Professional Documents

Culture Documents

Product Information Product Information Product Information Product Information

Uploaded by

MorkizgaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Information Product Information Product Information Product Information

Uploaded by

MorkizgaCopyright:

Available Formats

Product Information

Product Information

VESTAKEEP® 4000FP

Unreinforced, high-

high-viscosity polyether ether ketone fine powder

VESTAKEEP 4000FP is an unreinforced, high- VESTAKEEP 4000FP is supplied as powder in

viscosity polyether ether ketone fine powder. boxes with moisture-proof polyethylene

It can be used as a basic resin or in blends liners.

with different additives for manufacturing

compression molding parts. For guidance processing of VESTAKEEP

please follow the general recommendations

The semi-crystalline polymer features in our brochure “VESTAKEEP Polyether Ether

superior thermal and chemical resistance. Ketone“.

VESTAKEEP 4000FP is self-extinguishing.

For further information, please contact us at evonik-

evonik-hp@evonik.com.

VESTAKEEP® = registered trademark of the Evonik Degussa GmbH October 2011

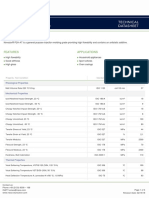

Powder Information

Test method VESTAKEEP

Property

Property Unit

international national 4000FP

App. bulk density ISO 60 DIN 53 468 g/dm3 250

Average particle size d50 Malvern Mastersizer m approx. 60

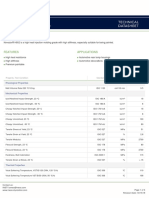

Application technology properties

Test method VESTAKEEP

Property Unit

international national 4000FP

Density 23°C ISO 1183 DIN EN ISO 1183 g/cm3 1.30

Tensile test ISO 527-1 DIN EN ISO 527-1

Stress at yield ISO 527-2 DIN EN ISO 527-2 MPa 96

Strain at yield % 5

Strain at break % 30

Tensile modulus ISO 527-1/2 DIN EN ISO 527-1/2 MPa 3500

CHARPY impact strength ISO 179/1eU DIN EN ISO 179/1eU

23°C kJ/m2 N1)

-30°C kJ/m2 N1)

CHARPY notched impact strength ISO 179/1eA DIN EN ISO 179/1eA

23°C kJ/m² 7 C1)

-30°C kJ/m² 6 C1)

Temperature of deflection ISO 75-1 DIN EN ISO 75-1

under load ISO 75-2 DIN EN ISO 75-2

Method A 1.8 MPa °C 150

Method B 0.45 MPa °C 205

Vicat softening temperature ISO 306 DIN EN ISO 306

Method A 10 N °C 335

Method B 50 N °C 305

Melting range ISO 11357

DSC 2nd heating °C approx. 340

Melt volume-flow rate (MVR) ISO 1133 DIN EN ISO 1133

380°C /5 kg cm³/10 min 11

Flammability acc. UL94 3.2 mm IEC60695 UL94 V-0

Pigmentation may affect values

1) C = Complete break, incl. hinge break H

N = No break

® = registered trademark

This information and all technical and other advice are based on Evonik’s present knowledge and experience. However, Evonik assumes no

liability for such information or advice, including the extent to which such information or advice may relate to third party intellectual

property rights. Evonik reserves the right to make any changes to information or advice at any time, without prior or subsequent notice.

Evonik disclaims all representations and warranties, whether express or implied, and shall have no liability for, merchantability of the

product or its fitness for a particular purpose (even if Evonik is aware of such purpose), or otherwise. Evonik shall not be responsible for

consequential, indirect or incidental damages (including loss of profits) of any kind. It is the customer’s sole responsibility to arrange for

inspection and testing of all products by qualified experts. Reference to trade names used by other companies is neither a

recommendation, nor an endorsement of the corresponding product, and does not imply that similar products could not be used.

