Professional Documents

Culture Documents

Osha Fire Watch

Uploaded by

jonathan cambaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Osha Fire Watch

Uploaded by

jonathan cambaCopyright:

Available Formats

Shipyard

Employment

Fact Sheet

Fire Watch Duties during Hot Work

Hot work has the potential to ignite combustible material that can quickly grow out of control and result

in the injury of workers and loss of property. Shipyard work involving riveting, welding, burning, grinding,

drilling, abrasive blasting, and the use of powder-actuated tools, or similar spark- or fire-producing

operations are considered hot work that can result in fire or explosion. Adequate planning, training

workers, and quick response are necessary measures to prevent fires from advancing beyond the

incipient stage. OSHA’s Fire Protection standard for shipyard employment requires employers to develop

and implement a written fire safety plan (29 CFR 1915.502) and a fire watch policy (29 CFR 1915.504).

What is a fire watch?

A fire watch is the person or persons responsible for continuously 4. Hot work occurs on or near insulation, combustible coatings,

observing hot work activity for the detection of, and response to, or sandwich-type construction that cannot be shielded, cut

fires during hot work operations. A fire watch has the authority to back, or removed, or in a space within a sandwich-type

stop work if necessary and conduct essential steps for restoring construction or inter-barrier space that cannot be inerted.

safe conditions within the hot work area.

5. Combustible materials adjacent to the opposite sides of

The person performing the hot work cannot be the fire watch. That bulkheads, decks, overheads, metal partitions, or sandwich-

worker is concentrating on their own work and will not be able type construction may be ignited by conduction or radiation.

to react quickly enough should a fire ignite. Therefore, another

6. The hot work is close enough to cause ignition through heat

employee or employees must be assigned the fire watch duty.

radiation or conduction on the following:

Similarly, personnel actively engaged as the fire watch cannot

perform other duties. Their focus and only duty is to watch for and • Insulated pipes, bulkheads, decks, partitions, or overheads;

respond to fires that occur during hot work. • Combustible materials and/or coatings; or

• Unprotected combustible pipes or cable runs.

When is a fire watch required?

7. A Marine Chemist, a Coast Guard-authorized person, or a

OSHA requires employers to post a fire watch during hot work if shipyard competent person (SCP), as defined in 29 CFR Part

any of the following conditions are present (1915.504(b)): 1915, Subpart B, requires that a fire watch be posted.

1. Slag, weld splatter, or sparks which might pass through an The number and location of personnel performing fire watch duty

opening and cause a fire. depends on the scope of work. For example, if multiple blind

2. Fire-resistant guards or curtains are not used to prevent the compartments (e.g., areas separated by a bulkhead) are involved in

ignition of combustible materials on or near decks, bulkheads, the hot work operation, a fire watch must be posted simultaneously

partitions, or overheads. in each blind area. Similarly, where hot material from hot work could

spread or fall over more than one level, as in trunks, plenums, cargo

3. Combustible material is located closer than 35 feet to the hot holds, and machinery spaces, a fire watch must be posted at each

work area, in either the horizontal or vertical direction, that affected level, unless positive means are available to prevent the

cannot be removed, protected with flame-proof covers, nor spread or fall of hot material. To ensure an adequate number of fire

otherwise shielded with metal or fire-resistant guards or curtains. watch personnel are posted, some ports or shipyards designate a

U.S. Department of Labor t www.osha.gov t (800) 321-OSHA (6742)

minimum ratio of personnel performing hot work to the number of • Determine if any flammable materials, hazardous processes, or

employees assigned as a fire watch (e.g., one fire watch per every other potential fire hazards are present, or likely to be present in

four workers performing hot work in the same location, assigning the work area where hot work is to take place;

additional fire watches appropriate for the number of workers that • Ensure the appropriate number and location of designated fire

exceed that amount). Employers should also consult with local and watch personnel, extinguishing equipment, and fire protection

state officials prior to performing hot work to determine if there are measures; and

other regional requirements that they must follow. • Maintain communication with fire watch personnel if conditions

change during hot work that could result in or contribute to the

What are the duties and responsibilities of spread of fire.

the employer?

Employers are responsible for protecting all workers from fire What are the duties and responsibilities of

hazards in shipyard employment by: the fire watch?

