Professional Documents

Culture Documents

Approval of Piping Systems: © Westone Services 2013 Eng2068 7

Uploaded by

Mohamed amine El mtalakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Approval of Piping Systems: © Westone Services 2013 Eng2068 7

Uploaded by

Mohamed amine El mtalakCopyright:

Available Formats

Approval of piping systems

There must be a high degree of quality control when high-pressure pipe systems are

being fabricated to ensure that they meet the specifications of the relevant codes.

The inspecting authority may be the machinery inspection branch of the state

or territory government, the insurance company underwriting the job or the

representatives of the client for whom the pipework is being fabricated.

The quality control program includes the following steps.

1. Approval of the design of the pipe system.

2. Approval of the fabricator who may have to prove that there is adequate equipment

and expert personnel to successfully meet the requirements of the relevant

code(s).

3. Frequent checks to ensure that the specified material is being used.

4. Approval of welding procedures and regular inspections to ensure that these

procedures are being followed.

5. Qualification of welders who are tested to ensure that they are capable of carrying

out the approved procedures successfully.

6. Non-destructive testing as required by the code(s).

7. Post-weld heat treatment as required by the code(s).

8. Final hydrostatic testing or alternative testing method.

Fabricators are responsible for the quality of the work they perform and for the

coordination of all inspection and testing procedures as required by the relevant

code(s).

© WestOne Services 2013 ENG2068 7

You might also like

- Method Statement of Fire Alarm SystemDocument10 pagesMethod Statement of Fire Alarm Systemmidhun murali100% (6)

- Qualification of Equipment - A Risk-Based ApproachDocument6 pagesQualification of Equipment - A Risk-Based ApproachJorge Humberto Herrera100% (9)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Method of Statement NDTDocument11 pagesMethod of Statement NDTAhmed Iraky0% (1)

- Performance Qualification Protocol and Report For AutoclaveDocument19 pagesPerformance Qualification Protocol and Report For AutoclaveMubarak PatelNo ratings yet

- Qa-Qc Check ListDocument8 pagesQa-Qc Check ListShankarEllampriam100% (3)

- Integrity ManagementDocument8 pagesIntegrity Managementgurdeepsarora8738No ratings yet

- Purchasing and Commissioning of AutoclaveDocument28 pagesPurchasing and Commissioning of Autoclavenorhafizahstoh89100% (2)

- Validation and Calibration of Master PlanDocument12 pagesValidation and Calibration of Master PlanHk Hk100% (5)

- Incoming Material ProcedureDocument2 pagesIncoming Material ProcedureTridib Dey100% (6)

- b9 IwDocument11 pagesb9 IwlakshmipathictiNo ratings yet

- Switch GearDocument7 pagesSwitch GearpanduranganraghuramaNo ratings yet

- Asset Integrity: 2.1 Project Quality ManagementDocument21 pagesAsset Integrity: 2.1 Project Quality Managementshahbaz akram100% (1)

- Technical Specification 1Document2 pagesTechnical Specification 1Buliga Marian100% (1)

- CSWIP QCC 20 08 Requirements For The Certification of A Welding Quality Control Co Ordinator 3rd Edition January 2021Document7 pagesCSWIP QCC 20 08 Requirements For The Certification of A Welding Quality Control Co Ordinator 3rd Edition January 2021Ho-Rim JUNo ratings yet

- Qa QC ProgrammeDocument6 pagesQa QC ProgrammesrisetNo ratings yet

- NR216 Chap01Document16 pagesNR216 Chap01Phu NguyenNo ratings yet

- 17 QC Procedure (QA SOP)Document9 pages17 QC Procedure (QA SOP)QAD LotusNo ratings yet

- Welding of High Pressure Vessels and Pipelines Procedure RoadmapDocument3 pagesWelding of High Pressure Vessels and Pipelines Procedure RoadmapCraigHunterNo ratings yet

- Maintenance Inspections: GAP.1.3.0.ADocument2 pagesMaintenance Inspections: GAP.1.3.0.ANovancyNo ratings yet

- Inspection and Acceptance Precast and Prestressed Concrete Bridge UnitsDocument14 pagesInspection and Acceptance Precast and Prestressed Concrete Bridge UnitsKaan TekinturhanNo ratings yet

