Professional Documents

Culture Documents

Atb 001

Uploaded by

Tejon AguilarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Atb 001

Uploaded by

Tejon AguilarCopyright:

Available Formats

Technical Bulletin #001

Transmission: Chrysler A-604

Subject: Electrical diagnosis

Issue Date: January, 1990

Chrysler A-604

Electrical Diagnosis

Solenoid Assembly

The solenoid assembly (figure 1) for the Chrysler A-604 consists of 4

solenoids, 4 ball valves, 3 pressure switches and 3 resistors. The ball

valves are operated by the solenoids and together they shift the

transmission through the various gears and control lock up. The 3

pressure switches and resistors are used to signal the

computer that a shift has occurred. Figure 1

During rebuild or repair, the solenoid assembly should be checked for proper operation. This can be done

through the 8 pin connector (figure 2). Refer to figure 3 for the function of each of the 8 pins.

Figure 2

Pin# Function

1 2-4 Pressure Switch

2 Low-Reverse Pressure Switch

3 Overdrive Pressure Switch

4 12 Volt Input

5 Underdrive Solenoid

6 Overdrive Solenoid

7 Low-Reverse/Lock-Up Solenoid

8 2-4/Low-Reverse Solenoid Figure 3

Copyright © 2003 ATRA. All Rights Reserved. ! Page 1 of 3

Technical Bulletin #001

Checking the Switches and Resistors

To check the 3 switches and resistors use an ohmmeter set at ohms x 1 (RX1). Connect a lead from pin 4 to the

solenoid housing (ground) then connect the two leads of the ohmmeter to pins 1 and 4 (see figure 2). The resist-

ance should be 270-330 ohms. You have just checked the resistor for the 2-4 pressure switch.

To check the switch, leave the ohmmeter connected and apply compressed air to the 2-4 pressure switch feed

hold (see figure 4). The ohmmeter should read zero ohms resistance.

Now perform the same procedure at pins 2 and 4 for the low-reverse resistor and switch. Once again resistance

should be 270-330 ohms (300 ohms = or -30) and go to zero ohms when the switch is pressurized. Use pins 3

and 4 to check the overdrive pressure switch.

Now perform the same procedure at pins 2 and 4 for the low-reverse resistor and switch. Once again resistance

should be 270-330 ohms (300 ohms + or - 30) and go to zero ohms when the switch is pressurized. Use pins 3

and 4 to check the overdrive pressure swtich.

View of the Bottom of the Solenoid Assembly

Figure 4

! Page 2 of 3 Copyright © 2003 ATRA. All Rights Reserved.

Technical Bulletin #001

Checking the Solenoids

Each of the 4 solenoids should be checked next. Connect the ohmmeter leads to pins 4 and 5 to check the resist-

ance of the underdrive solenoid. The resistance should be 1.5 ohms. (A digital ohmmeter works best for this

test). The other solenoids are checked in the same manner using pins 4 and 6, 4 and 7, and 4 and 8.

Shifting the Transaxle

Many times it is necessary to shift a transmission with jumper leads to determine if a problem is in the transmis-

sion or in the computer system. On the A-604 this can be done by providing 12 volts through a fused (20 amp)

jumper wire to pin 4 (12 volt input) and grounding pins 6, 7, and 8 in the proper sequence. (See the chart below)

Range Ground These Pins

First Gear 7 and 8

Second Gear 0

Third Gear 6 and 8

Fourth Gear 5 and 6

Lock-Up 7

If you supply 12 volts to pin 4 and then ground pins 7 and 8 the transaxle should be in 1st gear. Remove the

grounds to shift to 2nd. Connect the grounds to pins 6 and 8 for 3rd gear. Grounding 5 and 6 will give you 4th

gear. Anytime you're in 2nd, 3rd or 4th you can ground pin 7 for lock-up (TCC).

Copyright © 2003 ATRA. All Rights Reserved. ! Page 3 of 3

You might also like

- Passive and Discrete Circuits: Newnes Electronics Circuits Pocket Book, Volume 2From EverandPassive and Discrete Circuits: Newnes Electronics Circuits Pocket Book, Volume 2No ratings yet

- Atb 001 ADocument3 pagesAtb 001 ATejon AguilarNo ratings yet

- Subaru 4EATDocument2 pagesSubaru 4EATGuilherme ZoboliNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- C68RCDocument67 pagesC68RCYovani Gamaliel100% (5)

- SP0012Document10 pagesSP0012Rolando BarretoNo ratings yet

- Experiment Number: 5: Study and Test 3-Phase Ac Voltage RegulatorDocument7 pagesExperiment Number: 5: Study and Test 3-Phase Ac Voltage RegulatorDineshKanawatNo ratings yet

