Professional Documents

Culture Documents

Fuel Injection System: 1/16/2023 BY: Yonathan M. 1

Uploaded by

Mengistu GebeyehuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fuel Injection System: 1/16/2023 BY: Yonathan M. 1

Uploaded by

Mengistu GebeyehuCopyright:

Available Formats

Fuel injection

system

1/16/2023 BY: Yonathan M. 1

Fuel Injection in the CI Engine

▪ For the compression ignition engine, it is very important to

promote a means of injecting fuel into the cylinder at the

proper time in the cycle.

▪ This is so because the injection system starts and controls the

combustion process.

Function of fuel injection

▪ The function of the fuel injection system is to provide

the right amount of fuel at the right moment and a

suitable condition for the combustion process.

▪ There must therefore be some form of metered supply,

a means of timing the delivery, of atomization and

distribution of fuel.

1/16/2023 BY: Yonathan M. 3

Direct injection method

▪ Most new commercial-

vehicle diesel engines are of

the direct-injection type.

▪ Here, the fuel is injected

directly into the compression

chamber via the piston.

▪ The special shape of intake

port in the cylinder head

generates a swirl effect and

therefore draws in the

incoming air more vigorously.

1/16/2023 BY: Yonathan M. 4

Direct injection method Cont…

▪ The fuel is evenly distributed through the combustion

chamber as a result of the multi-orifice injection

nozzles.

▪ A distinction is made between wall-applied and air-

distributed direct injection, according to the injection

procedure.

▪ Direct-injection engines generate considerable

combustion noise on account of the relatively high

ignition delay.

▪ However, they achieve low specific fuel consumption

and exhibit good cold-starting properties.

1/16/2023 BY: Yonathan M. 5

Fuel injection systems consist of three types.

1. Individual (Inline) pump system: This consists of a separate

metering and compression pump for each cylinder.

2. Distribution system: This consists of a single pump for

compressing the fuel (which may also meter), plus a delivery

device for distributing the fuel to the cylinders (which may

also meter).

3. Common rail system: A single pump for compressing the

fuel, plus a metering element for each cylinder.

1/16/2023 BY: Yonathan M. 6

Distributor-type pumps

▪ Unlike the inline injection pump, the distributor type

pump has only one pump element with one piston for all

cylinders.

▪ The piston operates as many strokes as there are

cylinders for every revolution of the crankshaft.

1/16/2023 BY: Yonathan M. 7

Distributor-type pumps Cont…

▪ The simultaneous movement of the piston during

the stroke distributes the fuel to the various inlets and

pumps it to the corresponding injectors.

▪ A mechanical speed governor and a hydraulic

injection timing device are integrated into the

distributor pump housing.

▪Distributor-type pumps are used on high speed

passenger-car and commercial vehicle diesel

engines with an output per cylinder of up to 25 kW.

▪ The injection pressure is approximately 700 bar

Distributor type pumps with electronic control are

capable of injection pressures as high as 1400 bar.

1/16/2023 BY: Yonathan M. 8

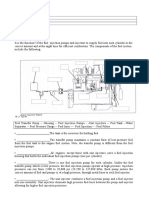

Fuel-injection system with mechanically-controlled (governed) distributor

injection pump

1 Fuel tank, 2 Fuel filter, 3 Distributor fuel-injection pump, 4 Nozzle holder with

nozzle, 5 Fuel return line, 6 glow plug 7 Battery, 8 Glow-plug and starter switch, 9

Glow control unit .

1/16/2023 BY: Yonathan M. 9

Inline injection pumps

▪ Inlineinjection pumps have a separate camshaft and one

pump element per engine cylinder.

▪ The stroke of the pistons always remains the same. The

pump rate is regulated via metering ramps.

1/16/2023 BY: Yonathan M. 10

Inline injection pumps Cont…

▪The fuel is pumped through a separate high-pressure

line to the corresponding injector for each cylinder of

the engine.

▪ The injection pumps camshaft, driven by the engine,

controls the injection processes in the individual

injectors.

▪A mechanical injection timing device adjusts the start

of delivery according to engine speed, as necessary.

▪ It rotates the camshaft in relation to the engine

crankshaft, thus displacing the start of delivery.