- WI Quality AssuranceDocument3 pagesWI Quality Assurancearifin rizalNo ratings yet

- Quality Assurance and Quality ControlDocument4 pagesQuality Assurance and Quality ControlRuli DarmawanNo ratings yet

- Quality Assurance Quality ControlDocument23 pagesQuality Assurance Quality ControlIrsyad RosyidiNo ratings yet

- Annex 8 QUALITY ASSURANCE & TESTS - AddendumDocument9 pagesAnnex 8 QUALITY ASSURANCE & TESTS - Addendumguven dalgaNo ratings yet

- 514 - Painting of Structural Steel (2012) PDFDocument21 pages514 - Painting of Structural Steel (2012) PDFDanilo de JurasNo ratings yet

- Quality Control Manual: Function and ObjectiveDocument6 pagesQuality Control Manual: Function and ObjectivechandraNo ratings yet

- Quality Control System in The Fabrication of Heat ExchangersDocument5 pagesQuality Control System in The Fabrication of Heat ExchangersCorine CaracasNo ratings yet

- Visual Weld InspectionDocument7 pagesVisual Weld InspectioninsiderrNo ratings yet

- Fabrication Quality Control 2-20-08Document4 pagesFabrication Quality Control 2-20-08Vinoth KumarNo ratings yet

- Scope of Work (Sow)Document10 pagesScope of Work (Sow)Asongwe HansNo ratings yet

- MIL-STD-45662 10 June 1980 Superseding MIL-c-45662A 9 February 1962Document12 pagesMIL-STD-45662 10 June 1980 Superseding MIL-c-45662A 9 February 1962standardliegeNo ratings yet

- Method Statement For Handling, Storage, Installation, Testing and Commissioning For Clean Agent SystemDocument20 pagesMethod Statement For Handling, Storage, Installation, Testing and Commissioning For Clean Agent Systemvin ssNo ratings yet

- FAT Procedure GresikDocument56 pagesFAT Procedure GresikAriz Joelee Artha100% (1)

- No. 17 Guidelines For The Acceptance of Manufacturer's Quality Assurance Systems For Welding Consumables No. 17Document9 pagesNo. 17 Guidelines For The Acceptance of Manufacturer's Quality Assurance Systems For Welding Consumables No. 17French Sarah NeraNo ratings yet

- 2023 SD QC Outsource Support RequisitionDocument6 pages2023 SD QC Outsource Support RequisitionKit AnnoncerNo ratings yet

- TestingDocument28 pagesTestingsbpathiNo ratings yet

- Procedure For ProductionDocument7 pagesProcedure For ProductionTuan Anh100% (1)

- Cpi Quality ProceduresDocument18 pagesCpi Quality ProceduresAdrian RogersNo ratings yet

- All About TPI InspectionDocument31 pagesAll About TPI InspectionAneesh JoseNo ratings yet

- QUALITY CONTROL PROCEDURE FOR INSTALLATION & TESTING OF FIRE FIGHTING PIPING SYSTEM AND ACCESSORIES - The Engineer's BlogDocument12 pagesQUALITY CONTROL PROCEDURE FOR INSTALLATION & TESTING OF FIRE FIGHTING PIPING SYSTEM AND ACCESSORIES - The Engineer's BlogNESTOR YUMULNo ratings yet

- Work Method StatementDocument7 pagesWork Method StatementBOUZAIDANo ratings yet

- NRC Inspection ManualDocument5 pagesNRC Inspection Manualelsayed abdemagiedNo ratings yet

- Construction Specification 494-Contractor Quality Control: 1. ScopeDocument3 pagesConstruction Specification 494-Contractor Quality Control: 1. Scopedarlene zaraNo ratings yet

- Api 510 Exam 2021Document14 pagesApi 510 Exam 2021eng_far100% (2)

- Automotive Auditor TrainingDocument46 pagesAutomotive Auditor TrainingJoherNo ratings yet

- What Is InspectionDocument6 pagesWhat Is InspectionRathnakrajaNo ratings yet

- Procedure For QADocument7 pagesProcedure For QASharif Khan100% (1)

