Professional Documents

Culture Documents

AOZ123 Datasheet

Uploaded by

martin sembinelliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AOZ123 Datasheet

Uploaded by

martin sembinelliCopyright:

Available Formats

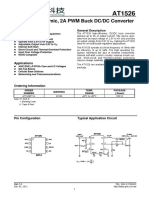

AOZ1232-01

28V/6A Synchronous EZBuckTM Regulator

General Description Features

The AOZ1232-01 is a high-efficiency, easy-to-use DC/DC Wide input voltage range

synchronous buck regulator that operates up to 28V. – 2.7V to 28V

The device is capable of supplying 6A of continuous

6A continuous output current

output current with an output voltage adjustable down to

0.8V (±1.0%). Output voltage adjustable down to 0.8V (±1.0%)

Low RDS(ON) internal NFETs

The AOZ1232-01 integrates an internal linear regulator

– 35m high-side

to generate 5.3V VCC from input. If input voltage is lower

than 5.3V, the linear regulator operates at low drop- – 12m low-side SRFET™

output mode, which allows the VCC voltage is equal to Constant On-Time with input feed-forward

input voltage minus the drop-output voltage of the Programmable frequency up to 1MHz

internal linear regulator.

Internal 5.3V/20mA linear regulator

A proprietary constant on-time PWM control with input Ceramic capacitor stable

feed-forward results in ultra-fast transient response while Adjustable soft start

maintaining relatively constant switching frequency over

Power Good output

the entire input voltage range. The switching frequency

can be externally programmed up to 1MHz. Integrated bootstrap diode

Cycle-by-cycle current limit

The device features multiple protection functions such as Short-circuit protection

VCC under-voltage lockout, cycle-by-current limit, output

over-voltage protection, short-circuit protection, as well Thermal shutdown

as thermal shutdown. Thermally enhanced 5mm x 5mm QFN-30L package

The AOZ1232-01 is available in a 5mm x 5mm QFN-30L Applications

package and is rated over a -40°C to +85°C ambient

Portable computers

temperature range.

Compact desktop PCs

Servers

Graphics cards

Set-top boxes

LCD TVs

Cable modems

Point-of-load DC/DC converters

Telecom/Networking/Datacom equipment

Rev. 1.3 October 2012 www.aosmd.com Page 1 of 18

AOZ1232-01

Typical Application for VIN = 12V or above

Input = 12V or above

IN RTON

C2

22μF AIN TON

BST

VCC C5

R3 C4 0.1μF

1μF AOZ1232-01

100kΩ

Power Good PGOOD LX Output

L1

R1

Off On EN

FB C3

R2 100μF

SS AGND

CSS

PGND

Analog Ground

Power Ground

Typical Application for VIN = 5V

Input = 5V

IN RTON

C2

22μF AIN TON

BST

VCC C5

R3 C4 0.1μF

1μF AOZ1232-01

100kΩ

Power Good PGOOD LX Output

L1

R1

Off On EN

FB C3

R2 100μF

SS AGND

CSS

PGND

Analog Ground

Power Ground

Rev. 1.3 October 2012 www.aosmd.com Page 2 of 18

AOZ1232-01

Typical Application for High Light Load Efficiency Requirement or VIN = 2.7V ~ 6.5V

Input

IN RTON

C2

22μF AIN TON

BST

5V VCC C5

R3 C4 0.1μF

1μF AOZ1232-01

100kΩ Output

Power Good PGOOD LX

L1

R1

Off On EN

FB C3

R2 100μF

SS AGND

CSS

PGND

Analog Ground

Power Ground

Ordering Information

Part Number Ambient Temperature Range Package Environmental

AOZ1232QI-01 -40°C to +85°C 30-Pin 5mm x 5mm QFN Green Product

AOS Green Products use reduced levels of Halogens, and are also RoHS compliant.

Please visit www.aosmd.com/media/AOSGreenPolicy.pdf for additional information.

Rev. 1.3 October 2012 www.aosmd.com Page 3 of 18

AOZ1232-01

Pin Configuration

AGND

PGND

VCC

BST

SS

LX

LX

LX

30 29 28 27 26 25 24 23

PGOOD 1 22 LX

EN 2 21 LX

PFM 3 AGND 20 LX

AGND 4 LX 19 PGND

FB 5 18 PGND

17 PGND

TON 6 IN 16 PGND

AIN 7 15 PGND

8 9 10 11 12 13 14

IN

IN

IN

IN

PGND

PGND

PGND

30-pin 5mm x 5mm QFN

(Top View)

Pin Description

Pin Number Pin Name Pin Function

Power Good Signal Output. PGOOD is an open-drain output used to indicate the status

of the output voltage. It is internally pulled low when the output voltage is 10% lower than

1 PGOOD

the nominal regulation voltage for 50µs (typical time) or 15% higher than the nominal

regulation voltage. PGOOD is pulled low during soft-start and shut down.

Enable Input. The AOZ1232-01 is enabled when EN is pulled high. The device shuts

2 EN

down when EN is pulled low.

PFM Selection Input. Connect PFM pin to VCC/VIN for forced PWM operation. Connect

3 PFM

PFM pin to ground for PFM operation to improve light load efficiency.

4, 29 AGND Analog Ground.

Feedback Input. Adjust the output voltage with a resistive voltage-divider between the

5 FB

regulator’s output and AGND.

6 TON On-Time Setting Input. Connect a resistor between VIN and TON to set the on time.

7 AIN Supply Input for analog functions.

8, 9, 10, 11 IN Supply Input. IN is the regulator input. All IN pins must be connected together.

12, 13, 14, 15, 16,

PGND Power Ground.

17, 18, 19, 26

20, 21, 22, 23,

LX Switching Node.

24, 25

Bootstrap Capacitor Connection. The AOZ1232-01 includes an internal bootstrap diode.

27 BST Connect an external capacitor between BST and LX as shown in the Typical Application

diagrams.

Output for internal linear regulator. Bypass VCC to AGND with a 1µF ceramic capacitor.

28 VCC

Place the capacitor close to VCC pin.

Soft-Start Time Setting Pin. Connect a capacitor between SS and AGND to set the

30 SS

soft-start time.

Rev. 1.3 October 2012 www.aosmd.com Page 4 of 18

AOZ1232-01

Absolute Maximum Ratings Maximum Operating Ratings

Exceeding the Absolute Maximum Ratings may damage the

The device is not guaranteed to operate beyond the

device.

Maximum Operating ratings.

