Professional Documents

Culture Documents

10.1038@s41563 019 0399 Z

Uploaded by

Khue VanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10.1038@s41563 019 0399 Z

Uploaded by

Khue VanCopyright:

Available Formats

Letters

https://doi.org/10.1038/s41563-019-0399-z

Oxysulfide photocatalyst for visible-light-driven

overall water splitting

Qian Wang1,9, Mamiko Nakabayashi2, Takashi Hisatomi 3, Song Sun4,5, Seiji Akiyama6,7,

Zheng Wang 3, Zhenhua Pan1, Xiong Xiao7,8, Tomoaki Watanabe8, Taro Yamada1, Naoya Shibata 2,

Tsuyoshi Takata3 and Kazunari Domen 1,3*

Oxysulfide semiconductors have narrow bandgaps suitable for oxysulfides is small1. Here, we report promising photocatalytic

for water splitting under visible-light irradiation, because the water-splitting activity for Y2Ti2O5S2, which responds to a large por-

electronegative sulfide ions negatively shift the valence band tion of the solar spectrum owing to its narrow bandgap (1.9 eV),

edges of the corresponding oxides1,2. However, the instability and directly decomposes water into hydrogen and oxygen in a stoi-

of sulfide ions during the water oxidation is a critical obstacle chiometric ratio.

to simultaneous evolution of hydrogen and oxygen3. Here, we The Y2Ti2O5S2 unit cell comprises alternating rocksalt slabs

demonstrate the activation and stabilization of Y2Ti2O5S2, [Y2S2]2+ and ReO3-type blocks formed from -(TiO2)–(O)–(TiO2)-

with a bandgap of 1.9 eV, as a photocatalyst for overall water layers stacked along the c direction (Fig. 1a)12,13. The X-ray dif-

splitting. On loading of IrO2 and Rh/Cr2O3 as oxygen and fraction (XRD) pattern for the Y2Ti2O5S2 synthesized through a

hydrogen evolution co-catalysts, respectively, and fine-tuning solid-state reaction indicates a single Y2Ti2O5S2 phase with tetrag-

of the reaction conditions, simultaneous production of stoi- onal symmetry (I4/mmm) (Fig. 1b)12, which agrees with both the

chiometric amounts of hydrogen and oxygen was achieved on simulated and measured patterns reported in the literature12,14–16.

Y2Ti2O5S2 during a 20 h reaction. The discovery of the overall The scanning electron microscopy (SEM) image in Fig. 2a reveals

water splitting capabilities of Y2Ti2O5S2 extends the range of that the particle size ranges from several micrometres to 10 µm.

promising materials for solar hydrogen production. Particles 1–2 µm in size are single crystals, whereas larger particles

Light-driven water splitting using particulate semiconduc- (>2 µm) are secondary particles made up of these primary particles

tor photocatalysts via single photo-excitation is driving down the (Fig. 2b,c). Elemental analysis using inductively coupled plasma

projected cost of solar hydrogen, potentially to a level that is com- atomic emission spectroscopy (ICP-AES) and also oxygen/nitrogen

petitive with fossil-fuel-derived hydrogen because of the simplic- and carbon/sulfur analyses showed that the powder composition

ity of this system4,5. Photocatalytic water-splitting panels retain the is Y:Ti:S:O = 2.0:2.0:2.2:5.1, which is close to stoichiometry. The

intrinsic activity of the photocatalysts and are essentially extensible valence states of Y, Ti and S species in Y2Ti2O5S2 were determined

beyond the scale of square metres6. However, to harvest the solar by X-ray photoelectron spectroscopy (XPS) to be Y3+, Ti4+ and

energy efficiently, the development of narrow-bandgap photo- S2−, respectively, consistent with the composition (Supplementary

catalysts capable of splitting water under visible-light irradiation is Fig. 1). The oxygen species were attributed to oxidic compounds

critically necessary7,8. Metal chalcogenides have shown promise for and adsorbed O2 and/or ambient moisture17.

efficient solar energy harvesting due to their narrow bandgaps9–11; Y2Ti2O5S2 absorbs light with wavelength up to 650 nm, as shown

however, the water oxidation reaction competes with oxidation of by the diffuse reflectance spectrum (DRS) in Fig. 3a. The bandgap

the lattice chalcogen ions9. Simultaneous H2 and O2 production is estimated to be 1.9 eV from the onset wavelength in the DRS.

by CdS nanorods decorated with nanoparticulate reduction and Mott–Schottky plots and current–potential profiles for Y2Ti2O5S2

molecular oxidation co-catalysts has been reported10, but the H2/O2 electrodes (Fig. 3b and Supplementary Figs. 2 and 3) exhibit positive

ratio strongly deviated from the stoichiometric value of 2 due to slopes and photoanodic current characteristics of n-type semicon-

oxidation of the S2− and cysteine ligands by photogenerated holes10. ductors, respectively, similar to analogous oxysulfides, as exem-

Oxysulfides are expected to be more durable against self-oxidation, plified by Sm2Ti2O5S2 (ref. 1). The flat-band potential of Y2Ti2O5S2

because the surface S2− ions are stabilized by hybridization of the was estimated to be −1.05 V versus the normal hydrogen electrode

S-3p and O-2p orbitals1,2, although the utilization of such oxysul- (NHE) and was almost independent of pH in the range of 5–13,

fides for light-driven photocatalytic overall water splitting still unlike metal oxides1. Similar behaviour was observed for Sm2Ti2O5S2

remains elusive. Complete suppression of the oxidation of sulfur and BiCuOS and is indicative of a small acid dissociation constant

ions is a challenging task3 that requires an efficient hole extraction for hydroxyl groups on the Y2Ti2O5S2 surface1,18. Hence, the conduc-

mechanism. Additionally, under neutral conditions, the difference tion band minimum (CBM) for Y2Ti2O5S2 was determined to lie

between the oxidation potential of water and the valence band top between −1.1 and −1.0 V versus NHE given a potential difference

1

Department of Chemical System Engineering, School of Engineering, The University of Tokyo, Tokyo, Japan. 2Institute of Engineering Innovation, The

University of Tokyo, Tokyo, Japan. 3Center for Energy & Environmental Science, Shinshu University, Nagano, Japan. 4School of Chemistry and Chemical

Engineering, Anhui University, Anhui, China. 5National Synchrotron Radiation Laboratory, Collaborative Innovation Center of Chemistry for Energy

Materials, University of Science & Technology of China, Anhui, China. 6Mitsubishi Chemical Corporation, Yokohama R&D center, Kanagawa, Japan. 7Japan

Technological Research Association of Artificial Photosynthetic Chemical Process (ARPChem), Tokyo, Japan. 8Department of Applied Chemistry, School of

Science and Technology, Meiji University, Kanagawa, Japan. 9Present address: Department of Chemistry, University of Cambridge, Cambridge, UK.

*e-mail: domen@chemsys.t.u-tokyo.ac.jp; domen@shinshu-u.ac.jp

Nature Materials | VOL 18 | AUGUST 2019 | 827–832 | www.nature.com/naturematerials 827

Letters Nature Materials

a b

Y

Ti

Intensity (a.u.)

