Professional Documents

Culture Documents

TRO CX7323 - E11 - Ad PDF

Uploaded by

Josip DuvnjakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TRO CX7323 - E11 - Ad PDF

Uploaded by

Josip DuvnjakCopyright:

Available Formats

Product Information

Product Information

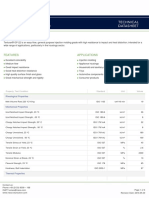

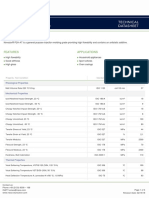

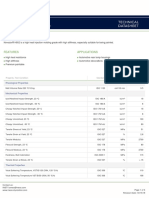

TROGAMID® CX7323

CX7323

Microcrystalline, permanently transparent

transparent polyamide

TROGAMID CX7323 is a microcrystalline Furthermore the product meets the USP

transparent polyamide for the manufacture of Class VI (United States Pharmacopeia)

parts according the injection molding approval.

procedure.

TROGAMID CX7323 is supplied as spherical

The crystallites are so small, that they do not pellets in polyethylene- packaging.

scatter visible light, and the material appears

transparent to the human eye. The crystalline Deviations of molds or in processing are

structure causes the excellent crack possible to a certain extent, if they are

resistance for this polymer. required by the cavity or the process itself.

The product has been approved for direct

contact with foodstuffs by the European

Community (Directive 2002/72/EC).

For further information, please contact us at evonik-

evonik-hp@evonik.com.

TROGAMID® = registered trademark of the Evonik Degussa GmbH October 2011

Test method TROGAMID

Property Unit

international national CX7323

CX7323

Density 23°C ISO 1183 DIN EN ISO 1183 g/cm3 1.02

Tensile test ISO 527-1 DIN EN ISO 527-1

Stress at yield ISO 527-2 DIN EN ISO 527-2 MPa 60

Strain at yield % 8

Strain at break % > 50

Tensile modulus ISO 527-1 DIN EN ISO 527-1 MPa 1400

ISO 527-2 DIN EN ISO 527-2

CHARPY impact strength ISO 179/1eU DIN EN ISO 179/1eU

23°C kJ/m2 N1)

-30°C kJ/m2 N1)

CHARPY notched impact strength ISO 179/1eA DIN EN ISO 179/1eA

23°C kJ/m² 14 C1)

-30°C kJ/m² 11 C1)

Shore-hardness D ISO 868 DIN EN ISO 868 81

Temperature of deflection ISO 75-1 DIN EN ISO 75-1

under load ISO 75-2 DIN EN ISO 75-2

Method A 1.8 MPa °C 108

Method B 0.45 MPa °C 122

Vicat softening temperature ISO 306 DIN EN ISO 306

Method A 10 N °C 137

Method B 50 N °C 130

Linear thermal expansion 23–55°C ISO 11359 DIN 53752

longitudinal / transverse 10-4K-1 0.9 / 0.9

Relative permittivity IEC 60250 DIN VDE 0303-T4

100 Hz 3.6

Dissipation factor IEC 60250 DIN VDE 0303-T4

100 Hz 10-4 115

Surface resistance ROA IEC 60093 IEC 60093 Ohm 1013

Melting range ISO 11357

DSC 2nd heating °C 250

Melt volume-flow rate (MVR) ISO 1133 DIN EN ISO 1133

280°C/2.16kg cm³/10 min approx. 15

Comparative tracking index IEC 60112 IEC 60112

Test solution A CTI 600

100 drops value 575

Flammability acc. UL94 IEC 60695 UL94

0.8 mm HB

1.6 mm HB

Water absorption saturation ISO 62 DIN EN ISO 62 % 3.5

Mold shrinkage determined on 2 mm sheets

in flow direction with film gate at rim, % 0.65

in transverse direction mold temperature 80°C, ISO 294-4 % 0.80

Pigmentation may affect values.

1) C = Complete break, incl. hinge break H

N = No break

® = registered trademark

This information and all technical and other advice are based on Evonik’s present knowledge and experience. However, Evonik assumes no

liability for such information or advice, including the extent to which such information or advice may relate to third party intellectual

property rights. Evonik reserves the right to make any changes to information or advice at any time, without prior or subsequent notice.

