Professional Documents

Culture Documents

Chapter 1 - Introduction To Pipe Fabrication

Uploaded by

Mohamed amine El mtalak0 ratings0% found this document useful (0 votes)

13 views1 pageOriginal Title

Untitled

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views1 pageChapter 1 - Introduction To Pipe Fabrication

Uploaded by

Mohamed amine El mtalakCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

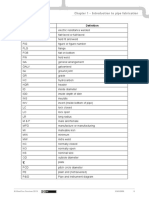

Chapter 1 – Introduction to pipe

fabrication

About pipe fabrication

Pipelines are used to transport fluids, including vapours, gases, slurries and powders

which flow through pipes at various pressures and temperatures. The transmission of

these materials invariably subjects the pipe to intense stresses and strains and this

demands the highest possible performance from the pipe.

All pipework must be designed and fabricated in a way that ensures the safety of plant

operators, the plant, the public and the environment.

The fabricator is responsible for the quality of the pipework and pipe fabrication must

be carried out in accordance with all relevant standards and specifications. One faulty

weld could lead to damage costing millions of dollars, personal injury and in serious

cases even death. Welded pipe systems demand the highest degree of excellence in

materials and quality of work.

Because high standards are required, the cost of pipework is extremely high. Typical

costs for pipework in a manufacturing plant are shown in Table 1.1.

Field labour costs 47%

Material costs 23%

Design engineering costs 20%

Table 1.1: Fabrication costs

It is essential that pipework is fabricated by suitably trained and competent

tradespersons.

© WestOne Services 2013 ENG2068 5

You might also like

- 1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerFrom Everand1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Method Statement For Plumbing Piping Works Rev.01Document46 pagesMethod Statement For Plumbing Piping Works Rev.01zenoses76% (37)

- Method Statement For Plumbing Piping Works Rev 01 PDFDocument46 pagesMethod Statement For Plumbing Piping Works Rev 01 PDFjaianit8980% (5)

- Introduction To Piping Engineering PDFDocument6 pagesIntroduction To Piping Engineering PDFKavin KumarNo ratings yet

- Piping Study Material - RoltaDocument49 pagesPiping Study Material - Roltahummingbird4u92% (12)

- Transformer Database ReserchDocument8 pagesTransformer Database ReserchJignesh100% (1)

- Method Statement For PVC Conduits InstallationDocument9 pagesMethod Statement For PVC Conduits InstallationAnandu AshokanNo ratings yet

- MS009 Water Treatment PlantDocument11 pagesMS009 Water Treatment PlantMhando Ignas100% (1)

- 15 10 13 Tn17 ElectrofusionDocument12 pages15 10 13 Tn17 ElectrofusionErlinawati Bintu SupiyoNo ratings yet

- Piping Method StatmentDocument54 pagesPiping Method StatmentAyman Elsayed ElMehy50% (2)

- A Virtual Engineering Methodology To Prevent Erosion-Related Accidents in The Petroleum IndustryDocument5 pagesA Virtual Engineering Methodology To Prevent Erosion-Related Accidents in The Petroleum IndustryMD. MOHIUDDIN IfteharNo ratings yet

- Scope of Work For Prefab ContractorDocument4 pagesScope of Work For Prefab ContractorgodennyNo ratings yet

- Book - Vol.3O - OrbitalWelding - 22junDocument50 pagesBook - Vol.3O - OrbitalWelding - 22junlth770310No ratings yet

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- UntitledDocument289 pagesUntitledarjunprasannan7No ratings yet

- Piping Book2Document204 pagesPiping Book2sufiyanahmed1611No ratings yet

- Automated Tie-In - New Tie-In Technology For Pipeline ConstructionDocument20 pagesAutomated Tie-In - New Tie-In Technology For Pipeline Constructionأنس القرقنيNo ratings yet

- Part BDocument164 pagesPart BsanjaykmrNo ratings yet

- LEGAL NOTICE NO. . The Engineers Act, 2011Document41 pagesLEGAL NOTICE NO. . The Engineers Act, 2011Emily MuthigaNo ratings yet

- Alkazri - 2008 - A Quick Guide To Pipeline Engineering - 4 Pipeline Decommissioning and Industry DevelopmentsDocument9 pagesAlkazri - 2008 - A Quick Guide To Pipeline Engineering - 4 Pipeline Decommissioning and Industry DevelopmentsRUSSEL SAHDA MALAKANo ratings yet

- Nalanda Residential Specifications Part II Services 2018Document280 pagesNalanda Residential Specifications Part II Services 2018paldesigndeepNo ratings yet

- Nalanda Non Residential Specifications Part II ServicesDocument325 pagesNalanda Non Residential Specifications Part II ServicesJothimanikkam SomasundaramNo ratings yet

- P3ductal Catalogue PDFDocument136 pagesP3ductal Catalogue PDFriteish singhNo ratings yet

- Tie in OperationDocument20 pagesTie in OperationChijioke ObiNo ratings yet

- U & I Technologies Sdn. BHDDocument10 pagesU & I Technologies Sdn. BHDNrsyfqah SuleimanNo ratings yet

- ENVIDocument3 pagesENVISydney Jaydean KhanyileNo ratings yet

- S F A M T B T S P T F Ethiopian Electric Utility (Eeu)Document12 pagesS F A M T B T S P T F Ethiopian Electric Utility (Eeu)Ahmed AbdellaNo ratings yet

- Utility EngineeringDocument12 pagesUtility Engineeringkamran khalidNo ratings yet