(103)

(110)

(107)

(004)

(200)

(109)

(118)

(215)(208)

(116)

(217)

z

(10 15)

(213)

(11 12)

(219)

(20 12)

(105)

(00 12)

(112)

(220)

(008)

(10 17)

(204)

(00 10)

(101)

(228)

(302)

(006)

(202)

(206)

(224)

(114)

x y

10 20 30 40 50 60 70 80

2θ (deg)

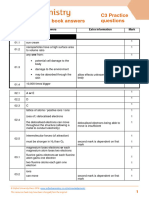

Fig. 1 | Structure of Y2Ti2O5S2. a, Crystal structure of Y2Ti2O5S2. b, XRD pattern for as-prepared Y2Ti2O5S2 (red spectra) and simulated data14

(black spectra) for comparison.

of 0−0.1 V between the flat-band potential and the CBM in n-type S2− in Y2Ti2O5S2, which competes with the water oxidation reaction,

oxysulfides1. From the bandgap energy, the valence band maximum as observed for other metal chalcogenides9,10. Loading with the IrO2

(VBM) was estimated to be 0.8–0.9 V versus NHE. This is in good OEC is therefore necessary to stably oxidize water to O2 (refs. 10,20,21).

agreement with that obtained by photoelectron spectroscopy in air In addition, Y2Ti2O5S2 loaded only with IrO2 exhibited negligible

(PESA) (−5.2 eV versus vacuum, Supplementary Fig. 4). According H2 and O2 evolution in water buffered with La2O3, indicating the

to the proposed band structure (Fig. 3c), in mildly alkaline (for need for co-loading with both the HEC and OEC. Isotopic labelling

example, pH 9) solutions, the CBM is more negative than the using H218O (97 at% 18O) as a reactant confirmed that the ratio of

reduction potential of water to produce H2, while the VBM is more 18

O atoms in the O2 generated over Cr2O3/Rh/IrO2-loaded Y2Ti2O5S2

positive than the oxidation potential of water to produce O2. Thus, was ~97% after a 3 h reaction (Supplementary Fig. 9). Thus, the O2

Y2Ti2O5S2 meets the thermodynamic requirements for photocata- was produced from water.

lytic water splitting for pH values around 8–9. The partial density of The Cr2O3/Rh co-catalyst nanocomposites were deposited

states (PDOS) computed using CASTEP is presented in Fig. 3d and on different regions of the Y2Ti2O5S2 to the IrO2 nanoparticles

Supplementary Fig. 5. The CBM for Y2Ti2O5S2 consists predomi- (Supplementary Table 1 and Supplementary Figs. 10 and 11). This

nately of Ti-3d orbitals, while the VBM is composed of O-2p, S-3p is because the photodeposition method allows selective deposition

and Y-3d orbitals. The S-3p band strongly overlaps with states due of Cr2O3/Rh nanoparticles on reduction sites and the IrO2 nanopar-

to O-2p orbitals, implying significant hybridization between S and ticles function as oxidation sites. XPS analysis (Supplementary

O atoms. In addition, Y2Ti2O5S2 exhibits a more negative VBM than Fig. 12) revealed that the Ir, Rh and Cr species on the surface of

Sm2Ti2O5S2 (2.1 eV)1,2, suggesting that Y-3d orbitals also contribute Y2Ti2O5S2 had valence states attributable to IrO2, metallic Rh and

to the VBM2. Cr2O3, respectively. This indicates successful deposition of Cr2O3/

The Y2Ti2O5S2 was decorated by adsorption of IrO2 as an oxygen Rh on Y2Ti2O5S2 without blocking the pre-loaded IrO2 nanopar-

evolution co-catalyst (OEC). As a hydrogen evolution co-catalyst ticles or changing the oxidation state of IrO2. Notably, Y2Ti2O5S2

(HEC) and surface modification for HEC, core/shell Rh/Cr2O3 was powder loaded first with Cr2O3/Rh and then with IrO2 split water

deposited subsequently by two-step photodeposition using Rh3+ 30% less efficiently than that loaded with IrO2 and then Cr2O3/Rh

and Cr6+ species. The functionality of the IrO2 and Rh species on (Supplementary Fig. 13) because the IrO2 was deposited non-selec-

Y2Ti2O5S2 was evaluated by oxygen evolution reactions in an aque- tively and covered part of the Cr2O3/Rh HEC. This result suggests

ous AgNO3 solution and hydrogen evolution reactions in an aque- that the HEC and OEC should be co-loaded on one single photocat-

ous Na2S–Na2SO3 solution, respectively (Supplementary Fig. 6). In alyst particle but on different regions to promote the overall water-

strong agreement with absorption onset in the DRS, both H2 and O2 splitting activity effectively.

generation were observed up to 640 nm (Fig. 4a,b), indicating that The photocatalytic activity of the Cr2O3/Rh/IrO2-loaded

the photoreactions proceeded via bandgap transitions. The apparent Y2Ti2O5S2 varied significantly with the pH of the reaction solution

quantum yield (AQY) at wavelengths of 420−480 nm was 5.3 ± 0.3% (Fig. 5b). Stoichiometric H2 and O2 evolution occurred in the pH

and 2.3 ± 0.1% for H2 and O2 production, respectively. The photo- range of 8−9, indicating that the rates of the O2 and H2 evolution

catalytic water-splitting activity of Cr2O3/Rh/IrO2-loaded Y2Ti2O5S2 reactions were balanced at this pH. The difference between the

was independent of the background pressure (Supplementary Fig. 7) water-oxidation potential and the VBM potential of Y2Ti2O5S2 in

because the Cr2O3 shell serves as a diffusion barrier to prevent pure water (pH 6.8) seems to be too small to drive the water oxida-

backward reactions on the noble metal surface during the reaction19. tion reaction efficiently. This was confirmed by the fact that a neg-

Stoichiometric evolution of H2 and O2 occurred over Cr2O3/Rh/ ligible amount of oxygen was evolved over IrO2-loaded Y2Ti2O5S2

IrO2-loaded Y2Ti2O5S2 in distilled water buffered by La2O3 (pH 8.5) in an AgNO3 aqueous solution at neutral pH. On the other hand,

under visible-light irradiation (λ > 420 nm) (Fig. 5a). Cr2O3/ the XPS results in Supplementary Fig. 14 show that the Cr2O3 shell

Rh-loaded Y2Ti2O5S2 also produced H2 and O2 under the same con- was partially dissolved at pH 10, resulting in a strong back reac-

ditions (Supplementary Fig. 8). However, the H2/O2 ratio deviated tion on the exposed Rh nanoparticles. Therefore, careful tuning of

from the stoichiometric value of 2, probably due to oxidation of the pH of the reactant is vital for achieving water splitting over

828 Nature Materials | VOL 18 | AUGUST 2019 | 827–832 | www.nature.com/naturematerials

Nature Materials Letters

a b

B1

B2

B3

200 nm

C3 C2

C1

20 µm 1 µm

B1 B2 B3

2 nm–1 2 nm–1 2 nm–1

C1 C2 C3

5 nm–1 5 nm–1 5 nm–1

Fig. 2 | Morphology of Y2Ti2O5S2. a, SEM image of as-prepared Y2Ti2O5S2 powder. b,c, High-resolution transmission electron microscopy (HRTEM) images

and corresponding selected area electron diffraction (SAED) patterns (bottom two rows) for Y2Ti2O5S2 particles with size of ~1 µm and thickness of ~0.4 µm

(b) and Y2Ti2O5S2 particles larger than 2 µm (c).

Cr2O3/Rh/IrO2-loaded Y2Ti2O5S2. The catalysts collected after a 6 h unfavourable in photocatalytic reactions because photoexcited car-

reaction in an aqueous NaOH solution at pH 9 were examined. The riers have to migrate a long distance to reach active sites on the

XRD patterns reveal that the crystallinity of the Y2Ti2O5S2 was essen- surface22. Moreover, the TEM images in Supplementary Fig. 16

tially unchanged (Supplementary Fig. 15). Furthermore, the bulk reveal grain boundaries in large particles (>2 µm). Such boundar-

Y2Ti2O5S2 was confirmed to have a stoichiometric elemental ratio ies trap photoexcited carriers and enhance charge recombination,

of Y:Ti:S:O = 2.0:2.0:2.0:5.1 after the reaction. The binding energies which lowers the quantum efficiency23. Therefore, methods for

of the Y-3d, Ti-2p, S-2p, S-2s and O-1s peaks and the proportions reducing the Y2Ti2O5S2 particle size were investigated. It was found

of surface Ti, S and O species did not undergo large changes either that smaller particles (<5 µm) of single-phase Y2Ti2O5S2 could

(Supplementary Fig. 1 and Supplementary Table 2). These results, be obtained by decreasing the calcination temperature to 973 K

along with the isotopic labelling experiment and the numbers of (Supplementary Fig. 17). As shown in Fig. 5a, the Cr2O3/Rh/IrO2-

outmost sulfide and oxide ions (see Supplementary Information), loaded Y2Ti2O5S2 synthesized at 973 K generated almost three times

indicate that hydrogen and oxygen generation over Cr2O3/Rh/IrO2- as much H2 and O2 as the catalyst produced at 1,073 K. The AQYs

loaded Y2Ti2O5S2 powder are due not to self-oxidation of S2‒ species at 420, 500 and 600 nm were 0.36%, 0.23% and 0.05%, respectively

on Y2Ti2O5S2 but to water splitting. and the solar-to-hydrogen conversion efficiency (STH) was 0.007%

As discussed above, the particle size in the Y2Ti2O5S2 calcined (Figs. 4c and 5c).

at 1,073 K ranged from several micrometres to 10 µm. Although Stoichiometric evolution of hydrogen and oxygen was confirmed

the particles were well crystallized, excessively large particles are for Cr2O3/Rh/IrO2-loaded Y2Ti2O5S2 powders during the 20 h

Nature Materials | VOL 18 | AUGUST 2019 | 827–832 | www.nature.com/naturematerials 829

Letters Nature Materials

a b 1.5

pH 13.0

pH 6.8

pH 5.1

C –2 (1011 F–2 cm4)

1.0

KM (a.u.)

