Professional Documents

Culture Documents

Thorn Conductivityprobe Qs

Uploaded by

cristian198113Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thorn Conductivityprobe Qs

Uploaded by

cristian198113Copyright:

Available Formats

200CR Conductivity/Resistivity Instrument Initial Set-Up

3. Instrument Calibration - (Chapter 8)

This instrument is factory calibrated within

specifications and does not require re-calibration. If

Quality Assurance requirements call for verification,

follow the procedures in the manual.

4. Connect sensors to patch cords.

200CR Front Panel 5. IMPORTANT: Enter cell (sensor) constants for

resistance and temperature for each channel.

The keypad has 6 keys which access specific menus as • Press menus key then use arrow keys until:

follows: Edit Sensor Cal

measure - menus to change measurement modes. • Press OK/NEXT key

setpoint - menus for programming setpoints. A Cell M=.10000_

relays - menus for programming relays.

• Select (A Cell, A Temp, B Cell, B Temp) using

outputs - menus for programming outputs.

up and down arrow keys

calibrate - menus to perform calibration. • Shift cursor using the right arrow key to enter M

menus - all other menus (cell constants, security, , the multiplier.

averaging, compensation, etc.) • Shift cursor using the right arrow key to enter

the precise value of the cell constant found on

The control keys which are used to make changes the sensor.

within a menu are: • Shift cursor back to the first field and repeat the

OK/Next is used to accept a selection and proceed to the above procedure for each of the other three

next menu level. constants.

Up arrow is used to scroll up through a list of • Press the OK/NEXT key

options (& increase numbers).

Save Changes?Yes

Down arrow is used to scroll down through a list of

options (& decrease numbers). • Press the OK/NEXT key

Left arrow is used to move the cursor to the left

within a menu. 6. Select desired measurements for each sensor

Right arrow is used to move the cursor to the right • Press measure key

within a menu. Channel Primary (A,B) settings:

For resistivity, ohm-cm (Auto) - recommended.

Each digit can be scrolled through the values: For conductivity, S/cm (Auto) - recommended.

. (decimal point), 0, 1, 2, 3, 4, 5, 6, 7, 8 and 9. The first By selecting Auto, the instrument will automatically

digit of each number can also be set to neg.(-) scale the sensor value to be read by the

instrument.

Following are the steps necessary to install a 200CR Channel Secondary (a,b) settings:

instrument and begin operation. Secondaries are usually temperatures (°F, °C)

• Press the OK/NEXT key once all 4 measurement

1. Instrument installation - (Chapter 2) selections are made.

The 200CR can be panel, pipe or wall mounted Save Changes?Yes

and a sealed IP65 rear cover is optional but is • Press the OK/NEXT key to save changes.

required for wall and pipe mounting. Drill holes in the

rear cover as needed for conduit or cable grips.

7. Program the analog outputs. (Chapter 7). Do not

calibrate analog outputs.

2. Wiring - (Chapter 2)

Make all necessary electrical connections to the

For additional information refer to Manual 84295. For

instrument. The wiring procedure is outlined on the

coverage of digital RS232/RS422 communications refer

back of this sheet.

to Manual 84364.

200CR Back Panel

Warning: Make sure power to all wires is turned off Output Connections continued

before proceeding with the power installation. High TB2 RS232 RS422

voltage may be present on the input power wires Label Function Function

and relay wires. RXD- Receive Data Receive Data -

RXD+ Not Used Receive Data +

Terminal Block TB1 TXD- Transmit Data Transmit Data -

200CR models 6220 and 6222 have 2 relays

TXD+ Not Used Transmit Data +

200CR model 6224 has 4 relays

GND Ground* Not Used

The wiring sequence is shown in the table below.

Relays 3 and 4 are solid state, for AC only. Refer to AO2- Analog Output 2 -

Manual Chapter 2. AO2+ Analog Output 2 +

AO1- Analog Output 1 -

TB1 Input Power & Relay AO1+ Analog Output 1 +

*For RS232 only.

Label Function

CAUTION: Do not connect analog output wiring

L 115V/230VAC Line

shields to adjacent GND terminal. Connect them to

N 115V/230VAC Neutral

AC-power earth ground terminal only.

Earth Ground

NC1 Relay 1: Normally Closed Sensor Connections

C1 Relay 1: Common Wire sensor patch cord leads as shown below.

NO1 Relay 1: Normally Open Warning: Miswiring patch cords may damage

NC2 Relay 2: Normally Closed sensors. Blue wire #7 is not used. Leave clear

C2 Relay 2: Common shrink tube in place over it.

