Professional Documents

Culture Documents

Scaffold Design

Uploaded by

Juwisa Diky P0 ratings0% found this document useful (0 votes)

26 views6 pages1) Scaffolds should be designed to ensure safety during erection, use, and dismantling as required by regulations, which specify that scaffolds must either be designed through calculations or follow a generally recognized standard configuration.

2) Common generally recognized standard configurations include TG20:13 for tube and fitting scaffolds and manufacturer's instructions for system or aluminum scaffolds.

3) If a scaffold cannot fully follow a standard configuration, design advice should be sought, especially if it includes complex non-standard elements, to ensure safety is not compromised. The level of required design input depends on the type and complexity of the scaffold.

Original Description:

Original Title

scaffold-design

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1) Scaffolds should be designed to ensure safety during erection, use, and dismantling as required by regulations, which specify that scaffolds must either be designed through calculations or follow a generally recognized standard configuration.

2) Common generally recognized standard configurations include TG20:13 for tube and fitting scaffolds and manufacturer's instructions for system or aluminum scaffolds.

3) If a scaffold cannot fully follow a standard configuration, design advice should be sought, especially if it includes complex non-standard elements, to ensure safety is not compromised. The level of required design input depends on the type and complexity of the scaffold.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views6 pagesScaffold Design

Uploaded by

Juwisa Diky P1) Scaffolds should be designed to ensure safety during erection, use, and dismantling as required by regulations, which specify that scaffolds must either be designed through calculations or follow a generally recognized standard configuration.

2) Common generally recognized standard configurations include TG20:13 for tube and fitting scaffolds and manufacturer's instructions for system or aluminum scaffolds.

3) If a scaffold cannot fully follow a standard configuration, design advice should be sought, especially if it includes complex non-standard elements, to ensure safety is not compromised. The level of required design input depends on the type and complexity of the scaffold.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

Scaffold Design Edition

02

At the leading edge of height safety

Wallis House, Birchwood Park, Warrington, WA3 6FW

Page 1 of 6

Tel: 0345 6022418 Email: hello@simian-risk.com www.simian-risk.com Rev 1 - 08/17

What if a Scaffold Cannot be Built to a

What is a Generally Recognised Standard Generally Recognised Standard

Configuration? Configuration?

A generally recognised standard In many situations, it is possible to construct

Scaffold Design configuration can be interpreted as being an scaffolding entirely to the most appropriate

Why Should Scaffolds be Designed? authoritative document that specifies how a standard configuration and since the

scaffold should be constructed to ensure that introduction of TG20:13, which significantly

it remains safe throughout erection, use and increased the number of ‘standard’

The Work at Height Regulations 2005 contain

dismantling.

explicit requirements in relation to

scaffolds, the requirement for design input

scaffolding.

There are many different types of generally has decreased. However, in situations where

recognised standard configurations, but the the scaffold is non-complex in configuration

Schedule 3, Part 2 of the Regulations, titled

most commonly known and accepted are: - but contains a smaller complex element,

‘Additional Requirements for Scaffolding’

design advice should be sought to

states, “Strength and stability calculations for

❖ TG20:13 for tube and fitting scaffolding ensure that the complex (or ‘non-standard’)

scaffolding shall be carried out unless: -

❖ Manufacturer’s instructions for system element does not compromise the rest of the

scaffolds structure. It should be noted that TG20’s

a) a note of the calculations, covering the

❖ Manufacturer’s instructions for aluminium eGuide also contains the ability to include

structural arrangements contemplated,

scaffolds ‘add-on’ features that would previously have

is available; or

required design advice.

In short, if a scaffold is constructed in

b) it is assembled in conformity with a

accordance with the most appropriate The level of design input required will vary

generally recognised standard

standard, then it will be legally compliant and depending upon the type of scaffold and the

configuration…”

one of the easiest ways to achieve this is by level of required deviation, but this can often

working to a TG20 compliance sheet which be confirmed quickly and easily by a

This effectively gives those erecting the

can be found within Chapter 3 of TG20’s competent Design Engineer.

scaffold two options: -

Operational Guide or be generated for an

extended scope of structures by the TG20

1. Have the scaffold designed by

eGuide.

calculation, or

2. Construct the scaffold in accordance

with a known standard. (A generally

recognised standard configuration)

