Professional Documents

Culture Documents

Pizarra 23 Mar. 2023

Uploaded by

Flavia PereiraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pizarra 23 Mar. 2023

Uploaded by

Flavia PereiraCopyright:

Available Formats

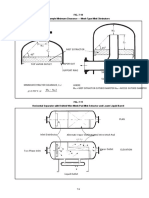

SUB-TRANSMISSION

FINAL DRIVE SHAFT

12-7)

NOTE:

assembly removal (page

. The final drive shaft assembly installation

The final drive shaft

. (page 12-13).

DISASSEMBLYI/ASSEMBLY

SPECIAL WASHER NEEDLEBEARING

(26 x 30 x 21 mm)

(22 x 43 x 2 mm)

HIGHSHIFTER

ASSEMBLY

FINAL DRIVE LOW GEAR

DOUBLE COIL REVERSE DRIVE

RING GEAR

CLIP

STEEL BALL

WASHER

(39 PCS) (26 x 44 x 1 mm)

HIGH SHIFTER

COLLAR DOUBLE

COIL RING NEEDLE

HIGH SHIFTER LOW SHIFTER BEARING

ASSEMBLY (29 x 34 x 24 mm)

CLIP WASHER

CLIP (29 x 43 x 1mm)

STEEL BALL

DOUBLE COIL (42 PCS)

RING

LOW REVERSE

SHIFTER COLLAR FINAL DRIVE

WASHER

SHAFT

(26 x44 x1mm)

LOW REVERSE

SHIFTER

FINAL DRIVE

HIGH GEAR

CLIP

NEEDLE BEARING

(26 x 30 x 17 mm)

DOUBLE COIL RING

WASHER

(26 x 44 x1 mm)

WASHER (29 x43 x1mm)

Shifter grooves, splines,and needle beari

NOTE:

" After

solventdisassembly,

thoroughly. clean all disassembled parts in

Keep track of the

disassembled

onto a tool or a piece of wire.

parts by sliding them

When

oil and assembling, coat

check for smootheach gear with clean engine

Final drive high movement.

low gear needlegear needle bearing and final drive

slot. bearing have one empty needle

You might also like

- Shillong Teer Formula: 10 Successful Formulae B Y Mukund DoshiDocument6 pagesShillong Teer Formula: 10 Successful Formulae B Y Mukund DoshiMarfot Ali100% (1)

- John Deere - Parts Catalog - Frame 9Document2 pagesJohn Deere - Parts Catalog - Frame 9Jorge MendozaNo ratings yet

- Options Trader 0505Document43 pagesOptions Trader 0505mhosszu100% (2)

- Toyota Land Cruiser 1998 2007 Transfer Repair ManualDocument5 pagesToyota Land Cruiser 1998 2007 Transfer Repair Manualerin100% (49)

- John Deere X300 Parts ManualDocument2 pagesJohn Deere X300 Parts ManualYew Lim0% (4)

- Republic V Sps. Llamas (Illegal Taking of Subdivision Roads), GR 194190, 25 Jan 2017Document19 pagesRepublic V Sps. Llamas (Illegal Taking of Subdivision Roads), GR 194190, 25 Jan 2017Madam JudgerNo ratings yet

- Enduro Fork Seals: 36 Talas Rc2Document23 pagesEnduro Fork Seals: 36 Talas Rc2Juan Manuel AcebedoNo ratings yet

- RHCSADocument3 pagesRHCSABigaBabu0% (1)

- RZR 170 EfiDocument114 pagesRZR 170 EfiFlavia PereiraNo ratings yet

- Vibrating Grizzly FeedersDocument2 pagesVibrating Grizzly FeedersAnonymous 3TsMffdNo ratings yet

- Overcurrent Relay Setting & Coordination For A Power TransformerDocument9 pagesOvercurrent Relay Setting & Coordination For A Power TransformerRisharto Yustitiardi100% (1)

- Arbus 2000-850 USADocument76 pagesArbus 2000-850 USAdanielNo ratings yet

- Model Airplane International - Issue 180 - July 2020 PDFDocument68 pagesModel Airplane International - Issue 180 - July 2020 PDFKeith Durbau Berkut100% (1)