NO2 Relay 2: Normally Open

C3 Relay 3: Common TB3 Wire Sensor

NO3 Relay 3: Normally Open Label Color Connection

C4 Relay 4: Common GND(6) BLACK

NO4 Relay 4: Normally Open SIG5(5) RED Channel B Sensor

SIG4(4) GREEN Connections

Input Voltage SIG3(3) WHITE

The input voltage is preset at the factory. To change the SIG2(2) CLEAR

input voltage refer to Manual Chapter 2. SIG1(1) WHT/BLUE

Output Connections GND(6) BLACK

Connections for all outputs are made to terminal block SIG5(5) RED Channel A Sensor

TB2. The serial port can be configured as an RS-232 SIG4(4) GREEN Connections

port or an RS-422 port. Analog outputs, if included, are SIG3(3) WHITE

powered. Do not connecto circuits that provide external SIG2(2) CLEAR

power. SIG1(1) WHT/BLUE

Tel: 781-839-6400 Fax: 781-890-5507

SmartLine: 1-800-642-4418

Thornton Inc. E-mail: info@thorntoninc.com

1432 Main Street Web: www.thorntoninc.com

Waltham, MA 02451 USA OM 84304 Rev D 10/00

You might also like

- Bull CA71 EDocument4 pagesBull CA71 Edandi zlkNo ratings yet

- Handy CalibratorsDocument5 pagesHandy CalibratorsDan Hidalgo QuintoNo ratings yet

- RTP Rata Flujo ManualDocument18 pagesRTP Rata Flujo ManualFabian PerezNo ratings yet

- Typical Wiring Diagram: Deep Sea ElectronicsDocument2 pagesTypical Wiring Diagram: Deep Sea ElectronicsBERANGER DAVESNE DJOMALIA SIEWENo ratings yet

- DSE2541 Installation Instructions PDFDocument2 pagesDSE2541 Installation Instructions PDFDEYNERNo ratings yet

- DSE2541 Installation Instructions PDFDocument2 pagesDSE2541 Installation Instructions PDFBERANGER DAVESNE DJOMALIA SIEWENo ratings yet

- EC410 / EC430 Operation Manual: Microprocessor Resistivity & Conductivity Monitor/ControllerDocument21 pagesEC410 / EC430 Operation Manual: Microprocessor Resistivity & Conductivity Monitor/ControllerAurangzaib ArshadNo ratings yet

- 16.voltmeter Calibration Punzalan - Tuliao.dumangasDocument87 pages16.voltmeter Calibration Punzalan - Tuliao.dumangasjomar lipaopaoNo ratings yet

- DataKom 040 USERDocument45 pagesDataKom 040 USERsebastianNo ratings yet

- DK-40 Compressor Controller User ManualDocument45 pagesDK-40 Compressor Controller User ManualVykintas ImbrasasNo ratings yet

- Tec40 User v2Document45 pagesTec40 User v2sebastian100% (1)

- Versatile Microcontroller Based Scanner ManualDocument16 pagesVersatile Microcontroller Based Scanner ManualkpbaijuNo ratings yet

- Masibus Digital Controller 5002uDocument20 pagesMasibus Digital Controller 5002uSOURISH100% (2)

- BM315 BM319 Automotive Multimeter: User'S ManualDocument16 pagesBM315 BM319 Automotive Multimeter: User'S ManualSanjay Singh RawatNo ratings yet

- Adtr 2K PLUS DS - 17Document4 pagesAdtr 2K PLUS DS - 17Jackson MokwatloNo ratings yet

- X-RAY SERVICE MANUALDocument54 pagesX-RAY SERVICE MANUALManuel LinaresNo ratings yet

- Manual n1050 v10x F EnglishDocument10 pagesManual n1050 v10x F EnglishmilosNo ratings yet

- Manson HCS-3202 Alimentatore 0 60V 0 5ADocument20 pagesManson HCS-3202 Alimentatore 0 60V 0 5Apaolo.defalcoNo ratings yet

- Encoder Tester ModuleDocument2 pagesEncoder Tester ModulealexNo ratings yet

- Masibus 85XXDocument50 pagesMasibus 85XXVenish Patel92% (12)

- Operational Manual For 85Xx: IndexDocument23 pagesOperational Manual For 85Xx: Indexmahesh100% (2)

- RCMA420 Datasheet NAE1042051Document6 pagesRCMA420 Datasheet NAE1042051jmmendesNo ratings yet