At the leading edge of height safety

Wallis House, Birchwood Park, Warrington, WA3 6FW

Page 2 of 6

Tel: 0345 6022418 Email: hello@simian-risk.com www.simian-risk.com Rev 1 - 08/17

There are no hard and fast rules that dictate (see image overleaf) or basic design will not

the level of detail that should be included in a normally be required. However, BS5975:2008

design drawing and in reality, some design (Code of Practice for Temporary Works

drawings are scant on detail and do not Procedures) recommends that design checks be

adequately portray what is required, leaving carried out in greater depth as the complexity of

Scaffold Design Scaffolders to second-guess specific the design increases and this may extend to a full

requirements and defeats the entire design design review for those scaffolds that are highly

It is good practice to ensure that all variations objective. complex in nature.

and their approvals are documented as this

ensures traceability throughout the lifecycle ❖ Engineer’s name The Design Brief

of the scaffold. ❖ Drawing revision status, number and

date In almost all situations, it is important that the

Scaffold Design Calculations ❖ Site address client (or the agency acting on behalf of the client)

❖ Scaffold dimensions, including bay is involved in specifying what is required and this

It should be noted that where there is a legal lengths and lift heights etc is often referred to as a ‘design brief’.

requirement for a ‘scaffold design’, this means ❖ Tie requirements – including tie variety,

that the calculations that prove the integrity tie configuration, frequency and required For non-complex scaffolds, this process is usually

of a scaffold must be provided and does not test loading etc very simple, but for more complex jobs, for

refer to a drawing or sketch. However, it is ❖ Maximum number of ‘working’ lifts example a hanging scaffold supported by an

common practice for Design Engineers to ❖ Leg loads existing structure, this process will become more

supplement their calculations with a design ❖ Couplers to be used involved as the complexity increases and should

drawing as this is a simple way of ❖ Detail of inherent hazardous situations include the provision of all necessary information

communicating their requirements to those during the build relating to design requirements.

tasked with erecting the scaffolding structure

they have designed. It should be noted that Scaffolders generally Handover and Inspection of Scaffolds

prefer 2 dimensional drawings that show plan

What Should a Scaffold Design Drawing views, elevations, sections and details of As with all scaffolds, the completed scaffold must

Look Like & What Detail Should it Contain? complex or important elements. be inspected prior to handover. More information

on handover is available in issue one of The

To ensure the design drawing accurately Design Checking Scaffold Standard.

conveys the Design Engineer’s requirements,

the following detail should be included: - Third party Engineer checks of ‘basic’

scaffolds constructed in accordance with a

TG20:13 compliance sheet

At the leading edge of height safety

Wallis House, Birchwood Park, Warrington, WA3 6FW

Page 3 of 6

Tel: 0345 6022418 Email: hello@simian-risk.com www.simian-risk.com Rev 1 - 08/17

Scaffold Design

Further Reading

HASAWA 1974

The Work at Height Regulations 2005

TG20:13 – A Comprehensive Guide to Good

Practice for Tube & Fitting Scaffolding (NASC)

BS5975:2008 - Code of Practice for

Temporary Works Procedures and the

Permissible Stress Design of Falsework

www.nasc.org.uk

Health & Safety Executive – Scaffold

Checklist

At the leading edge of height safety

Wallis House, Birchwood Park, Warrington, WA3 6FW

Page 4 of 6

Tel: 0345 6022418 Email: hello@simian-risk.com www.simian-risk.com Rev 1 - 08/17

Scaffold Design

At the leading edge of height safety

Wallis House, Birchwood Park, Warrington, WA3 6FW

Page 5 of 6

Tel: 0345 6022418 Email: hello@simian-risk.com www.simian-risk.com Rev 1 - 08/17

Feedback:

Scaffold Design

Briefing Acknowledgement

Name Date Signed

At the leading edge of height safety

Wallis House, Birchwood Park, Warrington, WA3 6FW

Page 6 of 6

Tel: 0345 6022418 Email: hello@simian-risk.com www.simian-risk.com Rev 1 - 08/17

You might also like

- CMOS IC Layout: Concepts, Methodologies, and ToolsFrom EverandCMOS IC Layout: Concepts, Methodologies, and ToolsRating: 4.5 out of 5 stars4.5/5 (3)

- tw18.073 Information Sheet No 4 Final Scaffolding Faqs 26.10.18Document10 pagestw18.073 Information Sheet No 4 Final Scaffolding Faqs 26.10.18Mohamed AdelNo ratings yet

- Industrial Pavement DisputesDocument2 pagesIndustrial Pavement DisputesKristin MunozNo ratings yet