• Developing and implementing a written Fire Safety Plan; Personnel assigned as fire watch are essential during hot work

• Reviewing the Fire Safety Plan with employees; operations. Their duties begin before the hot work starts and

continue well after the work is complete. Therefore, employees

• Providing outside organizations expected to respond to fires with

assigned fire watch duties must be:

a copy of the Fire Safety Plan;

• Informing all employers on the worksite about the Fire Safety • Trained to detect fires that occur in areas exposed to hot work

Plan, fire-related hazards, and emergency procedures; (29 CFR 1915.504(c)(2)(v);

• Making sure safety and health responsibilities for fire protection • Able to effectively communicate with workers, including alerting

are assigned; personnel when a fire has progressed beyond the incipient

• Establishing designated and non-designated areas for hot work; stage (29 CFR 1915.504(c)(2)(ii) and (vii));

• Maintaining safe conditions that are free from fire hazards, such • Physically capable of performing the physical demands

as unattended fuel gas and oxygen hose lines or torches; and necessary for fire watch duties (29 CFR 1915.504(c)(3)); and

• Training employees in accordance with 29 CFR 1915.508(b), • Aware of their responsibilities as a fire watch (29 CFR

(c), and (e). 1915.504(c) and 1915.508).

Employers must also create and maintain a written fire watch Before and During Hot Work

policy that specifies the requirements for employees performing fire Before hot work begins, communication must be established

watch duties (29 CFR 1915.504). Within that policy, the following between the employee(s) performing hot work and all their fire

items must be detailed: watches. The appropriate fire extinguishing equipment for the

• Fire watch training requirements; conditions of the work (e.g., carbon dioxide, dry chemical, or

• Fire watch duties; water) should be fully charged for prompt use by the fire watch

• Equipment to be used by the fire watch; if needed. It is important that fire watch personnel are informed

by the person(s) performing the hot work, or the supervisor, of

• Personal protective equipment that must be made available and

any restrictions or authorizations related to the hot work activity.

used by the fire watch; and

This should also be documented on the hot work permit, Marine

• Training records. Chemist Certificate, and/or the SCP’s log of inspections and tests.

Unless the area where hot work is to be performed has been Further, fire watch duties are continuous, including during breaks

authorized by a Marine Chemist’s certificate or shipyard competent in hot work activities. If the fire watch needs to leave the hot work

person’s log, as identified at 29 CFR 1915.14, employers are area, the employer must assign a qualified replacement (temporary

responsible for visually inspecting the area before and during hot or permanent).

work to ensure it is free from fire hazards. Employers should consult Stopping Hot Work

NFPA 306 for information on preparation of a vessel for hot work

Fire watches have the responsibility to stop work if any changes

(Part 5) and required safety designations and conditions (Part 7).

occur during hot work that have the potential to result in or

Employers must also maintain those conditions while hot work contribute to the spread of fire (e.g., introduction of flammable/

operations continue. Hot work is only permitted in areas that combustible materials). The fire watch should contact a supervisor,

are free of fire hazards, or that have been controlled by physical superintendent, or the employer’s PAI for instruction on how

isolation, fire watches or other positive means. Employers often best to restore safe conditions. Whenever multiple workers are

designate a permit authorizing individual (PAI) to perform this performing hot work in a designated fire watch area, all hot work

function, which helps: activity must cease until safe conditions are restored. In the event

U.S. Department of Labor t www.osha.gov t (800) 321-OSHA (6742)

of an incipient stage fire, the fire watch must attempt to extinguish For More Information

the fire with the extinguishing equipment available, and within Your nearest OSHA office can provide more information. Also,

their training qualifications. Should the fire watch determine that OSHA’s On-Site Consultation Program offers no-cost and confidential

the fire is beyond the capabilities of the extinguishing equipment, occupational safety and health services to small and medium-sized

they must immediately alert employees in the area and contact the businesses in all states, with priority given to high-hazard worksites.

appropriate emergency response personnel. On-Site consultation services are separate from enforcement

and do not result in penalties or citations. For more information

What are the post-hot work requirements?

or to find the local On-Site Consultation office in your state, visit

After hot work has concluded, the fire watch employees’ job is not www.osha.gov/consultation, or call 1-800-321-OSHA (6742).

finished. Fire watches must continue monitoring the hot work area

for at least 30 minutes after completion of the hot work to ensure Workers’ Rights

nothing ignites. This includes all areas that required additional fire Workers have the right to:

watch personnel (e.g., blind compartments and different levels within

a space). If the employer inspects the hot work area and determines • Working conditions that do not pose a risk of serious harm.

there is no further fire hazard, the fire watch may be released. • Receive information and training (in a language and

vocabulary the worker understands) about workplace

CAUTION: The by-products of hot work, such as sparks, slag,

hazards, methods to prevent them, and the OSHA

or embers, can reach areas that are not easily seen including:

standards that apply to their workplace.

