Professional Documents

Culture Documents

BMS Sequence of Operation for AHU and VAV Systems

Uploaded by

mohmmad alam KhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BMS Sequence of Operation for AHU and VAV Systems

Uploaded by

mohmmad alam KhanCopyright:

Available Formats

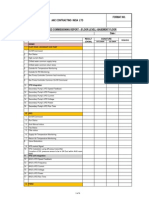

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

SEQUENCE OF OPERATION

FOR

BUILDING MANAGEMENT SYSTEM (BMS)

MEP HSE QA/QC MEP/ CIVIL Const.

Coordinator Manager Manager Coordinator Manager

Reviewed Reviewed Reviewed Approved

Originated by Date Date Date Date Date

by By by by

Sequence of Operation Building Management System (BMS) Rev. 00

Page 1 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

EQUIPMENT SEQUENCE OF OPERATION

1 - AIR HANDLING UNIT – (AHU) WITH VAV

General

Units are direct air type and consists with variable speed supply. They are controlled and

monitored by BMS, fan flow status is monitored by BMS through differential air pressure switch,

fan trip status and Auto (HOA) status through the starter panel/MCC. BMS can operate the unit if

MCC or starter is in Auto mode only hence “Not in Auto mode” alarm is generated in BMS

workstation.

• Chilled water-cooling coil with PICV modulating valve is controlled by BMS according to

the cooling demand.

• BMS regulates heating output of thyristor as per the heating demand, Temperature /

Humidity control

• Filter sections are monitored by BMS through air differential pressure switch across each

filter, i.e., Pre- filters & Bag in return air stream.

• Temperature and Humidity combine sensors are mounted in return air duct and

temperature sensor in supply air duct to monitor temperature and humidity

• Chilled water temperature entering the cooling coil is monitored.

• Fire alarm signal is connected to this AHU starter panel to switch off the fan in case of

fire. Main fire alarm panel is interfaced to BMS and status is update on the DDC though

network.

• Smoke Detector which is fixed in Return air duct (connected to Fire Alarm System), in

case monitors smoke then it will generate an Alarm and fire panel will “STOP” this AHU

immediately as per Fire Cause and Effect Matrix. It will Re-start only after Fire panel is

Resetted OR Alarm is cleared.

Start-up sequence:

The fan enable normally operates as determined by the time schedule or by the operator.

1. When the System Command is ON the following sequence starts:

2. The supply Air Fan is Commanded to start

3. The supply Air VFD is Commanded to start and ramp up gradually, and the fan speed

will be modulated to maintain the static pressure.

Sequence of Operation Building Management System (BMS) Rev. 00

Page 2 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

4. The two-way modulating valve controls the chilled water flow through the coil to

maintain the Return air temperature set point.

The supply fan will be ON if the following conditions are satisfied:

1. The System Command is ‘ON’.

2. HOA switch is in ‘AUTO’.

3. There is no Fire Alarm Signal.

4. Trip Status is ‘NORMAL’.

Shutdown sequence:

The AHU will shut down in case of the following:

1. When the System Command is ‘OFF’ based on the time schedule or by the operator.

2. If there is no flow detected by the Differential Pressure Switch across the Supply Fan.

3. If a Trip Alarm is generated for the Supply Fan.

4. The HOA switch is off.

The AHU will be shut down in the following sequence:

1. The supply fan will stop.

2. The supply air and return air dampers will close.

3. The cooling coil valve will be closed when the supply fan is OFF.

Temperature control:

The AHU return air is maintained at 220C DB (Set point has to be confirmed by Client).

When the supply fan status is “ON” and the Return air temperature is below the set point (i.e., 220C

DB), the cooling valve is modulated towards close position.

When the supply fan status is “ON” and the return air temperature is above the set point, the

cooling valve is modulated towards open position to maintain the return air temperature at the set

point. Cooling valve is controlled using proportional plus integral control loop.

The cooling valve command is interlocked with the supply fan status. When the supply fan status is

off, the cooling valve is driven to closed position (0%open).

Heater control:

Heaters have stages; each stage will be commanded to start depending on the heating

requirement and to regulate the sensed space humidity i.e., if the Return air temperature is below

the Set Point OR the Return air humidity is at or above 65% the heater will get activated.

The heater command will be interlocked with fan run status i.e., heater will be turned “ON” only if

the Fan run status is proven “ON”.

Sequence of Operation Building Management System (BMS) Rev. 00

Page 3 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

VFD Speed control:

The supply fan VFD of AHU will be modulated based on the Differential pressure transmitter

installed at the 2/3rd of the duct riser. Whenever the VAV’s which are installed on the serving zones

are modulated towards opening based on the requirement the differential pressure will reduce and

goes below the setpoint (received from the TAB team) due to which the VFD will be ramped up

and when the VAV’s are modulated towards closing the differential pressure in the duct will

increase going above the setpoint then the VFD will be modulated to ramp down the speed.

Fail to start indication:

Supply Fan ‘Fail to Start’ alarm is raised when there is command sent to start the fan, and there is

no supply fan run status for more than 2 minutes.

Failure during normal operation indication:

An alarm advisory is raised at the BMS workstation when the supply fan fault is ON with complete

equipment tag.

Alarm indication:

An alarm advisory is raised when the air temperature is outside of the set limit. Alarms are raised

immediately when the supply fan trip alarm is detected.

Fire mode:

In case of Fire, an alarm advisory will be raised at the BMS workstation and the Fire Alarm System

will trigger through its control module to turn OFF the AHU and cooling valve will be modulated

towards closed position.

Sequence of Operation Building Management System (BMS) Rev. 00

Page 4 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

VARIABLE AIR VOLUME (VAV)

A- GENERAL

The VAV boxes will be controlling the air flow supplied to the serving area and will be controlled

based on the Zone temperature installed in the serving space.

B- SEQUENCE OF OPERATION

VAV will be interlocked with System Enable.

Once enabled, the temperature control loop shall be enabled.

The air flow rate through the VAV terminal unit shall be modulated via a Proportional plus Integral

control loop, to maintain a constant space temperature of 22°C.

The air flow rate shall be controlled by modulating the damper. The output signal from the velocity

sensor/volume controller shall compensate for variations in system pressure by resetting the position

of the damper through the VAV controller to maintain the required air flow rate. A control algorithm

in the controller shall prevent the air flow rate from exceeding a pre-set range. The upper limit of the

range shall be the V max, the lower limit V min which will be provided the TAB team.

Once there is a demand for heating, the air volume controller shall be set to a fixed volume and the

heater shall be enabled.

Sequence of Operation Building Management System (BMS) Rev. 00

Page 5 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

2 - AIR HANDLING UNIT – (AHU) WITHOUT VAV

General

Units are direct air type and consists with variable speed supply. They are controlled and

monitored by BMS, fan flow status is monitored by BMS through differential air pressure switch,

fan trip status and Auto (HOA) status through the starter panel/MCC. BMS can operate the unit if

MCC or starter is in Auto mode only hence “Not in Auto mode” alarm is generated in BMS

workstation.