▪ The inline injection pump is connected up to the

engine oil circuit for lubrication of the moving pump

components.

1/16/2023 BY: Yonathan M. 11

Common rail system

1 – Fuel tank 2 – Filter 3 – Pressure supply pump 4 – High pressure supply

pump 5 – Pressure limiting valve 6 – Pressure sensor 7 – Distributor rail

8 - Injectors 9 – Sensors 10 – Electronic control unit

1/16/2023 BY: Yonathan M. 12

Fuel delivery control

• The diesel fuel is delivered to the injectors by

individual pump elements (pistons).

• These have rotary mounts and fit in the cylinders with

very high precision.

• Depending on design, there are one or two inlet

orifices in the cylinder.

• The second inlet orifice is also known as the spill port.

These orifices connect the inlet and high pressure

chambers.

• Each pump element delivers the fuel to the injectors.

• The delivery process comprises the admission stroke,

preliminary stroke, delivery stroke and residual stroke

1/16/2023 BY: Yonathan M. 13

Fuel delivery control Cont…

1 - Delivery Valve 2- Inlet orifice 3 – Split port 4 – Longitudinal or perpendicular

groove 5 – Line to injector 6 – Delivery chamber 7 – Intake chamber 8 – pump

element 9- Control pump

1/16/2023 BY: Yonathan M. 14

Fuel delivery control Cont…

Admission stroke

• The pump element is at the base. The inlet orifices are open;

diesel fuel flows from the intake chamber (via a line from the fuel

supply pump) into the cylinder`s high-pressure chamber.

Preliminary stroke

• During the upward movement, the pump element closes the inlet

orifices. The delivery stroke proper now begins.

Delivery stroke

• As the stroke progresses, the pressure continues to rise until the

delivery valve opens. The pump element then pumps fuel

through the pressure line to the injector.

1/16/2023 BY: Yonathan M. 15

Fuel delivery control Cont…

Residual stroke

▪ When the lower end of the control ramp reaches the spill port, the

delivery stroke is completed. The fuel is forced back through the

longitudinal groove into the intake chamber.

▪ When TDC is reached, the inlet orifice is opened again during the

downward movement of the pump element. A partial vacuum is

generated, fuel is drawn in and a new delivery cycle begins.

1/16/2023 BY: Yonathan M. 16

First Generation Common Rail Diesel Injection System

▪ The Common Rail Diesel Injection System delivers a more

controlled quantity of atomized fuel, which leads to better fuel

economy; a reduction in exhaust emissions; and a significant

decrease in engine noise during operation.

1/16/2023 BY: Yonathan M. 17

Second Generation (Electronically Controlled) CRDI

1/16/2023 BY: Yonathan M. 18

Common rail diesel injection system

▪ In the Common Rail system, an accumulator, or rail, is

used to create a common reservoir of fuel under a

consistent controlled pressure that is separate from

the fuel injection points.

▪ A high-pressure pump increases the fuel pressure in

the accumulator up to 1,600 bar.

▪ The pressure is set by the engine control unit and is

independent of the engine speed and quantity of fuel

being injected into any of the cylinders.

▪ The fuel is then transferred through rigid pipes to the

fuel injectors, which inject the correct amount of fuel

into the combustion chambers.

1/16/2023 BY: Yonathan M. 19

Injectors for CRDI

▪ The injectors used in Common Rail systems are

triggered externally by an Electronic Diesel Control,

(EDC) unit.

▪ EDC controls all the engine injection parameters

including the pressure in the fuel rail and the timing

and duration of injection.

▪ Some common rail injectors are controlled by a

magnetic solenoid on the injector.

1/16/2023 BY: Yonathan M. 20

Injectors for CRDI

▪ In some injectors, hydraulic force from the pressure in

the system is used to open and close the injector, but

the available pressure is controlled by the solenoid

triggered by the Electronic Diesel Control unit.

▪ Some injectors use Piezo crystal wafers to actuate the

injectors.

▪ These crystals expand rapidly when connected to an

electric field.

▪ In a Piezo inline injector, the actuator is built into the

injector body very close to the jet needle and uses no

mechanical parts to switch injector needles.

1/16/2023 BY: Yonathan M. 21

Injectors for CRDI

▪ The electronic diesel control

unit precisely meters the

amount of fuel injected, and

improves atomization of the

fuel by controlling the injector

pulsations.