0.5

0.0

300 400 500 600 700 800 –1.4 –1.2 –1.0 –0.8 –0.6 –0.4 –0.2 0.0 0.2

Wavelength (nm) Potential (V versus Ag/AgCl)

c d 4

O

Density of states (electrons per eV)

S

Ti

–2 3

Y

Conduction band

(V versus NHE)

–1

H+/H2

Potential

2

(pH 9)

0 Bandgap (1.9 eV)

O2/H2O

1

Valence band 1

2

0

–6 –4 –2 0 2 4

Energy (eV)

Fig. 3 | Band structure of Y2Ti2O5S2. a, DRS for Y2Ti2O5S2. KM, Kubelka–Munk model (see Methods). Inset, photograph of the Y2Ti2O5S2 powder. b, Mott–

Schottky plots for an Y2Ti2O5S2 electrode in 0.1 M Na2SO4 at pH 5.1 (orange symbols), pH 6.8 (blue symbols) and pH 13.0 (red symbols). c, Schematic band

structure diagram for Y2Ti2O5S2. d, DOS for O (blue line), S (red line), Ti (orange line) and Y (light blue line).

a 7 b 3 c 0.5

6

0.4

5

2

0.3

KM (a.u.)

KM (a.u.)

AQY (%)

AQY (%)

KM (a.u.)

AQY (%)

3 0.2

1

2

0.1

1

0 0 0

300 350 400 450 500 550 600 650 700 750 800 300 350 400 450 500 550 600 650 700 750 800 300 350 400 450 500 550 600 650 700 750 800

Wavelength (nm) Wavelength (nm) Wavelength (nm)

Fig. 4 | Wavelength dependence of photocatalytic activity of Y2Ti2O5S2. a–c, Dependence of AQY for hydrogen production using Y2Ti2O5S2 loaded with

3 wt% Rh (a), oxygen production using Y2Ti2O5S2 loaded with 1 wt% IrO2 (b) and overall water splitting using Cr2O3/Rh/IrO2-modified Y2Ti2O5S2 (c) on

incident light wavelength, along with DRS of Y2Ti2O5S2 for comparison (green line). The hydrogen evolution reactions were carried out in aqueous solutions

of Na2S–Na2SO3 (20 mM each). The oxygen evolution reactions were carried out in aqueous solutions of AgNO3 (20 mM) buffered by La2O3 (pH 8.5). The

Y2Ti2O5S2 for the hydrogen and oxygen evolution reactions was synthesized at 1,073 K. The overall water-splitting reactions were carried out in distilled

water buffered by La2O3 (pH 8.5). The amounts of IrO2, Rh and Cr were 0.3, 2 and 1.5 wt%, respectively, for the overall water-splitting reaction. The

Y2Ti2O5S2 for the overall water-splitting reactions was synthesized at 973 K. The reactions were performed under illumination from a xenon lamp (300 W)

and various bandpass filters.

reaction (Fig. 5d). The photocatalyst retained 81% of the initial water of the OEC, rather than self-oxidation of S2−. However, as shown in

splitting activity in the second run. The thermogravimetric (TG) Supplementary Fig. 19, defects such as dislocations still exist in the

analysis results in Supplementary Fig. 18 indicate that the Y2Ti2O5S2 bulk Y2Ti2O5S2, working as recombination centres of photo-excited

remains stable up to 700 °C in both air and N2. The considerable charges24,25. There is therefore much room for improvement of the

mass loss at ~600 °C that is typical of oxysulfides due to evapora- efficiency by controlling the particle size and morphology, reducing

tion of sulfur is not observed for Y2Ti2O5S2 (ref. 18). This implies the defect density through refinement of the material preparation

that the S atoms in Y2Ti2O5S2 are relatively stable, and holes near method, managing the selective deposition of the dual co-catalysts,

the VBM can be employed for water oxidation with the assistance and valence band engineering via doping and forming solid solution.

830 Nature Materials | VOL 18 | AUGUST 2019 | 827–832 | www.nature.com/naturematerials

Nature Materials Letters

a 40 b 3.0

H2

Rates of gas evolution (µmol h–1)

Amount of evolved gases (µmol)

35

2.5 O2

H2(973 K)

30

2.0

25

20 1.5

O2(973 K)

15

1.0

10 H2(1073 K)

0.5

5 O2(1073 K)

0 0

0 1 2 3 4 5 6 7 6.8 8.0 9.0 10.0

Time (h) pH

c 30 d 70

Evacuation

Amount of evolved gases (µmol)

Amount of evolved gases (µmol)

25 60

H2

H2

50

20

40

15

O2 30

10 O2

20

5

10

0 0

0 1 2 3 4 5 6 7 0 2 4 6 8 10 12 14 16 18 20 22

Time (h) Time (h)

Fig. 5 | Photocatalytic performance of Y2Ti2O5S2 for overall water splitting. a, Time courses of water-splitting reaction on Cr2O3/Rh/IrO2-modified

Y2Ti2O5S2 in distilled water buffered by La2O3 (pH 8.5). The Y2Ti2O5S2 was synthesized at 1,073 K (open symbols) and 973 K (filled symbols). b, Dependence

of gas evolution rates on Cr2O3/Rh/IrO2-loaded Y2Ti2O5S2 on the pH of the reaction solution. The Y2Ti2O5S2 was synthesized at 1,073 K. The above reactions

were carried out under illumination from a xenon lamp (300 W, λ > 420 nm). Error bars in a and b indicate standard deviation. c, Time course of overall

water splitting on Cr2O3/Rh/IrO2-modified Y2Ti2O5S2 in distilled water buffered by La2O3 (pH 8.5) under simulated sunlight (AM 1.5G). The Y2Ti2O5S2 was

synthesized at 973 K. d, Time course of overall water splitting on Cr2O3/Rh/IrO2-modified Y2Ti2O5S2 in distilled water buffered by La2O3 (pH 8.5) under

illumination from a xenon lamp (300 W, λ > 420 nm) for 20 h, with evacuation every 10 h (dashed line). The Y2Ti2O5S2 was synthesized at 973 K.

3. Fujito, H. et al. Layered perovskite oxychloride Bi4NbO8Cl: a stable visible

The stability could be improved by replacing IrO2 with other more

light responsive photocatalyst for water splitting. J. Am. Chem. Soc. 138,

effective OECs to inhibit the oxidation of Cr3+ in Cr2O3 and S2‒ on 2082–2085 (2016).

the Y2Ti2O5S2 surface26. 4. Shaner, M. R., Atwater, H. A., Lewis, N. S. & McFarland, E. W. A comparative

We demonstrated that an oxysulfide semiconductor photocata- technoeconomic analysis of renewable hydrogen production using solar

lyst, Y2Ti2O5S2, evolved H2 and O2 via a water-splitting reaction energy. Energy Environ. Sci. 9, 2354–2371 (2016).