• Chilled water-cooling coil with PICV modulating valve is controlled by BMS according to

the cooling demand.

• BMS regulates heating output of thyristor as per the heating demand, Temperature /

Humidity control

• Filter sections are monitored by BMS through air differential pressure switch across each

filter, i.e., Pre- filters & Bag in return air stream.

• Temperature and Humidity combine sensors are mounted in return air duct and

temperature sensor in supply air duct to monitor temperature and humidity

• Chilled water temperature entering the cooling coil is monitored.

• Fire alarm signal is connected to this AHU starter panel to switch off the fan in case of

fire. Main fire alarm panel is interfaced to BMS and status is update on the DDC though

network.

• Smoke Detector which is fixed in Return air duct (connected to Fire Alarm System), in

case monitors smoke then it will generate an Alarm and fire panel will “STOP” this AHU

immediately as per Fire Cause and Effect Matrix. It will Re-start only after Fire panel is

Resetted OR Alarm is cleared.

Start-up sequence:

The fan enable normally operates as determined by the time schedule or by the operator.

1. When the System Command is ON the following sequence starts:

2. The supply Air Fan is Commanded to start

3. The supply Air VFD is Commanded to start and ramp up gradually, depending upon

Supply air temperature set point.

4. The two-way modulating valve controls the chilled water flow through the coil to

maintain the Return air temperature set point.

The supply fan will be ON if the following conditions are satisfied:

1. The System Command is ‘ON’.

2. HOA switch is in ‘AUTO’.

Sequence of Operation Building Management System (BMS) Rev. 00

Page 6 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

3. There is no Fire Alarm Signal.

4. Trip Status is ‘NORMAL’.

Shutdown sequence:

The AHU will shut down in case of the following:

1. When the System Command is ‘OFF’ based on the time schedule or by the operator.

2. If there is no flow detected by the Differential Pressure Switch across the Supply Fan.

3. If a Trip Alarm is generated for the Supply Fan.

4. The HOA switch is off.

The AHU will be shut down in the following sequence:

1. The supply fan will stop.

2. The supply air and return air dampers will close.

3. The cooling coil valve will be closed when the supply fan is OFF.

Temperature control:

The AHU return air is maintained at 220C DB (Set point has to be confirmed by Client).

When the supply fan status is “ON” and the Return air temperature is below the set point (i.e., 220C

DB), the cooling valve is modulated towards close position.

When the supply fan status is “ON” and the return air temperature is above the set point, the

cooling valve is modulated towards open position to maintain the return air temperature at the set

point. Cooling valve is controlled using proportional plus integral control loop.

The cooling valve command is interlocked with the supply fan status. When the supply fan status is

off, the cooling valve is driven to closed position (0%open).

Heater control:

Heaters have stages; each stage will be commanded to start depending on the heating

requirement and to regulate the sensed space humidity i.e., if the Return air temperature is below

the Set Point OR the Return air humidity is at or above 65% the heater will get activated.

The heater command will be interlocked with fan run status i.e., heater will be turned “ON” only if

the Fan run status is proven “ON”.

VFD Speed control:

The supply fan VFD of AHU will be modulated based on the Supply Air temperature setpoint.

Whenever the Supply air temperature goes above the setpoint (190C - adjustable) due to which the

VFD will be ramped up and when the Supply air temperature goes below the setpoint (190C -

adjustable) then the VFD will be modulated to ramp down the speed towards minimum setting and

will continue to run on minimum speed until the Return air temperature rises above the setpoint

again.

VFD is controlled using proportional plus integral control loop.

Sequence of Operation Building Management System (BMS) Rev. 00

Page 7 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

VFD command is interlocked with the supply fan status. When the supply fan status is off, the VFD

is driven to 0% speed.

Fail to start indication:

Supply Fan ‘Fail to Start’ alarm is raised when there is command sent to start the fan, and there is

no supply fan run status for more than 2 minutes.

Failure during normal operation indication:

An alarm advisory is raised at the BMS workstation when the supply fan fault is ON with complete

equipment tag.

Alarm indication:

An alarm advisory is raised when the air temperature is outside of the set limit. Alarms are raised

immediately when the supply fan trip alarm is detected.

Fire mode:

In case of Fire, an alarm advisory will be raised at the BMS workstation and the Fire Alarm System

will trigger through its control module to turn OFF the AHU and cooling valve will be modulated

towards closed position.

Sequence of Operation Building Management System (BMS) Rev. 00

Page 8 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

3- FRESH AIR HANDLING UNIT – (FAHU)

General

Units are direct fresh air type with dedicated supply and exhaust air fan. They are controlled and

monitored by BMS, fan flow status is monitored by BMS through differential pressure switch, fan

trip status and Auto (HOA) status through the starter panel/MCC. BMS can operate the unit if MCC

or starter is in Auto mode only, if “Not in Auto mode” alarm is generated at BMS workstation.

Unit equipped with Heat Recovery Wheel for enhanced energy efficiency and performance. A

standby exhaust fan equipped with motorized damper will be available in case of failure of exhaust

air fan of the FAHU unit.

• Chilled water-cooling coil with PICV modulating valve is controlled by BMS according to

the cooling demand.

• BMS regulates heating output of thyristor as per the heating demand, Temperature /

Humidity control.

• Filter sections are monitored by BMS through air differential pressure switch across each

filter, i.e., Pre- filters & Bag in return air stream.

• Temperature and Humidity combine sensors are mounted in return air duct and

temperature sensor in supply air duct to monitor temperature and humidity.

• Chilled water temperature entering the cooling coil is monitored.

• Extract air temperature and Ambient air temperature is monitored by BMS.

• Extract air damper is controlled and monitored by BMS.

• Outside Air Damper is controlled and monitored by BMS.

• Temperature before and after energy recovery wheel is monitored by BMS.

• Fire alarm signal is connected to starter panel to switch off the fan in case of fire. Main

fire alarm panel is interfaced to BMS and status is update on the DDC though network

• Smoke Detector which is fixed in Return air duct (connected to Fire Alarm System), in

case monitors smoke then it will generate an Alarm and fire panel will “STOP” this AHU

immediately as per Fire Cause and Effect Matrix. It will Re-start only after Fire panel is

Resetted OR Alarm is cleared.

Start-up sequence:

The fan enable normally operates as determined by the time schedule or by the operator.

When the System Command is ON the following sequence starts:

1. Motorized dampers at the Supply, Return and Fresh Air duct will be commanded ON.

Sequence of Operation Building Management System (BMS) Rev. 00

Page 9 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

2. Upon proof of opening of dampers, the Supply Air Fan & Extract Air Fan is Commanded

to start. Extract Air fan will be interlocked with Supply Fan i.e., Extract will be turned

“ON” only if Supply fan is in “ON” condition.

3. Heat Recovery wheel will be electrically interlocked with Extract fan i.e., the HRW will

be commanded ON along with Extract Air fan.

