Professional Documents

Culture Documents

RA For Painting - Exel

Uploaded by

SaifulOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RA For Painting - Exel

Uploaded by

SaifulCopyright:

Available Formats

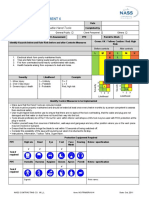

Risk Assessment

Task Name : Risk Assessment for touch up and spray painting

Location: Brahmangaon 100MW site Date :

Guidance: Risk Rating S x Risk Risk

Risk & Potential Hazards. factor

P=R Rating

S. Control Measures That Can Minimize The Risk To ALARP Level. with

Description of Task contro

No Exposed person(s)

Step/Aspects S P R l

.

• Use low volatile chemical.

• Use water based chemicals if possible.

• Painters and helpers must aware about the hazards and risk involved in

painting activity.

Paints (Oil based, Lead Respiratory tract problem & Chemical

1 3 1 3 • Communicate respective MSDS to the employees L

containing etc). exposure

• Consider human health, behavior and capacities.

• Provide tool box talk, safety Information, Instruction, training.

• Display safety signs in working area.

• Provide adequate PPE’s.

Paint mixing • Ingestion – dermatitis.

arrangements • Vapours inhalation – respiratory tract

2 3 1 3 Same as 1 L

(Mechanised Stirrer or problem Direct contact with paints

manually).

• Consider human health, behavior and capacities.

• Skin infection by contact with paints.

Paint application (Brush • Provide tool box talk, safety Information, Instruction, training.

3 • Eye Irritation & Inhalation. 2 1 2 L

/ Spray). • Display safety signs in working area.

Chemical exposure

• Provide adequate PPE’s. E.g. disposable coveralls, shoe cover and mask etc.

Pinch point/sharp edge of painting

Use cotton gloves, keep eyes on task & hand

objects

Slip-trip fall by colour pot or chemical Keep eyes and mind on path, clean the area if any colour chemiclas pour down

pouring on floor or any surface

Inhaletion problem,Health & fire hazard Use mask, full sleeve coverall, use safety glass/goggles, use hand gloves

from painting chemicals if the surface is (cotton/rubber), use WD-40 when the surface is cool, follow instructions of

hot MSDS (WD-40)

Grip tools firmly and use right sized tools, avoid standing under the job, use

Falling object(tools fall)

bump cap/hard hat, use certified lifting gears (clamp, belt, chain blocks)

4 Painting job 2 3 6 Don’t lift alone engage others to help following proper manual lifting L

Back pain from improper manual lifting

technique

Stand on a firm support(step ladder/steel bench/wooden block/concrete block

Working at height

etc)

Inadequate light Ensure sufficient lighting in painting place

Dust & skin contact with chemical(dry

Use dust mask, cotton gloves, eye protection and ensure full sleeve coverall

powder type) from the painting surface

Poor body posture due to confined

space(restricted access due to Electrical Use working bench & change personnel in every half an hour

Equipment) • Store the chemicals in secondary containment, if possible.

• Provide adequate fire prevention, detecting and fire fighting system.

• Provide shower near to chemical storage area.

• Provide tool box talk, safety information, instruction and training.

• Provide MSDS of chemicals.

• Affect environment as it will degrade

• No Smoking Policy should be applicable and communicated.

the environmental quality, •Unsafe

Storage & Disposal of • Display safety signs in working area.

storage of chemicals, •Unsafe handling

5 waste paints or empty paint 3 2 6 • Provide adequate PPE’s. • All L

drums.

and disposal by unauthorised contractor.

hazardous waste shall be stored in hazardous waste containers and to be

•Smoking

disposed of by EHS approved contractor. • All

•Fire and personnel injury

chemicals must be stored in designated and approved storage area.

• Provide spark proof lighting.

• Provide air blower in chemical storage room.

LOA Task recipient Name/Signature

Issuer name/Signatue

You might also like

- BOSHDocument5 pagesBOSHJeffrey RegondolaNo ratings yet

- SMB013 Risk Assessment Use Storage and Disposal of Flammable LiquidsDocument6 pagesSMB013 Risk Assessment Use Storage and Disposal of Flammable LiquidsRias SahulNo ratings yet

- Job Safety Analysis Page 1 of 1Document1 pageJob Safety Analysis Page 1 of 1HSE ManagerNo ratings yet

- JHA - Ladders TemplateDocument3 pagesJHA - Ladders TemplateShannon Williams100% (1)

- Risk Assessment For BricklayingDocument7 pagesRisk Assessment For BricklayingSathishKumar SkNo ratings yet