- Adobe Scan 23 Mar. 2023Document1 pageAdobe Scan 23 Mar. 2023Flavia PereiraNo ratings yet

- Pizarra 23 Mar. 2023Document2 pagesPizarra 23 Mar. 2023Flavia PereiraNo ratings yet

- Front-Loading Automatic Washer: Product Model Numbers Overall Dimensions WFW9550WDocument1 pageFront-Loading Automatic Washer: Product Model Numbers Overall Dimensions WFW9550WBilly TalaugonNo ratings yet

- Check List Tool Caddy: © Copy Right PT Krama Yudha Tiga Berlian Motors - JakartaDocument2 pagesCheck List Tool Caddy: © Copy Right PT Krama Yudha Tiga Berlian Motors - JakartaAwal PagiNo ratings yet

- Catalog Full KTM 65 (2012)Document40 pagesCatalog Full KTM 65 (2012)ichsan uyeeNo ratings yet

- Highlights: 1170 LB (531 KG)Document1 pageHighlights: 1170 LB (531 KG)MatNo ratings yet

- SMC VM Eu PDFDocument66 pagesSMC VM Eu PDFjoguvNo ratings yet

- Valvula MecanicaDocument66 pagesValvula Mecanicaflip-floNo ratings yet

- Manitowoc 3900W CatalogueDocument10 pagesManitowoc 3900W Cataloguesolly79No ratings yet

- Kuhn LSB 1270dx GBDocument4 pagesKuhn LSB 1270dx GBSedat KahramanNo ratings yet

- Front Suspension: Knuckle/Hub Illustrated IndexDocument1 pageFront Suspension: Knuckle/Hub Illustrated IndexsoftallNo ratings yet

- Cutting PlanDocument2 pagesCutting PlanAkhmad IttangNo ratings yet

- STR 602 JavpssDocument1 pageSTR 602 Javpsswww.everything4less.comNo ratings yet

- Check List Tools BoxDocument4 pagesCheck List Tools BoxBayu Aji PratamaNo ratings yet

- Cek List Tools MWS: No. Tools Name (Size) Q'TyDocument2 pagesCek List Tools MWS: No. Tools Name (Size) Q'TyAwal PagiNo ratings yet

- Sea Duck (Conwing L: Airc Pirates - The Sky Is Our Ocean!Document32 pagesSea Duck (Conwing L: Airc Pirates - The Sky Is Our Ocean!Matheus AlmadaNo ratings yet

- Bitelli DTV315-3Document2 pagesBitelli DTV315-3Paolo NapoleoniNo ratings yet

- 690 SMC USA 2008: Spare Parts Manual: ChassisDocument58 pages690 SMC USA 2008: Spare Parts Manual: ChassisRUTA 30 URABANo ratings yet

- Nammo Ammunition Handbook 2023Document184 pagesNammo Ammunition Handbook 2023Luc ServantNo ratings yet

- GR27-Rear AxleDocument34 pagesGR27-Rear AxleSusilo purwanggiNo ratings yet

- Compact 24": Standard EquipmentDocument1 pageCompact 24": Standard EquipmentImml TasbiNo ratings yet

- Check List ToolsDocument2 pagesCheck List ToolsagnisaNo ratings yet

- C P & C I .: Cema B4, B5, C5, C6, D6 & E7 Class IdlersDocument20 pagesC P & C I .: Cema B4, B5, C5, C6, D6 & E7 Class IdlersArdian20No ratings yet

- Waterman Standard Fabricated Gates FormDocument1 pageWaterman Standard Fabricated Gates FormJayNo ratings yet

- CRANE NATIONAL 800H-Data-Sheet-ImperialDocument12 pagesCRANE NATIONAL 800H-Data-Sheet-ImperialT ChandrashekarNo ratings yet

- Solid Modeling (Yoyo Car)Document35 pagesSolid Modeling (Yoyo Car)Wahyunie RahmaNo ratings yet