4. The two-way modulating valve controls the chilled water flow through the coil to

maintain the Supply air temperature set point.

The Supply fan will be ON if the following conditions are satisfied:

1. The System Command is ‘ON’.

2. HOA switch is in ‘AUTO’.

3. There is no Fire Alarm Signal.

4. Trip Status is ‘NORMAL’.

The Extract fan will be ON if the following conditions are satisfied:

1. The System Command is ‘ON’.

2. Supply Fan is “ON”

3. HOA switch is in ‘AUTO’.

4. There is no Fire Alarm Signal.

5. Trip Status is ‘NORMAL’.

Shutdown sequence:

The FAHU will shut down in case of the following:

1. When the System Command is commanded ‘OFF’ based on the time schedule or by

the operator.

2. If there is no flow detected by the Differential Pressure Switch across the Supply Fan.

3. If a Trip Alarm is generated for the Supply Fan.

4. The HOA switch is off.

The FAHU will be shut down in the following sequence:

1. The supply fan will stop.

2. Extract fan will stop.

3. The supply air, return air & Outside air dampers will close.

4. The cooling coil valve will be closed when the supply fan is OFF.

Temperature control:

The FAHU return air is maintained at 220C DB (Set point has to be confirmed by Client).

When the supply fan status is “ON” and the return air temperature is above the set point, the

cooling valve is modulated towards open position to maintain the return air temperature at the set

point. Cooling valve is controlled using proportional plus integral control loop.

When the Return air temperature is below the setpoint, the cooling valve will be modulated towards

minimum opening (provided by the HVAC team/consultant).

Sequence of Operation Building Management System (BMS) Rev. 00

Page 10 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

Once the Return air temperature setpoint is achieved the cooling valve will be locked on the

minimum opening setting and heater shall be activated in order to maintain the setpoint and to

provide continuous treated fresh air to the building.

The cooling valve command is interlocked with the supply fan status. When the supply fan status is

“OFF”, the cooling valve is driven closed position (0%open).

Heaters have stages; each stage will be commanded to start depending on the heating

requirement and to regulate the sensed space humidity i.e., if the Return air temperature is below

the Set Point OR the Return air humidity is at or above 65% the heater will get activated.

The heater command will be interlocked with fan run status i.e., heater will be turned “ON” only if

the Fan run status is proven “ON”.

VFD Speed control:

The supply fan VFD of AHU will be modulated based on the Supply Air temperature setpoint.

Whenever the Supply air temperature goes above the setpoint (190C - adjustable) due to which the

VFD will be ramped up and when the Supply air temperature goes below the setpoint (190C -

adjustable) then the VFD will be modulated to ramp down the speed towards minimum setting and

will continue to run on minimum speed until the Return air temperature rises above the setpoint

again.

Exhaust fan VFD will be slave to the Supply fan VFD i.e., it will follow the same frequency (speed)

as that of Supply fan.

VFD is controlled using proportional plus integral control loop.

VFD command is interlocked with the supply fan status. When the supply fan status is off, the VFD

is driven to 0% speed.

Heat Recovery Wheel

Heat recovery wheel will be electrically interlocked with the Supply / Exhaust Fan command i.e., it

will turn ON when the Supply / Exhaust Fan is turned ON.

Standby Exhaust Fan

In case of failure of exhaust air fan of the FAHU unit, the standby exhaust unit will be activated,

which will first open the associated motorized damper and upon proof of open status of the

damper, the exhaust fan will be started. Once the main exhaust fan is back to normal condition, the

standby exhaust fan will stop and the main exhaust fan will start to run.

Sequence of Operation Building Management System (BMS) Rev. 00

Page 11 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

Fail to start indication:

Supply Fan ‘Fail to Start’ alarm is raised when there is command sent to start the fan, and there is

no supply fan run status for more than 2 minutes.

Failure during normal operation indication:

An alarm advisory is raised at the BMS workstation when the supply fan fault is ON with complete

equipment tag.

Alarm indication:

An alarm advisory is raised when the air temperature is outside of the set limit. Alarms are raised

immediately when the supply fan trip alarm is detected.

Fire mode:

In case of Fire, an alarm advisory will be raised at the BMS workstation and the Fire Alarm System

will trigger through its control module to turn OFF the Supply and Extract fans of FAHU and cooling

valve will be modulated towards closed position.

Run hours:

The supply fan status is totalized to display the total run hours (RUN-HRS) of the equipment.

Sequence of Operation Building Management System (BMS) Rev. 00

Page 12 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

4- BASEMENT SMOKE EXTRACT SYSTEM

A- SYSTEM DESCRIPTION

Basement Smoke extract system consist of below listed equipment which will operate based on

CO level, time scheduling and in Fire mode.

Each Basement floor have dedicated set of Smoke Extract, Car Park Jet / Induction fans & Fresh

Air fan as mentioned in the below table and will be operated accordingly.

BASEMENT-1 QTY BASEMENT-2 QTY

EQUIPMENT NAME

NOS. NOS.

SMOKE EXTRACT FANS 4 4

CAR PARK JET / INDUCTION FANS 8 8

FRESH AIR FANS 4 4

B- SEQUENCE OF OPERATION

SCHEDULED CONTROLLING

All the Fans will be interlocked with System Enable, HAND-OFF-AUTO and Trip Status. Whenever

all the Fans are in Auto mode, Trip Status is Normal, System enable point is enabled and as per

Scheduling the Fans will run after every 2 hours (adjustable) at low speed i.e., Jet Fans will run at

Low speed and Smoke Extract / Fresh air fans will run at minimum speed 30Hz (adjustable).

CONTROLLING BASED ON CO LEVEL

Since the controlling of complete system need to be done based on CO level in each parking floor,

hence average of all the CO sensors in each parking floor will be the reference for controlling the

fans operation.

Considering all the interlock (mentioned in the scheduled operation) are satisfied and based on

average reading of 4 nos. of CO sensors in one zone (tower) on one floor the system will operate

in following sequence:

1. When the average reading of 4 nos. of CO sensors in one zone (tower) on one floor is

above the setpoint i.e., 25ppm (adjustable) then the Smoke extract fans and Fresh Air fan

serving that particular floor will start to run on minimum speed i.e., 30Hz (adjustable) and

Jet fan will start running on Low speed.

2. The VFD’s on Smoke extract fans and Fresh air fans will be modulated through

proportional and integral (PI) control loop

Sequence of Operation Building Management System (BMS) Rev. 00

Page 13 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

3. After a certain duration of Smoke extract, Fresh Air and Jet fan running, if the average CO

reading is still above setpoint i.e., 25ppm (adjustable), and continues to increase and

reaches 30ppm or more then the PI control loop will modulate the VFD’s of Smoke extract

and Fresh Air fans and ramp up to the speed of 40Hz and Jet Fans will continue to run on

Low speed.