▪ This results in quieter, more

fuel efficient engines; cleaner

operation; and more power

output.

1/16/2023 BY: Yonathan M. 22

ELECTRONIC FUEL

INJECTION SYSTEM

(EFI)

1/16/2023 BY: Yonathan M. 23

Electronic fuel injection system

(EFI)

▪ In the electronic controlled engine system, sensors

detect the state of the engine, and all information from

the sensors is sent to Engine Control Unit (ECU).

▪ According to the information from sensors, ECU

calculates injection volume and ignition timing.

▪ ECU also controls idle rotating speed by means of the

idle speed control valve (ISCV).

1/16/2023 BY: Yonathan M. 24

EFI

▪ ECU gathers information from sensors about the engine,

and then controls actuators for Electronic Fuel Injection

(EFI), Electronic Spark Advance (ESA) and Idle Speed

Control (ISC), according to that information.

▪ And there is “SELF DIAGNOSIS” function in this system.

▪ If there is problem with the electronic part of this

system (that means, in the sensors, the wire harness

and ECU itself) The ECU detects the problem part and

memorize it.

▪ When technicians check the “self diagnosis code”, they

can identify the problem easily.

1/16/2023 BY: Yonathan M. 25

EFI

ECU

1/16/2023 BY: Yonathan M. 26

Types of EFI

▪ Based on location and number of injector

o Throttle body (single point injection)

o Port (multi point injection)

1/16/2023 BY: Yonathan M. 27

Types of EFI

▪ Based on mixture formation

o External (manifold/indirect injection)

o Internal (direct injection)

1/16/2023 BY: Yonathan M. 28

Fuel Injection System

1/16/2023 BY: Yonathan M. 29

EFI

Advantages

▪ Improved Atomization

▪ Better fuel flow

▪ Smoother idle

▪ Improved fuel economy

▪ Lower emissions

▪ Better cold weather drivability

▪ Increased engine power

▪ Simpler

1/16/2023 BY: Yonathan M. 30

EFI

Engine Throttle Valve

▪ Controls air flow and gasoline to power engine.

▪ When butterfly valve is closed it restricts air-flow and the resulting

flow of fuel into the engine.

▪ When accelerator is pressed, the air-flow is increased in the intake

manifold.

▪ Engine sensors detect the resulting changes and increase fuel flow

through the injectors.

1/16/2023 BY: Yonathan M. 31

EFI

Electronic Fuel Injection uses various engine sensors and control

module to regulate the opening and closing of injector valve.

▪ Fuel delivery system

▪ Air induction system

▪ Sensor system

1/16/2023 BY: Yonathan M. 32

▪ Computer control system

Fuel Delivery system

•Electrical Fuel Pump draws fuel from

tank and forces it into the regulator.

•Pressure Regulator controls the amount

of pressure that enters the injector and any

extra fuel is returned to the fuel tank.

•Fuel Injector is simply a coil or solenoid

operated valve.

• Spring pressure holds the injector closed.

•When engaged, the injector sprays fuel

into the engine.

Injector Pulse Width indicates the time each

Injector is energized (Kept Open).

BY: Yonathan M. 33

1/16/2023

Air Induction System

•Air filter

•Throttle valve

•Sensors

•Connecting ducts

1/16/2023 BY: Yonathan M. 34

Sensor System

▪ Monitors engine operating condition and reports this information

to ECM (computer).

▪ Sensors are electrical devices that change resistance or voltage

with change in condition such as temperature, pressure and position.

1/16/2023 BY: Yonathan M. 35

Computer Control System

▪ Uses electrical data from the sensors to control the operation of

the fuel injectors.

▪ Engine Control Module (ECM)- “Brain” of the electronic fuel

injection.

1/16/2023 BY: Yonathan M. 36

sensors

▪ Converts a physical/chemical condition into an

electrical signal

▪ Is a transducer: to change from one form to

another

Sensor requirements

o High reliability

o Low manufacturing cost

o Severe operating conditions

o Low volume

o High accuracy

1/16/2023 BY: Yonathan M. 37

Engine Sensors

Oxygen Sensor

▪ Measures the oxygen content in engine

exhaust.