- Dec40 - User Service Rev5-0Document42 pagesDec40 - User Service Rev5-0Racob FherdzNo ratings yet

- 31 Radspeed Lab ManualDocument19 pages31 Radspeed Lab Manualkizen_5No ratings yet

- COUNTERDocument3 pagesCOUNTERkaran007_mNo ratings yet

- Hoistman'S Operator Panel Operations and Maintenance Manual: Benchmark P/N AMS4A043Document83 pagesHoistman'S Operator Panel Operations and Maintenance Manual: Benchmark P/N AMS4A043Cuenta InformacionNo ratings yet

- Temperature Controller ManualDocument12 pagesTemperature Controller ManualChrist Rodney MAKANANo ratings yet

- Instruments and MeteringDocument5 pagesInstruments and MeteringsallammohamedNo ratings yet

- FI 919X Notice AnglaisDocument24 pagesFI 919X Notice AnglaisRichard MERATNo ratings yet

- Panasonic TX-21at1p Chassis Z-8tDocument22 pagesPanasonic TX-21at1p Chassis Z-8taureliancoNo ratings yet

- Enda Ec442 Up/Down CounterDocument5 pagesEnda Ec442 Up/Down CounterMohamed ReyadNo ratings yet

- Capacitance Level Transmiter Instruction ManualDocument7 pagesCapacitance Level Transmiter Instruction ManualEmilNo ratings yet

- TV LG 21fu1rDocument16 pagesTV LG 21fu1rpurwants100% (1)

- DKM-250 DC Energy Analyzer: Description FeaturesDocument42 pagesDKM-250 DC Energy Analyzer: Description FeaturesAli almahdiNo ratings yet

- 1/4 Din Microbased Controller Operators Manual: FORM 3665 Edition 1 © OCT. 1995 PRICE $10.00Document71 pages1/4 Din Microbased Controller Operators Manual: FORM 3665 Edition 1 © OCT. 1995 PRICE $10.00kmpoulos100% (1)

- Operating and Programming Instructions For The Control Units For Vibratory Drives Type ESR 2000Document16 pagesOperating and Programming Instructions For The Control Units For Vibratory Drives Type ESR 2000Daniel Castro FloresNo ratings yet

- Ametek CSC200Document20 pagesAmetek CSC200Direccion TecnicaNo ratings yet

- Philips CED229Document25 pagesPhilips CED229Guilherme TeixeiraNo ratings yet

- K-BUS 4-Channel Binary Input User ManualDocument57 pagesK-BUS 4-Channel Binary Input User ManualMyth SwordNo ratings yet

- Operations and Maintenance Manual Ams4A048 Touch Screen Winch Operators PanelDocument60 pagesOperations and Maintenance Manual Ams4A048 Touch Screen Winch Operators PanelAyman MaezaNo ratings yet

- Color TV: Service ManualDocument23 pagesColor TV: Service ManualVictor Gonzales SanchezNo ratings yet

- 1verification 1735Document14 pages1verification 1735flavio torresNo ratings yet

- Harmon 4200A Selective Voltmeter Instruction Manual - April 1974Document68 pagesHarmon 4200A Selective Voltmeter Instruction Manual - April 1974Bob Laughlin, KWØRL100% (1)

- BasicLine Chasis 782-TS-2030 Con LA76931, SRA - MAGALYDocument37 pagesBasicLine Chasis 782-TS-2030 Con LA76931, SRA - MAGALYRafael Ernesto Torres MasabeNo ratings yet

- Denver Instrument Mod 215 CTL CalidadDocument23 pagesDenver Instrument Mod 215 CTL CalidadmiguelNo ratings yet

- TTM-P4W Instruction ManualDocument25 pagesTTM-P4W Instruction ManualpieterNo ratings yet

- Operation Manual: CMCP575-XXX-XXX Speed TransmitterDocument8 pagesOperation Manual: CMCP575-XXX-XXX Speed TransmitterYeral PobleteNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Proceedings of 2006 WSEAS Conference on Heat and Mass TransferDocument7 pagesProceedings of 2006 WSEAS Conference on Heat and Mass TransferAnonymous knICaxNo ratings yet

- Study On Intel 80386 MicroprocessorDocument3 pagesStudy On Intel 80386 MicroprocessorInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Plant Water Booster PumpDocument4 pagesPlant Water Booster PumpBanupriya BalasubramanianNo ratings yet

- EVCC Product Specifications-2.1.2Document11 pagesEVCC Product Specifications-2.1.2Windya SaputraNo ratings yet