Parameter Rating Parameter Rating

IN, AIN, TON, PFM to AGND -0.3V to 30V

Supply Voltage (VIN) 2.7V(1) to 28V

LX to AGND -2V to 30V

Output Voltage Range 0.8V to 0.85*VIN

BST to AGND -0.3V to 36V

Ambient Temperature (TA) -40°C to +85°C

SS, PGOOD, FB, EN to AGND -0.3V to 6V

Package Thermal Resistance

PGND to AGND -0.3V to +0.3V

HS MOSFET 25°C/W

Junction Temperature (TJ) +150°C

LS MOSFET 20°C/W

Storage Temperature (TS) -65°C to +150°C

PWM Controller 50°C/W

ESD Rating(1) 2kV

Note:

Note: 1. Connect VCC and AIN to external 5V for VIN = 2.7V ~ 6.5V

1. Devices are inherently ESD sensitive, handling precautions are application.

required. Human body model rating: 1.5k in series with 100pF.

2. LX to PGND Transient (t<20ns) ------ -7V to VIN + 7V.

Electrical Characteristics

TA = 25°C, VIN = 12V, EN = 5V, unless otherwise specified. Specifications in BOLD indicate a temperature range of -40°C to +85°C.

Symbol Parameter Conditions Min. Typ. Max Units

VIN IN Supply Voltage 2.7 28 V

Vcc rising 4.0 4.4

VUVLO Under-Voltage Lockout Threshold of Vcc V

Vcc falling 3.2 3.7

Iq Quiescent Supply Current of Vcc IOUT = 0, VFB = 1.0V, VEN > 2V 2 3 mA

IOFF Shutdown Supply Current VEN = 0V 1 20 A

TA = 25°C 0.792 0.800 0.808

VFB Feedback Voltage V

TA = 0°C to 85°C 0.788 0.800 0.812

Load Regulation 0.5 %

Line Regulation 1 %

IFB FB Input Bias Current 200 nA

Enable

Off threshold 0.5

VEN EN Input Threshold V

On threshold 2.5

VEN_HYS EN Input Hysteresis 100 mV

PFM Control

PFM Mode threshold 0.5

VPFM PFM Input Threshold V

Force PWM threshold 2.5

VPFMHYS PFM Input Hysteresis 100 mV

Modulator

RTON = 100k, VIN = 12V 200 250 300

TON On Time ns

RTON = 100k, VIN = 24V 150

TON_MIN Minimum On Time 100 ns

TOFF_MIN Minimum Off Time 250 ns

Rev. 1.3 October 2012 www.aosmd.com Page 5 of 18

AOZ1232-01

Symbol Parameter Conditions Min. Typ. Max Units

Soft-Start

ISS_OUT SS Source Current VSS = 0, CSS = 0.001F to 0.1F 7 10 15 A

Power Good Signal

VPG_LOW PGOOD Low Voltage IOL = 1mA 0.5 V

PGOOD Leakage Current ±1 A

VPGH FB rising 12 15 18

PGOOD Threshold %

VPGL FB falling -12 -10 -8

PGOOD Threshold Hysteresis 3 %

TPG_L PGOOD Fault Delay Time (FB falling) 50 s

Under Voltage and Over Voltage Protection

VPL Under Voltage Threshold FB falling -30 -25 -20 %

TPL Under Voltage Delay Time 128 s

VPH Over Voltage Threshold FB rising 12 15 18 %

TUV_LX Under Voltage Shutdown Blanking Time VIN = 12V, VEN = 0V, VCC = 5V 20 mS

Power Stage Output

RDS(ON) High-Side NFET On-Resistance VIN = 12V, VCC = 5V 35 45 m

High-Side NFET Leakage VEN = 0V, VLX = 0V 10 A

RDS(ON) Low-Side NFET On-Resistance VLX = 12V, VCC = 5V 12 15 m

Low-Side NFET Leakage VEN = 0V 10 A

Over-current and Thermal Protection

ILIM Valley Current Limit 6 A

TJ rising 145

Thermal Shutdown Threshold °C

TJ falling 100

Rev. 1.3 October 2012 www.aosmd.com Page 6 of 18

AOZ1232-01

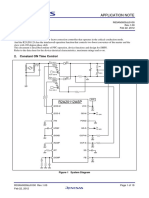

Functional Block Diagram

BST AIN IN PGood

LDO

VCC

EN UVLO TOFF_MIN

Reference Q PG Logic

& Bias Error Comp Timer

0.8V

SS S

Q

ISENSE R

(AC) FB ILIM Comp LX

FB Decode

ILIM_VALLEY

Current ISENSE (DC)

ISENSE Information

Processing ISENSE (AC)

OTP

Vcc

TON

Q

Timer

PFM

TON TON Light Load

Generator Comp

Light Load ISENSE

Threshold

PGND AGND

Rev. 1.3 October 2012 www.aosmd.com Page 7 of 18

AOZ1232-01

Typical Performance Characteristics

Circuit of Typical Application. TA = 25°C, VIN = 12V, VOUT = 1.5V, fs = 300kHz unless otherwise specified.

Normal Operation Load transient 1.2A (20%) to 4.8A (80%)

VLX

10V/div

VLX

10V/div ILX

ILX 5A/div

2A/div

VO Ripple VO Ripple

20mV/div 100mV/div

5μs/div 500μs/div

Full Load (6A) Start-UP Full Load Short

VLX

10V/div VLX

10V/div

EN

5V/div

ILX

2A/div IO

VO 5A/div

1V/div VO

500mV/div

1ms/div 1ms/div

Rev. 1.3 October 2012 www.aosmd.com Page 8 of 18

AOZ1232-01

Detailed Description

The AOZ1232-01 is a high-efficiency, easy-to-use, Constant-On-Time PWM Control with Input

synchronous buck regulator optimized for notebook Feed-Forward

computers. The regulator is capable of supplying 6A of

The control algorithm of AOZ1232-01 is constant-on-time

continuous output current with an output voltage

PWM Control with input feed-forward.

adjustable down to 0.8V. The programmable operating

frequency range of 100kHz to 1MHz enables optimizing The simplified control schematic is shown in Figure 1.

the configuration for PCB area and efficiency.

