Professional Documents

Culture Documents

RTN25 End Truck Top Joint Si

Uploaded by

Francisco San VicenteOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RTN25 End Truck Top Joint Si

Uploaded by

Francisco San VicenteCopyright:

Available Formats

1 2 3 4 5 6 7 8

This document is the absolute property of R&M Materials Handling, Inc. This document must not be copied without the written permission of R&M Materials Handling, Inc.

The contents thereof must not be disclosed to a third party nor be used for any unauthorized purpose. Contravention will be prosecuted.

A

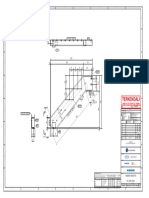

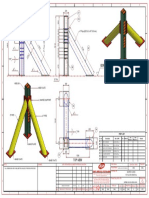

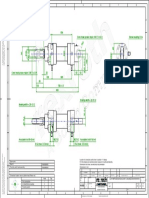

RTN25 END TRUCK TOP JOINT PLATE TYPE H

25 B max 25 JOINT PLATE BOLT

TIGHTENING TORQUE 180 128.6

250 min JPL M16 Bolt - Torque to 300Nm

B

M20 Bolt - Torque to 580 Nm 100

25

53.5

Ø

H1

H2

C

UU

L1 177 SS 177

20

UU = 54 - 99

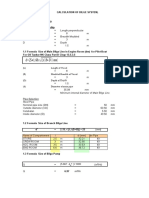

Wheelbase SS Max dyn whl load, (kN) Perm dyn whl load, (kN) Approx Wt./Trk, kg H1 H2 Buffer type L1 Ø

code (mm) SG DG ASCE 60 ASCE 85 SG DG SG DG SG DG (mm) (mm)

20 2000 185 - 114.6 126.5 375 - 315 - 150 - B 68 80

25 2500 171 185 114.6 126.5 419 459 315 315 150 150 C 85 100

D 32 3150 170 185 114.6 126.5 545 585 415 315 150 150 D 105 125

40 4000 158 185 114.6 126.5 637 677 415 415 150 150 K 80 80

45 4500 128 139 114.6 126.5 691 731 415 415 150 150 G 100 100

50 5000 138 182 114.6 126.5 904 944 420 420 155 155 E 150 100

55 5500 125 135 114.6 126.5 973 1013 420 420 155 155 F 190 125

Joint plate JPL B max H 160 160

I 200 200

Product Code example (mm) (mm)

A2

E M 125 125

RTN25-2574-H40610C0000-N H4 590 410

P 240 160

H5 700 520

N=standard, E=Special

S 300 200

H7 920 740

-primer paint, color code B, C, D rubber

H9 1170 990

(not in use with RTN25) K, G, E, F, H, I, M, P, S polyurethane

Buffer type The wheel loads listed are only a guideline. The max. wheel load listed is based on the

Joint plate distance (DG) structural integrity of the frame and load placement, and it does not take into account permissible Pos Description Specification Id Drawing

wheel loading or bearing life. SG load placement is at the center, and DG load placement is for a ETTPIA ETTPIA

Design Chd Appd Ref Drawing

Joint plate code trolley gage of 1400 mm [55 1/8"]. 2008-08-11

F - =1WD, D =2WD (per truck) The permissible dynamic wheel load listed is based on assumptions that the bridge speed is Date END TRUCK

1:7

40 m/min [130 fpm], end truck duty is Fem 2m, and the runway rail as listed. SLEQDOCV

Wheel groove =UU Dept

OUTLINE DRAWING Folder

Wheel base =SS If permissible dynamic wheel load is greater than the maximum dyn wheel load, use maximum dyn ECN25

R&M MATERIALS HANDLING, INC RTN25-H

- =std, C=asymmetrical joint wheel load to select the end truck. R&M HOIST & CRANE PRODUCTS Issue

MATERIALS

Type of end carriage Dyn wheel load = 1.15 x static wheel load HANDLING SPRINGFIELD, OHIO RTN25 END TRUCK TOP JOINT 10/2014

INC.