- Risk Assessment For Fabrication & Installation of Tensile Fabric ShadesDocument4 pagesRisk Assessment For Fabrication & Installation of Tensile Fabric ShadesSun Shade67% (3)

- Risk Assessment No 25 PAINTING in GENERAL Rev 02 20 03 09Document2 pagesRisk Assessment No 25 PAINTING in GENERAL Rev 02 20 03 09sizwe0% (1)

- Activity Hazard Analysis (AHA) : Risk Assessment Code (RAC) Matrix Severity ProbabilityDocument2 pagesActivity Hazard Analysis (AHA) : Risk Assessment Code (RAC) Matrix Severity ProbabilityYug DobariyaNo ratings yet

- Fencing, Installation and Repair.: Activity DescriptionDocument6 pagesFencing, Installation and Repair.: Activity DescriptionVictorNo ratings yet

- Repair Concrete PDFDocument3 pagesRepair Concrete PDFJaycee PagadorNo ratings yet

- Hazard Identification and Risk Assessment PaintingDocument2 pagesHazard Identification and Risk Assessment PaintingHariharan MuthukrishananNo ratings yet

- Carter'sriskassesement PaintingDocument4 pagesCarter'sriskassesement PaintingantonyNo ratings yet

- Risk Assessment No. 25 PAINTING in GENERAL Rev 0Document2 pagesRisk Assessment No. 25 PAINTING in GENERAL Rev 0Lalit ChoudharyNo ratings yet

- VIBRATOR - JSA-042 - Replacement of Vibrator Pump or Double Drive - 26-Apr-15Document7 pagesVIBRATOR - JSA-042 - Replacement of Vibrator Pump or Double Drive - 26-Apr-15hechame TamerhouletNo ratings yet

- Hazard and Risk LPDocument5 pagesHazard and Risk LPCupayDabuNo ratings yet

- 17-Using Portable Power ToolsDocument2 pages17-Using Portable Power Toolshsse.maltaNo ratings yet

- Hazard Identification, Risk Assessment & Control: A H H E E E B M H H E E C L M H E E D) L L M H EDocument9 pagesHazard Identification, Risk Assessment & Control: A H H E E E B M H H E E C L M H E E D) L L M H Eikram uddinNo ratings yet

- False CeilingDocument1 pageFalse CeilingGyanendra Narayan Nayak100% (1)

- AHA-007, Concrete PouringDocument4 pagesAHA-007, Concrete PouringBuddhikaNo ratings yet

- Smb019 High Pressure Liquid Chromatography (HPLC) : RiskwareDocument6 pagesSmb019 High Pressure Liquid Chromatography (HPLC) : RiskwaretafouzeltNo ratings yet

- UntitledDocument1 pageUntitledSaifulNo ratings yet

- Occupational Health & Safety-HazardsDocument36 pagesOccupational Health & Safety-HazardsSandaruwanNo ratings yet

- Module 20 - Job Hazard Analysis (JHA)Document8 pagesModule 20 - Job Hazard Analysis (JHA)Aviects Avie JaroNo ratings yet

- RA InsulationDocument23 pagesRA InsulationBeyar. ShNo ratings yet

- Updated - COSHH Risk Assessment 1 - Sherwin Willams PrimerDocument2 pagesUpdated - COSHH Risk Assessment 1 - Sherwin Willams PrimerPaul McGahanNo ratings yet

- Safety Engineering and JhaDocument29 pagesSafety Engineering and JhaDarren Dela CruzNo ratings yet

- Jsa Installing BracketDocument3 pagesJsa Installing BracketHow Chin Engineering Sdn Bhd100% (1)

- Bread and Pastry Production Ncii Chapter I: Health and Safety Practices in The WorkplaceDocument3 pagesBread and Pastry Production Ncii Chapter I: Health and Safety Practices in The WorkplaceAlain AlotsipeNo ratings yet

- SMB003 Risk Assessment AutoclavingDocument5 pagesSMB003 Risk Assessment AutoclavingtafouzeltNo ratings yet

- Hazardous Substances Risk AssessDocument2 pagesHazardous Substances Risk Assesstajdar adilNo ratings yet

- GeneralscaffoldingworkDocument3 pagesGeneralscaffoldingworkwisdom ukuejeNo ratings yet

- Updated-MARC ARBOUR CITY HOTEL-COSHH Assessment 2 - Paint Thinner PlusDocument2 pagesUpdated-MARC ARBOUR CITY HOTEL-COSHH Assessment 2 - Paint Thinner PlusPaul McGahanNo ratings yet

- Jhanoco 04 PaintingDocument2 pagesJhanoco 04 PaintingSafety DeptNo ratings yet

- Belt Conveyor Bearing InspectionDocument3 pagesBelt Conveyor Bearing InspectionKarthikeyan MNo ratings yet