FB Voltage/

The input voltage of AOZ1232-01 can be as low as 2.7V. IN AC Current

The highest input voltage of AOZ1232-01 can be 28V. Information

Constant on-time PWM with input feed-forward control –

PWM Programmable

scheme results in ultra-fast transient response while Comp

maintaining relatively constant switching frequency over One-Shot

+ 0.8V

the entire input range. True AC current mode control

scheme guarantees the regulator can be stable with a

ceramic output capacitor. The switching frequency can Figure 1. Simplified Control Schematic of AOZ1232-01

be externally programmed up to 1MHz. Protection

features include VCC under-voltage lockout, valley The high-side switch on-time is determined solely by a

current limit, output over voltage and under voltage one-shot whose pulse width can be programmed by one

protection, short-circuit protection, and thermal external resistor and is inversely proportional to input

shutdown. voltage (IN). The one-shot is triggered when the internal

0.8V is lower than the combined information of FB

The AOZ1232-01 is available in 30-pin 5mm x 5mm QFN voltage and the AC current information of inductor, which

package. is processed and obtained through the sensed lower-side

MOSFET current once it turns on. The added AC current

Input Power Architecture information can help the stability of constant-on time

The AOZ1232-01 integrates an internal linear regulator control even with pure ceramic output capacitors, which

to generate 5.3V VCC from input. If input voltage is lower have very low ESR. The AC current information has no

than 5.3V, the linear regulator operates at low drop- DC offset, which does not cause offset with output load

output mode; the VCC voltage is equal to input voltage change, which is fundamentally different from other V2

minus the drop-output voltage of internal linear regulator. constant-on time control schemes.

Enable and Soft Start The constant-on-time PWM control architecture is a

The AOZ1232-01 has external soft start feature to limit pseudo-fixed frequency with input voltage feed-forward.

in-rush current and ensure the output voltage ramps up The internal circuit of AOZ1232-01 sets the on-time of

smoothly to regulation voltage. A soft start process high-side switch inversely proportional to the IN.

begins when VCC rises to 4.0V and voltage on EN pin is – 12

26.3 10 R TON (1)

HIGH. An internal current source charges the external T ON = ----------------------------------------------------------------

soft-start capacitor; the FB voltage follows the voltage of V IN V

soft-start pin (VSS) when it is lower than 0.8V. When VSS

is higher than 0.8V, the FB voltage is regulated by

internal precise band-gap voltage (0.8V). The soft-start To achieve the flux balance of inductor, the buck

time can be calculated by the following formula: converter has the equation:

V OUT

TSS(s) = 330 x CSS(nF) F SW = --------------------------- (2)

V IN T ON

If CSS is 1nF, the soft-start time will be 330µs; if CSS is

10nF, the soft-start time will be 3.3ms.

Rev. 1.3 October 2012 www.aosmd.com Page 9 of 18

AOZ1232-01

Once the product of VIN x TON is constant, the switching function of the inductor value as well as input and output

frequency keeps constant and is independent with input voltages. The current limit will keep the low-side

voltage. MOSFET ON and will not allow another high-side on-

time, until the current in the low-side MOSFET reduces

An external resistor between the IN and TON pin sets the below the current limit. Figure 2 shows the inductor

switching frequency according to the following equation: current during the current limit.

12

V OUT 10

F SW = --------------------------------- (3)

26.3 R TON

Inductor

A further simplified equation will be: Current Ilim

38000 V OUT V

F SW kHz = ----------------------------------------------- (4)

R TON k Time

Figure 2. Inductor Current

If VOUT is 1.8V, RTON is 137k, the switching frequency

will be 500kHz. After 128s (typical), the AOZ1232-01 considers this is a

true failed condition and therefore, turns-off both high-

This algorithm results in a nearly constant switching side and low-side MOSFETs and latches off. When

frequency despite the lack of a fixed-frequency clock triggered, only the enable can restart the AOZ1232-01

generator. again.

True Current Mode Control Output Voltage Under-Voltage Protection

The constant-on-time control scheme is intrinsically If the output voltage is lower than 25% by over-current or

unstable if output capacitor’s ESR is not large enough as short circuit, the AOZ1232-01 will wait for 128s (typical)

an effective current-sense resistor. Ceramic capacitors and turns-off both high-side and low-side MOSFETs and

usually cannot be used as output capacitor. latches off. When triggered, only the enable can restart

the AOZ1232-01 again.

The AOZ1232-01 senses the low-side MOSFET current

and processes it into DC and AC current information Output Voltage Over-Voltage Protection

using AOS proprietary technique. The AC current The threshold of OVP is set 15% higher than 800mV.

information is decoded and added on the FB pin on When the VFB voltage exceeds the OVP threshold, high-

phase. With AC current information, the stability of side MOSFET is turned-off and low-side MOSFETs is

constant-on-time control is significantly improved even turned-on until VFB voltage is lower than 800mV.

without the help of output capacitor’s ESR, and thus the

pure ceramic capacitor solution can be applicable. The Power Good Output

pure ceramic capacitor solution can significantly reduce The power good (PGOOD) output, which is an open

the output ripple (no ESR caused overshoot and drain output, requires the pull-up resistor. When the

undershoot) and less board area design. output voltage is 10% below than the nominal regulation

voltage for 50s (typical), the PGOOD is pulled low.

Valley Current-Limit Protection When the output voltage is 15% higher than the nominal

The AOZ1232-01 uses the valley current-limit protection regulation voltage, the PGOOD is also pulled low.

by using RDSON of the lower MOSFET current sensing.

To detect real current information, a minimum constant- When combined with the under-voltage-protection circuit,

off (150ns typical) is implemented after a constant-on this current limit method is effective in almost every

time. If the current exceeds the valley current-limit circumstance. In forced-PWM mode, the AOZ1232-01

threshold, the PWM controller is not allowed to initiate a also implements a negative current limit to prevent

new cycle. The actual peak current is greater than the excessive reverse inductor currents when VOUT is

valley current-limit threshold by an amount equal to the sinking current.

inductor ripple current. Therefore, the exact current-limit

characteristic and maximum load capability are a

Rev. 1.3 October 2012 www.aosmd.com Page 10 of 18

AOZ1232-01

Application Information

The basic AOZ1232-01 application circuit is shown in For reliable operation and best performance, the input

pages 2 and 3. Component selection is explained below. capacitors must have current rating higher than ICIN-RMS

at worst operating conditions. Ceramic capacitors are

Input Capacitor preferred for input capacitors because of their low ESR

The input capacitor must be connected to the IN pins and and high ripple current rating. Depending on the

PGND pin of the AOZ1232-01 to maintain steady input application circuits, other low ESR tantalum capacitor or

voltage and filter out the pulsing input current. A small aluminum electrolytic capacitor may also be used. When

decoupling capacitor, usually 1F, should be connected selecting ceramic capacitors, X5R or X7R type dielectric

to the VCC pin and AGND pin for stable operation of the ceramic capacitors are preferred for their better

AOZ1232-01. The voltage rating of input capacitor must temperature and voltage characteristics. Note that the

be greater than maximum input voltage plus ripple ripple current rating from capacitor manufactures is

voltage. based on certain amount of life time. Further de-rating

may be necessary for practical design requirement.