You might also like

- Ma5 TT01-ST05-1C259-4: Grid Location TT01-ST05-1C259-4 B-A/2-1/E Assembly Top Level: EL. +14.800Document1 pageMa5 TT01-ST05-1C259-4: Grid Location TT01-ST05-1C259-4 B-A/2-1/E Assembly Top Level: EL. +14.800Gandara SugandhiNo ratings yet

- Grid Location TT01-ST01-1C259-2 B/2-1/EL. Assembly Top Level: EL. +11.300Document1 pageGrid Location TT01-ST01-1C259-2 B/2-1/EL. Assembly Top Level: EL. +11.300Gandara SugandhiNo ratings yet

- February Monthly Collection, Grade 5From EverandFebruary Monthly Collection, Grade 5Rating: 3 out of 5 stars3/5 (1)

- 1707-A-1-008 Road and Building LevelsDocument1 page1707-A-1-008 Road and Building LevelsAnonymous INyA4KbNo ratings yet

- Bumper Guide DrawingDocument1 pageBumper Guide DrawingarunNo ratings yet

- Designed Sgd. PS Drawing Verified Aproved Sgd. PS: 1st Angle Projection Dimensions in Mm. 6/24/2019 11/19/2018Document1 pageDesigned Sgd. PS Drawing Verified Aproved Sgd. PS: 1st Angle Projection Dimensions in Mm. 6/24/2019 11/19/2018Birlan AdrianNo ratings yet

- RB A225 APPROVAL REV 1 - 14 EndDocument1 pageRB A225 APPROVAL REV 1 - 14 EndTariqMahmoodNo ratings yet

- CDH2MT4 80 56 1650A3X A11CFDAZWWAWWWWC X DimsheetDocument1 pageCDH2MT4 80 56 1650A3X A11CFDAZWWAWWWWC X DimsheetMateus CamargoNo ratings yet

- 640 0003 0011b05ed00Document1 page640 0003 0011b05ed00IlyasaNo ratings yet

- DETAILS OF RCC GUTTER AT+122.10m LVL. - R1Document1 pageDETAILS OF RCC GUTTER AT+122.10m LVL. - R1ShashankSinghNo ratings yet

- AS119-4L-30 - Ver.7 DimensionDocument1 pageAS119-4L-30 - Ver.7 DimensionmilicevicbpNo ratings yet

- GA-01-Rev ADocument1 pageGA-01-Rev AMihailo ČabovićNo ratings yet

- Mas Que Tu Amigo Trombone IDocument2 pagesMas Que Tu Amigo Trombone IEdgardo Mendez GuzmanNo ratings yet

- Irb 4600Document3 pagesIrb 4600Arvydas Gaurilka0% (1)

- Mall Cetakan Shaft MaruisiDocument1 pageMall Cetakan Shaft MaruisiWawan SaputraNo ratings yet

- No Changes AA ICSDocument1 pageNo Changes AA ICSGerges RamzyNo ratings yet

- 7.629193.R 002 01Document1 page7.629193.R 002 01rajitkumar.3005No ratings yet

- Schematic Leach Amp 700W 2023-10-06Document1 pageSchematic Leach Amp 700W 2023-10-06Francisco MadridNo ratings yet

- 05 - Second Floor Beam & Slab Layout Details - r2 (05.08.21) - Sheet-1Document1 page05 - Second Floor Beam & Slab Layout Details - r2 (05.08.21) - Sheet-1PackiarajNo ratings yet

- SRTT-B 50 NM - 36 01 PDFDocument1 pageSRTT-B 50 NM - 36 01 PDFONURNo ratings yet

- Droplet - Separator - (Tag No. 6a25-V14) - MasterDocument4 pagesDroplet - Separator - (Tag No. 6a25-V14) - MasterJayan VKNo ratings yet

- No Morirã¡ - Trombã N 1Document2 pagesNo Morirã¡ - Trombã N 1eddy jarquin GutiérresNo ratings yet

- Prestressed Girder Elevation (Type V, L 33.00M) : Back of Backwall End of Girder 3 2 End of GirderDocument1 pagePrestressed Girder Elevation (Type V, L 33.00M) : Back of Backwall End of Girder 3 2 End of GirderErika Faye GutierrezNo ratings yet

- Assad Palace Pavilion 07062021 PDFDocument7 pagesAssad Palace Pavilion 07062021 PDFOmar AmirNo ratings yet

- Nadie Es Eterno Score PDFDocument3 pagesNadie Es Eterno Score PDFMartin Alejo NarvaezNo ratings yet

- Nadie Es Eterno ScoreDocument3 pagesNadie Es Eterno Scoreoscar loayza pereyraNo ratings yet

- SCALE 1:50 SCALE 1:50: Ground Floor First FloorDocument1 pageSCALE 1:50 SCALE 1:50: Ground Floor First Floortesfayeseid7No ratings yet

- Caballo - Viejo Trompeta BDocument1 pageCaballo - Viejo Trompeta BWilliams TutayaNo ratings yet

- La Gran Señora - Trompeta 2Document2 pagesLa Gran Señora - Trompeta 2Caes Diseño y publicidadNo ratings yet