Evonik Industries AG High Performance Polymers 45764 Marl Germany

Phone +49 2365 49-9878 E-mail evonik-hp@evonik.com

www.vestakeep.com

You might also like

- TRO CX7323 - E11 - Ad PDFDocument2 pagesTRO CX7323 - E11 - Ad PDFJosip DuvnjakNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- Technyl Safe C 116FC NCDocument3 pagesTechnyl Safe C 116FC NCkls.thorodinsonNo ratings yet

- Luran HH-120: Please SelectDocument3 pagesLuran HH-120: Please SelectDavid Costi da RosaNo ratings yet

- PocanB3235000000 GF30 1Document5 pagesPocanB3235000000 GF30 1rihabNo ratings yet

- Durethan B30S 000000: PA 6, Non-Reinforced, Injection Molding ISO Shortname: ISO 1874-PA 6, GR, 14-030Document3 pagesDurethan B30S 000000: PA 6, Non-Reinforced, Injection Molding ISO Shortname: ISO 1874-PA 6, GR, 14-030zoranNo ratings yet

- Celanex 3300-2 PBTDocument3 pagesCelanex 3300-2 PBTDiegoTierradentroNo ratings yet

- TECHNYL® A 216 Y10: DescriptionDocument2 pagesTECHNYL® A 216 Y10: DescriptionpaquienNo ratings yet

- Celanex 3316Document5 pagesCelanex 3316klausoshoNo ratings yet

- Bayblend T85 XF ISO enDocument3 pagesBayblend T85 XF ISO enryanNo ratings yet

- 2024 03 06 TDS Elastollan1185ADocument4 pages2024 03 06 TDS Elastollan1185AChaker AbdellatifNo ratings yet

- PET Technical Handbook 1Document61 pagesPET Technical Handbook 1karismaNo ratings yet

- POM Delrin 500Document2 pagesPOM Delrin 500countzeroaslNo ratings yet

- Riteflex 640aDocument3 pagesRiteflex 640aazaleaemersonNo ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- Crastin S600 F40 NC010Document11 pagesCrastin S600 F40 NC010TomGaliciaNo ratings yet

- Dupont™ Crastin S600F40 Nc010: Thermoplastic Polyester ResinDocument11 pagesDupont™ Crastin S600F40 Nc010: Thermoplastic Polyester ResinTomGaliciaNo ratings yet

- R42000249GKF - Celanex 2003 - PBT - TDSDocument4 pagesR42000249GKF - Celanex 2003 - PBT - TDSCarlos AgianiNo ratings yet

- Durethan B30S 000000 ISO enDocument3 pagesDurethan B30S 000000 ISO enjujuplasticNo ratings yet

- Styrolution PS 158N/L Heat Resistant GPPSDocument3 pagesStyrolution PS 158N/L Heat Resistant GPPSscribdichigoNo ratings yet

- TerluranGP-22Document5 pagesTerluranGP-22Chu ChuNo ratings yet

- Diakon® ST35G8: Lucite International Holland BVDocument3 pagesDiakon® ST35G8: Lucite International Holland BVbobNo ratings yet

- POLYFLAM_RABS_90000_UV5_LS_(E128762)Document3 pagesPOLYFLAM_RABS_90000_UV5_LS_(E128762)simonNo ratings yet

- CELANEX® 2000-K-EnDocument3 pagesCELANEX® 2000-K-EnCarlos AgianiNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- Allbro Material-Properties-Smc-DmcDocument1 pageAllbro Material-Properties-Smc-Dmcfajar agungNo ratings yet

- Asa Ineos Styrolution Europe GMBH: Luran® S 776seDocument6 pagesAsa Ineos Styrolution Europe GMBH: Luran® S 776sebobNo ratings yet

- TDS - Mosten - MA 745 - enDocument2 pagesTDS - Mosten - MA 745 - enTo RaNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ISO)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ISO)DiegoTierradentroNo ratings yet

- VictrexTDS150G 151GDocument2 pagesVictrexTDS150G 151GKumaar RanjanNo ratings yet

- Victrex™ Peek 450G™: Product DescriptionDocument2 pagesVictrex™ Peek 450G™: Product DescriptionBerkant CangalNo ratings yet

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNo ratings yet

- CAMPUS® Datasheet: Ultradur® B 4406 G6 Q798 SW 15138 - PBT-GF30 FR BasfDocument5 pagesCAMPUS® Datasheet: Ultradur® B 4406 G6 Q798 SW 15138 - PBT-GF30 FR BasfdivyarasinNo ratings yet

- Lanxess - Pocan B7425Document3 pagesLanxess - Pocan B7425rihabNo ratings yet

- Datasheet CX02-81Document2 pagesDatasheet CX02-81jprodriguezNo ratings yet

- Pulse A 35-105 BlackDocument3 pagesPulse A 35-105 BlackTaoufik KheddarNo ratings yet