The input ripple voltage can be approximated by

equation below: Inductor

The inductor is used to supply constant current to output

IO VO VO

- 1 – --------

---------------- - --------- when it is driven by a switching voltage. For given input

f C IN V IN V IN and output voltage, inductance and switching frequency

together decide the inductor ripple current, which is:

Since the input current is discontinuous in a buck VO VO

converter, the current stress on the input capacitor is I L = ----------- 1 – ---------

fL V IN

another concern when selecting the capacitor. For a buck

circuit, the RMS value of input capacitor current can be

calculated by: The peak inductor current is:

VO VO I L

I CIN_RMS = I O --------- 1 – --------- I Lpeak = I O + --------

V IN V IN 2

High inductance gives low inductor ripple current but

if let m equal the conversion ratio: requires a larger size inductor to avoid saturation. Low

VO ripple current reduces inductor core losses. It also

--------

- = m reduces RMS current through inductor and switches,

V IN which results in less conduction loss. Usually, peak to

peak ripple current on inductor is designed to be 30% to

The relation between the input capacitor RMS current 50% of output current.

and voltage conversion ratio is calculated and shown in

Figure 3. It can be seen that when VO is half of VIN, CIN it When selecting the inductor, make sure it is able to

is under the worst current stress. The worst current handle the peak current without saturation even at the

stress on CIN is 0.5 x IO. highest operating temperature.

The inductor takes the highest current in a buck circuit.

0.5

The conduction loss on the inductor needs to be checked

0.4

for thermal and efficiency requirements.

Surface mount inductors in different shapes and styles

ICIN_RMS(m) 0.3 are available from Coilcraft, Elytone and Murata.

IO Shielded inductors are small and radiate less EMI noise,

0.2

but they do cost more than unshielded inductors. The

0.1 choice depends on EMI requirement, price and size.

0

0 0.5 1

m

Figure 3. ICIN vs. Voltage Conversion Ratio

Rev. 1.3 October 2012 www.aosmd.com Page 11 of 18

AOZ1232-01

Output Capacitor Thermal Management and Layout

The output capacitor is selected based on the DC output Consideration

voltage rating, output ripple voltage specification and In the AOZ1232-01 buck regulator circuit, high pulsing

ripple current rating. current flows through two circuit loops. The first loop

The selected output capacitor must have a higher rated starts from the input capacitors, to the VIN pin, to the LX

voltage specification than the maximum desired output pins, to the filter inductor, to the output capacitor and

voltage including ripple. De-rating needs to be load, and then returns to the input capacitor through

considered for long term reliability. ground. Current flows in the first loop when the high side

switch is on. The second loop starts from the inductor, to

Output ripple voltage specification is another important the output capacitors and load, to the low side switch.

factor for selecting the output capacitor. In a buck con- Current flows in the second loop when the low side

verter circuit, output ripple voltage is determined by switch is on.

inductor value, switching frequency, output capacitor

value and ESR. It can be calculated by the equation In PCB layout, minimizing the two loops area reduces the

below: noise of this circuit and improves efficiency. A ground

plane is strongly recommended to connect the input

V O = I L ESR CO + -------------------------

1 capacitor, output capacitor and PGND pin of the

8fC AOZ1232-01.

O

where, In the AOZ1232-01 buck regulator circuit, the major

CO is output capacitor value and power dissipating components are the AOZ1232-01 and

ESRCO is the Equivalent Series Resistor of output capacitor. output inductor. The total power dissipation of the con-

verter circuit can be measured by input power minus out-

When a low ESR ceramic capacitor is used as output put power.

capacitor, the impedance of the capacitor at the

switching frequency dominates. Output ripple is mainly P total_loss = V IN I IN – V O I O

caused by capacitor value and inductor ripple current.

The output ripple voltage calculation can be simplified to: The power dissipation of inductor can be approximately

calculated by output current and DCR of inductor and

1

V O = I L ------------------------- output current.

8fC O

P inductor_loss = IO2 R inductor 1.1

If the impedance of ESR at switching frequency

dominates, the output ripple voltage is mainly decided by The actual junction temperature can be calculated with

capacitor ESR and inductor ripple current. The output power dissipation in the AOZ1232-01 and thermal

ripple voltage calculation can be further simplified to: impedance from junction to ambient.

V O = I L ESR CO T junction = P total_loss – P inductor_loss JA

For lower output ripple voltage across the entire

operating temperature range, X5R or X7R dielectric type The maximum junction temperature of AOZ1232-01 is

of ceramic, or other low ESR tantalum are recommended 150ºC, which limits the maximum load current capability.

to be used as output capacitors.

The thermal performance of the AOZ1232-01 is strongly

In a buck converter, output capacitor current is affected by the PCB layout. Extra care should be taken

continuous. The RMS current of output capacitor is by users during design process to ensure that the IC will

decided by the peak to peak inductor ripple current. operate under the recommended environmental

It can be calculated by: conditions.

I L

I CO_RMS = ----------

12

Usually, the ripple current rating of the output capacitor is

a smaller issue because of the low current stress. When

the buck inductor is selected to be very small and

inductor ripple current is high, the output capacitor could

be overstressed.

Rev. 1.3 October 2012 www.aosmd.com Page 12 of 18

AOZ1232-01

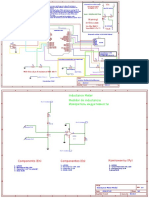

Several layout tips are listed below for the best electric

and thermal performance.

1. The LX pins and pad are connected to internal low 5. Decoupling capacitor CVCC should be connected to

side switch drain. They are low resistance thermal VCC and AGND as close as possible.

conduction path and most noisy switching node. 6. Voltage divider R1 and R2 should be placed as close

Connect a large copper plane to LX pin to help ther- as possible to FB and AGND.

mal dissipation.

7. RTON should be connected as close as possible to

2. The IN pins and pad are connected to internal high Pin 6 (TON pin).

side switch drain. They are also low resistance ther-

mal conduction path. Connect a large copper plane 8. A ground plane is preferred; Pin 26 (PGND) is con-

to IN pins to help thermal dissipation. nected to the ground plane through via.

3. Do not use thermal relief connection on the PGND 9. Keep sensitive signal traces such as feedback trace

pin. Pour a maximized copper area on the PGND pin far away from the LX pins.

to help thermal dissipation. 10. Pour copper plane on all unused board area and

4. Input capacitors should be connected to the IN pin connect it to stable DC nodes, like VIN, GND or

and the PGND pin as close as possible to reduce the VOUT.

switching spikes.