- Tủ điện 2Document1 pageTủ điện 2Nhật LêNo ratings yet

- Good For Construction: Schedule of Shear ReinfDocument1 pageGood For Construction: Schedule of Shear ReinfZaid HussainNo ratings yet

- Diyos Ay Pag-Ibig 1st TrumpetDocument1 pageDiyos Ay Pag-Ibig 1st TrumpetNonjTreborTendenillaToltol100% (1)

- Mohammed Asras ARDocument1 pageMohammed Asras AReman65178No ratings yet

- "Yo Quisiera": II TromboneDocument2 pages"Yo Quisiera": II TromboneSantiago GuerraNo ratings yet

- User Instruction HIC402A - 404A - 406A - 408A - 410A - 412A - 416ADocument2 pagesUser Instruction HIC402A - 404A - 406A - 408A - 410A - 412A - 416AHamd1971No ratings yet

- BL90-30 - 951784Document1 pageBL90-30 - 951784Bps PSNo ratings yet

- Va0722 0Document1 pageVa0722 0陆军No ratings yet

- Marshall Ma100 Ma50 SCHDocument5 pagesMarshall Ma100 Ma50 SCHMarco ZamoranoNo ratings yet

- Volusia County EvacDocument1 pageVolusia County EvacDaniel S LevineNo ratings yet

- (Trafo Katk-85-190-205)Document1 page(Trafo Katk-85-190-205)Laura Sofía VélezNo ratings yet

- Serie 1700 Pressure Booster Air Service UnitsDocument1 pageSerie 1700 Pressure Booster Air Service UnitsDiana AngelesNo ratings yet

- Tabg Jec 0 000 Pro Pid 0012 - GDocument1 pageTabg Jec 0 000 Pro Pid 0012 - GAfif FadhliNo ratings yet

- Samba Da Minha Terra - ClarinetDocument2 pagesSamba Da Minha Terra - ClarinetMatheus LuzNo ratings yet

- Dynasty Flute 1 R. Mutolo PDFDocument2 pagesDynasty Flute 1 R. Mutolo PDFSimone Piraino Official ChannelNo ratings yet

- As Built Drawing: Cilegon Sag LineDocument1 pageAs Built Drawing: Cilegon Sag LineYosses Sang NahkodaNo ratings yet

- Gas Springs Mounting Brackets For Gas Springs: Mounting Orientation Limited TypeDocument1 pageGas Springs Mounting Brackets For Gas Springs: Mounting Orientation Limited TypeKL JACKNo ratings yet

- Hard Chromium Plated Th.0.03: Skl01-Deflector - Roll - AssyDocument1 pageHard Chromium Plated Th.0.03: Skl01-Deflector - Roll - AssyhawyegNo ratings yet

- IyyyyyyyyyyyyyyykDocument3 pagesIyyyyyyyyyyyyyyykrim deNo ratings yet

- Whiplash-Bb TrumpetDocument1 pageWhiplash-Bb Trumpetluizmario15No ratings yet

- Rev 00 - Pumps 1Document1 pageRev 00 - Pumps 1Anonymous vwbLPTpjNo ratings yet

- Plan Elevation +18210 T.O.S.: No Holes Mentioned For Bolting Handrails A03-69& A03-70Document1 pagePlan Elevation +18210 T.O.S.: No Holes Mentioned For Bolting Handrails A03-69& A03-70HasmukhNo ratings yet

- Oruro Querido-Violin I PDFDocument1 pageOruro Querido-Violin I PDFArpad DebreczeniNo ratings yet

- Crank Ver 2.4Document1 pageCrank Ver 2.4Cao Đào NamNo ratings yet

- CDH1MP5 125 90 150A30X B11CAUAW DimsheetDocument1 pageCDH1MP5 125 90 150A30X B11CAUAW Dimsheetashfaq shaikhNo ratings yet

- 48PFL4150 K-P-L03 Schematic Diagram - PSUDocument1 page48PFL4150 K-P-L03 Schematic Diagram - PSUUDS pvtNo ratings yet

- 3 Guest Elevations and Stair DetailsDocument1 page3 Guest Elevations and Stair Detailstouati benNo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- IRB6700 - WORK ENVELOP - 03 - AllDocument8 pagesIRB6700 - WORK ENVELOP - 03 - AllZMCNo ratings yet

- Placement TestDocument7 pagesPlacement TestArstar ArsaleoNo ratings yet

- FC-M8120 FC-M8120 BB-MT800 SM-CRM85: DEORE XT CranksetDocument1 pageFC-M8120 FC-M8120 BB-MT800 SM-CRM85: DEORE XT Cranksetbird99No ratings yet