- PA6-30GF LANXESS Durethan BKV130P 702214 ISO ENDocument2 pagesPA6-30GF LANXESS Durethan BKV130P 702214 ISO ENKalipse FerreiraNo ratings yet

- Campus® Datasheet: Pocan® BF 4235 - Pbt-Gf30 FR Lanxess Deutschland GMBHDocument2 pagesCampus® Datasheet: Pocan® BF 4235 - Pbt-Gf30 FR Lanxess Deutschland GMBHAngererNo ratings yet

- CELCONM90Document5 pagesCELCONM90DiegoTierradentroNo ratings yet

- TerluranGP35Document5 pagesTerluranGP35cristinamss33No ratings yet

- TASNEE 100 Black PE Resin for Pressure PipesDocument2 pagesTASNEE 100 Black PE Resin for Pressure PipesHassanNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Kumho_750SWDocument1 pageKumho_750SWChu ChuNo ratings yet

- (DATASHEET) Peek DC4430 R - VESTAKEEPDocument2 pages(DATASHEET) Peek DC4430 R - VESTAKEEPProjetos KoppNo ratings yet

- Technical Data SheetDocument1 pageTechnical Data SheetGeorge DonosaNo ratings yet

- ABS - Novodur P2HGVDocument2 pagesABS - Novodur P2HGVarmandoNo ratings yet

- Nylon 6-BAYER DURATHAN BKV130-901510Document3 pagesNylon 6-BAYER DURATHAN BKV130-901510dcrypto2022No ratings yet

- CELCON® M90-EnDocument8 pagesCELCON® M90-EnJosue OrtizNo ratings yet

- Styrolution PS 454N: High Impact Polystyrene (HIPS)Document3 pagesStyrolution PS 454N: High Impact Polystyrene (HIPS)Inês MorgadoNo ratings yet

- Property Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)MohamadMostafaviNo ratings yet

- Luran 368 RDocument5 pagesLuran 368 RmucahitkaraballNo ratings yet

- Mechanical, Thermal and Electrical Properties of Durethan BKV130H2.0Document3 pagesMechanical, Thermal and Electrical Properties of Durethan BKV130H2.0RICARDONo ratings yet

- Dupont Delrin 527UV BK701Document4 pagesDupont Delrin 527UV BK701Phung LucNo ratings yet

- Bayblend FR1514 - en - 56967951 05122960 20070851Document3 pagesBayblend FR1514 - en - 56967951 05122960 20070851phairyNo ratings yet

- Advanced-PP 1102LQ - 0Document1 pageAdvanced-PP 1102LQ - 0Narender RawatNo ratings yet

- Victrex - Peek Data SheetDocument2 pagesVictrex - Peek Data SheetM J VoraNo ratings yet

- TDS MakrolonET3113Document3 pagesTDS MakrolonET3113It WittayaNo ratings yet

- Longo RobertsDocument58 pagesLongo RobertsMorkizgaNo ratings yet

- Lewis Super-Acids Catalyze New Fragrance RoutesDocument2 pagesLewis Super-Acids Catalyze New Fragrance RoutesMorkizgaNo ratings yet

- CN104629254B - A Kind of Manufacture Method of Continuous Lod Polyether-Ether-Ketone Composite Material Prepreg Tape and Equipment - Google PateDocument8 pagesCN104629254B - A Kind of Manufacture Method of Continuous Lod Polyether-Ether-Ketone Composite Material Prepreg Tape and Equipment - Google PateMorkizgaNo ratings yet

- Gps 1Document14 pagesGps 1MorkizgaNo ratings yet

- Gold(I)-Catalyzed Tandem Cyclization for Tetracyclic Indolines SynthesisDocument1 pageGold(I)-Catalyzed Tandem Cyclization for Tetracyclic Indolines SynthesisMorkizgaNo ratings yet

- High Purity Diphenyl Sulfone for Improved PAEK PolymersDocument21 pagesHigh Purity Diphenyl Sulfone for Improved PAEK PolymersMorkizgaNo ratings yet

- New Lightweight Material Is Stronger Than Steel - MIT News - Massachusetts Institute of TechnologyDocument5 pagesNew Lightweight Material Is Stronger Than Steel - MIT News - Massachusetts Institute of TechnologyMorkizgaNo ratings yet