- 1 SS PP 006Document24 pages1 SS PP 006SURAJ PRSADNo ratings yet

- Securing Application Deployment with Obfuscation and Code Signing: How to Create 3 Layers of Protection for .NET Release BuildFrom EverandSecuring Application Deployment with Obfuscation and Code Signing: How to Create 3 Layers of Protection for .NET Release BuildNo ratings yet

- Functional Requirements: 7.3 Timber FrameDocument19 pagesFunctional Requirements: 7.3 Timber FrameLiam DevineNo ratings yet

- Power Systems Engineering and Mathematics: International Series of Monographs in Electrical EngineeringFrom EverandPower Systems Engineering and Mathematics: International Series of Monographs in Electrical EngineeringRating: 3 out of 5 stars3/5 (2)

- Erecting Altering and Dismantling Scaffolding PDFDocument28 pagesErecting Altering and Dismantling Scaffolding PDFHeartyscorpionNo ratings yet

- The Complete Guide to Getting Certified Cisco CCNA 200-301: Complete Your CCNA Exam Training and Preparation with 400 Exam Level Practice QuestionFrom EverandThe Complete Guide to Getting Certified Cisco CCNA 200-301: Complete Your CCNA Exam Training and Preparation with 400 Exam Level Practice QuestionNo ratings yet

- Labc Warranty Technical Manual v8 Low Res PDFDocument374 pagesLabc Warranty Technical Manual v8 Low Res PDFGiannos KastanasNo ratings yet

- Scaffold Specification Template PDFDocument20 pagesScaffold Specification Template PDFDiki FirmansahNo ratings yet

- Guide To Appointing A Scaffolding ContractorDocument20 pagesGuide To Appointing A Scaffolding ContractorMohammed HafizNo ratings yet

- Top 10 Mistakes Made in PT Concrete DesignDocument5 pagesTop 10 Mistakes Made in PT Concrete DesignRodolfo Chua, Jr.No ratings yet

- False Work OshaDocument41 pagesFalse Work OshasuhaemiNo ratings yet

- 3 DesignDocument35 pages3 DesignaliNo ratings yet

- 4 DesignDocument20 pages4 DesignaliNo ratings yet

- 8003 e PDFDocument5 pages8003 e PDFFunny & InformativeNo ratings yet

- Steel ConstructionsDocument23 pagesSteel ConstructionsdanmertzNo ratings yet

- RTT StandardisierungDocument11 pagesRTT StandardisierungSvenNo ratings yet

- Short 56Document1 pageShort 56Suyog BhutawaleNo ratings yet

- GN Guideline 194Document1 pageGN Guideline 194bharat khanalNo ratings yet

- 5DBIM 30oct2020Document108 pages5DBIM 30oct2020ho Po wongNo ratings yet

- Subject: Production & Project Management (Ge)Document48 pagesSubject: Production & Project Management (Ge)sheeladeepakNo ratings yet

- Ground Mount System Overview PDFDocument26 pagesGround Mount System Overview PDFCARLOS ANDRES SARMIENTO CUEVASNo ratings yet

- Design Handbook IRC112Document111 pagesDesign Handbook IRC112zulfekharNo ratings yet

- SMT and Through Hole DFM GuidelinesDocument30 pagesSMT and Through Hole DFM Guidelinessmtdrkd100% (5)

- Basic Two Zone Cisco Gateway To Gatekeeper Configuration.................................................................... 1Document32 pagesBasic Two Zone Cisco Gateway To Gatekeeper Configuration.................................................................... 1api-19663123No ratings yet

- Joints in Steel Construction - Simple Connections - Part 01 PDFDocument4 pagesJoints in Steel Construction - Simple Connections - Part 01 PDFkakem61No ratings yet

- Release Notes SAFEv 2010Document6 pagesRelease Notes SAFEv 2010kheang amgNo ratings yet

- Spec Cold FormedDocument43 pagesSpec Cold Formedfarahazura88% (8)

- Panelization of Light Gage Steel Framing - From Start To FinishDocument2 pagesPanelization of Light Gage Steel Framing - From Start To FinishDaveNo ratings yet

- CWCT TN 021Document8 pagesCWCT TN 021antoineNo ratings yet

- PCI Standard Design PracticeDocument17 pagesPCI Standard Design Practicerodrigo.macedoNo ratings yet

- Esr-4749 From Icc Report 1Document7 pagesEsr-4749 From Icc Report 1api-46442094No ratings yet