▪ Mounted on the exhaust system before

the catalytic converter.

▪ Voltage out-put of O2 sensor changes

with the change in oxygen content of

exhaust.

▪ Lean mixture decreases the voltage

▪ Rich mixture increases the voltage

▪ Signal is sent to ECM and the ECM

changes the time that an injector is open

or close.

1/16/2023 BY: Yonathan M. 38

Oxygen Sensor

Open Loop

▪ When the electronic injection system doesn’t use the

input from the engine exhaust.

▪ System operates on information stored in the computer

(PROM).

▪ Computer ignores the sensors when the engine is cold.

Closed Loop

▪ Ones engine reaches the operating temperature,

computer uses information from oxygen sensor and the

other sensors.

1/16/2023 BY: Yonathan M. 39

Manifold Absolute Pressure Sensor (MAP)

▪ Measures the pressure, or vacuum

inside the engine intake manifold.

▪ Manifold pressure = Engine load

▪ High pressure (low intake

vacuum) = High load = Rich

mixture

▪ Low pressure (high intake

vacuum) = Little load = Lean

mixture

▪ Computer senses the change in

resistance and alters the fuel

mixture

1/16/2023 BY: Yonathan M. 40

Throttle Position Sensor (TPS)

▪ Variable resister connected to

the throttle plate.

▪ Change in throttle angle =

change in resistance.

▪ Based on the resistance,

ECM richens or leans the

mixture.

1/16/2023 BY: Yonathan M. 41

Engine Temperature Sensor

▪ Monitors the operating temperature

of the engine.

▪ Exposed to engine coolant.

▪ Engine cold = Low Resistance = Rich

Mixture

▪ Engine Hot = High Resistance = Lean

Mixture.

1/16/2023 BY: Yonathan M. 42

Mass Air Flow Sensor (MAF)

▪ Measures the amount of outside air entering the engine.

▪ Contains an air flap or door that operates a variable resistor.

▪ Helps computer to determine how much fuel is needed.

1/16/2023 BY: Yonathan M. 43

Inlet Air Temperature Sensor

▪ Measures the temperature of air entering the engine.

▪ Cold air (more dense) = More fuel for proper AF ratio.

1/16/2023 BY: Yonathan M. 44

Crankshaft Position Sensor

▪ Detects engine speed.

▪ Changes injector timing and duration

▪ Higher engine speed = More fuel

1/16/2023 BY: Yonathan M. 45

Water temperature sensor

▪ Detects the temperature of coolant

▪ Made of thermistor

▪ Signal is used for;

o Injection correction during;

o starting,

o after start,

o warm up,

o acceleration and deceleration

1/16/2023 BY: Yonathan M. 46

Engine Sensors

1/16/2023 BY: Yonathan M. 47

Engine Idle Speed Control

Fast Idle Thermo Valve

▪ Thermo wax plunger

expands and shrinks as the

engine warms up or cools

down.

▪ The thermo valve opens

when cold to allow air to

by-pass the throttle valve

▪ This extra air increases

engine idle speed to prevent

cold engine stalling.

1/16/2023 BY: Yonathan M. 48

Engine Idle Speed Control

Idle Air Control Motor (IAC)

▪ Computer opens the valve when temperature sensor signals

a cold engine.

▪ Open = More Air = Increased Idle Speed.

1/16/2023 BY: Yonathan M. 49

Throttle Body Injection

▪ Uses one or two injectors.

▪ Injectors (pulse) spray fuel into

the top of throttle body air horn.

▪ Atomized fuel mixes with air and

drawn into the engine.

▪ Fuel pressure regulator is spring

loaded and is part of the housing.

▪ Fuel is being injected whenever

the engine is running, also called

CIS: Continuous Injection

System.

1/16/2023 BY: Yonathan M. 50

EFI

EFI Multi port Injection System

▪ Injector is pressed into the

runner(Port) in the intake

manifold.

▪ Injector sprays towards an

engine intake valve.

▪ Each cylinder has it’s own

injector

EFI Direct fuel Injection System

▪ Injectors are pressed into the

combustion chamber and spray

fuel directly into the combustion

chamber.