- O&M Commission & Testing GuidelinesDocument2 pagesO&M Commission & Testing GuidelinesRami Mikati100% (1)

- Sample Procedure For Method Validation 1.: Document Control: SAP - Approved 20161221 Page 1 of 7Document7 pagesSample Procedure For Method Validation 1.: Document Control: SAP - Approved 20161221 Page 1 of 7YAMA ENGINEERSNo ratings yet

- Chapter 8 Quality ProcedureDocument6 pagesChapter 8 Quality Procedureมิตร อันมาNo ratings yet

- Welding Inspector Job and ResponsilbilitiesDocument5 pagesWelding Inspector Job and ResponsilbilitiesFelix GomintongNo ratings yet

- 10.400.412 General Inspection ProcedureDocument12 pages10.400.412 General Inspection ProcedureedwinsazzzNo ratings yet

- 1051 PDFDocument16 pages1051 PDFhazopmanNo ratings yet

- At SKTSZZ QA PRO 0008 000 C01 Quality Control InspectionDocument14 pagesAt SKTSZZ QA PRO 0008 000 C01 Quality Control InspectionAdil HasanovNo ratings yet

- Senior Welding Inspector Signing Off Handout Appendix 1 PDFDocument3 pagesSenior Welding Inspector Signing Off Handout Appendix 1 PDFkatfy1No ratings yet

- FMRC 1046 Fire Pump Flowmeter Systems PDFDocument18 pagesFMRC 1046 Fire Pump Flowmeter Systems PDFdyıldırım_4No ratings yet

- bd16080 FIELDTESTDocument23 pagesbd16080 FIELDTESTBrando Neil SarciaNo ratings yet

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AFrom EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANo ratings yet

- Total Quality Process Control for Injection MoldingFrom EverandTotal Quality Process Control for Injection MoldingRating: 5 out of 5 stars5/5 (1)

- Socket-Welding Flanges: Fig 2.25: A Slip-On FlangeDocument1 pageSocket-Welding Flanges: Fig 2.25: A Slip-On FlangeMohamed amine El mtalakNo ratings yet

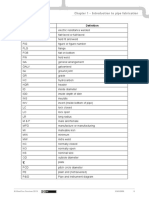

- Chapter 1 - Introduction To Pipe Fabrication 5: 3 © Westone Services 2013Document1 pageChapter 1 - Introduction To Pipe Fabrication 5: 3 © Westone Services 2013Mohamed amine El mtalakNo ratings yet

- Piping Schedule: Fig 4.5: Double-Line Orthographic View With DimensionsDocument1 pagePiping Schedule: Fig 4.5: Double-Line Orthographic View With DimensionsMohamed amine El mtalakNo ratings yet

- Pressure - Stress Conversion Chart: 100 Lbf/In2 689 Kpa 100kpa 14.50 Lbf/In2Document1 pagePressure - Stress Conversion Chart: 100 Lbf/In2 689 Kpa 100kpa 14.50 Lbf/In2Mohamed amine El mtalakNo ratings yet

- 4 Eng2068 © Westone Services 2013Document1 page4 Eng2068 © Westone Services 2013Mohamed amine El mtalakNo ratings yet

- Reducing Elbows: Return BendsDocument1 pageReducing Elbows: Return BendsMohamed amine El mtalakNo ratings yet

- Light/Extra Light Pipe To Australian Standards: Specification GalvanizingDocument1 pageLight/Extra Light Pipe To Australian Standards: Specification GalvanizingMohamed amine El mtalakNo ratings yet

- Abbreviation: © Westone Services 2013 Eng2068 9Document1 pageAbbreviation: © Westone Services 2013 Eng2068 9Mohamed amine El mtalakNo ratings yet

- Chapter 1 - Introduction To Pipe FabricationDocument1 pageChapter 1 - Introduction To Pipe FabricationMohamed amine El mtalakNo ratings yet

- Creative Commons Attribution 4.0 (CC BY 4.0) LicenseDocument1 pageCreative Commons Attribution 4.0 (CC BY 4.0) LicenseMohamed amine El mtalakNo ratings yet