4. Once the average of 4 nos. of CO level is controlled and is below the allowed setpoint i.e.,

20ppm, the Smoke Extract Fans and Fresh Air fans will modulate towards minimum speed

ultimately stopping the Fans and in conjunction to it Jet Fans will also stop running.

5. In this complete operation the Jet Fan will run on Low speed and will run in high speed in

case of Fire only.

FIRE MODE

In case of fire, all above mentioned controlling scheme will be overridden and the system will run at

full/maximum speed. The override action will be done by providing a trigger from Fire Alarm

system control module to the override contactor of each MCC panel. There will be no control from

BMS in case of Fire.

C- ALARM INDICATIONS

An alarm advisory is raised when any of the following event occurs.

1. Fan “HAND-OFF-AUTO” switch is in Auto mode and Fan DPS is not active after initial

waiting period (60 sec) of Fan command, then a “No Air flow” alarm shall be initiated at

BMS workstation.

2. Fan is Tripped.

3. Average of 4 nos. of CO level is above the allowed CO level setpoint.

5- DUCTED INLINE EXHAUST FAN

A- GENERAL

The fan operation is generally a continuous operation.

Sequence of Operation Building Management System (BMS) Rev. 00

Page 14 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

B- SEQUENCE OF OPERATION

NORMAL MODE

The exhaust air fan is twin motor fan it will be set from the BMS duty and standby. The fan shall start

and stop either locally at the MCC via the “HAND-OFF-AUTO” switch, for testing purposes, or

remotely from the BMS when the “HAND-OFF-AUTO” switch is on the AUTO Position.

When Enable command is generated from the BMS Station according to the time schedule

configured the motorized damper will be commanded to Open and upon proof of open status the

Fan will be commanded to turn “ON”.

FIRE MODE

In case of fire, above mentioned controlling scheme will be overridden and the system will run at

maximum speed. The override action will be done by providing a trigger from Fire Alarm system

control module to the MCC panel. There will be no control from BMS in case of Fire.

C- ALARM INDICATION

Alarm will be raised at the BMS workstation for the following event:

- Fan HOA switch is in Hand position

- Fan is tripped.

- When No Flow is detected by the DPS across the Fan after 30 sec. (adjustable) of “ON”

command to the Fan.

Sequence of Operation Building Management System (BMS) Rev. 00

Page 15 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

6- KITCHEN EXHAUST FAN (KEF)

A- GENERAL

The fan operation is generally a continuous operation.

B- SEQUENCE OF OPERATION

NORMAL MODE

The fan shall start and stop either locally at the Auto Changeover panel via the “HAND-OFF-AUTO”

switch, for testing purposes, or remotely from the BMS when the “HAND-OFF-AUTO” switch is on

the AUTO Position.

When Enable command is generated from the BMS Station according to the time schedule

configured the motorized damper will be commanded to Open and upon proof of open status the

Fan will be commanded to turn “ON”.

FIRE MODE

In case of fire, above mentioned controlling scheme will be overridden and the system will be

controlled by Fire Alarm system. The override action will be done by providing a trigger from Fire

Alarm system control module to the Auto Changeover panel. There will be no control from BMS in

case of Fire.

C- ALARM INDICATION

Alarm will be raised at the BMS workstation for the following event:

- Fan HOA switch is in Hand position

- Fan is tripped.

- When No Flow is detected by the DPS across the Fan after 30 sec. (adjustable) of “ON”

command to the Fan.

Sequence of Operation Building Management System (BMS) Rev. 00

Page 16 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

7- STAIRCASE PRESSURIZATION FAN (SPF)

A- GENERAL

These Fans will run for Pressurizing the stairwell in case of fire only.

B- SEQUENCE OF OPERATION

Staircase pressurization fans and its respective MVCD’s will operate only in case of fire; hence the

ON/OFF control will be done by Fire Alarm System through a trigger from control module to the

Starter control panel and dampers will be controlled through an interlock in the Starter control panel

itself.

Upon confirmation of Air flow status and Dampers opening status monitored by BMS and based on

the pressure sensor which will be monitoring the pressure in the stairwell, the VFD speed command

will be modulated by BMS to maintain a pressure of 45 to 55Pa (adjustable) in the stair well.

The VFD’s will be modulated through proportional and integral (PI) control loop.

If the pressure in the stairwell exceeds 55Pa then PI control loop will modulate the VFD’s of

Pressurization Fans to ramp down the speed and if the pressure falls below 45Pa then VFD’s will

be modulated to ramp up the speed.

Once the fire signal is reset, the VFD will be modulated towards 0Hz gradually and starter control

panel will turn OFF the fans and will close the dampers as well.

C-ALARM INDICATIONS

Alarm will be raised at the BMS work station for the following events:

- Air flow status

- MVCD’s open status

Sequence of Operation Building Management System (BMS) Rev. 00

Page 17 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

8- LIFT PRESSURIZATION FAN (LPF)

A- GENERAL

These Fans will run for Pressurizing the lift well in case of fire only.

B- SEQUENCE OF OPERATION

Lift pressurization fans and its respective MVCD’s will operate only in case of fire; hence the ON/OFF

control will be done by Fire Alarm System through a trigger from control module to the Starter control

panel and dampers will be controlled through an interlock in the Starter control panel itself.

Upon confirmation of Air flow status and Dampers opening status monitored by BMS and based on

the pressure sensor which will be monitoring the pressure in the Lift well, the VFD speed command

will be modulated by BMS to maintain a pressure of 25 to 40Pa (adjustable) in the stair well.

The VFD’s will be modulated through proportional and integral (PI) control loop.

If the pressure in the lift well exceeds 40Pa then PI control loop will modulate the VFD’s of

Pressurization Fans to ramp down the speed and if the pressure falls below 25Pa then VFD’s will

be modulated to ramp up the speed.

Once the fire signal is reset, the VFD will be modulated towards 0Hz gradually and starter control

panel will turn OFF the fans and will close the dampers as well.

C-ALARM INDICATIONS

Alarm will be raised at the BMS work station for the following events:

- Air flow status

- MVCD’s open status

Sequence of Operation Building Management System (BMS) Rev. 00

Page 18 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

9- FAN COIL UNIT (FCU) – FOR COMMON AREA

A- GENERAL

FCU (Fan Coil Unit) serving the common area is equipped with Fan and Cooling Coil with motorized

valve actuator. Zone temperature monitored and controlled by modulating cooling valve actuator.

FCU is controlled by dedicated thermostat which is connected to a controller and the same will be

communicating to the BMS workstation through an automation server.

B- SEQUENCE OF OPERATION:

FCU fan is turned “ON” once the command is given from the thermostat. The speed of the fan will

vary depending on the demand.

Filter sections are monitored by BMS through Air differential pressure switch across filter.

Cooling valve will be modulated to control the space temperature. When the space temperature is

above the set point, then cooling valve will be modulated towards open position. When the space

temperature is below the set point, the cooling valve is modulated towards close position and

accordingly Fan speed will be varied.