5. Bala, C. R., Breen, S., Shao, Y., Ardo, S. & Weber, A. Z. Evaluating particle-

under visible-light irradiation. Following spatially separated load- suspension reactor designs for Z-scheme solar water splitting via transport

ing of IrO2 and Cr2O3/Rh as the OEC and HEC, respectively, and and kinetic modeling. Energy Environ. Sci. 11, 115–135 (2018).

fine-tuning the pH of the reactant, photocatalytic water splitting 6. Goto, Y. et al. A particulate photocatalyst water-splitting panel for large-scale

into H2 and O2 in a stoichiometric ratio was achieved. The discov- solar hydrogen generation. Joule 2, 509–520 (2018).

ery of an oxysulfide photocatalyst with a narrow bandgap that is 7. Sivula, K. & van de Krol, R. Semiconducting materials for

photoelectrochemical energy conversion. Nat. Rev. Mater. 1, 15010 (2016).

applicable in both one-step and Z-scheme water-splitting systems 8. Tachibana, Y., Vayssieres, L. & Durrant, J. R. Artificial photosynthesis for

opens new opportunities for research into solar energy conversion. solar water-splitting. Nat. Photon. 6, 511–518 (2012).

9. Ellis, A. B., Kaiser, S. W., Bolts, J. M. & Wrighton, M. S. Study of n-type

Online content semiconducting cadmium chalcogenide-based photoelectrochemical cells

Any methods, additional references, Nature Research reporting employing polychalcogenide electrolytes. J. Am. Chem. Soc. 99,

2839–2848 (1977).

summaries, source data, statements of code and data availability and 10. Wolff, C. M. et al. All-in-one visible-light-driven water splitting by combining

associated accession codes are available at https://doi.org/10.1038/ nanoparticulate and molecular co-catalyst on CdS nanorods. Nat. Energy 3,

s41563-019-0399-z. 862–869 (2018).

11. Ran, J., Zhang, J., Yu, J., Jaroniec, M. & Qiao, S. Earth-abundant cocatalysts

Received: 10 October 2018; Accepted: 10 May 2019; for semiconductor-based photocatalytic water splitting. Chem. Soc. Rev. 43,

7787–7812 (2014).

Published online: 17 June 2019 12. Denis, S. G. & Clarke, S. J. Two alternative products from the intercalation of

alkali metals into cation-defective Ruddlesden–Popper oxysulfides. Chem.

References Commun. 22, 2356–2357 (2001).

1. Ishikawa, A. et al. Oxysulfide Sm2Ti2S2O5 as a stable photocatalyst for water 13. Hyett, G. et al. Electronically driven structural distortions in lithium

oxidation and reduction under visible light irradiation (λ ≤ 650 nm). J. Am. intercalates of the n = 2 Ruddlesden–Popper-type host Y2Ti2O5S2: synthesis,

Chem. Soc. 124, 13547–13553 (2002). structure and properties of LixY2Ti2O5S2 (0 < x < 2). J. Am. Chem. Soc. 126,

2. Ishikawa, A. et al. Oxysulfides Ln2Ti2S2O5 as stable photocatalysts for water 1980–1991 (2004).

oxidation and reduction under visible-light irradiation. J. Phys. Chem. B 108, 14. Kristin, P. Materials Data on Y2Ti2S2O5 (SG:139) by Materials Project

2637–2642 (2004). (Lawrence Berkeley National Lab, 2016); https://doi.org/10.17188/1200585

Nature Materials | VOL 18 | AUGUST 2019 | 827–832 | www.nature.com/naturematerials 831

Letters Nature Materials

15. Oki, H. & Takagi, H. Y2Ti2O5S2 as a high performance anode material for Li experiment. S.S. thanks Z. Song at Anhui University for assisting with the theoretical

ion batteries. Solid State Ion. 276, 80–83 (2015). calculations. This work was financially supported by the Artificial Photosynthesis Project

16. Rutt, O. J., Hill, T. L., Gál, Z. A., Hayward, M. A. & Clarke, S. J. The cation- of the New Energy and Industrial Technology Development Organization (NEDO) and

deficient Ruddlesden-Popper oxysulfide Y2Ti2O5S2 as a layered sulfide: topotactic a Grant-in-Aid for Scientific Research(A) (no. 16H02417) from the Japan Society for the

potassium intercalation to form KY2Ti2O5S2. Inorg. Chem. 42, 7906–7911 (2003). Promotion of Science. M.N. and N.S. performed work at the Advanced Characterization

17. Ingo, G., Paparazzo, E., Bagnarelli, O. & Zacchetti, N. XPS studies on cerium, Nanotechnology Platform of the University of Tokyo, supported through the

zirconium and yttrium valence states in plasma-sprayed coatings. Surf. ‘Nanotechnology Platform’ of the Ministry of Education, Culture, Sports, Science and

Interface Anal. 16, 515–519 (1990). Technology (MEXT), Japan.

18. BaQais, A. et al. Bismuth silver oxysulfide for photoconversion applications:

structural and optoelectronic properties. Chem. Mater. 29, 8679–8689 (2017).

19. Maeda, K. et al. Noble-metal/Cr2O3 core/shell nanoparticles as a cocatalyst Author contributions

for photocatalytic overall water splitting. Angew. Chem. Int. Ed. 118, Q.W. and K.D. designed the research. Q.W. prepared Y2Ti2O5S2 powder and conducted

7970–7973 (2006). XRD, DRS, XPS, PESA and SEM characterizations, and the water-splitting reactions.

20. Gu., J. et al. Water reduction by a p-GaInP2 photoelectrode stabilized by an Q.W. and T.Y. carried out the isotopic labelling experiment. M.N. and N.S. conducted

amorphous TiO2 coating and a molecular cobalt catalyst. Nat. Mater. 15, cross-sectional cutting of particles along with the STEM, STEM-EDS, TEM-EDS,

456–460 (2016). HRTEM and SAED analyses. S.S. performed the theoretical calculations. S.A.

21. Vequizo, J. J. M., Hojamberdiev, M., Teshima, K. & Yamakata, A. Role of carried out the TG analysis. Q.W. and Z.P. fabricated the electrodes by the particle

CoOx cocatalyst on Ta3N5 photocatalysts studied by transient visible to transfer method and conducted the Mott–Schottky measurements. X.X. and T.W.

mid-infrared absorption spectroscopy. J. Photochem. Photobiol. C 358, prepared the electrodes using the roll press method. Z.P. and X.X. carried out the

315–319 (2018). photoelectrochemical measurements. T.Y. supervised the elemental analysis. K.D. and

22. Kato, H., Asakura, K. & Kudo, A. Highly efficient water splitting into H2 and T.H. supervised the experimental work. Q.W., T.H., Z.W., T.Y., T.T. and K.D. discussed

O2 over lanthanum-doped NaTaO3 photocatalysts with high crystallinity and the results. Q.W., T.H. and K.D. wrote the manuscript with contributions from the

surface nanostructure. J. Am. Chem. Soc. 125, 3082–3089 (2013). other authors.

23. Sherkar, T. S. et al. Recombination in perovskite solar cells: significance of

grain boundaries, interface traps and defections. ACS Energy Lett. 2,

1214–1222 (2017). Competing interests

24. Inoue, Y. Photocatalytic water splitting by RuO2-loaded metal oxides and The authors declare no competing interests.

nitrides with d0- and d10-related electronic configurations. Energy Environ. Sci.

2, 364–386 (2009).

25. Kibria, M. G. et al. Visible light-driven efficient overall water splitting using Additional information

p-type metal-nitride nanowire arrays. Nat. Commun. 6, 6797 (2015). Supplementary information is available for this paper at https://doi.org/10.1038/

26. Lyu, H. et al. An Al-doped SrTiO3 photocatalyst maintaining sunlight-driven s41563-019-0399-z.

overall water splitting activity for over 1,000 h of constant illumination. Chem. Reprints and permissions information is available at www.nature.com/reprints.

Sci. 10, 3196–3201 (2019).

Correspondence and requests for materials should be addressed to K.D.