Evonik disclaims all representations and warranties, whether express or implied, and shall have no liability for, merchantability of the

product or its fitness for a particular purpose (even if Evonik is aware of such purpose), or otherwise. Evonik shall not be responsible for

consequential, indirect or incidental damages (including loss of profits) of any kind. It is the customer’s sole responsibility to arrange for

inspection and testing of all products by qualified experts. Reference to trade names used by other companies is neither a

recommendation, nor an endorsement of the corresponding product, and does not imply that similar products could not be used.

Evonik Industries AG High Performance Polymers 45764 Marl Germany

Phone +49 2365 49-9878 E-mail evonik-hp@evonik.com

www.trogamid.com

You might also like

- Product Information Product Information Product Information Product InformationDocument2 pagesProduct Information Product Information Product Information Product InformationMorkizgaNo ratings yet

- PET Technical Handbook 1Document61 pagesPET Technical Handbook 1karismaNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- Celanex 3316Document5 pagesCelanex 3316klausoshoNo ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- PE 100 & PP Material PropertiesDocument2 pagesPE 100 & PP Material PropertiesQuisperolandoNo ratings yet

- Pa 6 GF 30 (En)Document1 pagePa 6 GF 30 (En)Alessandro WeissNo ratings yet

- Allbro Material-Properties-Smc-DmcDocument1 pageAllbro Material-Properties-Smc-Dmcfajar agungNo ratings yet

- Styrolution Basf Terluran GP-22Document3 pagesStyrolution Basf Terluran GP-22medo.k016No ratings yet

- Terluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Mahdi VolgarNo ratings yet

- Durethan B30S 000000: PA 6, Non-Reinforced, Injection Molding ISO Shortname: ISO 1874-PA 6, GR, 14-030Document3 pagesDurethan B30S 000000: PA 6, Non-Reinforced, Injection Molding ISO Shortname: ISO 1874-PA 6, GR, 14-030zoranNo ratings yet

- ABS N Fisa TehnicaDocument1 pageABS N Fisa TehnicaFloare de PrimavaraNo ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNo ratings yet

- Durethan B30S 000000 ISO enDocument3 pagesDurethan B30S 000000 ISO enjujuplasticNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- High-Temp PI Stock ShapesDocument2 pagesHigh-Temp PI Stock ShapesGreeshmaNo ratings yet

- Lanxess - Pocan B7425Document3 pagesLanxess - Pocan B7425rihabNo ratings yet

- TECHNYL® A 216 Y10: DescriptionDocument2 pagesTECHNYL® A 216 Y10: DescriptionpaquienNo ratings yet

- TECACOMP PPA LDS Black 4108 0Document2 pagesTECACOMP PPA LDS Black 4108 0H. BeatsNo ratings yet

- PC Caracteristicas PDFDocument3 pagesPC Caracteristicas PDFIceMan3No ratings yet

- Material Data Sheet: Urban@plastum - CZ WWW - Plastum.czDocument1 pageMaterial Data Sheet: Urban@plastum - CZ WWW - Plastum.czDavis GNo ratings yet

- ProductFile 131206155656Document1 pageProductFile 131206155656Michael HajzerNo ratings yet

- B70 S Natural S1: Badamid®Document2 pagesB70 S Natural S1: Badamid®hocineNo ratings yet

- Bayblend T85 XF ISO enDocument3 pagesBayblend T85 XF ISO enryanNo ratings yet

- Technyl Safe C 116FC NCDocument3 pagesTechnyl Safe C 116FC NCkls.thorodinsonNo ratings yet

- PA6EDocument1 pagePA6EDiego ReggianiniNo ratings yet

- PA6-30GF LANXESS Durethan BKV130P 702214 ISO ENDocument2 pagesPA6-30GF LANXESS Durethan BKV130P 702214 ISO ENKalipse FerreiraNo ratings yet

- Celanex 3300-2 PBTDocument3 pagesCelanex 3300-2 PBTDiegoTierradentroNo ratings yet