C-ALARM INDICATION

Alarm will be raised at the BMS workstation when following events are occurred:

- Filter status is blocked

- Space temperature is above OR below setpoint.

Sequence of Operation Building Management System (BMS) Rev. 00

Page 19 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

10- PLATE TYPE HEAT EXCHANGER

A-GENERAL

Two sets of Plate type heat exchanger shall be installed in basement-2 ETS room of which primary

side will be connected to the district cooling plant (by others) and the secondary side will be

connected to the secondary pumps which will supply the required chilled water to the terminal units

in both the towers.

Each Heat exchanger will be equipped with Inlet/Outlet temperature on the secondary side,

Differential pressure transducer at the index circuit and PICV valve on the Bypass line.

B- BYPASS VALVE CONTROL

The PICV valve installed on the bypass line will operate based on inlet temperature on secondary

side of heat exchanger. If the inlet temperature is less than setpoint i.e., 14.5℃ (adjustable) then

PICV valve on the bypass will be modulated towards opening by the proportional and integral

control loop and will continue to open until the set temperature is more than 14.5℃.

If the inlet temperature at the secondary side increases more than setpoint i.e., 14.5℃ (adjustable)

then PICV will modulate towards closing and gradually it will be completely closed.

C- ALARM INDICATIONS

Alarm will be raised at the BMS workstation for the following events:

- Inlet Temperature of heat exchanger on secondary side is less than 9℃ (adjustable) OR

higher than 16.5℃ (adjustable).

D- INTERFACE WITH DISTRICT COOLING PLANT

Points which are available from the point list attached will be shared to the BBU PLC, through

BACnet/IP from the BMS.

Sequence of Operation Building Management System (BMS) Rev. 00

Page 20 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

11- SECONDARY CHILLED WATER PUMPS

A-GENERAL

Secondary Chilled water system will consist of 3nos. of Variable speed pumps (2 Duty + 1 Standby

/ Assist) serving the chilled water to two towers i.e., Tower-A & Tower-B. The chilled water riser of

both the towers will be equipped with Differential Pressure Transmitter which will be installed at the

2/3rd length of each riser i.e., in Tower-A DPT shall be installed at Level-10 and in Tower-B DPT

shall be installed at Level-6.

B- SEQUENCE OF OPERATION

All the Pumps will be interlocked with System Enable, HAND-OFF-AUTO and Trip Status. When all

the pumps are in Auto mode, Trip Status is Normal, System enable point is enabled, pumps are

ready to start.

Pumps will operate in 2 duty and 1 Standby / Assist combination. Also, whenever any of the duty

pump fails to operate or is tripped then the standby pump will take over and will continue the

operation and an alarm will be raised at the BMS workstation.

Since we have two differential pressure sensors on both the risers, amongst the two sensors,

whichever is reading the least value will be considered as reference for modulating the speed of

the pumps and will be operated in following sequence.

1. In addition to the above-mentioned interlock, whenever the reading on any of the two

differential pressure sensors installed is less than the desired setpoint (to be provided by

the TAB team) then the VFD will start to modulate, ramping up the speed of the Duty pump-

1 gradually towards 100%. The VFD will be modulated by Proportional and Integral (PI)

control loop module.

2. When the chilled water valve on each AHU/FCU start to open due to increasing load, the

differential pressure sensor shall send a signal to the BMS, which in turn shall control the

VFD on the CHW pumps to maintain the set differential pressure in the line, thus increasing

the CHW flow in the circuit.

3. When the differential pressure setpoint is not achieved by ramping up the VFD speed of

Duty Pump-1 to maximum allowed speed (to be received from the pump manufacturer),

then after a certain time delay its speed shall be ramped down gradually to the minimum

speed (to be received from the pump manufacturer) and then the Duty pump-2 will be

introduced and both the pumps will further be ramped up in synchronization in order to

achieve the desired differential pressure setpoint.

4. Once the desired setpoint is achieved then both the pump’s speed shall start reducing

gradually until it reaches to minimum speed (to be received from the pump manufacturer)

eventually stopping one pump after defined time delay and the differential pressure shall be

maintained by one pump.

Sequence of Operation Building Management System (BMS) Rev. 00

Page 21 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

5. In the event of minimum load in both the towers, only one pump will run at minimum speed

maintaining the chilled water circulation in the circuit and in the event of full load, the 2 duty

pumps shall operate and will be sequenced in such a way that each duty pump will be

rotated weekly and will be replaced by standby pumps.

C- ALARM INDICATIONS

Alarm will be raised at the BMS workstation for the following events:

- Any pump is tripped.

- Standby pump is turned ON.

- Differential pressure is less than setpoint.

- HOA switch is in Hand position.

- In the event of no flow on the pump, when command is “ON”

12- PRESSURIZATION UNIT

Pressurization unit shall have its control panel connected to the BMS to indicate its operation. It will

monitor pump health, common fault alarm, pressure alarm and HOA status.

A Graphical representation of the plant will be produced to indicate the status and alarms.

Sequence of Operation Building Management System (BMS) Rev. 00

Page 22 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

13- DOMESTIC WATER TRANSFER PUMPS

Transfer Pumps will be controlled by its own control panel and will be monitored only at the BMS for

Run and trip status of each pump through hardwired connection from DDC panel to Pump control

panel.

A Graphical representation of the plant will be produced to indicate the status and alarms.

14- IRRIGATION WATER PUMP SET

Irrigation Pumps will be controlled by its own control panel and will be monitored only at the BMS for

Run and trip status of each pump through hardwired connection from DDC panel to Pump control

panel.

A Graphical representation of the plant will be produced to indicate the status and alarms.

15- LIFTING/SUMP PUMP

Sump Pumps will be controlled by its own control panel and will be monitored only at the BMS for

Run and trip status of each pump and Sump Low-level & High-level alarm, through hardwired

connection from DDC panel to Pump control panel.

A Graphical representation of the plant will be produced to indicate the status and alarms.

16- FIRE PUMPS

Firefighting Pumps will run only in case and that too will be controlled by its own control panel and

will be monitored only at the BMS for Run and trip status of each pump through hardwired

connection from DDC panel to Pump control panel.

A Graphical representation of the plant will be produced to indicate the status and alarms.

17- BOOSTER PUMP

Booster Pumps will be controlled by its own control panel and will be monitored only at the BMS for

Run and trip status of each pump through hardwired connection from DDC panel to Pump control

panel.

A Graphical representation of the plant will be produced to indicate the status and alarms.

Sequence of Operation Building Management System (BMS) Rev. 00

Page 23 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

18- DOMESTIC WATER CIRCULATION PUMP SET

Domestic Water Circulation Pumps will be controlled by its own control panel and will be monitored

only at the BMS for Run and trip status of each pump through hardwired connection from DDC

panel to Pump control panel.

A Graphical representation of the plant will be produced to indicate the status and alarms.

19- HOT WATER CIRCULATION PUMP SET

Hot Water Circulation Pumps will be controlled by its own control panel and will be monitored only

at the BMS for Run and trip status of each pump through hardwired connection from DDC panel to

Pump control panel.