• Openings around pipes extending through decks, overheads, • Review records of work-related injuries and illnesses.

or bulkheads; • File a complaint asking OSHA to inspect their workplace if they

• Concealed spaces with combustible insulation material; believe there is a serious hazard or that their employer is not

• Gaps in fire barriers; following OSHA’s rules. OSHA will keep all identities confidential.

• Equipment with combustible linings; and • Exercise their rights under the law without retaliation, including

• Conveyors. reporting an injury or raising health and safety concerns with

their employer or OSHA. If a worker has been retaliated against

The fire watch period may need to be extended further if the

for using their rights, they must file a complaint with OSHA as

employer determines the fire hazards warrant an extension. NFPA

soon as possible, but no later than 30 days.

51B recommends that following the completion of the established

fire watch time period, fire monitoring is continued within the hot For additional information, see OSHA’s Workers page

work area for up to an additional 3 hours as determined by the PAI. (www.osha.gov/workers).

Additional Resources How to Contact OSHA

• Fire Watch Safety during Hot Work in Shipyards QuickCard™ Under the Occupational Safety and Health Act of 1970,

(OSHA 3494) employers are responsible for providing safe and healthful

• Evaluating Shipyard Competent Person Programs Fact Sheet workplaces for their employees. OSHA’s role is to help

(OSHA 3923) ensure these conditions for America’s workers by setting and

• Understanding Your Role as a Shipyard Competent Person enforcing standards, and providing training, education and

QuickCard™ (OSHA 4138) assistance. For more information, visit www.osha.gov or call

OSHA at 1-800-321-OSHA (6742), TTY 1-877-889-5627.

• OSHA Fire Protection Shipyard Employment eTool

All those involved, including the employer, contractors, PAI, fire

watch, and hot work personnel have the combined responsibility for

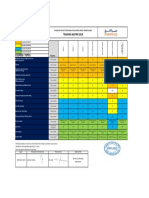

safety during hot work operations. Permits or checklists, such as

the example provided on the next page, can help remind personnel

of potential hazards at the jobsite.

U.S. Department of Labor t www.osha.gov t (800) 321-OSHA (6742)

Example Checklist/Permit

Scope of Work:________________________________________________________________

Date: ___________ Time: Start _______ Stop _______ Post watch end ________

Name: _______________________________________ Phone: __________

In the event of a fire, notify 1) [Contact Name], Phone: [(xxx) xxx-xxxx]

2) [Name of Fire Dept] Phone: 9 1 1 or [(xxx) xxx xxxx]

Type of Hot Work:

Grinding

Welding

Cutting [torch] [air arcing] [plasma]

Affected Spaces: _____________________________________________________________

Spaces inspected for project by Certified Marine Chemist (CMC) and/or Shipyard Competent Person

Piping and equipment removed from service, isolated, locked and/or tagged

Adequate ventilation provided

Other permits completed as required (e.g., Lock-out/tags plus, working at heights, live electrical work)

Location of nearest fire alarm

If no alarm present, determine method that will be used to raise the alarm (List in other precautions area below)

Escape routes maintained clear and known by personnel

Path of likely sparks evaluated

Nearby activities evaluated for conditions that could be affected by hot work

Remove combustible material where possible

Remove coatings in way of hot work (at least 4 inches in every direction)

Remove insulation or lagging from hot work area to prevent the spread of fire

Fire resistive covers and metal shields provided as needed

Combustible materials, dust, lint and oily deposits removed and floor swept clean