- Use Personnel Lift Aerial Lift 06 2015 1Document2 pagesUse Personnel Lift Aerial Lift 06 2015 1Margielyn CaoileNo ratings yet

- QD0002-ADM-TEM-HSE-00027 HSE Issues Tracking Log Rev 0A 5.11.2020Document43 pagesQD0002-ADM-TEM-HSE-00027 HSE Issues Tracking Log Rev 0A 5.11.2020shah fahadNo ratings yet

- Works of Short and Long Duration, Protection Arrangements EtcDocument82 pagesWorks of Short and Long Duration, Protection Arrangements EtcThiyagarajan kNo ratings yet

- Esquema Electrico D6R - CDA CatDocument15 pagesEsquema Electrico D6R - CDA CatOrlando RimarachinNo ratings yet

- Paris Dublin A321nDocument55 pagesParis Dublin A321nLouisNo ratings yet

- Auto Abbreviation DictionaryDocument7 pagesAuto Abbreviation Dictionarytime2grow100% (1)

- D 25+1,68 X LX (B+D) (MM) : (L) Length of VesselDocument2 pagesD 25+1,68 X LX (B+D) (MM) : (L) Length of VesselAndika SatriyaNo ratings yet

- Technology Course Reader SDocument181 pagesTechnology Course Reader SJuanmi EspinNo ratings yet

- Excavadora 336NGHDocument16 pagesExcavadora 336NGHFinning CatNo ratings yet

- Unscheduled Proppeller Feathering: Standar Operational ProceduresDocument2 pagesUnscheduled Proppeller Feathering: Standar Operational ProceduresAlëxândër KošëNo ratings yet

- Hino 700 Rear Suspension.Document10 pagesHino 700 Rear Suspension.Joki MarzukiNo ratings yet

- Intelligent Transportation SystemDocument11 pagesIntelligent Transportation SystemCollins omondi onyangoNo ratings yet

- MandateDocument3 pagesMandateGabor FarkasNo ratings yet

- Mahaba Lip Ur AmDocument322 pagesMahaba Lip Ur AmPrabaldeep GautamNo ratings yet

- Hyundai Robex 170Document10 pagesHyundai Robex 170Phong ExcavatorNo ratings yet

- Stands ARAIDocument20 pagesStands ARAIKanhaiyaPrasadNo ratings yet

- Car and Driver USA 10.2019Document100 pagesCar and Driver USA 10.2019AparecidoKazuoNagahiroNo ratings yet

- 2022-06-27 FY22 SGR Project ManualDocument259 pages2022-06-27 FY22 SGR Project ManualMuhammad SulemanNo ratings yet

- Product Information: Molygen New Generation 5W-30Document2 pagesProduct Information: Molygen New Generation 5W-30Vinicius Vilbert RodriguesNo ratings yet

- Layout Optimization of Rail Expansion Joint On Long-Span Cable-Stayed Bridge For High-Speed RailwayDocument15 pagesLayout Optimization of Rail Expansion Joint On Long-Span Cable-Stayed Bridge For High-Speed RailwayParth TrivediNo ratings yet

- Iparts 8BDRU15-36118 TY 8BRU PDF-1541174755Document160 pagesIparts 8BDRU15-36118 TY 8BRU PDF-1541174755Carlos GómezNo ratings yet

- 009.21-0227.6 E-Y05 0Document150 pages009.21-0227.6 E-Y05 0popo20084455No ratings yet

- Fully Actuated vs. Semi-Actuated Traffic Signal SystemsDocument6 pagesFully Actuated vs. Semi-Actuated Traffic Signal SystemsMuhammad AxeemNo ratings yet

- Haynes Max Power Modifying ManualsDocument128 pagesHaynes Max Power Modifying ManualsPablo DpNo ratings yet

- Road Safety Week 2017 ReportDocument47 pagesRoad Safety Week 2017 ReportBhanu SudheerNo ratings yet

- Dharmavaram Katpadi Cost Estimate Accompanying MatterDocument22 pagesDharmavaram Katpadi Cost Estimate Accompanying MatterRahul GuptaNo ratings yet

- Kgoro Residential BrochureDocument24 pagesKgoro Residential BrochureLeila Dougan100% (2)

- Mistral Simbad-Rc: Remotely Controlled Self-Defence SystemDocument2 pagesMistral Simbad-Rc: Remotely Controlled Self-Defence SystemAdetya GuritnaNo ratings yet