- 2006-Post-Tensioning Manual - 6th Edition PDFDocument370 pages2006-Post-Tensioning Manual - 6th Edition PDFArdiaTiaraR93% (14)

- SWD CP 65 99Document66 pagesSWD CP 65 99mcpayodNo ratings yet

- Data Center Design PlaybookDocument224 pagesData Center Design PlaybookAlban DASSI100% (1)

- Rigid Global Buildings Erection and Safety ManualDocument82 pagesRigid Global Buildings Erection and Safety ManualRajanbabuNo ratings yet

- PCE CIRCULAR 202 (R3) DT 29.07.2022Document7 pagesPCE CIRCULAR 202 (R3) DT 29.07.2022Rahul NirbaanNo ratings yet

- Touch Shoring 2Document15 pagesTouch Shoring 2Taztika Audea PutriNo ratings yet

- Paper 118 Guidelines For Prequalification and Design of Post-Installed and Cast-In Anchors in AustraliaDocument11 pagesPaper 118 Guidelines For Prequalification and Design of Post-Installed and Cast-In Anchors in Australiacons2engNo ratings yet

- Formwork Activities in Construction - Sample Site Safety ChecklistDocument7 pagesFormwork Activities in Construction - Sample Site Safety ChecklistatiNo ratings yet

- Concrete Construction ArticleCoping With Formwork SpecificationsDocument5 pagesConcrete Construction ArticleCoping With Formwork SpecificationscrdavalosNo ratings yet

- Az in E: Structural DesignDocument3 pagesAz in E: Structural DesignRafael BorelliNo ratings yet

- Key Features: Business BenefitsDocument1 pageKey Features: Business BenefitsSkr9143 ShivNo ratings yet

- Checklist For DG Set Foundation Design & DrawingDocument3 pagesChecklist For DG Set Foundation Design & DrawingRupesh KhandekarNo ratings yet

- AD 435 - Beams Supporting Precast Planks - Checks in The Temporary Condition, November 2019Document1 pageAD 435 - Beams Supporting Precast Planks - Checks in The Temporary Condition, November 2019symon ellimacNo ratings yet

- Business Applications MinibookDocument40 pagesBusiness Applications Minibooksami abdallaNo ratings yet

- GDS FinalDocument1,317 pagesGDS FinalRachad BachaNo ratings yet

- PCI Standard Design Practice Manual - 2014Document32 pagesPCI Standard Design Practice Manual - 2014rahuljoagNo ratings yet

- Cup Lock ScaffoldingDocument5 pagesCup Lock ScaffoldingSitharamaiah VasireddyNo ratings yet

- 2000 Foliente PBBCSdevelopments FPJDocument11 pages2000 Foliente PBBCSdevelopments FPJ15pwciv4273No ratings yet

- Engineered For Higher-Quality Installation: Simpler Faster BetterDocument24 pagesEngineered For Higher-Quality Installation: Simpler Faster BetterMelrose FabianNo ratings yet

- Gnthroughbolts PDFDocument2 pagesGnthroughbolts PDFChandru MohanNo ratings yet

- The Design of Welding Tooling For Split Console FrameDocument5 pagesThe Design of Welding Tooling For Split Console FrameVaibhav ShahNo ratings yet

- Guideline and Procedure - Docx DPR July 14Document28 pagesGuideline and Procedure - Docx DPR July 14anilNo ratings yet

- 2021 WRI WWR Design Detailing Guide FullDocument269 pages2021 WRI WWR Design Detailing Guide FullSuhas JoshiNo ratings yet

- IEC TR 61241-2-2-1993 ScanDocument24 pagesIEC TR 61241-2-2-1993 ScanJuwisa Diky PNo ratings yet

- List Peralatan InspeksiDocument1 pageList Peralatan InspeksiJuwisa Diky PNo ratings yet

- QC Manual Check ListDocument16 pagesQC Manual Check ListJuwisa Diky PNo ratings yet

- PD 0017 Well Intervention Pressure Control Syllabus Level 2Document54 pagesPD 0017 Well Intervention Pressure Control Syllabus Level 2Juwisa Diky PNo ratings yet

- Lecture 10 - DrillingWellDocument38 pagesLecture 10 - DrillingWellJuwisa Diky PNo ratings yet

- DNVGL Os c301Document54 pagesDNVGL Os c301Juwisa Diky PNo ratings yet

- Service Manual Alisson Transmission PDFDocument368 pagesService Manual Alisson Transmission PDFJuwisa Diky PNo ratings yet