1/16/2023 BY: Yonathan M. 51

You might also like

- 2.fuel Inj Compresion IgnitionDocument19 pages2.fuel Inj Compresion IgnitionJo VialNo ratings yet

- Gasoline Electronic Fuel Injection SystemsDocument35 pagesGasoline Electronic Fuel Injection SystemsatulsemiloNo ratings yet

- Cusrow Wadia Institute of Technology,: Pune-411001Document63 pagesCusrow Wadia Institute of Technology,: Pune-411001Amit RoshanNo ratings yet

- 6 Gasoline Electronic Fuel Injection SystemsDocument34 pages6 Gasoline Electronic Fuel Injection Systemsloganathanpalani100% (1)

- Chapter 10.2pdfDocument4 pagesChapter 10.2pdfഅമീർ സുഹൈൽNo ratings yet

- 3 - Diesel Injection SystemsDocument60 pages3 - Diesel Injection SystemsAyman AbazaNo ratings yet

- UntitledDocument41 pagesUntitledMengistu GebeyehuNo ratings yet

- UntitledDocument29 pagesUntitledanilNo ratings yet

- Common Rail Diesel Injection (Done)Document14 pagesCommon Rail Diesel Injection (Done)Dejan MaticNo ratings yet

- Unit II - Electronically Controlled Fuel InjectionDocument38 pagesUnit II - Electronically Controlled Fuel InjectiondrkbalaNo ratings yet

- 1 Gasoline Electronic Direct Injection System1Document40 pages1 Gasoline Electronic Direct Injection System1EZHILARASAN RNo ratings yet

- Engine Managment SystemDocument13 pagesEngine Managment SystemF Man Temu100% (1)

- Qip Ice 12 Fuel Injection SystemsDocument40 pagesQip Ice 12 Fuel Injection SystemsAnonymous eyxVFR100% (1)

- Common Rail Diesel InjectionDocument13 pagesCommon Rail Diesel InjectionDejan Matic100% (1)

- Unit 2 - IceDocument30 pagesUnit 2 - IceSugumar MuthusamyNo ratings yet

- Unit Injector: Nozzle Types, Electronic Fuel Injection System (EFI), GDI, MPFI, DTSIDocument65 pagesUnit Injector: Nozzle Types, Electronic Fuel Injection System (EFI), GDI, MPFI, DTSIMUDIT DWIVEDINo ratings yet

- Unit-4 Automobile EngineeringDocument52 pagesUnit-4 Automobile EngineeringShubham GuptaNo ratings yet

- Common Rail Diesel InjectionDocument13 pagesCommon Rail Diesel InjectionDejan Matic67% (3)

- Automobile Engg (Unit-02)Document20 pagesAutomobile Engg (Unit-02)SUDHARSHAN REDDYNo ratings yet

- Ignition System and Lubricating SystemDocument26 pagesIgnition System and Lubricating SystemshubhamNo ratings yet

- Hino j08c j05c Type EngineDocument29 pagesHino j08c j05c Type EngineNaseer Ahmed Awan88% (8)

- Diesel Engine Mixture Formation: 5.4. Fuel Injection SystemDocument30 pagesDiesel Engine Mixture Formation: 5.4. Fuel Injection SystemGODNo ratings yet

- IC Engines Lab ReportDocument7 pagesIC Engines Lab ReportnewUserNo ratings yet

- Experiment No: 2 Fuel Pump & InjectorsDocument4 pagesExperiment No: 2 Fuel Pump & InjectorsAjay JachakNo ratings yet

- Electronic Diesel ControlDocument31 pagesElectronic Diesel ControlAnteneh MesfinNo ratings yet

- Fuel System FDocument5 pagesFuel System FEfrain DYNo ratings yet

- Prepared By: Amanuel Gebisa May 2015Document69 pagesPrepared By: Amanuel Gebisa May 2015Yalew MekonnenNo ratings yet

- Fuel Supply System Petrol EngineDocument7 pagesFuel Supply System Petrol EngineAmarChaudhary0% (1)

- bài thầy đứcDocument23 pagesbài thầy đứcnguyenductai.lop93.lhpNo ratings yet

- Chapter - 1: Fig 1.1: Schematic Diagram of GDI EngineDocument39 pagesChapter - 1: Fig 1.1: Schematic Diagram of GDI EngineArun KpNo ratings yet