Vo

R2

R1

Rton

PGOOD

AGN

TON

PFM

AIN

ND

EN

FB

D

7

IN 8 30 SS Cvcc

IN 9 29 AGND

D

AGN

AGND

IN

IN 10 28 VCC Vcc

Cin

IN 11 27 BST

26 GND

PGND Cb

PGND 12 25 LX

LX

PGND 13 24 LX

PGND 14 23 LX

15

16

17

18

19

20

21

22

PGND

PGND

PGND

PGND

PGND

LX

LX

LX

Cout

LX

Vo

Vo

Rev. 1.3 October 2012 www.aosmd.com Page 13 of 18

AOZ1232-01

Package Dimensions, QFN 5x5, 30 Lead EP3_S

D

A

D/2 B

22 15

2 23 14

INDEX AREA E/2

(D/2xE/2)

A3/2

E

aaa C

e

2x

30 8

1 7

2x A3

aaa C

TOP VIEW

A3/2 A3

ccc C

C

A

SEATING

PLANE

4 A1

30 x b 3

ddd C

bbb M C A B

SIDE VIEW

PIN#1 DIA D1

C0.35x45˚ e

e/2

1 7 L5

30 8

E1 D2 E1

L3

L1 L1

2e

L2 L4 e/2

E2

L5

23 14

L

22 15 L5

D3/2

D3 L5

Notes:

1. All dimensions are in millimeters.

2. The location of the terminal #1 identifier and terminal numbering convention conforms to JEDEC publication 95 SPP-002.

3. Dimension b applies to metallized terminal and is measured between 0.20mm and 0.35mm from the terminal tip.

If the terminal has the optional radius on the other end of the terminal, the dimension b should not be measured in that radius area.

Rev. 1.3 October 2012 www.aosmd.com Page 14 of 18

AOZ1232-01

Package Dimensions, QFN 5x5, 30 Lead EP3_S (Continued)

3.76

0.25 0.22

0.80

1.88

0.22

15

22

23 14

0.75

2.50

0.386

0.116

0.25

1.996

0.44

0.71

1.494

2.50

30 8

0.30X45°

7

0.22

1 1.25

0.25 0.500 REF

UNIT: MM

0.22 2.32 1.17

2.50 2.50

RECOMMENDED STENCIL DESIGN

1.04

0.22

0.27

0.14 0.27

0.80

0.52

0.27

15

22

23 14

0.873

0.75

2.50

0.436

0.25

0.116

0.39

0.15

0.622

0.81

2.50

30 8

0.15

0.30X45° 7

1

0.27

0.25 0.500 REF

0.27 0.37

0.27

0.975 1.07 UNIT: MM

2.50 2.50

Rev. 1.3 October 2012 www.aosmd.com Page 15 of 18

AOZ1232-01

Package Dimensions, QFN 5x5, 30 Lead EP3_S (Continued)

Dimensions in millimeters Dimensions in inches

Symbols Min. Typ. Max. Symbols Min. Typ. Max.

A 0.80 0.90 1.00 A 0.031 0.035 0.039

A1 0.00 0.02 0.05 A1 0.000 0.001 0.002

A3 0.20 REF A3 0.008 REF

b 0.20 0.25 0.35 b 0.008 0.010 0.014

D 5.00 BSC D 0.197 BSC

D1 2.12 2.22 2.32 D1 0.083 0.087 0.091

D2 0.97 1.07 1.17 D2 0.038 0.042 0.046

D3 3.56 3.66 3.76 D3 0.140 0.144 0.148

E 5.00 BSC E 0.197 BSC

E1 1.294 1.394 1.494 E1 0.051 0.055 0.059

E2 1.796 1.896 1.996 E2 0.110 0.114 0.118

e 0.50 BSC e 0.020 BSC

L 0.30 0.40 0.50 L 0.012 0.016 0.020

L1 0.336 0.436 0.536 L1 0.013 0.017 0.021

L2 — 0.066 0.166 L2 — 0.003 0.007

L3 0.29 0.39 0.49 L3 0.011 0.015 0.019

L4 0.66 0.76 0.86 L4 0.026 0.030 0.034

L5 0.17 0.27 0.37 L5 0.007 0.011 0.015

aaa 0.15 aaa 0.006

bbb 0.10 bbb 0.004

ccc 0.10 ccc 0.004

ddd 0.08 ddd 0.003

Rev. 1.3 October 2012 www.aosmd.com Page 16 of 18

AOZ1232-01

Tape and Reel Dimensions, QFN 5x5, 30 Lead EP3_S

Carrier Tape

P1

D1 P2

T

E1

E2

E

B0

K0 D0

P0 A0

Feeding Direction

UNIT: mm

Package A0 B0 K0 D0 D1 E E1 E2 P0 P1 P2 T

QFN 5x5 5.25 5.25 1.10 1.50 1.50 12.00 1.75 5.50 8.00 4.00 2.00 0.30

(12mm) ±0.10 ±0.10 ±0.10 Min. +0.10/-0 +0.3 ±0.10 ±0.05 ±0.10 ±0.10 ±0.05 ±0.05

Reel W1

S

G

M N

K

V

W

UNIT: mm

Tape Size Reel Size M N W W1 H K S G R V

12mm ø330 ø330.0 ø79.0 12.4 17.0 ø13.0 10.5 2.0 — — —

±2.0 ±1.0 +2.0/-0.0 +2.6/-1.2 ±0.5 ±0.2 ±0.5

Leader/Trailer and Orientation

Trailer Tape Components Tape Leader Tape

300mm min. Orientation in Pocket 500mm min.

75 Empty Pockets 125 Empty Pockets

Rev. 1.3 October 2012 www.aosmd.com Page 17 of 18

AOZ1232-01

Part Marking

Z1232QI1

Part Number Code

FAYWLT

Fab & Assembly Location Assembly Lot Code

Year & Week Code

LEGAL DISCLAIMER

Alpha and Omega Semiconductor makes no representations or warranties with respect to the accuracy or

completeness of the information provided herein and takes no liabilities for the consequences of use of such

information or any product described herein. Alpha and Omega Semiconductor reserves the right to make changes

to such information at any time without further notice. This document does not constitute the grant of any intellectual

property rights or representation of non-infringement of any third party’s intellectual property rights.

LIFE SUPPORT POLICY

ALPHA AND OMEGA SEMICONDUCTOR PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL

COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS.

As used herein:

1. Life support devices or systems are devices or 2. A critical component in any component of a life

systems which, (a) are intended for surgical implant into support, device, or system whose failure to perform can

the body or (b) support or sustain life, and (c) whose be reasonably expected to cause the failure of the life

failure to perform when properly used in accordance support device or system, or to affect its safety or

with instructions for use provided in the labeling, can be effectiveness.

reasonably expected to result in a significant injury of

the user.

