty officer must immediately inform C/O, who must check out the stress

and take positive action to correct any alarming rise in the stress factor. It may necessitate

stopping cargo work until ballasting / de-ballasting is back on schedule (C/O will consult

master in case necessary to stop cargo-work)

All ballast / de-ballasting operation carried out must be recorded in the ballast log, ballast

water record book and in the case of ballast water exchange, also in the ballast water

reporting form.

There are port state regulations or controls that require the vessels calling at the ports of their

states to carry out a mid-ocean ballast water exchange.

In line with this, the IMO has adopted Resolution A.868(20) on 27 November 1997, viz.,

“Guidelines for the control and management of ship’s ballast water to minimize the transfer of

harmful aquatic organisms and pathogens” and further the International Convention for the

Control and Management of Ship’s Ballast and Sediments.

There can be penalties for ballast overflow in ports which shall be checked.

You might also like

- Joint Agreement On Readiness To DischargeDocument2 pagesJoint Agreement On Readiness To DischargeOlink Achmad KafaillahNo ratings yet

- 10 Important Points To Remember After Completing Cargo Operations On TankersDocument4 pages10 Important Points To Remember After Completing Cargo Operations On Tankersindumarnicaragua100% (3)

- Project D2 - Bilge, Ballast Systems, Brem PavloDocument7 pagesProject D2 - Bilge, Ballast Systems, Brem PavloПавел БремNo ratings yet

- Procedures For Ballasting, Deballasting and Loading OperationsDocument35 pagesProcedures For Ballasting, Deballasting and Loading Operationshutsonianp100% (9)

- Ballast Operation at Sea, Ballast Exchange Requirement & More GuidelineDocument5 pagesBallast Operation at Sea, Ballast Exchange Requirement & More GuidelineVasil RaykovNo ratings yet

- Compiled byDocument8 pagesCompiled byJaner James Jamera JalecoNo ratings yet

- Sa014 Cargo Damage Due To Water Ingress From Ballast Tanks and Bilge Lines PDFDocument2 pagesSa014 Cargo Damage Due To Water Ingress From Ballast Tanks and Bilge Lines PDFSunil KumarNo ratings yet

- Ship BallastingDocument7 pagesShip BallastingTammam HassanNo ratings yet

- D2 Bilge, Ballast SystemsDocument10 pagesD2 Bilge, Ballast SystemsGica Si PopescuNo ratings yet

- 10 Important Points to Remember After Completing Cargo Operations on TankersDocument5 pages10 Important Points to Remember After Completing Cargo Operations on TankerscassandraNo ratings yet

- OIL TANKER OPERATIONS (Loading) - Conventional Tanker BasicsDocument3 pagesOIL TANKER OPERATIONS (Loading) - Conventional Tanker BasicsShoaib100% (2)

- VALVEDocument2 pagesVALVEOlink Achmad KafaillahNo ratings yet

- Ballasting and Deballasting Procedures GuideDocument12 pagesBallasting and Deballasting Procedures Guidelusifadilah100% (2)

- Ilovepdf Merged 3Document61 pagesIlovepdf Merged 3Biswajit Q MalakarNo ratings yet

- LOADING CHECKLIST PART I&II and BallastDocument3 pagesLOADING CHECKLIST PART I&II and BallastPavel ViktorNo ratings yet

- Damage To Bulk Cargo (Edited)Document4 pagesDamage To Bulk Cargo (Edited)Asif Siddiqui100% (2)

- Hose ConnectionDocument3 pagesHose ConnectionPanagiotis MouzenidisNo ratings yet

- BV Rules For Inclining TestDocument3 pagesBV Rules For Inclining Testhlsimon100% (1)

- Measurement and calculation of bulk cargo quantitiesDocument18 pagesMeasurement and calculation of bulk cargo quantitiesAbdel Nasser Al-sheikh Yousef100% (1)

- Ballast Water ExchangeDocument3 pagesBallast Water ExchangePolisciuc Radu100% (1)

- What Is Ballasting and deDocument5 pagesWhat Is Ballasting and dezalzizaNo ratings yet

- Oil Tanker Loading ProceduresDocument13 pagesOil Tanker Loading Proceduresdhanaskr12100% (2)

- CH Off's Standing OrdersDocument10 pagesCH Off's Standing OrdersVivek Pratap Singh100% (1)

- Duties of Ship's Chief Officer When Entering Dock: Preparing The Ship For Dry DockingDocument12 pagesDuties of Ship's Chief Officer When Entering Dock: Preparing The Ship For Dry DockingMohan Krishnan100% (1)

- Task 4Document5 pagesTask 4fariskongrockefellerNo ratings yet

- Cargo Operations Manual for TankersDocument61 pagesCargo Operations Manual for TankersTabu La Rasa100% (3)

- Bulk Cargo Measurement GuideDocument18 pagesBulk Cargo Measurement GuideHRodas EcNo ratings yet

- Measurement of Bulk Cargoes - Draught SurveysDocument18 pagesMeasurement of Bulk Cargoes - Draught SurveysPaulo Ricardo100% (1)

- Liquid Cargo Load PlanDocument13 pagesLiquid Cargo Load PlanNaresh Sharma100% (3)