- Fuel Injection SystemDocument49 pagesFuel Injection SystemRavi Teja KarumuriNo ratings yet

- UnitII UpdatedDocument53 pagesUnitII UpdatedChandraSekharKondaveetiNo ratings yet

- VP44 Electronic Inj Pump2Document6 pagesVP44 Electronic Inj Pump2Elmer Ong100% (6)

- Diesel Engine Fuel Injection SystemDocument17 pagesDiesel Engine Fuel Injection SystemKen ColeyNo ratings yet

- New Microsoft Office Word DocumentDocument11 pagesNew Microsoft Office Word DocumentJunaid YNo ratings yet

- Supply Pump Internal Fuel FlowDocument7 pagesSupply Pump Internal Fuel FlowErlis SaputraNo ratings yet

- Chapter 10Document78 pagesChapter 10Si Thu AungNo ratings yet

- Engine Izusu 4h Shop ManualDocument0 pagesEngine Izusu 4h Shop Manualsolserengsa100% (12)

- Fuel Valve, Fuel Pump, Relief Valve, Starting Air Valve, Air Distributor Automatic Valve, EXHAUSTDocument81 pagesFuel Valve, Fuel Pump, Relief Valve, Starting Air Valve, Air Distributor Automatic Valve, EXHAUSTsuraj0% (1)

- Automobile Engineering: Unit Ii Part I - Fuel Systems Part Ii - Ci EnginesDocument103 pagesAutomobile Engineering: Unit Ii Part I - Fuel Systems Part Ii - Ci EnginesNikhilraj rudraNo ratings yet

- Fuel Feed SystemDocument26 pagesFuel Feed SystemKarnal 0388No ratings yet

- Fuel D13Document12 pagesFuel D13Eduardo Pai Tocarlo90% (40)

- Inj 1Document4 pagesInj 1anon_122284601No ratings yet

- Unit 2Document49 pagesUnit 2Ramanathan DuraiNo ratings yet

- Unit 5Document123 pagesUnit 5Sakthivelan SNo ratings yet

- 7.fuel Metering SystemDocument48 pages7.fuel Metering Systemanik 01No ratings yet

- Automobile Engineering Unit-IDocument14 pagesAutomobile Engineering Unit-IKAMESWARARAO DOMMETINo ratings yet

- Dicor EngineDocument8 pagesDicor Enginepkhurana22No ratings yet

- Developments in IC EnginesDocument41 pagesDevelopments in IC EnginesRohit K Murthy67% (3)

- Electronic Fuel Injection System: Damian CastelinoDocument23 pagesElectronic Fuel Injection System: Damian CastelinoRamjiNo ratings yet

- Fuel Injection SystemDocument24 pagesFuel Injection SystemDevendra Pratap SinghNo ratings yet

- Fuel PumpDocument9 pagesFuel Pumpstevenotienoodhiambo141100% (1)

- Lucas CAV DPA Injection Pump Instruction BookDocument8 pagesLucas CAV DPA Injection Pump Instruction BookRicardo Jorge Horta Pequeno83% (12)

- Common Rail Fuel Injection SystemDocument56 pagesCommon Rail Fuel Injection SystemMarcos Maciel100% (1)

- Engine Controls & SensorsDocument23 pagesEngine Controls & Sensorsrudey18No ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- UntitledDocument15 pagesUntitledMengistu GebeyehuNo ratings yet

- Cardiovascular Physiology: For HO StudentsDocument77 pagesCardiovascular Physiology: For HO StudentsMengistu GebeyehuNo ratings yet

- UntitledDocument15 pagesUntitledMengistu GebeyehuNo ratings yet

- UntitledDocument41 pagesUntitledMengistu GebeyehuNo ratings yet

- New Doc 1Document15 pagesNew Doc 1Mengistu GebeyehuNo ratings yet

- Health PPT 3 - Muscle 2013-1Document50 pagesHealth PPT 3 - Muscle 2013-1Mengistu GebeyehuNo ratings yet

- Doc. No. - Page No. - Book No. - Series of 2014Document2 pagesDoc. No. - Page No. - Book No. - Series of 2014mgllacunaNo ratings yet