Rev. 1.3 October 2012 www.aosmd.com Page 18 of 18

You might also like

- An 1197Document20 pagesAn 1197Ade Hadi SantosoNo ratings yet

- SMD CatalogDocument80 pagesSMD Catalogpbradaric91% (11)

- First Reset Signal On Laptop MotherboardDocument2 pagesFirst Reset Signal On Laptop Motherboardangelito alarasNo ratings yet

- E40951307-TCON Troubleshooting 10-22-09 - OPTDocument44 pagesE40951307-TCON Troubleshooting 10-22-09 - OPTSAMURAI_K100% (6)

- Experiment 2 - DC-DC Step-Up (Boost) ConverterDocument6 pagesExperiment 2 - DC-DC Step-Up (Boost) Converter刘辰哲SPIKE100% (2)

- AozDocument16 pagesAozAndreNo ratings yet

- AOZ1267QI-01: General Description FeaturesDocument16 pagesAOZ1267QI-01: General Description Featuresvictory_1410No ratings yet

- Aoz2262qi 1Document16 pagesAoz2262qi 1Eric ArcherNo ratings yet

- AOZ1268QI 01 AlphaOmegaSemiconductorsDocument15 pagesAOZ1268QI 01 AlphaOmegaSemiconductorsrcgruwanNo ratings yet

- 28V/10A Synchronous Buck Regulator with 0.8V OutputDocument15 pages28V/10A Synchronous Buck Regulator with 0.8V OutputРоман ІкалюкNo ratings yet

- General Description Features: 28V/6A Synchronous Ezbuck RegulatorDocument15 pagesGeneral Description Features: 28V/6A Synchronous Ezbuck RegulatorholinsunNo ratings yet

- AOZ2260QI-18 - 2 Up9011q Atau 5388 Di HP AmdDocument15 pagesAOZ2260QI-18 - 2 Up9011q Atau 5388 Di HP AmdNgipik Komp PatiNo ratings yet

- A05c 0S 000060 - Aoz2261nqi 11Document18 pagesA05c 0S 000060 - Aoz2261nqi 11Chiapin LeeNo ratings yet

- General Description Features: 28V/12A Synchronous Ezbuck RegulatorDocument16 pagesGeneral Description Features: 28V/12A Synchronous Ezbuck RegulatorholinsunNo ratings yet

- General Description Features: 28V/10A Synchronous Ezbuck RegulatorDocument15 pagesGeneral Description Features: 28V/10A Synchronous Ezbuck RegulatorholinsunNo ratings yet

- AOZ2023PIDocument11 pagesAOZ2023PIjuliocunachiNo ratings yet

- Z1031ADocument15 pagesZ1031ALORIUNEANo ratings yet

- Datasheet - Aoz1280 Simple Buck RegulatorDocument13 pagesDatasheet - Aoz1280 Simple Buck RegulatorCesar ServidoneNo ratings yet

- AOZ6623DI Regulador de VoltajeDocument15 pagesAOZ6623DI Regulador de VoltajeDaiverJuarezNo ratings yet

- RT8059Document10 pagesRT8059Bijan AmiriNo ratings yet

- AOZ3015AIDocument14 pagesAOZ3015AIIcomNo ratings yet

- Hysteretic Boost-Buck (Ćuk) LED Driver IC: Features General DescriptionDocument16 pagesHysteretic Boost-Buck (Ćuk) LED Driver IC: Features General DescriptionJohnNo ratings yet

- 2.5A Switch Step Down Switching Regulator: DescriptionDocument10 pages2.5A Switch Step Down Switching Regulator: DescriptionVictor CuaicalNo ratings yet

- Data SheetDocument16 pagesData SheetHugo BurgosNo ratings yet

- Tps 61197Document22 pagesTps 61197Sahaly RandNo ratings yet

- AT1526 GlobalMixed ModetechnologyDocument2 pagesAT1526 GlobalMixed ModetechnologyFafa MangstabNo ratings yet

- AOZ1282CIDocument13 pagesAOZ1282CIBelalang TempurNo ratings yet

- 1571fDocument16 pages1571fSanele LangaNo ratings yet

- Microsoft Word - 5011203309-SE09Document1 pageMicrosoft Word - 5011203309-SE09JORGE RODNo ratings yet

- RT9080N Datasheet ModDocument14 pagesRT9080N Datasheet ModDavid MAILLOTNo ratings yet

- LWNMNM : General Description FeaturesDocument16 pagesLWNMNM : General Description FeaturesSergio BarbozaNo ratings yet

- AOZ1038DIDocument15 pagesAOZ1038DIjiledarNo ratings yet

- 1.5A Switch Step Down Switching Regulator: 1 General FeaturesDocument11 pages1.5A Switch Step Down Switching Regulator: 1 General FeaturesRene gNo ratings yet

- AT9917 Automotive LED Driver IC With High Current Accuracy Data Sheet 20005557ADocument20 pagesAT9917 Automotive LED Driver IC With High Current Accuracy Data Sheet 20005557AJohnNo ratings yet

- Ezbuck™ 3A Synchronous Buck Regulator: General Description FeaturesDocument15 pagesEzbuck™ 3A Synchronous Buck Regulator: General Description FeaturesJulio BarrosNo ratings yet

- Apu8836 3Document6 pagesApu8836 3dataNo ratings yet

- Application Note: Figure 1 System DiagramDocument21 pagesApplication Note: Figure 1 System DiagramJosé Manuel Izea NavarroNo ratings yet

- IR2171/IR2172 Data Sheet GuideDocument6 pagesIR2171/IR2172 Data Sheet GuideBlackArnabNo ratings yet

- Catalog Khoi Dong Mem Chint NJR2 ZXDocument6 pagesCatalog Khoi Dong Mem Chint NJR2 ZXsatthubattuongNo ratings yet

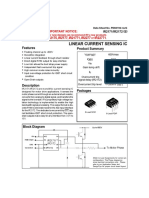

- Ir2175 (S) & (PBF) : Linear Current Sensing IcDocument7 pagesIr2175 (S) & (PBF) : Linear Current Sensing IcDavid CoronadoNo ratings yet

- Fixed Frequency, 99% Duty Cycle Peak Current Mode Notebook System Power ControllerDocument44 pagesFixed Frequency, 99% Duty Cycle Peak Current Mode Notebook System Power ControllerAualasNo ratings yet

- LED Step-Up Converter Drives Up to Five White LEDsDocument9 pagesLED Step-Up Converter Drives Up to Five White LEDsBudi PrayitnoNo ratings yet