- Marking Scheme Bio Paper 3 07Document16 pagesMarking Scheme Bio Paper 3 07genga100% (1)

- Tests On Educational Interest and Its ImpactDocument2 pagesTests On Educational Interest and Its ImpactSusan BenedictNo ratings yet

- Python Module 7 AFV Core-Data-StructureDocument48 pagesPython Module 7 AFV Core-Data-StructureLeonardo FernandesNo ratings yet

- Partial Molar PropertiesDocument6 pagesPartial Molar PropertiesNISHTHA PANDEYNo ratings yet

- Nucor at A Crossroads: Group-2, Section - BDocument8 pagesNucor at A Crossroads: Group-2, Section - BHimanshiNo ratings yet

- IPv4 - IPv4 Header - IPv4 Header Format - Gate VidyalayDocument15 pagesIPv4 - IPv4 Header - IPv4 Header Format - Gate VidyalaySakshi TapaseNo ratings yet

- Isoefficiency Function A Scalability Metric For PaDocument20 pagesIsoefficiency Function A Scalability Metric For PaDasha PoluninaNo ratings yet

- HAM Processing Technique for Ocular Surface ReconstructionDocument4 pagesHAM Processing Technique for Ocular Surface ReconstructionJoel JohnsonNo ratings yet

- Project management software and techniquesDocument2 pagesProject management software and techniquesbinduannNo ratings yet

- Dual Band DAB Pocket Radio: User Manual Manuel D'utilisation Manual Del Usuario Benutzerhandbuch GebruikershandleidingDocument21 pagesDual Band DAB Pocket Radio: User Manual Manuel D'utilisation Manual Del Usuario Benutzerhandbuch Gebruikershandleidingminerva_manNo ratings yet

- The Definition of WorkDocument2 pagesThe Definition of WorkCarlton GrantNo ratings yet

- SMPP Gateway Interface Programming GuideDocument21 pagesSMPP Gateway Interface Programming GuideVamsi Krishna TalasilaNo ratings yet

- Safety Budget PlannerDocument12 pagesSafety Budget Plannersidhant nayakNo ratings yet

- Incremental Analysis Decision MakingDocument4 pagesIncremental Analysis Decision MakingMa Teresa B. CerezoNo ratings yet

- SDS SikarugasolDocument9 pagesSDS SikarugasolIis InayahNo ratings yet

- Firm vs. Environment: May Florence J. Yaranon Edric P. Oloresisimo Mba-IDocument28 pagesFirm vs. Environment: May Florence J. Yaranon Edric P. Oloresisimo Mba-IMay YaranonNo ratings yet

- CUMINDocument17 pagesCUMIN19BFT Food TechnologyNo ratings yet

- Y12 - Hand - Book - 2019 2Document22 pagesY12 - Hand - Book - 2019 2tiagoNo ratings yet

- Insulation Coordination in Power System - Electrical4UDocument13 pagesInsulation Coordination in Power System - Electrical4UR.SivachandranNo ratings yet

- 5 Ear Disorders of DogsDocument14 pages5 Ear Disorders of DogsKoleen Lopez ÜNo ratings yet

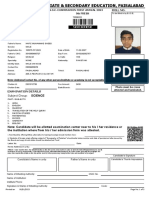

- Roll No. Form No.: Private Admission Form S.S.C. Examination First Annual 2023 9th FRESHDocument3 pagesRoll No. Form No.: Private Admission Form S.S.C. Examination First Annual 2023 9th FRESHBeenish MirzaNo ratings yet

- Legal Disclaimer - Learn About Our Limited Liability and Legal DisclaimerDocument2 pagesLegal Disclaimer - Learn About Our Limited Liability and Legal DisclaimermagamuthaNo ratings yet

- PSC Marpol InspectionDocument1 pagePSC Marpol InspectionΑΝΝΑ ΒΛΑΣΣΟΠΟΥΛΟΥNo ratings yet

- Lighthouse Institute Mathematics Cala D 2023Document4 pagesLighthouse Institute Mathematics Cala D 2023Kudakwashe RushwayaNo ratings yet

- NI Kontakt Vintage Organs Manual EnglishDocument31 pagesNI Kontakt Vintage Organs Manual Englishrocciye100% (1)

- Understanding and Applying The ANSI/ ISA 18.2 Alarm Management StandardDocument260 pagesUnderstanding and Applying The ANSI/ ISA 18.2 Alarm Management StandardHeri Fadli SinagaNo ratings yet