- Spare Parts Manual: Chassis: ART - NO.: 3CF6101H0ENDocument47 pagesSpare Parts Manual: Chassis: ART - NO.: 3CF6101H0ENcostaNo ratings yet

- Service Parts List: M18™ 1/4" Hex Impact Driver - Single SpeedDocument2 pagesService Parts List: M18™ 1/4" Hex Impact Driver - Single SpeedhiramfgarciaNo ratings yet

- Remanufacturing Instructions CF217A-CF230A-XDocument10 pagesRemanufacturing Instructions CF217A-CF230A-XJUAN CarlosNo ratings yet

- Front Brake: ComponentsDocument3 pagesFront Brake: ComponentsRichard Andrianjaka LuckyNo ratings yet

- Specifications: Environmentally-Friendly ProductDocument4 pagesSpecifications: Environmentally-Friendly Productluis armando rosero narvaezNo ratings yet

- Differential PDFDocument31 pagesDifferential PDFDean BNo ratings yet

- DECOY CF TECHNICAL INFORMATION CUSTOMER5dfa08337022dDocument4 pagesDECOY CF TECHNICAL INFORMATION CUSTOMER5dfa08337022dlukaradrienNo ratings yet

- 2010 250xcfwceDocument54 pages2010 250xcfwceNathan LinharesNo ratings yet

- Hal Co Maintenance Manual Low ResDocument61 pagesHal Co Maintenance Manual Low ResClaudio EspinozaNo ratings yet

- Features: - Everyday Tub/ShowersDocument2 pagesFeatures: - Everyday Tub/ShowerssimonNo ratings yet

- Catalog f9 05 24Document2 pagesCatalog f9 05 24Raúl Manuel Espinoza RetamozoNo ratings yet

- Vapor Out N: FIG. 7-10 Example Minimum Clearance - Mesh Type Mist EliminatorsDocument1 pageVapor Out N: FIG. 7-10 Example Minimum Clearance - Mesh Type Mist EliminatorsВалентин СелищевNo ratings yet

- Low and Reverse Brake: Automatic TransmissionDocument7 pagesLow and Reverse Brake: Automatic TransmissionAnton FortovNo ratings yet

- Tren TraseroDocument6 pagesTren TraseroA.JNo ratings yet

- 2016 Outlander-MAX-XT ENDocument1 page2016 Outlander-MAX-XT ENcampshawn446No ratings yet

- Draw WorkDocument3 pagesDraw Workrodon falathNo ratings yet

- Operational Mode Transportation Mode: Track-Mounted ScreenDocument2 pagesOperational Mode Transportation Mode: Track-Mounted ScreenBubbaNo ratings yet

- Suspension and AxleDocument185 pagesSuspension and AxleAirton SenaNo ratings yet

- GR00001500 27Document5 pagesGR00001500 27DaniNo ratings yet

- Remanufacturing Instructions: Lexmark C792 Hopper Cleaning and Assembly InstructionsDocument9 pagesRemanufacturing Instructions: Lexmark C792 Hopper Cleaning and Assembly InstructionsCesar FernandezNo ratings yet

- K-1184 Spec US-CA Kohler enDocument2 pagesK-1184 Spec US-CA Kohler ensilviagrd713No ratings yet

- Manitowoc 4100Document19 pagesManitowoc 4100Manu BadilloNo ratings yet

- Column Base Plate DesignDocument1 pageColumn Base Plate DesignChidambaram SethumahadevanNo ratings yet

- Control Point TrenchDocument1 pageControl Point TrenchALSIRAT CONTRACTINGNo ratings yet

- TransferDocument51 pagesTransferWaqas HaiderNo ratings yet

- STM RP Suzuki Samurai Transmission Rebuild Kits and Parts Parts I IIDocument118 pagesSTM RP Suzuki Samurai Transmission Rebuild Kits and Parts Parts I IIHatnean CristianNo ratings yet