- DatasheetDocument7 pagesDatasheetDarcio TolottiNo ratings yet

- Aoz1212ai PDFDocument18 pagesAoz1212ai PDF060279No ratings yet

- Niko-Sem: 0.8A Fixed and Adjustable Low Dropout Linear Regulator (LDO)Document6 pagesNiko-Sem: 0.8A Fixed and Adjustable Low Dropout Linear Regulator (LDO)Lite HhhNo ratings yet

- Aoz2261qi 18Document16 pagesAoz2261qi 18Ecc CobaNo ratings yet

- AT9932 Automotive Boost Buck LED Lamp Driver IC Data Sheet 20005789ADocument18 pagesAT9932 Automotive Boost Buck LED Lamp Driver IC Data Sheet 20005789AJohnNo ratings yet

- Adjustable 5A LDO Regulator for High Current ApplicationsDocument9 pagesAdjustable 5A LDO Regulator for High Current ApplicationsJMSNo ratings yet

- High Input Voltage Buck-Boost Converter With 2A Switch CurrentDocument31 pagesHigh Input Voltage Buck-Boost Converter With 2A Switch Currentbarmircea10No ratings yet

- Ultra-High Efficiency, Dual Step-Down Controller For Notebook ComputersDocument25 pagesUltra-High Efficiency, Dual Step-Down Controller For Notebook ComputersCarlos Henrique RibasNo ratings yet

- Ame5269 AmeDocument18 pagesAme5269 AmeCharles PNo ratings yet

- KA5x03xx-SERIES: KA5H0365R, KA5M0365R, KA5L0365R KA5H0380R, KA5M0380R, KA5L0380R Fairchild Power Switch (FPS)Document14 pagesKA5x03xx-SERIES: KA5H0365R, KA5M0365R, KA5L0365R KA5H0380R, KA5M0380R, KA5L0380R Fairchild Power Switch (FPS)Bidu BiduNo ratings yet

- LM392 Low Power Operational Amplifier/Voltage Comparator: General DescriptionDocument7 pagesLM392 Low Power Operational Amplifier/Voltage Comparator: General DescriptionAndrés Cely AgudeloNo ratings yet

- Datasheet LTC3728L & LTC3728LX PDFDocument32 pagesDatasheet LTC3728L & LTC3728LX PDFSelmar CavalcantiNo ratings yet

- Dual Voltage Comparator LM393: FeaturesDocument4 pagesDual Voltage Comparator LM393: FeaturesSteven ChowNo ratings yet

- LWNMNP : General Description FeaturesDocument16 pagesLWNMNP : General Description FeaturesArturo ArmuellesNo ratings yet

- ACPL-C87AT/ACPL-C87BT: Data SheetDocument16 pagesACPL-C87AT/ACPL-C87BT: Data SheetMattias RahmNo ratings yet

- Programmable DC/DC Controller For Advanced Microprocessors: Device Package Temp Range (T)Document6 pagesProgrammable DC/DC Controller For Advanced Microprocessors: Device Package Temp Range (T)ibrahim başderNo ratings yet

- AOZ3018PIDocument14 pagesAOZ3018PIpravin jadavNo ratings yet

- Dual, High-Efficiency, Step-Down Controller With Accurate Current LimitDocument27 pagesDual, High-Efficiency, Step-Down Controller With Accurate Current LimitEdson HenriqueNo ratings yet

- BL0940 APPNote TSSOP14 V1.04 ENDocument6 pagesBL0940 APPNote TSSOP14 V1.04 ENGeorgi IlievNo ratings yet

- DatasheetDocument14 pagesDatasheetsamaya egNo ratings yet

- General Description Features: EzbuckDocument9 pagesGeneral Description Features: EzbuckCristina NistorNo ratings yet

- 3-Phase Brushless Fan Motor DriverDocument30 pages3-Phase Brushless Fan Motor DriverAravind Prasad Sounder RajNo ratings yet

- 276967956ad7908 18 28 0Document25 pages276967956ad7908 18 28 0martin sembinelliNo ratings yet

- Dual PWM Control IC with SCP/DTC FunctionDocument26 pagesDual PWM Control IC with SCP/DTC Functionmartin sembinelliNo ratings yet

- Amd Amd: +3V/+5V S5 +1.1VS5/+2.5VDocument44 pagesAmd Amd: +3V/+5V S5 +1.1VS5/+2.5VvinuNo ratings yet

- Dell 7447 DA0AM7MB8D0 AM7Document51 pagesDell 7447 DA0AM7MB8D0 AM7martin sembinelliNo ratings yet

- EC50117Document11 pagesEC50117martin sembinelliNo ratings yet

- Acer Aspire V3 372 Wistron BA30 Mihawk SL 13 15208-3 KabylakeDocument105 pagesAcer Aspire V3 372 Wistron BA30 Mihawk SL 13 15208-3 Kabylakemartin sembinelliNo ratings yet

- Tps 61041Document36 pagesTps 61041Diego EmanuelNo ratings yet

- Product Sheet Ddr3 So DimmDocument3 pagesProduct Sheet Ddr3 So Dimmmartin sembinelliNo ratings yet

- WinboadDocument79 pagesWinboadRoda RodaNo ratings yet

- Pegatron AIC70 Rev.2.0 (2011)Document77 pagesPegatron AIC70 Rev.2.0 (2011)Алекс ХомичNo ratings yet

- Pgood Ic For PCDocument9 pagesPgood Ic For PCmartin sembinelliNo ratings yet

- 6 Chipset c200 Chipset DatasheetDocument934 pages6 Chipset c200 Chipset Datasheetmmm64mmmNo ratings yet

- HMC746LC3C: 13 GBPS, Fast Rise Time And/Nand/Or/Nor Gate, W/ Programmable Output Voltage & Positive SupplyDocument8 pagesHMC746LC3C: 13 GBPS, Fast Rise Time And/Nand/Or/Nor Gate, W/ Programmable Output Voltage & Positive Supplymartin sembinelliNo ratings yet

- B154ew08 V1Document36 pagesB154ew08 V1Alfa alfaNo ratings yet

- Arduino Multimeter PRO V 1.0.4Document2 pagesArduino Multimeter PRO V 1.0.4Joel TulcanazoNo ratings yet

- 002-14796 CYW43438 Single-Chip IEEE 802.11ac B G N MAC Baseband Radio With Integrated Bluetooth 4.1 and FM Receiver PDFDocument91 pages002-14796 CYW43438 Single-Chip IEEE 802.11ac B G N MAC Baseband Radio With Integrated Bluetooth 4.1 and FM Receiver PDFmartin sembinelliNo ratings yet