Acknowledgements Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in

Q.W. thanks Y. Kuromiya, K. Kato and M. Yamaguchi at The University of Tokyo for published maps and institutional affiliations.

performing ICP-AES and elemental analysis, and assisting with the isotopic labelling © The Author(s), under exclusive licence to Springer Nature Limited 2019

832 Nature Materials | VOL 18 | AUGUST 2019 | 827–832 | www.nature.com/naturematerials

Nature Materials Letters

Methods IrO2 colloid (0.05 mg ml−1) onto the surface. Electrical contact was established by

Synthesis of Y2Ti2O5S2. The Y2Ti2O5S2 powder was prepared by a solid-state embedding a copper wire in indium (Nilaco) at the bottom or back of the sample.

reaction. Y2O3 (Wako Pure Chemical Industries, 99.99%), Y2S3 (High Purity The copper wire and indium were coated with epoxy (Araldite).

Chemicals, 99.9%) and TiO2 (Rare Metallic, 99.99%) were mixed at a ratio of 1:2:6 Photoelectrochemical water splitting properties were investigated in the three-

in an argon-filled recirculating glovebox with an O2 concentration of less than electrode configuration using a Ag/AgCl reference electrode (in saturated KCl

3 ppm. The dew point was lower than 193 K. To obtain a sulfur-rich environment aqueous solution) and a Pt wire counter-electrode. The potential of the working

during the reaction, sulfur powder (High Purity Chemicals, 99.99%, 5 wt% with electrode was controlled by a potentiostat (Hokuto Denko, HSV-100). Potassium

respect to the total of the other starting materials) was added to the precursor. The phosphate solution (pH 9 and 13) was used as the electrolyte solution under

resulting mixture was sealed in an evacuated quartz tube and calcined in a muffle stirring and purging with Ar gas. The photoelectrode was irradiated with a solar

furnace. The calcination temperature was increased from room temperature to simulator (AM 1.5G; Sanei Electric, XES-40S2-CE). Current‒potential curves were

773 K at a rate of 5 K min−1, elevated to 873–1,073 K at 1 K min−1, and maintained measured at a scan rate of 10 mV s‒1 from positive to negative potential. Note that

at the target value for 96 h before natural cooling. To remove the sulfur species the photoelectrochemical performance has not yet been optimized.

adsorbed on the surface, the Y2Ti2O5S2 powder was annealed in air at 473 K for 1 h,

thoroughly rinsed with distilled water and dried in vacuum at 313 K. Photocatalytic reactions for hydrogen evolution. In the reactions for producing

hydrogen, Na2S and Na2SO3 (20 mM each) were used as sacrificial reagents and

Characterization. The XRD patterns for the samples were recorded with a Rigaku were dissolved in 150 ml of distilled water containing a photocatalyst sample

SmartLab diffractometer using a Cu Kα source operated at 40 kV and 30 mA. DRS (0.3 g). Rh nanoparticles (3 wt%) as HECs were loaded on the Y2Ti2O5S2 powder

measurements were made using an ultraviolet–visible–near–infrared spectrometer by photodeposition. A calculated amount of RhCl3·3H2O (Wako Pure Chemical

(V-670, JASCO) and were converted from reflectance into the Kubelka–Munk Industries, 99.9%) was added to the solution and reduced to metallic Rh by

(KM) function. PESA was carried out using a surface analyser (Riken-Keiki, AC-3). photoexcited electrons from the photocatalyst in the initial stage of the reaction

XPS measurements were performed using a monochromatic Mg Kα source (Supplementary Fig. 12). The reactions were conducted in a Pyrex top-irradiation

(hν = 1,253.6 eV) excited at 8 kV and 10 mA. The analysis chamber pressure was on reaction vessel connected to a glass-closed gas circulation system. Argon gas was

the order of 1 × 10−6 Pa. The binding energies were corrected using the C 1s peak introduced into the circulation system as a carrier gas after removing the air. The

(285.0 eV) as a reference. The SEM images were obtained using a Hitachi SU8020 total background pressure of argon and water vapour was ~7 kPa. The temperature

system operated at an acceleration voltage of 5 kV. Scanning transmission electron of the reactant solution was maintained at 288 K using cooling water. The reactions

microscope (STEM), scanning transmission electron microscope and energy- were performed under irradiation from a 300 W xenon lamp (Lamp House, R300-

dispersive X-ray spectroscopy (STEM-EDS) mapping, HRTEM images and SAED 3J) equipped with a cutoff filter (λ > 420 nm). The amounts of gas produced were

patterns were recorded using a JEM-2800 system (JEOL). Cross-sectional cuts of measured by gas chromatography (Shimadzu GC-8A with a thermal conductivity

the particles were prepared using an ion slicer (EM-09100IS, JEOL). Subsequently, detector, MS-5A columns and argon carrier gas). The reaction rates were determined

a NanoMill Model 1040 (Fichione Instruments) was applied to remove the from a linear regression fit once hydrogen evolution became mostly stable.

amorphous damage layer on TEM specimens prepared by the ion beam. TEM-EDS

was performed using an X-MAX 100TLE SDD detector (Oxford Instruments). Photocatalytic reactions for oxygen evolution. As a co-catalyst for oxygen

Elemental analysis of the Y2Ti2O5S2 powder was conducted using ICP-AES (ICPS- evolution, IrO2 nanoparticles (1 wt%) were loaded on the Y2Ti2O5S2 powder

8100, Shimazu), an EMGA 620 W oxygen/nitrogen analyser (HORIBA) and an through an adsorption process in a colloidal IrO2 solution. The preparation details

EMIA 220 V carbon/sulfur analyser (HORIBA). TG analysis (Thermo plus EVO2, for the IrO2 colloid have been described previously30. The as-prepared Y2Ti2O5S2

Rigaku Corporation) was conducted to examine the thermal stability of Y2Ti2O5S2, powder was suspended in an aqueous solution containing the desired amount of

monitoring the total mass loss from ambient temperature to 700 °C in static air and IrO2 colloid and stirred for 40 min. The procedure allowed IrO2 nanoparticles to

N2 at a heating rate of 10 °C min−1. be adsorbed onto the Y2Ti2O5S2 surface. The IrO2-loaded Y2Ti2O5S2 powder was

collected by filtration and dried at 313 K under vacuum. For the oxygen evolution

Theoretical calculations. The DOS and related calculations for Y2Ti2O5S2 were reaction, IrO2-loaded Y2Ti2O5S2 powder (0.3 g) was dispersed in 150 ml of an AgNO3

performed using the Cambridge Serial Total Energy Package (CASTEP) code (20 mM) aqueous solution, where Ag+ cations acted as sacrificial electron acceptors.

based on density functional theory27,28. The generalized gradient approximation The reaction trials were performed in the same top-irradiation system at the same

of Perdew–Burke–Ernzerhof as implemented in the CASTEP code was adopted temperature and background pressure as the hydrogen evolution reactions. The

for the exchange-correlation functional. The calculations were carried out on reaction rate was determined from the amount of oxygen evolved in the first hour.

the following basis: (1) an ultra-soft pseudopotential description of electron–ion

interactions represented in reciprocal space, (2) a finite plane-wave basis set with Photocatalytic reactions for overall water splitting. The Y2Ti2O5S2 powder

corrections for the description of the wavefunction, truncated at a cutoff energy was added to an aqueous solution containing a calculated amount of the IrO2

of 340 eV, (3) an iterative scheme for self-consistent electronic minimization, colloid and stirred for 40 min, followed by rinsing with distilled water, filtration

using a convergence tolerance of 1.0 × 10−6 eV atom−1. During the calculations, the and drying at 313 K in vacuum. Subsequently, the IrO2-loaded Y2Ti2O5S2 powder

DOS incorporated a 7 × 7 × 1 Monkhorst–Pack k-vector grid for the irreducible was dispersed in a Na2S–Na2SO3 (20 mM each) aqueous solution containing

part of the first Brillouin zone with a 25 k-vector set. For geometry optimization the desired amount of RhCl3·3H2O. Photodeposition of the Rh co-catalyst was

of the crystal structure, the Broyden–Fletcher–Goldfarb–Shanno algorithm was performed under visible-light illumination (λ > 420 nm) until steady gas evolution

applied with the following convergent tolerances: the changes in energy ∆E, rates were obtained (typically for 2–3 h). After rinsing, filtrating and drying

the maximum force, the maximum stress and the maximum displacement were at 313 K in vacuum, the Rh/IrO2-loaded powder was dispersed in an aqueous