- Out-Of-Autoclave Processing - < 1% Void ContentDocument3 pagesOut-Of-Autoclave Processing - < 1% Void ContentMorkizgaNo ratings yet

- US4882397Document19 pagesUS4882397MorkizgaNo ratings yet

- D&D Dark Sun 3.5 Edition - Core BookDocument314 pagesD&D Dark Sun 3.5 Edition - Core BookDustin Reindl100% (3)

- 7,034,187 Reaction of PEEK Explained Pros & ConsDocument29 pages7,034,187 Reaction of PEEK Explained Pros & ConsMorkizgaNo ratings yet

- US8969504Document14 pagesUS8969504MorkizgaNo ratings yet

- Consolidating Thermoplastic Composites in PlaceDocument6 pagesConsolidating Thermoplastic Composites in PlaceMorkizgaNo ratings yet

- Out-Of-Autoclave Prepregs - Hype or RevolutionDocument8 pagesOut-Of-Autoclave Prepregs - Hype or RevolutionMorkizgaNo ratings yet

- 3D Printing Ultra-High Performance Polymers - Why PEKK Is The Ultimate ChoiceDocument3 pages3D Printing Ultra-High Performance Polymers - Why PEKK Is The Ultimate ChoiceMorkizgaNo ratings yet

- Kepstan® PEKK Polymer RangeDocument4 pagesKepstan® PEKK Polymer RangeMorkizgaNo ratings yet

- Polymer Manufacturing Processes - A 4000+ Words Comprehensive GuideDocument31 pagesPolymer Manufacturing Processes - A 4000+ Words Comprehensive GuideMorkizgaNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2015/0033429 A1Document19 pagesPatent Application Publication (10) Pub. No.: US 2015/0033429 A1MorkizgaNo ratings yet

- I Want To Say Two Words To You - "Thermoplastic Tapes"Document7 pagesI Want To Say Two Words To You - "Thermoplastic Tapes"MorkizgaNo ratings yet

- A Comparison of Crushing Parameters of Graphite Composite Thin-WaDocument76 pagesA Comparison of Crushing Parameters of Graphite Composite Thin-WaMorkizgaNo ratings yet

- Dark Sun Grand Compendium - Volume 1 - Atlas of AthasDocument258 pagesDark Sun Grand Compendium - Volume 1 - Atlas of AthasMorkizga100% (1)

- Psychoportive Powers: Movement and LocationDocument24 pagesPsychoportive Powers: Movement and LocationMorkizgaNo ratings yet

- DarkSun Atlas The World of AthasDocument1 pageDarkSun Atlas The World of AthasMorkizga100% (2)

- Fantasy Bestiary 1Document31 pagesFantasy Bestiary 1MorkizgaNo ratings yet

- Action Check 1Document16 pagesAction Check 1MorkizgaNo ratings yet

- Action Check TransmissionsDocument10 pagesAction Check TransmissionsBenNo ratings yet

- CR3000 Cyberpunk Red - Jumpstart Worldbook (2019)Document53 pagesCR3000 Cyberpunk Red - Jumpstart Worldbook (2019)Rafał Archie Roszkiewicz100% (19)

- Just A Few BaublesDocument65 pagesJust A Few BaublesMorkizgaNo ratings yet

- Book 5, Chapter 5, Part 1: Power Control: Ranks 4, 8, & 12 - Greater Extension: at The IndicatedDocument5 pagesBook 5, Chapter 5, Part 1: Power Control: Ranks 4, 8, & 12 - Greater Extension: at The IndicatedMorkizgaNo ratings yet

- Cinematic Science-Fiction Roleplaying Game Skill-Based Resolution System-No ClassesDocument290 pagesCinematic Science-Fiction Roleplaying Game Skill-Based Resolution System-No ClassesMorkizgaNo ratings yet

- Chemical Engineering Science: T.L. Rodgers, L. Gangolf, C. Vannier, M. Parriaud, M. CookeDocument10 pagesChemical Engineering Science: T.L. Rodgers, L. Gangolf, C. Vannier, M. Parriaud, M. CookeYusrilNo ratings yet

- Day 3 - HW Test Review SOL G.14 Practice 3 - Similar SolidsDocument3 pagesDay 3 - HW Test Review SOL G.14 Practice 3 - Similar SolidsRyan AndersonNo ratings yet