- REXROTH 4wrz 16 5x-6x Series PDFDocument20 pagesREXROTH 4wrz 16 5x-6x Series PDFمحمدلمينابراهيمالموريتاني100% (1)

- H / P P S E Man Alpha One/7R/8R/8P Amplifier Service ManualDocument16 pagesH / P P S E Man Alpha One/7R/8R/8P Amplifier Service Manual王军No ratings yet

- Atb 320Document2 pagesAtb 320Taller MarioNo ratings yet

- Asco Series 8551 Installation Maintenance Instructions 2000Document4 pagesAsco Series 8551 Installation Maintenance Instructions 2000Alexis Sepond AlexisNo ratings yet

- Mercedes Automatic Transmission Conductor PlateDocument4 pagesMercedes Automatic Transmission Conductor PlateAnonymous WzR5h9g8VNo ratings yet

- Interfacing of Stepper MotorDocument5 pagesInterfacing of Stepper MotorTalhaNo ratings yet

- 1 Design A Protection System Using IDMT Relay To Protect System For Given Fault Currents & Plot The Operating Time Characteristics of The Relay UsedDocument6 pages1 Design A Protection System Using IDMT Relay To Protect System For Given Fault Currents & Plot The Operating Time Characteristics of The Relay UsedMR. SUSHIL BARAPATRENo ratings yet

- Relay RoomDocument6 pagesRelay RoomAANo ratings yet

- Power Electronics - Basic MCQDocument14 pagesPower Electronics - Basic MCQDinesh SNo ratings yet

- Mecc Alte Portable Ts GuideDocument9 pagesMecc Alte Portable Ts GuidesfeNo ratings yet

- Winco 60711-018 Rotating Field Ts GuideDocument4 pagesWinco 60711-018 Rotating Field Ts GuideZeck100% (1)

- Testing of Relays and Detailed ProcedureDocument30 pagesTesting of Relays and Detailed Proceduresetyo nugrohoNo ratings yet

- Trouble Shooting Pancake GeneratorsDocument7 pagesTrouble Shooting Pancake GeneratorsRomel José Londoño CamachoNo ratings yet

- 42re PDFDocument2 pages42re PDFEderNo ratings yet

- Overvoltage and Undervoltage Protection System: Mohit Mishra, Rajiv Kumar Saw, Deepak Saraswat, Harpreet KaurDocument16 pagesOvervoltage and Undervoltage Protection System: Mohit Mishra, Rajiv Kumar Saw, Deepak Saraswat, Harpreet Kaurshein htetNo ratings yet

- Report Lab1Document15 pagesReport Lab1Minh NgocNo ratings yet

- Table (4b) Actuator Dimensions (OM-2 To OM-3, OM-4 To OM-6) Table (4a) Actuator Dimensions (OM-1)Document5 pagesTable (4b) Actuator Dimensions (OM-2 To OM-3, OM-4 To OM-6) Table (4a) Actuator Dimensions (OM-1)NaveenRajNo ratings yet

- 20EE504-PE Lab ManualDocument59 pages20EE504-PE Lab Manual20EUEE018 - DEEPAK. MNo ratings yet

- Troubleshooting and Service Information For Voltmaster GeneratorsDocument15 pagesTroubleshooting and Service Information For Voltmaster GeneratorsMd Rodi Bidin100% (1)

- Report Power eDocument17 pagesReport Power enor anisNo ratings yet

- Cablemaster CM - Troubleshooting GuideDocument4 pagesCablemaster CM - Troubleshooting GuideGlendinning Products, LLC.No ratings yet

- Alternator Delco With Integral RegulatorDocument10 pagesAlternator Delco With Integral Regulatormad659100% (1)

- AVR ComparisionDocument7 pagesAVR ComparisionGrupos GeradoresNo ratings yet

- Dynatek-S-Electronic-Ignition Dual FireDocument4 pagesDynatek-S-Electronic-Ignition Dual FireAdrián CasarrubiasNo ratings yet

- GROUP 5 EPPR (Electro Proportional Pressure Reducing) VALVEDocument3 pagesGROUP 5 EPPR (Electro Proportional Pressure Reducing) VALVERiahi RezegNo ratings yet

- Major Project PDFDocument5 pagesMajor Project PDFSudipta DebnathNo ratings yet

- Horns: Description and OperationDocument6 pagesHorns: Description and OperationLilisbethBasantaNo ratings yet

- Trouble Shooting Capacitor Regulated Pancake Light Tower GeneratorsDocument7 pagesTrouble Shooting Capacitor Regulated Pancake Light Tower GeneratorsBilly MecanizadoNo ratings yet

- Lock Out Relay PDFDocument10 pagesLock Out Relay PDFshaikhsajid242No ratings yet