1 × 10−5 eV atom−1, 0.03 eV Å−1, 0.05 GPa and 0.001 Å, respectively. methanol solution (10 vol%) containing the desired amount of K2CrO4. The

resultant suspension was illuminated with visible light (λ > 420 nm) for 12 h to

Mott–Schottky measurements. Electrodes of Y2Ti2O5S2 were fabricated by reduce K2CrO4 to Cr2O3 (Supplementary Fig. 12). The nominal loading amounts

a particle transfer method29. Y2Ti2O5S2 powder (60 mg) was suspended in of IrO2, Rh and Cr were 0.3, 2 and 1.5 wt%, respectively, unless otherwise noted

isopropanol (99.9%, 0.5 ml) and dropcast onto a glass substrate (~3 × 3 cm). After (Supplementary Fig. 20). The final product was washed thoroughly with distilled

drying at room temperature, a thin titanium layer was deposited by sputtering water, filtrated and then allowed to dry at 313 K in vacuum.

(MPS-254, ULVAC KIKO) to a thickness of 3 μm to ensure continuity and Unless otherwise noted, photocatalytic reactions for overall water splitting

conductivity. Electrochemical impedance spectroscopy was performed using a were carried out in the same closed gas circulation system with top illumination

three-electrode configuration with an Ag/AgCl reference electrode (in a saturated from a 300 W xenon lamp equipped with a cutoff filter (λ > 420 nm) that was used

KCl aqueous solution) and a Pt wire counter-electrode. An aqueous solution of for the hydrogen/oxygen evolution measurements. The Cr2O3/Rh/IrO2-loaded

0.1 M Na2SO4 was used as the electrolyte, and was stirred and purged with Ar gas. Y2Ti2O5S2 (0.2 g) powder was dispersed in 150 ml of distilled water. The pH of

The pH of the electrolyte solution was adjusted by adding H2SO4 (aq.) or NaOH the reactant was adjusted by adding La2O3 (0.1 g) as a buffer (pH 8.5) or H2SO4

(aq.) when necessary. Before the impedance spectroscopy test, cyclic voltammetry (aq.) or NaOH (aq.) when necessary. No gas production was detected in the

was carried out at a scan rate of 10 mV s−1. The impedance spectra were recorded system containing only La2O3 with or without light illumination. Besides, the gas

at a frequency of 1 kHz unless otherwise noted, with an a.c. amplitude of 10 mV evolution rates did not show large differences from the systems using an aqueous

under darkness. NaOH for pH adjustment and those using La2O3 as a buffer (Fig. 5b). Therefore,

it can be concluded that the La2O3 served only as a buffer for pH adjusting. The

Photoelectrochemical measurements. The Y2Ti2O5S2 electrodes were fabricated reaction vessel was evacuated several times before the reaction to ensure that no air

by the particle transfer method presented above and a roll press method. In the remained. The reaction temperature was kept at 288 K. The background pressure

particle transfer method, the Ti and Au layers, 1 and 3 μm thickness, respectively, was 7 kPa unless otherwise noted.

were deposited by vacuum evaporation in sequence. In the roll press method,

Y2Ti2O5S2 powder (6 mg) was dispersed in 0.5 ml of isopropanol. The powder ink Quantum yield measurements. The AQY of the photocatalytic reactions was

was then dropcast on a 1 × 2 cm Ti substrate (Nilaco). The electrode was fabricated calculated using

using a roll-to-roll machine (Yoshida Kinen, 25/100-2H) with a force of 9 kN.

AQY(%) = (AR∕I ) × 100%

The IrO2 co-catalyst was coated on the Y2Ti2O5S2/Ti electrode by dropping 150 μl

Nature Materials | www.nature.com/naturematerials

Letters Nature Materials

where R and I denote the gas evolution rate and the photon flux of monochromatic visible-light irradiation (λ > 420 nm) was carried out in a small Pyrex cell.

light, respectively, and A is the number of electrons needed to generate one The reaction was performed in 5 ml of H218O containing 0.1 g of Cr2O3/Rh/IrO2-

molecule of H2 or O2, that is, 2 or 4 for hydrogen or oxygen evolution, respectively. loaded Y2Ti2O5S2 and 0.1 g of La2O3 (pH 8.5). The amount of gas produced in 3 h

The water-splitting reaction was carried out using the same experimental set-up was analysed by both gas chromatography and mass spectrometry

described above, except for the use of bandpass filters with central wavelengths (Hiden Analytical).

of 420.3, 441.3, 460.0, 478.7, 499.7, 518.8, 541.5, 559.5, 582.3, 599.8, 619.8, 639.6

and 658.7 nm and a full-width at half-maximum of 13 ± 1 nm. The number of Data availability

incident photons illuminating the reaction cell was measured using a grating The data that support the findings of this study are available from the

spectroradiometer. corresponding author upon reasonable request.

STH measurement. The water-splitting reaction was conducted under simulated

sunlight illumination. The STH is given as References

27. Milman, V. et al. Electronic structure, properties and phase stability of

STH(%) = (R (H 2) × ΔGr) ∕ (P × S ) × 100 inorganic crystals: a pseudopotential plane-wave study. Int. J. Quantum Chem.

77, 895–910 (2000).

where R(H2), ∆Gr, P and S indicate the rate of hydrogen evolution during the 28. Materials Studio CASTEP (Accelrys, 2001).

water-splitting reaction, the reaction Gibbs energy of the water-splitting reaction, 29. Minegishi, T., Nishimura, N., Kubota, J. & Domen, K. Photoelectrochemical

the energy intensity of the AM 1.5G solar irradiation (100 mW cm−2) and the properties of LaTiO2N electrodes prepared by particle transfer for sunlight-

irradiated sample area (38 cm2), respectively. driven water splitting. Chem. Sci. 4, 1120–1124 (2013).

30. Le, P.-T. C. et al. Photoelectrochemical properties of crystalline perovskite

Isotopic labelling. The water-splitting reaction using 18O-labelled water lanthanum titanium oxynitride films under visible light. J. Phys. Chem. C 113,

(water-18O, Aldrich, 97 at% 18O) over Cr2O3/Rh/IrO2-loaded Y2Ti2O5S2 under 6156–6162 (2009).

Nature Materials | www.nature.com/naturematerials

You might also like

- Cga g-4 1 1985Document22 pagesCga g-4 1 1985Jarbas MoraesNo ratings yet

- Solution-Processed Solar Cells Based On Environmentally Friendly AgBiS2 NanocrystalsDocument6 pagesSolution-Processed Solar Cells Based On Environmentally Friendly AgBiS2 Nanocrystalsandres granadosNo ratings yet

- v1 CoveredDocument14 pagesv1 CoveredrajkumarNo ratings yet

- Journal of The European Ceramic Society: Donggeng Zheng, Ruzhong ZuoDocument6 pagesJournal of The European Ceramic Society: Donggeng Zheng, Ruzhong ZuoJJ SerraltaNo ratings yet

- Electrical Characterization and Poole-Frenkel Effect in Sol-Gel Derived Zno:Al Thin FilmsDocument11 pagesElectrical Characterization and Poole-Frenkel Effect in Sol-Gel Derived Zno:Al Thin Filmsचन्द्रभाल सिंहNo ratings yet

- Wet Chemical Controllable Synthesis of Hematite Ellipsoids With Structurally Enhanced Visible Light PropertyDocument6 pagesWet Chemical Controllable Synthesis of Hematite Ellipsoids With Structurally Enhanced Visible Light PropertyIetha Sunshine Of LoveeNo ratings yet