A Graphical representation of the plant will be produced to indicate the status and alarms.

20- WATER TANKS

Water Level in tank shall be monitor through Level switch. A Hooter and Audio-visual unit shall be

connected through control panel. When Level switch indicated High level then control panel shall

trigger the Hooter NO/NC switch position from NO to NC, and Hooter and Audio alarm shall have

triggered. Once the Tank Level comes to normal state, the NC point shall toggle to NO position

and Hooter and Audio alarm shall settle to normal.

21- WATER SOFTENER

Water Softener will be controlled by its own control panel and will be monitored only at the BMS for

Hand/Auto, Run and trip status of the system and Level Status, through hardwired connection

from DDC panel to Water Softener control panel.

A Graphical representation of the plant will be produced to indicate the status and alarms.

Sequence of Operation Building Management System (BMS) Rev. 00

Page 24 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

22- POOL WATER HEAT EXCHANGER

Primary and secondary side inlet and outlet of the heat exchanger will be equipped with the

immersion temperature sensor and a DPT will be installed at the index on the secondary side

which will be connected to a DDC through which it will be monitored at the BMS.

The PICV at the outlet of the heat exchanger will be open OR close based on temperature setpoint

of the heat exchanger outlet temperature and will serve as isolation for inlet of the pool.

A Graphical representation of the plant will be produced to indicate the status and alarms.

23- POOL FILTRATION PUMP

Pool Filtration Pump will be controlled by its own control panel and will be monitored only at the BMS

for Panel Live, Run and trip status of each pump through hardwired connection from DDC panel

to Pump control panel and pressure will be monitored at the header of the pump set through an in-

line pressure sensor which will be connected to the DDC.

Also, DPS will be installed across the filter to monitor the filter status which will be connected to

DDC.

A Graphical representation of the plant will be produced to indicate the status and alarms.

24- OIL INTERCEPTOR

Oil interceptor panel will provide volt free contact for the Tank level status and the Tank overflow

status which will be monitored at the BMS.

A Graphical representation of the system will be produced to indicate the status and alarms.

25- GARBAGE ROOM ODOR CONTROL UNIT

The GROC Fan Run, Trip status and VOC level through VOC sensor will be monitored by the BMS

and Necessary alarms will be initiated accordingly.

A Graphical representation of the system will be produced to indicate the status and alarms

26- GARBAGE ROOM DX REFRIGERANT UNIT

The Garbage room DX Unit will be monitored for Run Status, Trip Status and Room temperature

via a Room temperature sensor.

A hooter will be used for annunciating the alarm for temperature monitored by BMS.

A Graphical representation of the system will be produced to indicate the status and alarms

Sequence of Operation Building Management System (BMS) Rev. 00

Page 25 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

27- GARBAGE CHUTE PANEL

Garbage Chute will be controlled by its own control panel and will be monitored only at the BMS for

Panel Live, Run and trip status through hardwired connection from DDC panel to control panel.

A Graphical representation of the plant will be produced to indicate the status and alarms.

28- ELECTRIC WATER HEATER

The following points pertinent to the Electric water heater will be monitored by the BMS and

Necessary alarms will be initiated accordingly:

-INLET/OUTLET CHW Temperature shall be monitored through Immersion temperature sensor.

-EWH run/trip status shall be monitored through volt free contact in the unit respective panel.

A Graphical representation of the plant will be produced to indicate the status and alarms.

29- WATER LEAK DETECTION SYSTEM

The BMS shall monitor the following signals from water leak detection system through the

Voltage free contacts from WLD.

- Panel Live status

- Panel Alarm signal

30- FIRE ALARM SYSTEM

The BMS shall monitor the following signals from FAS through the Voltage free contacts.

-Common fault alarm.

-Alarm status.

In addition to above the Fire Alarm system will be monitored at the BMS via. BACnet/IP

protocol.

31- LIGHTING CONTROL SYSTEM

Lighting control system critical points will be monitored at BMS via. BACnet/IP protocol.

32- UPS

The BMS shall monitor the following signals from UPS through the Voltage free contacts.

-Common fault alarm.

-Battery fault.

-Bypass mode

Sequence of Operation Building Management System (BMS) Rev. 00

Page 26 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

-Data monitoring

33- CCU SERVER

The BMS shall monitor the following signals from CCU through the Voltage free contact.

-CCU ON/OFF Status.

34- LIFT

The BMS shall monitor the following signals from Lift unit through the Voltage free contacts.

-Lift Run Status.

-Common fault alarm.

35- CBS

The BMS shall monitor the following signals from CBS system through the Voltage free

contacts.

-Common fault alarm.

-Mains Fault.

36- GENERATOR

The BMS shall monitor the following signals from the Diesel Generator through the Voltage

Free contacts by Generator supplier.

-Generator Breaker on/off status.

-Generator common fault alarm.

-Generator battery charger trouble alarm.

-Generator fails to start.

-Generator fuel level alarm.

37- CAPACITOR BANK

The BMS shall monitor the following signals from CB system through the Voltage free

contacts.

-Common fault alarm.

38- ATS LV ROOM

The BMS shall monitor the following signals from the ATS LV Room through the Voltage

Sequence of Operation Building Management System (BMS) Rev. 00

Page 27 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

Free contacts by ATS supplier.

-Duty Selector switch Monitoring (HOA)

-Generator Breaker on/off status.

-Generator TV IP Status.

-Main Breaker ON/OFF status.

- Main Breaker TV IP Status.

-Battery charger status.

39- EMP

The BMS shall monitor the following signals from the EMP Panel through the Voltage

Free contacts.

-EMP panel on/off status.

-EMP panel trip Status.

40- SOFT-INTEGRATION

40.1- BTU METER SOFT-INTEGRATION (via. M-BUS)

BTU meter shall be mapped to the billing software through a converter from which the consumption

report for each meter can be monitored and bills can be generated for each tenant.

40.2- COLD WATER METER SOFT-INTEGRATION (via. M-BUS)

Cold water meter shall be mapped to the billing software through a converter from which the

consumption report for each meter can be monitored and bills can be generated for each tenant.

40.3- HOT WATER METER SOFT-INTEGRATION (via. M-BUS)

Cold water meter shall be mapped to the billing software through a converter from which the

consumption report for each meter can be monitored and bills can be generated for each tenant.

40.4- KWH METER SOFT-INTEGRATION (via. MODBUS RTU)

KWH meter shall be monitored at the BMS via. Modbus protocol. All the meters will be monitored

for different parameters which are received at the BMS server from each meter.

40.5- ZCV SOFT-INTEGRATION (via. BACNET/IP)

ZCV shall be monitored at the BMS via. Fire Alarm system to which it will be connected directly

through hardwired connection. Fire Alarm system shall share the data to BMS via. BACnet/IP

protocol.