Fire watch is provided with suitable extinguishers

Class ABC

Dry Chemical

Carbon Dioxide

Water

Other:______________________________________________________

Fire watch is trained in use of equipment and in sounding alarm

Fire watch has communication with person performing hot work

Fire watch has appropriate personal protective equipment (PPE) (eye protection, respirator,

Other: _________________________)

Fire watch will remain in position for a minimum of 30 minutes after work has ceased, or fire watch is

relieved by employer representative

DSG FS-4188 09/2022

This is one in a series of informational fact sheets highlighting OSHA programs, policies or standards. It does not impose any new compliance

requirements. For a comprehensive list of compliance requirements of OSHA standards or regulations, refer to Title 29 of the Code of Federal

Regulations. This information will be made available to sensory-impaired individuals upon request. The voice phone is (202) 693-1999;

teletypewriter (TTY) number: 1-877-889-5627.

U.S. Department of Labor t www.osha.gov t (800) 321-OSHA (6742)

You might also like

- Acting Fire Wardens Online Final v1Document23 pagesActing Fire Wardens Online Final v1jonathan cambaNo ratings yet

- Safety Fire Watch TrainingDocument55 pagesSafety Fire Watch TrainingAhsan HasanNo ratings yet

- Reverse Parking FOUR A3Document4 pagesReverse Parking FOUR A3jonathan cambaNo ratings yet

- Mandatyory Ppe A3 4XDocument3 pagesMandatyory Ppe A3 4Xjonathan cambaNo ratings yet

- Fire Extinguisher Inspection Tag DLPSDocument1 pageFire Extinguisher Inspection Tag DLPSjonathan camba100% (1)

- Right Tool For The Right Job Topic PDFDocument1 pageRight Tool For The Right Job Topic PDFjonathan cambaNo ratings yet

- Caution Oxygen CylinderDocument1 pageCaution Oxygen Cylinderjonathan cambaNo ratings yet

- Caution Argon GasDocument1 pageCaution Argon Gasjonathan cambaNo ratings yet

- Extranet User Access Request Form (SA 8205-5)Document1 pageExtranet User Access Request Form (SA 8205-5)jonathan cambaNo ratings yet

- SA-9696 Saudi Aramco Computer Use Agreement (Non-Employee Users)Document4 pagesSA-9696 Saudi Aramco Computer Use Agreement (Non-Employee Users)Mrk KhanNo ratings yet

- Caution Acetylene CylinderDocument1 pageCaution Acetylene Cylinderjonathan cambaNo ratings yet

- Laydown Yard ChecklistDocument6 pagesLaydown Yard Checklistjonathan cambaNo ratings yet

- Light Equiment Daily CheckllistDocument2 pagesLight Equiment Daily Checkllistjonathan cambaNo ratings yet

- Smoke Detector Monthly Inspection ChecklistDocument1 pageSmoke Detector Monthly Inspection Checklistjonathan cambaNo ratings yet

- Training Matrix Marafiq JubailDocument1 pageTraining Matrix Marafiq Jubailjonathan cambaNo ratings yet

- Fees Brent Subic Sy2223Document3 pagesFees Brent Subic Sy2223jonathan cambaNo ratings yet

- Take Me Home Country Roads Guitar ChordsDocument1 pageTake Me Home Country Roads Guitar Chordsjonathan cambaNo ratings yet

- List of Saudi Aramco Approved Mark For Power AdaptorDocument1 pageList of Saudi Aramco Approved Mark For Power Adaptorjonathan camba67% (3)

- Site Security PlanDocument14 pagesSite Security Planjonathan camba63% (8)

- Fire Watch Plan For MDCDocument7 pagesFire Watch Plan For MDCjonathan cambaNo ratings yet

- HSE QTN and AnswersDocument22 pagesHSE QTN and AnswersRamana ReddyNo ratings yet

- Hse Action Plan 2019 Marafiq JubailDocument17 pagesHse Action Plan 2019 Marafiq Jubailjonathan camba100% (5)

- Emergency Response Plan - Marafiq Jubail 21Document1 pageEmergency Response Plan - Marafiq Jubail 21jonathan cambaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- PH & TemperatureDocument8 pagesPH & TemperatureNanaNo ratings yet

- Volvo Penta GensetDocument4 pagesVolvo Penta GensetafandybaharuddinNo ratings yet

- Presentation AcetanilideDocument22 pagesPresentation AcetanilideNovitasarii JufriNo ratings yet