- Nmat 4168Document7 pagesNmat 4168Michel MarcondesNo ratings yet

- Rajbongshi 2018Document4 pagesRajbongshi 2018bijumani2011No ratings yet

- Effect of Tio Nanoparticles On Mechanical Properties of Epoxy-Resin SystemDocument9 pagesEffect of Tio Nanoparticles On Mechanical Properties of Epoxy-Resin SystemDhananjay ShimpiNo ratings yet

- Nphys3676 PDFDocument7 pagesNphys3676 PDFGetachew FeyissaNo ratings yet

- 1D Cerium Oxide Nanorods Synthesis, Characterization and Their Humidity Sensing ApplicationDocument8 pages1D Cerium Oxide Nanorods Synthesis, Characterization and Their Humidity Sensing ApplicationIJRASETPublicationsNo ratings yet

- 1 s2.0 S0927775712007303 MainDocument12 pages1 s2.0 S0927775712007303 MainJôsy SouzaNo ratings yet

- Enhanced Photocatalytic Co - Reduction Activity of Anatase Tio by Coexposed (001) and (101) FacetsDocument8 pagesEnhanced Photocatalytic Co - Reduction Activity of Anatase Tio by Coexposed (001) and (101) FacetsyemosiNo ratings yet

- Deposition of Cu2ZnSnS4 Thin Films by Solution RouteDocument5 pagesDeposition of Cu2ZnSnS4 Thin Films by Solution RouteYoussef ArbaNo ratings yet

- Controlled hydrothermal synthesis of CeO2 nanocubes with excellent optical and magnetic propertiesDocument7 pagesControlled hydrothermal synthesis of CeO2 nanocubes with excellent optical and magnetic propertiesSHERLY KIMBERLY RAMOS JESUSNo ratings yet

- 7 Ceria Fluorite Electrolytes From Ionic To Mixed Electronic and Ionic MembranesDocument26 pages7 Ceria Fluorite Electrolytes From Ionic To Mixed Electronic and Ionic MembranesWashington Sta RosaNo ratings yet

- Investigation of Structural, Electrical and Electrochemical Properties of La SR Fe MN O As An Intermediate Temperature Solid Oxide Fuel Cell CathodeDocument15 pagesInvestigation of Structural, Electrical and Electrochemical Properties of La SR Fe MN O As An Intermediate Temperature Solid Oxide Fuel Cell CathodeKiy IhNo ratings yet

- Bi2Se3 Sol-GelDocument11 pagesBi2Se3 Sol-Gelhitesh chaudharyNo ratings yet

- Nature Materials 13, 897-903 (2014)Document7 pagesNature Materials 13, 897-903 (2014)elderwanNo ratings yet

- 2021-Chemical Mechanism of Formation of Two-Dimensional Electron Gas at The Al2O3TiO2 Interface by Atomic Layer DepositionDocument6 pages2021-Chemical Mechanism of Formation of Two-Dimensional Electron Gas at The Al2O3TiO2 Interface by Atomic Layer DepositionPartha sarathi padhiNo ratings yet

- Raman and Photovoltaic Properties of Rare Earth Doped Bismuth Ferrite CeramicsDocument9 pagesRaman and Photovoltaic Properties of Rare Earth Doped Bismuth Ferrite CeramicsBojan StojadinovićNo ratings yet

- 2000 Simwonis SldStateIonics NickelCoarseningInAnnealedNi8YSZAnodeSubstratesforSOFCDocument11 pages2000 Simwonis SldStateIonics NickelCoarseningInAnnealedNi8YSZAnodeSubstratesforSOFCAndres CamposNo ratings yet

- Dilute Electrodeposition of TiO2 and ZnO Thin Film MemristorsDocument6 pagesDilute Electrodeposition of TiO2 and ZnO Thin Film Memristorsalagar krishna kumarNo ratings yet

- Effects of K Bi Tio Addition On Dielectric Properties of Batio CeramicsDocument4 pagesEffects of K Bi Tio Addition On Dielectric Properties of Batio CeramicsSamah SamahNo ratings yet

- Oxygen Vacancies As Active Sites For Water Dissociation On Rutile TioDocument4 pagesOxygen Vacancies As Active Sites For Water Dissociation On Rutile TioiprateekNo ratings yet

- Abraham, Yusuff - 2003 - Copper (II) Complexes of Embelin and 2-Aminobenzimidazole Encapsulated in Zeolite Y-Potential As Catalysts For RDocument9 pagesAbraham, Yusuff - 2003 - Copper (II) Complexes of Embelin and 2-Aminobenzimidazole Encapsulated in Zeolite Y-Potential As Catalysts For Rcukaasam123456No ratings yet

- Photoelectrochemical Cell Study of Closely Arranged CdSe and Zn Doped CdSe Nanorod FilmsDocument5 pagesPhotoelectrochemical Cell Study of Closely Arranged CdSe and Zn Doped CdSe Nanorod FilmsarthurvargheseNo ratings yet

- 1 s2.0 S2238785421014204 MainDocument10 pages1 s2.0 S2238785421014204 MaincamilaNo ratings yet

- Drevet 2010Document10 pagesDrevet 2010hayet debbichNo ratings yet

- Corrosion Behaviour of Tinplate in SynthDocument11 pagesCorrosion Behaviour of Tinplate in SynthdouslasNo ratings yet

- 1 s2.0 S0010938X18305274 MainDocument9 pages1 s2.0 S0010938X18305274 MainHilios MonosNo ratings yet

- Materials LettersDocument4 pagesMaterials LettersSahin CoskunNo ratings yet

- A Novel Method To Prepare Metal Oxide Electrode: Spin-Coating With Thermal DecompositionDocument4 pagesA Novel Method To Prepare Metal Oxide Electrode: Spin-Coating With Thermal Decompositionhayet debbichNo ratings yet

- Gerasimos AgBiS2 2016Document6 pagesGerasimos AgBiS2 2016rbalamur15No ratings yet

- Spectral and FTIR Analysis of Tm3+ Doped in Zinc Lithium Tungsten Sodalime Borotellurite GlassesDocument8 pagesSpectral and FTIR Analysis of Tm3+ Doped in Zinc Lithium Tungsten Sodalime Borotellurite GlassesIJRASETPublicationsNo ratings yet

- 10 1002@slct 202002713Document5 pages10 1002@slct 202002713Fahad AzadNo ratings yet

- Electronic Structure of Oxide-Supported Tungsten Oxide CatalystsDocument5 pagesElectronic Structure of Oxide-Supported Tungsten Oxide CatalystsPedro lopezNo ratings yet

- Nanoscale Yttrium Distribution in Yttrium-Doped Ceria PowderDocument9 pagesNanoscale Yttrium Distribution in Yttrium-Doped Ceria PowderLeon PanjaitanNo ratings yet

- Paper 1Document9 pagesPaper 1Cristian RozoNo ratings yet

- Sol-gel Aluminum-doped ZnO thin films: synthesis and characterizationDocument9 pagesSol-gel Aluminum-doped ZnO thin films: synthesis and characterizationMurtaza SieamNo ratings yet

- Article Alloys CompoundsDocument11 pagesArticle Alloys CompoundsAbdelmagid El BakaliNo ratings yet

- Dye-Sensitized Solar Cells Using Ionic Liquid-Based ElectrolytesDocument5 pagesDye-Sensitized Solar Cells Using Ionic Liquid-Based ElectrolytesManojj21No ratings yet

- Thermal and Spectroscopic Investigation of Sol-Gel Derived Aluminosilicate Bioglass MatricesDocument5 pagesThermal and Spectroscopic Investigation of Sol-Gel Derived Aluminosilicate Bioglass MatricesAlina PopaNo ratings yet

- XPS Characterization of TiO2 Layers on QuartzDocument5 pagesXPS Characterization of TiO2 Layers on QuartzGabriel Vazquez VegaNo ratings yet

- Materials 10 00227Document11 pagesMaterials 10 00227GaganaNo ratings yet

- Energies 05 05363 v2Document9 pagesEnergies 05 05363 v2mevlut46No ratings yet

- Electrochemical Behavior of Corrosion Resistance of X65/Inconel 625 Welded JointsDocument11 pagesElectrochemical Behavior of Corrosion Resistance of X65/Inconel 625 Welded JointsÉlida AlvesNo ratings yet