Sequence of Operation Building Management System (BMS) Rev. 00

Page 28 of 29

Dev Manager/ Client Rep: Lead Consultant Main Contractor MEP contractor: BMS Sub Contractor:

40.6- CCU SEVER (via. BACNET/IP)

CCU Server shall be monitored at the BMS server through BACnet/IP protocol. Critical parameters

of each CCU will be monitored at the BMS.

40.7- SECURITY SYSTEM (via. BACNET/IP)

Security System shall be monitored at the BMS server through BACnet/IP protocol. Critical

parameters of each CCU will be monitored at the BMS.

40.8- LIGHTING CONTROL SYSTEM (via. BACNET/IP)

Lighting control system shall be monitored at the BMS server through BACnet/IP protocol.Critical

parameters of each CCU will be monitored at the BMS.

Sequence of Operation Building Management System (BMS) Rev. 00

Page 29 of 29

You might also like

- Chiller Operating SequenceDocument3 pagesChiller Operating Sequencejomy_pj8106No ratings yet

- Sequence of Operation ChillerDocument2 pagesSequence of Operation ChillerOoi Tze Hoong50% (4)

- Sequence of Operation For Floor Mounted AHUDocument1 pageSequence of Operation For Floor Mounted AHUaneesh88No ratings yet

- Sequence of OperationsDocument12 pagesSequence of Operationseyad100% (2)

- Sequence of Operation For Constant Air Volume Air Conditioning SystemDocument7 pagesSequence of Operation For Constant Air Volume Air Conditioning SystemDong VanraNo ratings yet

- Chilled Water Sequence of OperationDocument8 pagesChilled Water Sequence of OperationRaulSaavedra100% (1)

- BMS Chiller Plant Management SystemDocument100 pagesBMS Chiller Plant Management SystemNadeem khanNo ratings yet

- Fan Coil Units, AHUs Sequence of OperationDocument18 pagesFan Coil Units, AHUs Sequence of OperationRa Ar100% (2)

- General Bms PresentationDocument18 pagesGeneral Bms PresentationsinyjoNo ratings yet

- Itcc Bms Io HvacDocument40 pagesItcc Bms Io Hvacuddinnadeem0% (1)

- Chiller Control SequenceDocument16 pagesChiller Control SequenceCool Shary100% (2)

- VRF Systems PDFDocument11 pagesVRF Systems PDFhonismeNo ratings yet

- DDC ControllerDocument14 pagesDDC ControllerharishupretiNo ratings yet

- Tata Projects Limited: Doc. No: Operation & Control PhilosophyDocument10 pagesTata Projects Limited: Doc. No: Operation & Control Philosophyvenkatraman JNo ratings yet

- BMS SpecificationDocument10 pagesBMS SpecificationsharafanyNo ratings yet

- SOP - CPM Chiller Plant Sequence of Operation PDFDocument10 pagesSOP - CPM Chiller Plant Sequence of Operation PDFSuren VelletheryNo ratings yet

- BMS Single Line Diagram Schedule of Points PDFDocument11 pagesBMS Single Line Diagram Schedule of Points PDFcalidad67% (3)

- IO SummaryDocument8 pagesIO SummaryVineeth VKNo ratings yet

- T&C of Pressurization UnitDocument6 pagesT&C of Pressurization UnitMohamed YousufNo ratings yet

- Installation of HVAC VRF & DX Units Systems Method StatementDocument35 pagesInstallation of HVAC VRF & DX Units Systems Method Statementمقاول تكييف كهرباء وصحيNo ratings yet

- BMS Method StatementDocument9 pagesBMS Method Statementengin_eerNo ratings yet

- BMSDocument1 pageBMSGlishna Peushan WidanapathiranaNo ratings yet

- BMSDocument44 pagesBMSHari Krishna100% (4)

- DDC System Test Procedure-0831Document20 pagesDDC System Test Procedure-0831Abdul Mohid SheikhNo ratings yet

- Method of Statement For Precommissioning & Commissioning of Chiller Plant ManagerDocument3 pagesMethod of Statement For Precommissioning & Commissioning of Chiller Plant Managervin ssNo ratings yet

- CPD Elv BMSDocument93 pagesCPD Elv BMSscribd99190No ratings yet

- Chiller System BMS PDFDocument42 pagesChiller System BMS PDFYahya SalemNo ratings yet

- Final Project Deliverables and HVAC Control SequenceDocument25 pagesFinal Project Deliverables and HVAC Control Sequenceamechmar5935No ratings yet

- BMT Check List - XLSXDocument6 pagesBMT Check List - XLSXNedunuri.Madhav MurthyNo ratings yet

- BMS IO Summary For QC2 R1 20.02.2013Document9 pagesBMS IO Summary For QC2 R1 20.02.2013Nedunuri.Madhav Murthy100% (1)

- HVAC Maintenance ActivitiesDocument23 pagesHVAC Maintenance ActivitiesLungisaniNo ratings yet

- Chiller Plant CommissioningDocument38 pagesChiller Plant Commissioningavbsky100% (1)

- Chiller Plant Manager Control SequenceDocument5 pagesChiller Plant Manager Control SequenceBhagyaraj NPNo ratings yet

- HvacDocument15 pagesHvacKiran KumarNo ratings yet

- BTU Meter Installation GuideDocument1 pageBTU Meter Installation GuidePraveen SagayarajNo ratings yet

- Install Air Cooled ChillersDocument17 pagesInstall Air Cooled ChillersVibinNo ratings yet

- Hvac Notes: Vapor-Compression Absorption Refrigeration Cycle Heat ExchangerDocument36 pagesHvac Notes: Vapor-Compression Absorption Refrigeration Cycle Heat ExchangerMohd Tarique AnwarNo ratings yet

- BMS Standard for Building Control SystemsDocument64 pagesBMS Standard for Building Control Systemssriteja79No ratings yet

- Optimizing HVAC Water Pumping SystemsDocument49 pagesOptimizing HVAC Water Pumping SystemsVasanth KumarNo ratings yet

- HRH Prince Khaled Bin Sultan Project HVAC System Package Unit AC RooftopDocument11 pagesHRH Prince Khaled Bin Sultan Project HVAC System Package Unit AC Rooftopemanuel92No ratings yet

- Testing & Commissioning of Fan Coil Units FCU'sDocument3 pagesTesting & Commissioning of Fan Coil Units FCU'svin ssNo ratings yet

- ABC Building EEMS Control Write UpDocument9 pagesABC Building EEMS Control Write UpHnin Pwint100% (1)

- BMS Scope and I/O Summary for Integrated Building Management SystemDocument13 pagesBMS Scope and I/O Summary for Integrated Building Management Systemamhosny6483% (6)

- FAHU SubmittalDocument62 pagesFAHU SubmittalEngr.MmosaadNo ratings yet

- Ahu BoqDocument2 pagesAhu BoqRajesh BMNo ratings yet

- UBC BMS Design Guidelines Revised November 2012Document94 pagesUBC BMS Design Guidelines Revised November 2012amhosny64No ratings yet