- Workplace Hazard Assessment Form: Task Hazard(s) PPE Required Notes DepartmentDocument2 pagesWorkplace Hazard Assessment Form: Task Hazard(s) PPE Required Notes DepartmentMashur Al JunaibiNo ratings yet

- Safety Talk - Chemical Safety & PPE: June 2012Document1 pageSafety Talk - Chemical Safety & PPE: June 2012Jithu PappachanNo ratings yet

- 4.2 - Risk Assessment ProjectDocument3 pages4.2 - Risk Assessment ProjectMuhammad Nauman100% (1)

- VIBRATOR - C52JSA-225 - Vibrator Steering Cylinder Replacement - 9-May-15Document7 pagesVIBRATOR - C52JSA-225 - Vibrator Steering Cylinder Replacement - 9-May-15hechame TamerhouletNo ratings yet

- Hazard Identification and Risk Evaluation TableDocument2 pagesHazard Identification and Risk Evaluation TableaisyahNo ratings yet

- MSRA FOR Line Marking WorkDocument24 pagesMSRA FOR Line Marking WorkR. Ayyanuperumal Ayyanuperumal100% (1)

- TA AsbestosDocument8 pagesTA AsbestosTony ZhangNo ratings yet

- Bricklaying Risk - AssessmentDocument3 pagesBricklaying Risk - AssessmentStephenNo ratings yet

- HIRAC RegisterDocument41 pagesHIRAC RegisterPNCPL PLANNINGNo ratings yet

- Clearing Brush With Weed Trimmer: Job Safety AnalysisDocument2 pagesClearing Brush With Weed Trimmer: Job Safety AnalysisRetselisitsoe100% (1)

- RA of Grass Cutting by Strimmer Brushcutter & Removing Weeds MannualyDocument1 pageRA of Grass Cutting by Strimmer Brushcutter & Removing Weeds MannualySaifulNo ratings yet

- Apds-Ra-011 Filtration Operation of Apds Filtration System Rev BDocument4 pagesApds-Ra-011 Filtration Operation of Apds Filtration System Rev BHua Tien DungNo ratings yet

- Abdullah ShafeiDocument2 pagesAbdullah Shafeiabdullah shafei50% (2)

- NC-FRM-DRA 6-4 Rev.0 Use of Portable Hand ToolsDocument1 pageNC-FRM-DRA 6-4 Rev.0 Use of Portable Hand ToolsPatrick Bibila NdansiNo ratings yet

- Risk Assessment Project 3Document3 pagesRisk Assessment Project 3luxorNo ratings yet

- Risk Assessment Welding and CuttingDocument2 pagesRisk Assessment Welding and CuttingdaddyanataNo ratings yet

- AHA-009, Construction & Removing FormsDocument4 pagesAHA-009, Construction & Removing FormsBuddhikaNo ratings yet

- Risk Assessment NO. 37 WASH PAINTING Rev 0Document2 pagesRisk Assessment NO. 37 WASH PAINTING Rev 0Lalit Choudhary0% (1)

- Construction Risk Assessment Form Example PDFDocument3 pagesConstruction Risk Assessment Form Example PDFZaka Ur RehmanNo ratings yet

- False CeilingDocument1 pageFalse CeilingChandru67% (3)

- AHA - Asbestos Abatement-11-11-2019Document7 pagesAHA - Asbestos Abatement-11-11-2019Eyal BabuNo ratings yet

- Make Up ToolstringDocument2 pagesMake Up Toolstringmikewebster76No ratings yet

- Ref: Section / Dept: Civil Activity: Risk Assessment For False CeilingDocument1 pageRef: Section / Dept: Civil Activity: Risk Assessment For False CeilingJack PNo ratings yet

- Workplace Vocabulary for Esl Students: With Exercises and TestsFrom EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsNo ratings yet

- UntitledDocument1 pageUntitledSaifulNo ratings yet

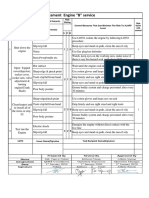

- Risk Assessment Engine "B" ServiceDocument1 pageRisk Assessment Engine "B" ServiceSaifulNo ratings yet

- RA of Oil Top Up and Old Oil RemovingDocument1 pageRA of Oil Top Up and Old Oil RemovingSaifulNo ratings yet

- RA of Grass Cutting by Strimmer Brushcutter & Removing Weeds MannualyDocument1 pageRA of Grass Cutting by Strimmer Brushcutter & Removing Weeds MannualySaifulNo ratings yet

- RA of Lifting Operation by JCB or Forklift - ExelDocument2 pagesRA of Lifting Operation by JCB or Forklift - ExelSaifulNo ratings yet