- Measurement of Bulk Cargoes: Draught Surveys - PracticeDocument5 pagesMeasurement of Bulk Cargoes: Draught Surveys - PracticeZhu Chen ChuanNo ratings yet

- Cargo Line Clearance Safe Procedure For Chemical TankersDocument8 pagesCargo Line Clearance Safe Procedure For Chemical TankersJeet SinghNo ratings yet

- Dry Docks and Docking Procedures GuideDocument16 pagesDry Docks and Docking Procedures GuideIshan Vyas100% (1)

- Crude Oil Washing Precautions ProceduresDocument2 pagesCrude Oil Washing Precautions ProceduresArun Rocky100% (1)

- CH 04 Fittings On Ballast & Other TanksDocument10 pagesCH 04 Fittings On Ballast & Other TanksAmit PandeyNo ratings yet

- Safe Bunkering Procedures ExplainedDocument4 pagesSafe Bunkering Procedures ExplainedMeghali Borle100% (1)

- Preparation For Dry DockingDocument8 pagesPreparation For Dry DockingWin Min100% (8)

- Topping Off ProcedureDocument1 pageTopping Off ProcedurePavel ViktorNo ratings yet

- The Undocking ProcedureDocument3 pagesThe Undocking Proceduredanilo lara33% (3)

- Cargo Oil SystemDocument8 pagesCargo Oil SystemAayush Agrawal100% (3)

- Oil Tanker Cargo Loading ProcedureDocument7 pagesOil Tanker Cargo Loading ProcedureAnonymous UCveMQ100% (5)

- Oil Tanker Cargo Loading Procedure at SBMDocument10 pagesOil Tanker Cargo Loading Procedure at SBMdinar rosandy100% (1)

- Dry Docking Procedures ExplainedDocument4 pagesDry Docking Procedures ExplainedBhupender RamchandaniNo ratings yet

- The Importance of Maintaining Stability During Loading and Unloading and inDocument8 pagesThe Importance of Maintaining Stability During Loading and Unloading and inClint Oceas Ibaya60% (5)

- 7.1 Proposed Annex VII - BWM ConventionDocument38 pages7.1 Proposed Annex VII - BWM ConventionDennis IndayNo ratings yet

- Chief Mate OralDocument8 pagesChief Mate OralJonathan McCarthyNo ratings yet

- Bunker IngDocument6 pagesBunker IngJackielou LagmanNo ratings yet

- Tanker Ballast Capacities and Emergency First Aid ProceduresDocument23 pagesTanker Ballast Capacities and Emergency First Aid ProceduresYusuf Bagus PangestuNo ratings yet

- Seam 213Document8 pagesSeam 213John Gonzaga EscuadroNo ratings yet

- Tanker Operation ProcedureDocument2 pagesTanker Operation ProcedureAnand KhotNo ratings yet

- Loading LPG Cargo and Related Safety FactorsDocument5 pagesLoading LPG Cargo and Related Safety FactorsVasil RaykovNo ratings yet

- Fig. 7.2: A Tanker Voyage Cycle: A. B. C. D. Loading Rate Pumping Capacity Piping Arrangements Venting CapabilitiesDocument43 pagesFig. 7.2: A Tanker Voyage Cycle: A. B. C. D. Loading Rate Pumping Capacity Piping Arrangements Venting CapabilitiesSunil Dayalu100% (3)

- Bunker ProcedureDocument24 pagesBunker ProcedureDimas Bangkit100% (2)

- Loading ProcedureDocument77 pagesLoading ProcedureAnkit Vyas100% (2)

- Discharging Operation in Oil TankersDocument6 pagesDischarging Operation in Oil TankersSatyabrat Gaan100% (1)

- Preparation For Receiving Nitrogen From ShoreDocument7 pagesPreparation For Receiving Nitrogen From Shoreelfantasma100% (1)

- Proclamation 1258 — Rules for the Measurement of Vessels for the Panama CanalFrom EverandProclamation 1258 — Rules for the Measurement of Vessels for the Panama CanalNo ratings yet

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentFrom EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentNo ratings yet

- BRCL-005 Arrival ChecklistDocument2 pagesBRCL-005 Arrival ChecklistAnonymous 1No ratings yet

- BRCL-006 Departure ChecklistDocument2 pagesBRCL-006 Departure ChecklistAnonymous 1No ratings yet

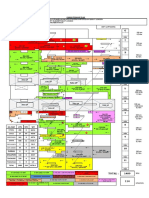

- AMY Stowage Plan Dep. Cartagena Voy 098A With Discharge RouteDocument4 pagesAMY Stowage Plan Dep. Cartagena Voy 098A With Discharge RouteAnonymous 1No ratings yet