- BFSZU-Volume 2022-Issue 1 - Page 30-36Document7 pagesBFSZU-Volume 2022-Issue 1 - Page 30-36Siddu KLEITNo ratings yet

- Advance Fuel Cells (Al2O3-nNaAlO2)Document9 pagesAdvance Fuel Cells (Al2O3-nNaAlO2)1DS19CH002 Akash SamantaNo ratings yet

- LIS 2022 New 1-77-81Document5 pagesLIS 2022 New 1-77-81Lppm Politeknik JambiNo ratings yet

- Physical and Optical Properties of Sprayed Cu Znsns (CZTS) Thin Film: Effect of Cu ConcentrationDocument9 pagesPhysical and Optical Properties of Sprayed Cu Znsns (CZTS) Thin Film: Effect of Cu ConcentrationSihem MansouriNo ratings yet

- Synthesis, Crystal Structure and Characterization of A New Oxalate Chromium (III) ComplexDocument7 pagesSynthesis, Crystal Structure and Characterization of A New Oxalate Chromium (III) ComplexSansanNo ratings yet

- J Cattod 2011 07 008Document8 pagesJ Cattod 2011 07 008Syeda Ammara AnwarNo ratings yet

- Raman Spectroscopy Reveals Phase Transformation of TiO2 Nanotubular Water Splitting CatalystsDocument7 pagesRaman Spectroscopy Reveals Phase Transformation of TiO2 Nanotubular Water Splitting CatalystsMelis YararNo ratings yet

- 3-D Solar Cells by Electrochemical-Deposited Se LaDocument8 pages3-D Solar Cells by Electrochemical-Deposited Se LaIndrajit ShriwastavNo ratings yet

- Article 3Document1 pageArticle 3amineNo ratings yet

- In Vitro Degradation of AZ31 Magnesium Alloy Coated With Nano TiO2 Film by Sol-Gel MethodDocument6 pagesIn Vitro Degradation of AZ31 Magnesium Alloy Coated With Nano TiO2 Film by Sol-Gel MethodRahul MadanNo ratings yet

- Synthesis, Structural and Electrical Properties of Bi Dy Feo Multiferroic CeramicsDocument5 pagesSynthesis, Structural and Electrical Properties of Bi Dy Feo Multiferroic CeramicsDr. S.K. BarbarNo ratings yet

- Electronics: A Study On The Transition of Copper Oxide by The Incorporation of NitrogenDocument11 pagesElectronics: A Study On The Transition of Copper Oxide by The Incorporation of NitrogenPauloValdiviesoNo ratings yet

- Casiterita ANP - 2016021516120865Document7 pagesCasiterita ANP - 2016021516120865Haydee ContrerasNo ratings yet

- Nonami 2004Document6 pagesNonami 2004Khue VanNo ratings yet

- Pure ZnO and Composite ZnO-TiO2 Catalyst PlatesDocument6 pagesPure ZnO and Composite ZnO-TiO2 Catalyst PlatesJohnny Lorenz Galvez CubasNo ratings yet

- 10 1021@acs Inorgchem 0c00594Document9 pages10 1021@acs Inorgchem 0c00594Khue VanNo ratings yet

- 10 1016@bs Adomc 2018 02 004Document45 pages10 1016@bs Adomc 2018 02 004Khue VanNo ratings yet

- Adsorption of Acetic Acid On Charcoal SurfaceDocument3 pagesAdsorption of Acetic Acid On Charcoal SurfaceFrankyFan90% (10)

- Report On Passive Solar DesignDocument46 pagesReport On Passive Solar DesignAMIT K SINGH60% (5)

- AQA GCSE Chem C3 Practice Question AnswersDocument2 pagesAQA GCSE Chem C3 Practice Question AnswersJawaria MazharNo ratings yet

- Cours Us AteqDocument73 pagesCours Us AteqNico VNo ratings yet

- CoatingDocument8 pagesCoatingMuhammad Rizki Ash-ShidiqNo ratings yet

- CHEM12 - C1805 - SRVS (Correct)Document2 pagesCHEM12 - C1805 - SRVS (Correct)xr aimNo ratings yet

- Equations of Use in The Closed-Book Exam (Use This Page For Your Work)Document5 pagesEquations of Use in The Closed-Book Exam (Use This Page For Your Work)mozam haqNo ratings yet

- Tergitol 3Document1 pageTergitol 3Shyam SharmaNo ratings yet

- Group 17-Solid State NMR - Questions-AnswersDocument5 pagesGroup 17-Solid State NMR - Questions-AnswersOmkar AkulwarNo ratings yet

- S - BENT 4843 Chapter 3Document114 pagesS - BENT 4843 Chapter 3Leslie WeeNo ratings yet

- Detailed Analysis of Toe-To-Heel Air Injection For Heavy Oil ProductionDocument14 pagesDetailed Analysis of Toe-To-Heel Air Injection For Heavy Oil ProductionMejbahul SarkerNo ratings yet

- Cryogenics: Published In: The Macmillan Encyclopedia of Chemistry, New York, 2002Document3 pagesCryogenics: Published In: The Macmillan Encyclopedia of Chemistry, New York, 2002ijasnazeerNo ratings yet

- Thermoacoustic Refrigeration ExplainedDocument14 pagesThermoacoustic Refrigeration ExplainedAbijith SureshNo ratings yet

- Summary of Organic Chemistry2 - Week19Document105 pagesSummary of Organic Chemistry2 - Week19Dollar'sCornerNo ratings yet

- Organic Lab - Distillation PDFDocument2 pagesOrganic Lab - Distillation PDFDaryayBaharNo ratings yet

- Thermal power plant introductionDocument39 pagesThermal power plant introductionPhanindra Guttula50% (2)

- Tutorial-2015-16 Modern PhysDocument6 pagesTutorial-2015-16 Modern PhysmirckyNo ratings yet

- Refrigeration and Air ConditioningDocument23 pagesRefrigeration and Air ConditioningSAIKATNo ratings yet

- A Non-Ideal HydrateDocument382 pagesA Non-Ideal Hydratelokeshkumar_mNo ratings yet

- Question Bank For Air ConditioningDocument3 pagesQuestion Bank For Air ConditioningAbhishek SainiNo ratings yet

- Bio Enzymes ExercisesDocument4 pagesBio Enzymes ExercisesMariamNo ratings yet

- SUMSEM2-2018-19 ECE1006 ETH VL2018199000757 Reference Material I 02-Jun-2019 Statistical Mechanics Bose Einstein and Fermi Dirac DistributionsDocument18 pagesSUMSEM2-2018-19 ECE1006 ETH VL2018199000757 Reference Material I 02-Jun-2019 Statistical Mechanics Bose Einstein and Fermi Dirac Distributionsaghil ashokan aghilNo ratings yet

- Bell Ringer - Chemical BondsDocument38 pagesBell Ringer - Chemical BondsqazNo ratings yet

- AnaChem Conjugate Acid Base Pairs 3Document3 pagesAnaChem Conjugate Acid Base Pairs 3Jei HernandezNo ratings yet

- C136W14E2Document18 pagesC136W14E2diamono794No ratings yet

- CN111330459A - Preparation Method of High-Flux Composite Reverse Osmosis Membrane and Prepared Reverse Osmosis Membrane - Google PatentsDocument7 pagesCN111330459A - Preparation Method of High-Flux Composite Reverse Osmosis Membrane and Prepared Reverse Osmosis Membrane - Google Patentssahar vahdatifarNo ratings yet

- Lesson Plan-Transport PhenomenaDocument3 pagesLesson Plan-Transport PhenomenaJeyakumar RajaNo ratings yet

- COMPARITIVE STUDY OF COMMERCIAL ANTACIDS-CBSE 12 ProjectDocument26 pagesCOMPARITIVE STUDY OF COMMERCIAL ANTACIDS-CBSE 12 ProjectKrishna Murthy60% (5)

- Purity FG Heat Transfer FluidDocument4 pagesPurity FG Heat Transfer FluidPetrus MalailakNo ratings yet