- MDS102RG600x47 1Document2 pagesMDS102RG600x47 1Khawla BkNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- Nylon 6-BAYER DURATHAN BKV130-901510Document3 pagesNylon 6-BAYER DURATHAN BKV130-901510dcrypto2022No ratings yet

- Riteflex 640aDocument3 pagesRiteflex 640aazaleaemersonNo ratings yet

- TDS - Terluran GP-22 PDFDocument3 pagesTDS - Terluran GP-22 PDFebercueNo ratings yet

- Styro Lution Tds 400900240714Document3 pagesStyro Lution Tds 400900240714vrjrNo ratings yet

- Fisa Tehnica Linoleum Natural MarmoretteDocument1 pageFisa Tehnica Linoleum Natural MarmoretteSurdu AncaNo ratings yet

- Product Summary: CZ-1030 Is A 30% Pitch Based Carbon Fiber Reinforced PPS Color: BlackDocument1 pageProduct Summary: CZ-1030 Is A 30% Pitch Based Carbon Fiber Reinforced PPS Color: BlackMark DingalNo ratings yet

- Duracon M90 44Document2 pagesDuracon M90 44PradeepNo ratings yet

- Advanced-PP 1102LQ - 0Document1 pageAdvanced-PP 1102LQ - 0Narender RawatNo ratings yet

- PLEXIGLAS Satinice df20 8N - ENDocument2 pagesPLEXIGLAS Satinice df20 8N - ENmstevkaNo ratings yet

- Caring Formula High Flow Glass Filled PA6Document3 pagesCaring Formula High Flow Glass Filled PA6ratz23695No ratings yet

- Styrolution PS 158N/L Heat Resistant GPPSDocument3 pagesStyrolution PS 158N/L Heat Resistant GPPSscribdichigoNo ratings yet

- Property Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)MohamadMostafaviNo ratings yet

- Property Test Method Unit Typicalvalue : BL3 License Grade Code HF 4670 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL3 License Grade Code HF 4670 (THT)MohamadMostafaviNo ratings yet

- Durethan BKV240H2.0XCP properties guideDocument3 pagesDurethan BKV240H2.0XCP properties guideshahin_723No ratings yet

- Pe-Uhmw Technical Data SheetDocument1 pagePe-Uhmw Technical Data SheetPrashant MalikNo ratings yet

- PP Compound - PP15T1020Document2 pagesPP Compound - PP15T1020Chaimae HanynyNo ratings yet

- Data Sheet Advanced-PP 1102 K: Properties Unit Test Method ValueDocument1 pageData Sheet Advanced-PP 1102 K: Properties Unit Test Method ValueSekar AyuNo ratings yet

- Advanced PP 1102KDocument1 pageAdvanced PP 1102KLaxman AhirNo ratings yet

- Matrox TDS PDFDocument1 pageMatrox TDS PDFrajanarenderNo ratings yet

- Flame retardant lining material technical data sheetDocument1 pageFlame retardant lining material technical data sheetrajanarenderNo ratings yet

- A301 - EN MethodDocument1 pageA301 - EN MethodAhmad ElghazolyNo ratings yet

- Luran HH-120: Please SelectDocument3 pagesLuran HH-120: Please SelectDavid Costi da RosaNo ratings yet

- PBT - Lanxess Pocan B3235 000000Document3 pagesPBT - Lanxess Pocan B3235 000000armandoNo ratings yet

- Data Sheet Advanced-PP 1102 K: Properties Unit Test Method ValueDocument1 pageData Sheet Advanced-PP 1102 K: Properties Unit Test Method ValueErnesto Cheguavara100% (1)

- Propertie NilonDocument3 pagesPropertie Nilonmuhammad daffaNo ratings yet

- Vesbo PPR EnglishDocument50 pagesVesbo PPR Englishcool.boys4200No ratings yet

- Elix ABS M220: Technical InformationDocument3 pagesElix ABS M220: Technical InformationDiegoTierradentroNo ratings yet

- Desmopan 453 DPS 041: 400 Grade Series, Ester / Shore Hardness D 50 - 54Document2 pagesDesmopan 453 DPS 041: 400 Grade Series, Ester / Shore Hardness D 50 - 54Johnny SyluanciaNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Heat Transfer Enhancement Techniques: Presented by Dr.D.MALADocument18 pagesHeat Transfer Enhancement Techniques: Presented by Dr.D.MALASontappagariViswanathNo ratings yet