- ZF 4 HP 16Document6 pagesZF 4 HP 16RIGOBERTO MARTINEZNo ratings yet

- Trouble Shooting - Magnaplus / Mariner / Harsh DutyDocument10 pagesTrouble Shooting - Magnaplus / Mariner / Harsh Dutyrizky ListyawanNo ratings yet

- 1986-1988 SuzukiSamurai Ignition ManualDocument11 pages1986-1988 SuzukiSamurai Ignition ManualRoads MomentsNo ratings yet

- Ee2302 - Electrical Machines Ii Question Bank Short Answer QuestionsDocument5 pagesEe2302 - Electrical Machines Ii Question Bank Short Answer QuestionsKarthi RamachandranNo ratings yet

- Maintenence of Double Line Block Instrument Used in Indian RailwaysDocument7 pagesMaintenence of Double Line Block Instrument Used in Indian RailwaysVikas Srivastav100% (1)

- Experiment FinalDocument29 pagesExperiment FinalmallikarjunbpatilNo ratings yet

- 01 MDocument2 pages01 MGuilherme ZoboliNo ratings yet

- Diagramas de Conexion VR6Document22 pagesDiagramas de Conexion VR6David ArbildoNo ratings yet

- 62te GDDocument4 pages62te GDluiz fernando leal verneNo ratings yet

- A604 A606 42rleDocument2 pagesA604 A606 42rleGuilherme ZoboliNo ratings yet

- TB6560 Mach3 CNC Stepper Motor Controller Operation InstructionDocument19 pagesTB6560 Mach3 CNC Stepper Motor Controller Operation InstructionCornel BordeiNo ratings yet

- Lab ReportDocument9 pagesLab ReportMuhammad Faizan Tariq100% (1)

- 312 - EXP - 3 - Three Phase Six PulseDocument7 pages312 - EXP - 3 - Three Phase Six PulseSamiul TashbirNo ratings yet

- Electrical Machines: Investigations Regarding Equivalent Circuit Parameters of A Real TransformerDocument5 pagesElectrical Machines: Investigations Regarding Equivalent Circuit Parameters of A Real TransformerAsghar AliNo ratings yet

- Write Up 3Document4 pagesWrite Up 3cynicmonkNo ratings yet

- Axis Drive Systems PDFDocument62 pagesAxis Drive Systems PDFJoshNo ratings yet

- 555 Timer TutorialDocument43 pages555 Timer TutorialcprofesionalNo ratings yet

- Ford 4EAT-F (F4A-EL) 1997 & UP Escort Mazda Protégé UP To 1998Document2 pagesFord 4EAT-F (F4A-EL) 1997 & UP Escort Mazda Protégé UP To 1998AUTOPARTES 1987No ratings yet

- Electronic Circuit Symbols: Power Supplies Component Circuit Symbol Function of ComponentDocument8 pagesElectronic Circuit Symbols: Power Supplies Component Circuit Symbol Function of ComponentImran AhmedNo ratings yet

- Maintenance: Change Top UnitDocument11 pagesMaintenance: Change Top UnitPhụng Trần DuyNo ratings yet

- 3 Axis 4AUPC Rev0 Driver Board Kit InstructionsDocument3 pages3 Axis 4AUPC Rev0 Driver Board Kit InstructionsmarceloNo ratings yet

- Attachment PDFDocument2 pagesAttachment PDFJORFRENo ratings yet

- PS Lab ManualDocument25 pagesPS Lab ManualPRAVEEN KUMAR SINGHNo ratings yet

- Atb 009Document1 pageAtb 009Tejon AguilarNo ratings yet

- Atb 005Document4 pagesAtb 005Tejon AguilarNo ratings yet

- Atb 008Document3 pagesAtb 008Tejon AguilarNo ratings yet

- Atb 002Document3 pagesAtb 002Tejon AguilarNo ratings yet

- Atb 006Document3 pagesAtb 006Tejon AguilarNo ratings yet

- Atb 007Document2 pagesAtb 007Tejon AguilarNo ratings yet

- 164 169 PDFDocument6 pages164 169 PDFTejon AguilarNo ratings yet

- Atb 003Document2 pagesAtb 003Tejon Aguilar100% (1)

- ZF4HP22: Technical Bulletin #004Document2 pagesZF4HP22: Technical Bulletin #004Tejon AguilarNo ratings yet

- TF 60 SNDocument5 pagesTF 60 SNTejon AguilarNo ratings yet

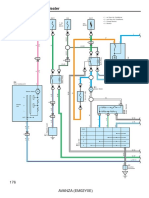

- Air Conditioner With Heater: 176 Avanza (Em02Y0E)Document4 pagesAir Conditioner With Heater: 176 Avanza (Em02Y0E)Tejon AguilarNo ratings yet