- Pgood Ic For PCDocument9 pagesPgood Ic For PCmartin sembinelliNo ratings yet

- 6 Chipset c200 Chipset DatasheetDocument934 pages6 Chipset c200 Chipset Datasheetmmm64mmmNo ratings yet

- Mobile Intel Celeron Processor On .13 Micron Process in Micro-FCPGA PackageDocument40 pagesMobile Intel Celeron Processor On .13 Micron Process in Micro-FCPGA Packagemartin sembinelliNo ratings yet

- 002-14796 CYW43438 Single-Chip IEEE 802.11ac B G N MAC Baseband Radio With Integrated Bluetooth 4.1 and FM Receiver PDFDocument91 pages002-14796 CYW43438 Single-Chip IEEE 802.11ac B G N MAC Baseband Radio With Integrated Bluetooth 4.1 and FM Receiver PDFmartin sembinelliNo ratings yet

- HMC746LC3C: 13 GBPS, Fast Rise Time And/Nand/Or/Nor Gate, W/ Programmable Output Voltage & Positive SupplyDocument8 pagesHMC746LC3C: 13 GBPS, Fast Rise Time And/Nand/Or/Nor Gate, W/ Programmable Output Voltage & Positive Supplymartin sembinelliNo ratings yet

- 002-14796 CYW43438 Single-Chip IEEE 802.11ac B G N MAC Baseband Radio With Integrated Bluetooth 4.1 and FM Receiver PDFDocument91 pages002-14796 CYW43438 Single-Chip IEEE 802.11ac B G N MAC Baseband Radio With Integrated Bluetooth 4.1 and FM Receiver PDFmartin sembinelliNo ratings yet

- Aspire 5920 Service ManualDocument104 pagesAspire 5920 Service Manualax0r7ag0z100% (1)

- Three and Four Cell Lithium-Ion or Lithium-Polymer Battery Protection AfeDocument39 pagesThree and Four Cell Lithium-Ion or Lithium-Polymer Battery Protection Afemartin sembinelliNo ratings yet

- Datasheet PDFDocument29 pagesDatasheet PDFKST5No ratings yet

- Aspire 5920 Service ManualDocument104 pagesAspire 5920 Service Manualax0r7ag0z100% (1)

- Module 4Document16 pagesModule 4yakomi suraNo ratings yet

- UCC28880 700-V Lowest Quiescent Current Off-Line Switcher: 1 Features 3 DescriptionDocument35 pagesUCC28880 700-V Lowest Quiescent Current Off-Line Switcher: 1 Features 3 DescriptionFrancisReisNo ratings yet

- Modeling and Control for a Current-Mode Buck Converter with a Secondary LC FilterDocument8 pagesModeling and Control for a Current-Mode Buck Converter with a Secondary LC FilterkamalNo ratings yet

- PYQ ChoppersDocument20 pagesPYQ Choppers14 Asif AkhtarNo ratings yet

- Converter Based On Energy Injection Control For AC-AC, AC-DC, DC-DC, DC-ACDocument5 pagesConverter Based On Energy Injection Control For AC-AC, AC-DC, DC-DC, DC-ACbima bagusNo ratings yet

- Hybrid Energy SystemDocument87 pagesHybrid Energy SystemFaizan AadilNo ratings yet

- Adaptive Constant On-Time (D-CAP™) Control Study inNotebookApps - Slva281bDocument9 pagesAdaptive Constant On-Time (D-CAP™) Control Study inNotebookApps - Slva281bMalli ArjunNo ratings yet

- DC DC Buck Converter ThesisDocument7 pagesDC DC Buck Converter Thesisaprilbellhartford100% (2)

- AOZ1031AIDocument15 pagesAOZ1031AIrachnologistNo ratings yet

- Simulation of AC-DC Step Up and Step Down Converter: B.Partheeban, P.G. ScholarDocument6 pagesSimulation of AC-DC Step Up and Step Down Converter: B.Partheeban, P.G. ScholarVeeramuthu LingamNo ratings yet

- Tps 565242Document31 pagesTps 565242AdarshNo ratings yet

- Design of High Efficiency DC-DC Converters Using SimetrixDocument6 pagesDesign of High Efficiency DC-DC Converters Using Simetrixrio azizNo ratings yet

- Power Management Ics: Fujitsu Microelectronics LimitedDocument12 pagesPower Management Ics: Fujitsu Microelectronics LimitedBoboNo ratings yet

- AP1501Document12 pagesAP1501muessliNo ratings yet

- Buck ConverterDocument2 pagesBuck ConverterBhadreshkumar SharmaNo ratings yet

- Design of A Single Phase Unity Power FactorDocument42 pagesDesign of A Single Phase Unity Power FactorAgus HiwansyahNo ratings yet

- Design of Two Switch Buck Boost ConverterDocument16 pagesDesign of Two Switch Buck Boost ConvertermithunprayagNo ratings yet

- An Adaptive I-V Curve Detecting Method For Photovoltaic ModulesDocument6 pagesAn Adaptive I-V Curve Detecting Method For Photovoltaic ModulesKORAKRIT ANANTA-AUOYPORNNo ratings yet

- An Experimental Prototype of Buck Converter Fed Series DC Motor Implementing Speed and Current ControlsDocument4 pagesAn Experimental Prototype of Buck Converter Fed Series DC Motor Implementing Speed and Current ControlsdevchandarNo ratings yet

- Pspice Pe ManualDocument41 pagesPspice Pe Manualfylobedo99No ratings yet

- Step-Down DC-DC Converter PDFDocument8 pagesStep-Down DC-DC Converter PDFGenetic JohnNo ratings yet

- Design of Buck DC-DC Converter Space ApplicationDocument7 pagesDesign of Buck DC-DC Converter Space ApplicationIJRASETPublicationsNo ratings yet

- Datasheet lm2595Document29 pagesDatasheet lm2595Dayana Serrano ParedesNo ratings yet

- Switching RegulatorDocument29 pagesSwitching RegulatorBindia HandaNo ratings yet

- Design of Solar Power System For Home ApplicationDocument43 pagesDesign of Solar Power System For Home ApplicationsanthosecvpNo ratings yet

- Double Frequency Buck ConverterDocument36 pagesDouble Frequency Buck ConverterSanthosh Guduru100% (1)

- Synchronous Buck Nexfet Power Block: Features DescriptionDocument22 pagesSynchronous Buck Nexfet Power Block: Features DescriptionRawi MontillaNo ratings yet

- Datasheet APW7142Document22 pagesDatasheet APW7142José Aparecido BarbosaNo ratings yet