- Rockhopper Comp 1X: Specs Specifications Subject To Change Without NoticeDocument1 pageRockhopper Comp 1X: Specs Specifications Subject To Change Without NoticeReinaldo Martinez LunaNo ratings yet

- 2009 170 Service ManualDocument187 pages2009 170 Service ManualFlavia PereiraNo ratings yet

- Page173 187Document15 pagesPage173 187Flavia PereiraNo ratings yet

- Page87 172Document86 pagesPage87 172Flavia PereiraNo ratings yet

- Assignment MicrofinanceDocument28 pagesAssignment MicrofinanceKamrul MozahidNo ratings yet

- 19.format Hum A Study of Pradhan Mantri Jan Dhan YojanaDocument6 pages19.format Hum A Study of Pradhan Mantri Jan Dhan YojanaImpact JournalsNo ratings yet

- MGT3102 Case StudyDocument2 pagesMGT3102 Case StudyMon LuffyNo ratings yet

- URI Protocol Scheme For MatrixDocument6 pagesURI Protocol Scheme For MatrixDhanNo ratings yet

- SOD882 / SOD923 / 0402 Board Adapter For PrototypingDocument2 pagesSOD882 / SOD923 / 0402 Board Adapter For Prototypingteix9360No ratings yet

- Order LetterDocument13 pagesOrder LetterdellaNo ratings yet

- World SeriesDocument106 pagesWorld SeriesanonymousNo ratings yet

- Question: 1. A Motor Draws Electric Power (Pelec) of 26 KW From A SupplDocument3 pagesQuestion: 1. A Motor Draws Electric Power (Pelec) of 26 KW From A SupplEdilunarNo ratings yet

- External Factor Evaluation: Dr. Priyanka ShrivastavDocument13 pagesExternal Factor Evaluation: Dr. Priyanka ShrivastavRajan SinghNo ratings yet

- En CD00168872 PDFDocument16 pagesEn CD00168872 PDFLeonel ValençaNo ratings yet

- Time Manegment 4Document2 pagesTime Manegment 4Osman ElmaradnyNo ratings yet

- Case Study #3Document4 pagesCase Study #3Annie Morrison AshtonNo ratings yet

- Satanic CRAIYON AI READS Various Text Converted To DECIMAL - HEX NCRS and PRODUCES ACCURATE OUTPUT/STEREOTYPESDocument140 pagesSatanic CRAIYON AI READS Various Text Converted To DECIMAL - HEX NCRS and PRODUCES ACCURATE OUTPUT/STEREOTYPESAston WalkerNo ratings yet

- Sampling ProceduresDocument14 pagesSampling ProceduresNaina SinghNo ratings yet

- Social Security, Medicare and Medicaid Work For South Carolina 2012Document22 pagesSocial Security, Medicare and Medicaid Work For South Carolina 2012SocialSecurityWorksNo ratings yet

- Descriptive Research Design: Survey and Observation: Sadhu 1Document20 pagesDescriptive Research Design: Survey and Observation: Sadhu 1ak5775No ratings yet

- BRM Unit-2Document17 pagesBRM Unit-2PunithNo ratings yet

- Requirement-Analysis-Software-Engineering (Set 1)Document9 pagesRequirement-Analysis-Software-Engineering (Set 1)Week KeeNo ratings yet

- (Soho Series Topp Pro - V1.1) PDFDocument16 pages(Soho Series Topp Pro - V1.1) PDFArvin OcampoNo ratings yet

- CasesDocument11 pagesCasesMitchi BarrancoNo ratings yet

- Quantum ComputingDocument17 pagesQuantum ComputingAnkush100% (1)

- 41 Commandments Inside The ScilabDocument3 pages41 Commandments Inside The ScilabAlexie AlmohallasNo ratings yet

- JCPenney Coupons & Promo CodesDocument1 pageJCPenney Coupons & Promo CodesGenesis Veronica ColonNo ratings yet

- (Term Paper) The Rationale of Shari'ah Supporting Contracts - A Case of MPODocument22 pages(Term Paper) The Rationale of Shari'ah Supporting Contracts - A Case of MPOHaziyah HalimNo ratings yet