- Unit 2 PDFDocument39 pagesUnit 2 PDFMoulod Mouloud100% (1)

- AEM For Series SE and SEHDocument30 pagesAEM For Series SE and SEHdimNo ratings yet

- Transistor MOSFET - K2761Document3 pagesTransistor MOSFET - K2761David Jonatan Alayo LlajarunaNo ratings yet

- SCR DatasheetDocument9 pagesSCR DatasheetSarah DuranNo ratings yet

- Infrarrojos y UltrasónicosDocument81 pagesInfrarrojos y UltrasónicosgdiliogNo ratings yet

- 86262GS Portable Generators 1Document128 pages86262GS Portable Generators 12457gary100% (2)

- Marshall Class 5 Owner ManualDocument4 pagesMarshall Class 5 Owner ManualJuan Cruz LeónNo ratings yet

- Physics Worksheet Class: X Chapter: ElectricityDocument2 pagesPhysics Worksheet Class: X Chapter: ElectricityMohit GargNo ratings yet

- Catalogue Havells Power Solutions ComponentsDocument24 pagesCatalogue Havells Power Solutions Componentssiddhant103No ratings yet

- Study Guide OSHA 30 Construction Focus Four Electrocuction HazardsDocument86 pagesStudy Guide OSHA 30 Construction Focus Four Electrocuction HazardssuperpiojoNo ratings yet

- Universal-XR60CX: The All in One ControlDocument2 pagesUniversal-XR60CX: The All in One ControlMostafa ShannaNo ratings yet

- GE Tetra Led Lighting Systems Power Supply BrochureDocument8 pagesGE Tetra Led Lighting Systems Power Supply BrochureJuan Manuel BazánNo ratings yet

- A Seminar On: Battery Energy Storage For Enabling Distributed Solar Power GenerationDocument25 pagesA Seminar On: Battery Energy Storage For Enabling Distributed Solar Power GenerationUvarajGopalNo ratings yet

- LT1083 Power Supply Regulated 7Document3 pagesLT1083 Power Supply Regulated 7Collie de KloeNo ratings yet

- ANSI CodesDocument12 pagesANSI CodesmgkvprNo ratings yet

- TFT-LCD - Claa215fa01 - Chunghwa Picture TubesDocument30 pagesTFT-LCD - Claa215fa01 - Chunghwa Picture TubesLucian TrifinaNo ratings yet

- Questions & Answers On Transmission LinesDocument43 pagesQuestions & Answers On Transmission Lineskibrom atsbha100% (2)

- MBR20200Document10 pagesMBR20200Luis BreaNo ratings yet

- Bettis™ EHO Electro-Hydraulic Operator: Product Data SheetDocument15 pagesBettis™ EHO Electro-Hydraulic Operator: Product Data SheetCristobal HernandezNo ratings yet

- 7 Induction MachDocument88 pages7 Induction MachzianurhaqiNo ratings yet

- Esm-4450 Man Env11Document125 pagesEsm-4450 Man Env11Cristian SerbanoiuNo ratings yet

- Comparison of Different Types of Generator For Wind Energy Conversion System TopologiesDocument6 pagesComparison of Different Types of Generator For Wind Energy Conversion System TopologiesCristian NietoNo ratings yet

- Physics Practical-5Document12 pagesPhysics Practical-5www.jyotirmay1234No ratings yet

- Life Safety and Firefighting Power Supplies - SampleDocument12 pagesLife Safety and Firefighting Power Supplies - Samplebdaminda6701No ratings yet

- 110mm HDPE Double Wall Corrugated Pipe Extrusion Line-BEIER210701JDocument9 pages110mm HDPE Double Wall Corrugated Pipe Extrusion Line-BEIER210701JAdoniyas Abayneh Negash100% (1)

- 94151d ABB BR 31 TrafoStar FlipChart12ReasonsDocument28 pages94151d ABB BR 31 TrafoStar FlipChart12ReasonsRigoberto Urrutia100% (1)

- Thermo Trex Thermocouple Extension WireDocument2 pagesThermo Trex Thermocouple Extension WireKhin Aung ShweNo ratings yet

- Guia de Instalacion Panel 1057 1058Document108 pagesGuia de Instalacion Panel 1057 1058Amy ThompsonNo ratings yet

- Yonos PARA RS /7.5 RKA: DatasheetDocument8 pagesYonos PARA RS /7.5 RKA: DatasheetPodariu CosminNo ratings yet

- Bang Olufsen Beocenter 7700 (ET)Document36 pagesBang Olufsen Beocenter 7700 (ET)Minna VirtanenNo ratings yet