- BucklingDocument7 pagesBucklingMohammad BurhanNo ratings yet

- Mechanical Failure of Materials 9789814560375-c2Document23 pagesMechanical Failure of Materials 9789814560375-c2Recep Vatansever0% (1)

- Final HallDocument29 pagesFinal HallUnknownNo ratings yet

- Detailing To Eurocode 2Document12 pagesDetailing To Eurocode 2Bhandari_007100% (1)

- Ec3452 Iat1 EmfDocument2 pagesEc3452 Iat1 EmfDr.M.SubbulakshmiNo ratings yet

- Chemistry Term PaperDocument14 pagesChemistry Term PaperAkash SinghNo ratings yet

- B.Tech Mechanical Engineering 4 Semester: Assam Science and Technology University GuwahatiDocument17 pagesB.Tech Mechanical Engineering 4 Semester: Assam Science and Technology University GuwahatiPrasanta GogoiNo ratings yet

- Table A-1 Basic Allowable Stresses in Tension For MetalsDocument28 pagesTable A-1 Basic Allowable Stresses in Tension For MetalsMohamed ElsayedNo ratings yet

- ASME B30.2 Lifting LugDocument8 pagesASME B30.2 Lifting LugEliza Nightry De Large100% (1)

- Basic Electronics Tutorial 2Document4 pagesBasic Electronics Tutorial 2Susheel SrinivasNo ratings yet

- Iso-Tc 25 N 470Document49 pagesIso-Tc 25 N 470ashey7777No ratings yet

- Stress AnalysisDocument60 pagesStress AnalysisTejas DesaiNo ratings yet

- Assess Pipeline Girth Weld DefectsDocument3 pagesAssess Pipeline Girth Weld Defectsbumoh1No ratings yet

- OTC-29534-MS Strain-Life Fatigue Analysis For HPHT Equipment: Theory To ValidationDocument17 pagesOTC-29534-MS Strain-Life Fatigue Analysis For HPHT Equipment: Theory To Validationcamilo777No ratings yet

- Objective:: σ and hasDocument9 pagesObjective:: σ and hasfareeha saeedNo ratings yet

- A11 Thermodynamics PDFDocument15 pagesA11 Thermodynamics PDFEMAMBOCUS Muhammad Ibraheem JunaidNo ratings yet

- Effects of Mixing State of Composite Powders On Sintering Behavior ofDocument6 pagesEffects of Mixing State of Composite Powders On Sintering Behavior ofask teacher roseNo ratings yet

- Spyrakos Et Al. (2011)Document13 pagesSpyrakos Et Al. (2011)Rolando AlvaradoNo ratings yet

- G8 Science Q3 Adm Module For PrintingDocument36 pagesG8 Science Q3 Adm Module For PrintingJenn ElardeNo ratings yet

- 6 Pushover AnalysisDocument6 pages6 Pushover AnalysisUALU333No ratings yet

- Spinodal Decomposition PDFDocument3 pagesSpinodal Decomposition PDFOmar VillanuevaNo ratings yet

- Conservation of momentum derivationDocument15 pagesConservation of momentum derivationDarvik YadavNo ratings yet

- Emi Book 2Document97 pagesEmi Book 2Arya SharmaNo ratings yet

- Iron-Iron Carbide Phase Diagram ExampleDocument4 pagesIron-Iron Carbide Phase Diagram ExampleWanda Andreas WidyatmokoNo ratings yet

- Material Science Question Paper Summer2019Document49 pagesMaterial Science Question Paper Summer2019Yogesh PandeyNo ratings yet

- Quattro DatasheetDocument4 pagesQuattro DatasheetIngIrvingFCervantesNo ratings yet

- Water PVT RelationshipsDocument4 pagesWater PVT RelationshipsJennifer PaceNo ratings yet

- Ipc2022-86856 Influence of Strain Hardening Model On The Corlastm Model ForDocument12 pagesIpc2022-86856 Influence of Strain Hardening Model On The Corlastm Model ForOswaldo MontenegroNo ratings yet