- Cacl 3Document10 pagesCacl 3arthurNo ratings yet

- Soil Water MovementDocument7 pagesSoil Water MovementZohaibShoukatBalochNo ratings yet

- Scalable Formation of Concentrated Monodisperse Lignin Nanoparticles by Recirculation-Enhanced Flash NanoprecipitationDocument10 pagesScalable Formation of Concentrated Monodisperse Lignin Nanoparticles by Recirculation-Enhanced Flash NanoprecipitationFarooq MuhammadNo ratings yet

- Light Emitting Diodes: Figure 1: Schematic Diagram of An LEDDocument9 pagesLight Emitting Diodes: Figure 1: Schematic Diagram of An LEDVikash SingleNo ratings yet

- Greek MathematicsDocument6 pagesGreek MathematicsNeilAngeloFullenteNo ratings yet

- TNPSC: I Prelims Test Plan - 2020Document5 pagesTNPSC: I Prelims Test Plan - 2020s.ranjithNo ratings yet

- The 2020 Magnetism Roadmap: Journal of Physics D: Applied PhysicsDocument45 pagesThe 2020 Magnetism Roadmap: Journal of Physics D: Applied PhysicsFrancisco EstrellaNo ratings yet

- Answer Tutorial 3Document29 pagesAnswer Tutorial 3Sofea IzyanNo ratings yet

- Cambridge International AS & A Level: PHYSICS 9702/42Document24 pagesCambridge International AS & A Level: PHYSICS 9702/42Gulnur KenzheevaNo ratings yet

- Metfloor 60 - Composite Deck Slab Concrete VolumeDocument4 pagesMetfloor 60 - Composite Deck Slab Concrete VolumeHardeo Dennis ChattergoonNo ratings yet

- Hitachi OESDocument2 pagesHitachi OESRahul DubeyNo ratings yet

- 3 6 2-SHMDocument57 pages3 6 2-SHMeren parkNo ratings yet

- Cheat Sheet - ElectromagnetismDocument26 pagesCheat Sheet - Electromagnetismu2100128No ratings yet

- Graphing Secant and Cosecant 1Document26 pagesGraphing Secant and Cosecant 1WilmarieNo ratings yet

- Earth Sci Experiment 1Document9 pagesEarth Sci Experiment 1jnnpctngNo ratings yet

- So You Want To Learn Physics... - Susan FowlerDocument48 pagesSo You Want To Learn Physics... - Susan FowlerYianniNo ratings yet

- AEM 3e Chapter 11Document11 pagesAEM 3e Chapter 11AKIN ERENNo ratings yet

- Reflection, Refraction & Dispersion in a Perspex BlockDocument1 pageReflection, Refraction & Dispersion in a Perspex BlockAditya GhoseNo ratings yet

- Landslides2014 ArticolopubblicatoDocument29 pagesLandslides2014 ArticolopubblicatolozaNo ratings yet

- Laser and MaserDocument10 pagesLaser and MaserDrAnkita V. KushwahaNo ratings yet

- Kruger Optics Catalog 2010Document12 pagesKruger Optics Catalog 2010NickchiosNo ratings yet

- Ansaldo List of Cleaning AgentDocument2 pagesAnsaldo List of Cleaning AgentEDB100% (1)

- Experimental Analysis of E-Glass /epoxy & E-Glass /polyester Composites For Auto Body PanelDocument8 pagesExperimental Analysis of E-Glass /epoxy & E-Glass /polyester Composites For Auto Body PanelmusebladeNo ratings yet

- Astm D523Document5 pagesAstm D523CeliaNo ratings yet

- Cone Penetration Test (CPT) for soil investigationDocument53 pagesCone Penetration Test (CPT) for soil investigationDaanyal Ibn UmarNo ratings yet

- Hypothesis Development: Module I - Topic VDocument12 pagesHypothesis Development: Module I - Topic VLissetteMachadoNo ratings yet

- Design & Development of Diverter Damper With Improved Heat DissipationDocument10 pagesDesign & Development of Diverter Damper With Improved Heat DissipationUGCJOURNAL PUBLICATION100% (1)

- PD 6695 - 2 - 2008Document94 pagesPD 6695 - 2 - 2008William Harrow100% (2)