- Ryan Higa's How To Write Good: PrologueDocument9 pagesRyan Higa's How To Write Good: PrologueIsabella Biedenharn89% (9)

- Strategic Management PaperDocument97 pagesStrategic Management PaperElle Woods100% (3)

- Luca Utzeri, A087 211 857 (BIA July 16, 2014)Document10 pagesLuca Utzeri, A087 211 857 (BIA July 16, 2014)Immigrant & Refugee Appellate Center, LLCNo ratings yet

- Mockingbird Corrective Action PlanDocument11 pagesMockingbird Corrective Action Planthe kingfishNo ratings yet

- 10.21.2022 - 10.27.2022 - Gov. Wolf CalendarDocument7 pages10.21.2022 - 10.27.2022 - Gov. Wolf CalendarGovernor Tom WolfNo ratings yet

- Level Switch Vibration Liquiphant S FTL 70 71 TIDocument20 pagesLevel Switch Vibration Liquiphant S FTL 70 71 TIHerman SandyNo ratings yet

- HF 40 - EspecificaçõesDocument1 pageHF 40 - EspecificaçõesVenicio AchermanNo ratings yet

- MICA 4scaleDocument3 pagesMICA 4scaleMadawi AlotaibiNo ratings yet

- 14 WartsprotocolDocument9 pages14 WartsprotocolLakshmi Deepak INo ratings yet

- CE 2022 Estimating and SpecificationsDocument102 pagesCE 2022 Estimating and SpecificationsKyaw Zin HeinNo ratings yet

- Bug Bounty Course ContentDocument5 pagesBug Bounty Course ContentJdjdjdjdjNo ratings yet

- SDDSDDocument2 pagesSDDSDKaushalya PereraNo ratings yet

- Asas Kebersihan Makanan KKMDocument6 pagesAsas Kebersihan Makanan KKMMario RushdeeNo ratings yet

- MDF Declaration Verification AffidavitDocument3 pagesMDF Declaration Verification AffidavitcarlamachadoclementeNo ratings yet

- Otto Weitzenkorn - BiographyDocument5 pagesOtto Weitzenkorn - BiographyKatie MNo ratings yet

- Prestressed Transfer Plate Design and ConstructionDocument16 pagesPrestressed Transfer Plate Design and Constructiona96lhf0% (1)

- Planetary Gear TrainDocument2 pagesPlanetary Gear TrainUmesh JadhavNo ratings yet

- LR24A-SR Datasheet En-Gb PDFDocument3 pagesLR24A-SR Datasheet En-Gb PDFmikegalvezNo ratings yet

- Roles Responsibilities A Handbook For CGST OfficersDocument64 pagesRoles Responsibilities A Handbook For CGST OfficersHr legaladviserNo ratings yet

- Chapter 7Document36 pagesChapter 718071052 Nguyễn Thị MaiNo ratings yet

- AP8 q1 Mod1 Ang Katangiang Pisikal NG Daigdig v3Document34 pagesAP8 q1 Mod1 Ang Katangiang Pisikal NG Daigdig v3Leah BatillerNo ratings yet

- Huawei VoLTE Commercial Deployment Practice - 1209Document45 pagesHuawei VoLTE Commercial Deployment Practice - 1209Ahmed GadNo ratings yet

- Machine Learning NotesDocument115 pagesMachine Learning Notescocacola_thanda100% (1)

- Acr ArtrozaDocument14 pagesAcr Artrozacodruta soareNo ratings yet

- Flotation Plant Optimisation s16Document223 pagesFlotation Plant Optimisation s16Jerzain AguilatNo ratings yet

- Case Study: Vodafone EgyptDocument2 pagesCase Study: Vodafone EgyptIslam Ayman Mashaly50% (2)

- Full Text 02Document95 pagesFull Text 02Vineeth VsNo ratings yet

- Development Strategies of The Bahari Jawai Marine Tourism Coast Area Based On Community Empowerment in Sambas RegencyDocument10 pagesDevelopment Strategies of The Bahari Jawai Marine Tourism Coast Area Based On Community Empowerment in Sambas Regencyberagam09No ratings yet

- Air Compressor Room Exhaust (30000CMH)Document1 pageAir Compressor Room Exhaust (30000CMH)Kumar sssssNo ratings yet