- Ursina CollisionDocument3 pagesUrsina CollisionGilniro JúniorNo ratings yet

- Rohini 24928786475Document12 pagesRohini 24928786475aswinvirat84No ratings yet

- CC Assignments CurrentDocument53 pagesCC Assignments Currentranjeet100% (3)

- APO SNP Training - GlanceDocument78 pagesAPO SNP Training - GlanceAshwani SharmaNo ratings yet

- Experiment 2 Sku 3033Document8 pagesExperiment 2 Sku 3033Luw InNo ratings yet

- Chinese Worksheet SuppliDocument19 pagesChinese Worksheet SuppliEliza LimNo ratings yet

- 200+ TOP RADIOLOGY Online Quiz Questions - Exam Test 2023Document24 pages200+ TOP RADIOLOGY Online Quiz Questions - Exam Test 2023Ayub Alam100% (1)

- Sp3510 User ManualDocument48 pagesSp3510 User Manualchristos1157No ratings yet

- CP System For BulletsDocument37 pagesCP System For BulletsAnonymous TBAzJ8Ejd100% (1)

- Dinah HWDocument6 pagesDinah HWDinah AquinoNo ratings yet

- 2 Megabit (256 K X 8-Bit) CMOS EPROM: Distinctive CharacteristicsDocument12 pages2 Megabit (256 K X 8-Bit) CMOS EPROM: Distinctive CharacteristicsVictor TruccoNo ratings yet

- Testing God: Ron Julian Article Bible StudyDocument8 pagesTesting God: Ron Julian Article Bible StudyapcobarrubiasNo ratings yet

- Inspected by QCP Approval 1-APC 1 - APC 2 - DAR 2 - DAR Al-Handeseh 3 - Negemco 4 - Vendor 5 - Third PartyDocument4 pagesInspected by QCP Approval 1-APC 1 - APC 2 - DAR 2 - DAR Al-Handeseh 3 - Negemco 4 - Vendor 5 - Third PartyAhmad DagamsehNo ratings yet

- Moonshot Beer Summary of Rec 2Document4 pagesMoonshot Beer Summary of Rec 2Hassan AhmadNo ratings yet

- Concrete MixerDocument10 pagesConcrete MixerRafaqat NiaziNo ratings yet

- International M1 2019Document181 pagesInternational M1 2019Stone ZhongNo ratings yet

- Catalogo ComarDocument68 pagesCatalogo ComaralbertoNo ratings yet

- Degree ExercisesDocument3 pagesDegree ExercisesArjit Kapoor100% (1)

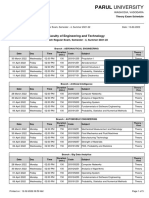

- Parul University: Faculty of Engineering and TechnologyDocument5 pagesParul University: Faculty of Engineering and TechnologySudhanshu SinghNo ratings yet

- Linear RegressionDocument541 pagesLinear Regressionaarthi devNo ratings yet

- Teksas Tone Control MonoDocument17 pagesTeksas Tone Control MonoRhenz TalhaNo ratings yet

- Biodiversiti UnescoDocument9 pagesBiodiversiti UnescoYullyFahmiNo ratings yet

- Electrochemistry Lecture 3 - NotesDocument14 pagesElectrochemistry Lecture 3 - NotesCraftychemistNo ratings yet

- Science - Grade 5 - Test QuestionsDocument6 pagesScience - Grade 5 - Test QuestionsJeric MaribaoNo ratings yet

- Hepatic TB ImagingDocument6 pagesHepatic TB ImagingHesbon MomanyiNo ratings yet

- Astrological Combinations For Job ChangesDocument2 pagesAstrological Combinations For Job ChangesSaravana Kumar100% (2)

- The 8051 Microcontroller and Embedded Systems: Motor Control: Relay, PWM, DC and Stepper MotorsDocument51 pagesThe 8051 Microcontroller and Embedded Systems: Motor Control: Relay, PWM, DC and Stepper MotorsAmAnDeepSingh100% (1)

- I. Objectives: Write The LC Code For EachDocument3 pagesI. Objectives: Write The LC Code For EachNica Joy AlcantaraNo ratings yet

- Foxconn G43M01 PDFDocument41 pagesFoxconn G43M01 PDFEduinMaracuchoFernandezChaparroNo ratings yet

- DP-3510 PartsDocument368 pagesDP-3510 PartsChung KimNo ratings yet