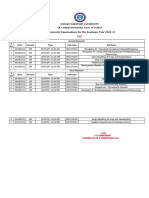

- M Tech - DHE PDFDocument1 pageM Tech - DHE PDFAnonymous 1No ratings yet

- 2020 M09.csvDocument1 page2020 M09.csvAnonymous 1No ratings yet

- DNS 09082021Document2 pagesDNS 09082021Anonymous 1No ratings yet

- DTS LawDocument22 pagesDTS LawAnonymous 1No ratings yet

- DLP 13082021Document1 pageDLP 13082021Anonymous 1No ratings yet

- ISM Code 2015Document18 pagesISM Code 2015Gaurav HarjaiNo ratings yet

- V.B. S. Purvanchal University, Jaunpur: Syllabus B.A. History (Med. & Mod.) B. A.-1Document15 pagesV.B. S. Purvanchal University, Jaunpur: Syllabus B.A. History (Med. & Mod.) B. A.-1Anonymous 1No ratings yet

- Document ComplianceDocument6 pagesDocument ComplianceAnonymous 1No ratings yet

- ISM Code 2015Document18 pagesISM Code 2015Gaurav HarjaiNo ratings yet

- Orion C.M. HVAC Case Study-07.25.23Document25 pagesOrion C.M. HVAC Case Study-07.25.23ledmabaya23No ratings yet

- Consumer Behavior PP Chapter 4Document36 pagesConsumer Behavior PP Chapter 4tuongvyvyNo ratings yet

- Sato Printer Api Reference DocumentDocument34 pagesSato Printer Api Reference Documentsupersteel.krwNo ratings yet

- AP Standard Data All PDFDocument963 pagesAP Standard Data All PDFSiva Kumar100% (1)

- Atomic Structure QuestionsDocument1 pageAtomic Structure QuestionsJames MungallNo ratings yet

- READMEDocument3 pagesREADMERadu TimisNo ratings yet

- Technical Information System Overview Prosafe-Com 3.00 Prosafe-ComDocument49 pagesTechnical Information System Overview Prosafe-Com 3.00 Prosafe-Comshekoofe danaNo ratings yet

- Search Engine Marketing Course Material 2t4d9Document165 pagesSearch Engine Marketing Course Material 2t4d9Yoga Guru100% (2)

- VIP 32 Hybrid VentDocument8 pagesVIP 32 Hybrid VentsagarNo ratings yet

- SMC Dialog Plus Conversion To Another SMC 8 - 22 - 2014Document15 pagesSMC Dialog Plus Conversion To Another SMC 8 - 22 - 2014vivek kumarNo ratings yet

- Creating Literacy Instruction For All Students ResourceDocument25 pagesCreating Literacy Instruction For All Students ResourceNicole RickettsNo ratings yet

- KJR 20 880 PDFDocument14 pagesKJR 20 880 PDFNam LeNo ratings yet

- Parts of The Analog MultitesterDocument4 pagesParts of The Analog MultitesterDestiny Marasigan CanacanNo ratings yet

- Amazon Invoice Books 4Document1 pageAmazon Invoice Books 4raghuveer9303No ratings yet

- From Memphis To KingstonDocument19 pagesFrom Memphis To KingstonCarlos QuirogaNo ratings yet

- TLM4ALL@1 Number System (EM)Document32 pagesTLM4ALL@1 Number System (EM)jkc collegeNo ratings yet

- ENVIRONMENTAL HEALTH (Compiled) PDFDocument119 pagesENVIRONMENTAL HEALTH (Compiled) PDFHarlyn PajonillaNo ratings yet

- Lodha GroupDocument2 pagesLodha Groupmanish_ggiNo ratings yet

- Neutron SourcesDocument64 pagesNeutron SourcesJenodi100% (1)

- BSNL TrainingDocument25 pagesBSNL TrainingAditya Dandotia68% (19)

- Arduino Programming Step by Step Guide To Mastering Arduino Hardware and SoftwareDocument109 pagesArduino Programming Step by Step Guide To Mastering Arduino Hardware and SoftwareMohan100% (3)

- Psych 1xx3 Quiz AnswersDocument55 pagesPsych 1xx3 Quiz Answerscutinhawayne100% (4)

- Material Safety Data Sheet Surfacecool© Roof CoatingDocument3 pagesMaterial Safety Data Sheet Surfacecool© Roof CoatingPremfeb27No ratings yet

- Tugas Bahasa Inggris Analytical Exposition Text: Disusun Oleh: Nama:Hansel Hendrawan Effendy Kelas:XI IPA 1Document4 pagesTugas Bahasa Inggris Analytical Exposition Text: Disusun Oleh: Nama:Hansel Hendrawan Effendy Kelas:XI IPA 1Hansel HendrawanNo ratings yet

- Lab Experiment 2Document6 pagesLab Experiment 2api-309262457No ratings yet

- Basketball 2011: Johnson CountyDocument25 pagesBasketball 2011: Johnson CountyctrnewsNo ratings yet

- DTS-00750 Mast Maintenance ManualDocument12 pagesDTS-00750 Mast Maintenance Manualsertecs polNo ratings yet

- Multibody Simulation of A Freight Bogie With Friction DampersDocument10 pagesMultibody Simulation of A Freight Bogie With Friction DampersGermán GoñiNo ratings yet

- F FS1 Activity 3 EditedDocument15 pagesF FS1 Activity 3 EditedRayshane Estrada100% (1)

- MINTZBERGDocument32 pagesMINTZBERGgeezee10004464100% (2)