- RA of A ServiceDocument1 pageRA of A ServiceSaifulNo ratings yet

- 8D Problem AnalysisDocument99 pages8D Problem AnalysisLorena Martinez LaraNo ratings yet

- CF Lecture 3 Risk and Return v1Document44 pagesCF Lecture 3 Risk and Return v1Tâm NhưNo ratings yet

- The War Against ComplacencyDocument88 pagesThe War Against ComplacencySammie WilliamsNo ratings yet

- Climate Finance: Engaging The Private SectorDocument32 pagesClimate Finance: Engaging The Private SectorIFC SustainabilityNo ratings yet

- Developing An Operational PlanDocument8 pagesDeveloping An Operational Planstasu prugaNo ratings yet

- Group AssignmentDocument50 pagesGroup Assignmentdelcia douglasNo ratings yet

- SSRN-id3099337 FinTech ResearchDocument38 pagesSSRN-id3099337 FinTech ResearchSHAME BOPENo ratings yet

- Taking The Measure of Product DevelopmentDocument8 pagesTaking The Measure of Product DevelopmentthaicicaNo ratings yet

- Hypertension Session Student ObjectivesDocument2 pagesHypertension Session Student ObjectivesAyman NabilNo ratings yet

- 1 - Unit 30 - Assignment Brief 1Document7 pages1 - Unit 30 - Assignment Brief 1Châu TrầnNo ratings yet

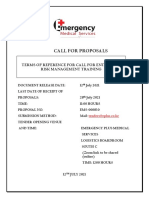

- Proposal No. EMS 000830 TOR For Call For Enterprise Risk Management TrainingDocument10 pagesProposal No. EMS 000830 TOR For Call For Enterprise Risk Management Trainingharsh houdharyNo ratings yet

- CHP 6 Factors of ProductionDocument14 pagesCHP 6 Factors of ProductionRoshniNo ratings yet

- Case Study: Air IndiaDocument29 pagesCase Study: Air IndiaSiddhardha Karanam83% (24)

- IPPF 2013 MontenegrinDocument242 pagesIPPF 2013 MontenegrinZeka PekaNo ratings yet

- SWMS Piling Machine Assembly RKDocument14 pagesSWMS Piling Machine Assembly RKrakeshkhanna78100% (1)

- Topic 1 - Introduction To Insurance Terkini With VoiceDocument20 pagesTopic 1 - Introduction To Insurance Terkini With VoiceAiry LeyNo ratings yet

- 1A Student ChecklistDocument2 pages1A Student ChecklistJulyanna AteNo ratings yet

- The Impact of Bullying in School On The ChildrenDocument29 pagesThe Impact of Bullying in School On The ChildrenJumaryse Marabut100% (5)

- Entrepreneurial Orientation and Business Performance in StartupsDocument4 pagesEntrepreneurial Orientation and Business Performance in StartupsYohana WijayaNo ratings yet

- Answer UpdatedDocument35 pagesAnswer UpdatedKrishnagopal KarNo ratings yet

- Abrogar V Cosmos PDFDocument2 pagesAbrogar V Cosmos PDFAnonymous JyhRypTNo ratings yet

- Decision Making (PUMA) - Engineering ManagementDocument17 pagesDecision Making (PUMA) - Engineering ManagementWilson ChengNo ratings yet

- Eusipa Derivative MapDocument2 pagesEusipa Derivative MapGENo ratings yet

- TRPL Site Selection - Email VersionDocument47 pagesTRPL Site Selection - Email VersionJeremy TurleyNo ratings yet

- Security and Safety: An Introduction: Bibi Van Den Berg & Pauline HuttenDocument18 pagesSecurity and Safety: An Introduction: Bibi Van Den Berg & Pauline HuttenA Vasquez Rd100% (2)

- Globalisation and Risks For Business: Implications of An Increasingly Interconnected WorldDocument56 pagesGlobalisation and Risks For Business: Implications of An Increasingly Interconnected WorldDan688No ratings yet

- Research On Resilience: Response To Commentaries: Suniya S. Luthar, Dante Cicchetti, and Bronwyn BeckerDocument3 pagesResearch On Resilience: Response To Commentaries: Suniya S. Luthar, Dante Cicchetti, and Bronwyn Beckerclaaa_fhrNo ratings yet

- Theory of ProfitDocument10 pagesTheory of ProfitKajal Patil100% (1)

- Synthesis of The Study GuideDocument3 pagesSynthesis of The Study GuideMark Jerome GuzmanNo ratings yet

- Risk Management Iso 31000Document7 pagesRisk Management Iso 31000Loc Vinh PhungNo ratings yet