- Air Handling Unit QC Checklist: AHU InformationDocument5 pagesAir Handling Unit QC Checklist: AHU InformationRaheel AhmedNo ratings yet

- BMS Point ScheduleDocument2 pagesBMS Point ScheduleN Faathimaa Shabrina67% (3)

- BMS Point ScheduleDocument4 pagesBMS Point ScheduleGlishna Peushan WidanapathiranaNo ratings yet

- Control Sequences For HVAC SystemsDocument14 pagesControl Sequences For HVAC SystemsridwanNo ratings yet

- Chiller System BMSDocument42 pagesChiller System BMSamhosny64100% (4)

- Complete Report On HvacDocument57 pagesComplete Report On HvacJunaid Khan100% (2)

- BMS Commissining ChecklistDocument52 pagesBMS Commissining ChecklistAnvay Patil100% (1)

- Control Systems GuideDocument53 pagesControl Systems GuideMario MendozaNo ratings yet

- Standard Operating Procedure - HVAC - V01 - 29082010Document10 pagesStandard Operating Procedure - HVAC - V01 - 29082010Karthik MandyaNo ratings yet

- Annexure II - Boq For AhuDocument11 pagesAnnexure II - Boq For AhuMohsin Shaikh100% (1)

- Chilled Water Design SpecificationsDocument56 pagesChilled Water Design SpecificationsNavami Vb100% (1)

- IO Summary For IBMS Service PDFDocument348 pagesIO Summary For IBMS Service PDFpratimNo ratings yet

- Analog Control SystemDocument11 pagesAnalog Control SystemYoginder KumarNo ratings yet

- DDC System Sequence of OperationDocument6 pagesDDC System Sequence of OperationSharath BogaNo ratings yet

- AHU CHW Coil ConnectionDocument1 pageAHU CHW Coil ConnectionMULTIKARTHI07100% (1)

- Cutters: C15.25 Material Max Cutting Diameter MM C15.40.1 Material Max Cutting Diameter MMDocument1 pageCutters: C15.25 Material Max Cutting Diameter MM C15.40.1 Material Max Cutting Diameter MMابو محمد البصري العراقيNo ratings yet

- Powered Air-Purifying Respirator (PAPR) Blower Units: OM-AW300 Rev. DDocument29 pagesPowered Air-Purifying Respirator (PAPR) Blower Units: OM-AW300 Rev. DTeknisi PanamedNo ratings yet

- F6 PDFDocument1 pageF6 PDF3 stacksNo ratings yet

- Electrical Connectors Catalog Sheet Asco en 7414680Document2 pagesElectrical Connectors Catalog Sheet Asco en 7414680ChangHuiChuanNo ratings yet

- JSA Land Clearing Safety AnalysisDocument10 pagesJSA Land Clearing Safety AnalysisYosua SitumorangNo ratings yet

- 3AS 38319 App - Boiler Plant Lay Out SFBW2728226SATFG .BakDocument3 pages3AS 38319 App - Boiler Plant Lay Out SFBW2728226SATFG .BakRabindranath Hendy TagoreNo ratings yet

- LUNA MCFE CAT - BookDocument138 pagesLUNA MCFE CAT - BookWalterNo ratings yet

- Maytag Dryer Medx700xw0 Service ManualDocument64 pagesMaytag Dryer Medx700xw0 Service Manualdan theman100% (1)

- Nawaloka Construction Company (PVT) Limited Stationary List: No Description Approved RateDocument5 pagesNawaloka Construction Company (PVT) Limited Stationary List: No Description Approved Ratejayanath nccNo ratings yet

- PPDBLAN-EAJ Full en Us LetterDocument5 pagesPPDBLAN-EAJ Full en Us LetterJustinNo ratings yet

- SPARE PARTS On The MDocument5 pagesSPARE PARTS On The MПавел ГалущенкоNo ratings yet

- 6, HM.2023Document5 pages6, HM.2023Want ONo ratings yet

- Can Bus Troubleshooting Rev BDocument4 pagesCan Bus Troubleshooting Rev Bjoendry100% (1)

- Heckler & Kock - MSG90 (Operator Manual)Document14 pagesHeckler & Kock - MSG90 (Operator Manual)Ricardo C TorresNo ratings yet

- XT2025 - Service and Repair ManualDocument74 pagesXT2025 - Service and Repair ManualOsvaldo Jair Ramirez PerezNo ratings yet

- Crane Proof Testing & LAG Revisions 2020 PDFDocument26 pagesCrane Proof Testing & LAG Revisions 2020 PDF朱峰No ratings yet

- Senarai Kod Barang Stor Baru Tahun 2019Document6 pagesSenarai Kod Barang Stor Baru Tahun 2019Syikin SharifNo ratings yet

- Hydraulic System 6015B Hydraulic Mining Shovel: Machine - Right Side ViewDocument4 pagesHydraulic System 6015B Hydraulic Mining Shovel: Machine - Right Side ViewJuan Carlos Inga Vasquez100% (1)

- Manpower Equipment Schedule Sistona VellarimoDocument2 pagesManpower Equipment Schedule Sistona VellarimoKirby LabadanNo ratings yet

- Parts Catalog Cummins, 6LTAA8.9G2 - ESN 82312099 - CPL 3079-55Document1 pageParts Catalog Cummins, 6LTAA8.9G2 - ESN 82312099 - CPL 3079-55Hardiansyah Simarmata100% (1)

- Fault Code 144: Coolant Temperature Sensor Circuit - Voltage Above Normal or Shorted To High SourceDocument3 pagesFault Code 144: Coolant Temperature Sensor Circuit - Voltage Above Normal or Shorted To High Sourcehamilton mirandaNo ratings yet

- Flextec 350X ConnectDocument180 pagesFlextec 350X ConnectRigoberto Delgado100% (1)

- HD Materi Operator Competency Assessment (OCA)Document74 pagesHD Materi Operator Competency Assessment (OCA)Mel MelisaNo ratings yet

- SPM Shock Pulse CableDocument1 pageSPM Shock Pulse Cableana.alantariganNo ratings yet

- BBS Cables Price List July 2020Document8 pagesBBS Cables Price List July 2020Md. Manirul Islam100% (1)

- Wattbox 300 VB Ip 5 Installation Guide Rev BDocument12 pagesWattbox 300 VB Ip 5 Installation Guide Rev BrobertduvallNo ratings yet

- Manual VX 500Document16 pagesManual VX 500Felipe oliveira guimarãesNo ratings yet

- Medium Voltage Switching Devices: Assembly Operation MaintenanceDocument52 pagesMedium Voltage Switching Devices: Assembly Operation MaintenanceGrid LockNo ratings yet

- XII PHYSICS INVESTIGATORY PROJECT Earth-Magnetic-Field-Using-Tangent-Galvanometer..Document16 pagesXII PHYSICS INVESTIGATORY PROJECT Earth-Magnetic-Field-Using-Tangent-Galvanometer..ind0boy634No ratings yet