- Carinthia Katalog DownloadDocument16 pagesCarinthia Katalog DownloadOperator_010100% (2)

- Theoretical CyclesDocument49 pagesTheoretical CyclesMariaEzzaSyUyNo ratings yet

- 988611457NK448908 Vehicle Scan ReportDocument5 pages988611457NK448908 Vehicle Scan ReportVictor Daniel Piñeros ZubietaNo ratings yet

- W0L0XCF0866101640 (2006 Opel Corsa) PDFDocument7 pagesW0L0XCF0866101640 (2006 Opel Corsa) PDFgianyNo ratings yet

- Discrete Wavelet TransformDocument10 pagesDiscrete Wavelet TransformVigneshInfotechNo ratings yet

- Exercise On Word Formation 2 (Unit 2 - Advanced) : Tran Dai Nghia High School For The GiftedDocument3 pagesExercise On Word Formation 2 (Unit 2 - Advanced) : Tran Dai Nghia High School For The GiftedEveryonehateshiuzo 2.0No ratings yet

- DIVAR IP All-In-One 7000 3U Datasheet 51 en 66297110155Document5 pagesDIVAR IP All-In-One 7000 3U Datasheet 51 en 66297110155Javier RochaNo ratings yet

- 9A02502 Transmission of Electric PowerDocument6 pages9A02502 Transmission of Electric PowersivabharathamurthyNo ratings yet

- Optical Scattering of Gold NanosphereDocument24 pagesOptical Scattering of Gold NanosphereParas KumarNo ratings yet

- Pharmalytica Exhibitor List 2023Document3 pagesPharmalytica Exhibitor List 2023Suchita PoojaryNo ratings yet

- SMAST - 150kW 02190 - 200929091953Document67 pagesSMAST - 150kW 02190 - 200929091953David GarciaNo ratings yet

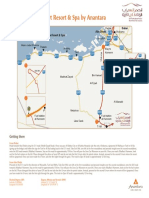

- Qasr Al Sarab Desert Resort Location Map June2012Document1 pageQasr Al Sarab Desert Resort Location Map June2012Anant GârgNo ratings yet

- 331-10 331 Operators Manual enDocument12 pages331-10 331 Operators Manual enYahir VidalNo ratings yet

- Gaffin, Biblical Theology and Westminster StandardsDocument16 pagesGaffin, Biblical Theology and Westminster StandardstheoarticlesNo ratings yet

- Danika Cristoal 18aDocument4 pagesDanika Cristoal 18aapi-462148990No ratings yet

- Petersen Coils Basic 20principle and ApplicationDocument3 pagesPetersen Coils Basic 20principle and ApplicationasotozuazuaNo ratings yet

- 23001864Document15 pages23001864vinodsrawat33.asiNo ratings yet

- Badminton ReviewerDocument10 pagesBadminton ReviewerHailsey WinterNo ratings yet

- Multi Organ Dysfunction SyndromeDocument40 pagesMulti Organ Dysfunction SyndromeDr. Jayesh PatidarNo ratings yet

- Ujian 1 THN 4Document13 pagesUjian 1 THN 4Che Shuk ShukaNo ratings yet

- Indoor Air Quality Standard Procedures - 2014 RevDocument12 pagesIndoor Air Quality Standard Procedures - 2014 RevFioriAmeliaHathawayNo ratings yet

- Chapter 7 Dopant Diffusion - IDocument32 pagesChapter 7 Dopant Diffusion - I강준호No ratings yet

- Line Differential Protection Red670Document8 pagesLine Differential Protection Red670igorsfaceNo ratings yet

- Comparative Study On Serial and Parallel Manipulators - ReviewDocument23 pagesComparative Study On Serial and Parallel Manipulators - ReviewShaik Himam SahebNo ratings yet

- Orbitol Motor TMTHWDocument20 pagesOrbitol Motor TMTHWRodolfo ErenoNo ratings yet

- Manual GA 55 VSD Atlas CompresorDocument114 pagesManual GA 55 VSD Atlas Compresormondaxa_mme50% (4)

- EXAMPLE 8.6 Veneer Grades and RepairsDocument2 pagesEXAMPLE 8.6 Veneer Grades and RepairsnickNo ratings yet