- Annexure - D Potential Environmental Impacts and Mitigation MeasuresDocument4 pagesAnnexure - D Potential Environmental Impacts and Mitigation MeasuresM ShahidNo ratings yet

- Scope of Work For Prefab ContractorDocument4 pagesScope of Work For Prefab ContractorgodennyNo ratings yet

- RTi-Broschuere EN 20191010-WEBDocument24 pagesRTi-Broschuere EN 20191010-WEBFlorentin DumitruNo ratings yet

- Key Take Aways Fugitive Emission Testing - UNDocument9 pagesKey Take Aways Fugitive Emission Testing - UNsandeshNo ratings yet

- Riopipeline2019 1135 Riopipeline2019 t1135 JST Av1Document8 pagesRiopipeline2019 1135 Riopipeline2019 t1135 JST Av1Marcelo Varejão CasarinNo ratings yet

- Double Wall Corrugated Pipes (DWC) HDPE PipesDocument15 pagesDouble Wall Corrugated Pipes (DWC) HDPE Pipesdesign teamNo ratings yet

- Sub Con AgreementDocument11 pagesSub Con Agreement'Zhi En WongNo ratings yet

- EBOM - EQc1 5 ConstructionIAQ Management Plan TemplateDocument4 pagesEBOM - EQc1 5 ConstructionIAQ Management Plan TemplatewhoenenNo ratings yet

- 7T04-CS-00-TS-018 R01 Project Specificationfor Cleaning Reequirements For Piping SystemsDocument9 pages7T04-CS-00-TS-018 R01 Project Specificationfor Cleaning Reequirements For Piping Systemsel_sharkawy2011100% (1)

- Electrical Solutions For The Oil and Gas IndustryDocument32 pagesElectrical Solutions For The Oil and Gas IndustrycubarturNo ratings yet

- A Review On Trenchless Technology: State of Art Technology For Underground Utility ServicesDocument15 pagesA Review On Trenchless Technology: State of Art Technology For Underground Utility ServicesKartik oNo ratings yet

- Scope of Work For Prefab ContractorDocument4 pagesScope of Work For Prefab ContractorgodennyNo ratings yet

- 1.WR232 - Building ServicesDocument50 pages1.WR232 - Building ServicesGaboNo ratings yet

- MS-PW InstallationDocument21 pagesMS-PW Installationvengat.jdwatersNo ratings yet

- ASME L&D B31.8 Natural Gas Pipelines GuideDocument12 pagesASME L&D B31.8 Natural Gas Pipelines GuideCalin NeagoieNo ratings yet

- BC3-2013 - Cal Sample Calculations For SeismicDocument11 pagesBC3-2013 - Cal Sample Calculations For SeismicLau Kim HwaNo ratings yet

- Piping Engineering DetailsDocument5 pagesPiping Engineering DetailsAadish vikramNo ratings yet

- Installation of GI Duct, Volume Dampers and Access DoorDocument20 pagesInstallation of GI Duct, Volume Dampers and Access DoorvinodkumarNo ratings yet

- Standard and Specs RE & Gen Final-Electrical PDFDocument31 pagesStandard and Specs RE & Gen Final-Electrical PDFAlok Kumar GuptaNo ratings yet

- Role of Piping EngineerDocument1 pageRole of Piping EngineerLinhNguyenVietNo ratings yet

- DesighDocument118 pagesDesighbhagathnagarNo ratings yet

- DWC HDPE Technical SpecDocument12 pagesDWC HDPE Technical SpecMoloy GoswamiNo ratings yet

- Assignment 3Document3 pagesAssignment 3gracie koiNo ratings yet

- Scope of Work For Prefab ContractorDocument4 pagesScope of Work For Prefab ContractorgodennyNo ratings yet

- Socket-Welding Flanges: Fig 2.25: A Slip-On FlangeDocument1 pageSocket-Welding Flanges: Fig 2.25: A Slip-On FlangeMohamed amine El mtalakNo ratings yet

- Chapter 1 - Introduction To Pipe Fabrication 5: 3 © Westone Services 2013Document1 pageChapter 1 - Introduction To Pipe Fabrication 5: 3 © Westone Services 2013Mohamed amine El mtalakNo ratings yet

- Piping Schedule: Fig 4.5: Double-Line Orthographic View With DimensionsDocument1 pagePiping Schedule: Fig 4.5: Double-Line Orthographic View With DimensionsMohamed amine El mtalakNo ratings yet

- Pressure - Stress Conversion Chart: 100 Lbf/In2 689 Kpa 100kpa 14.50 Lbf/In2Document1 pagePressure - Stress Conversion Chart: 100 Lbf/In2 689 Kpa 100kpa 14.50 Lbf/In2Mohamed amine El mtalakNo ratings yet

- 4 Eng2068 © Westone Services 2013Document1 page4 Eng2068 © Westone Services 2013Mohamed amine El mtalakNo ratings yet

- Reducing Elbows: Return BendsDocument1 pageReducing Elbows: Return BendsMohamed amine El mtalakNo ratings yet

- Light/Extra Light Pipe To Australian Standards: Specification GalvanizingDocument1 pageLight/Extra Light Pipe To Australian Standards: Specification GalvanizingMohamed amine El mtalakNo ratings yet

- Abbreviation: © Westone Services 2013 Eng2068 9Document1 pageAbbreviation: © Westone Services 2013 Eng2068 9Mohamed amine El mtalakNo ratings yet

- Approval of Piping Systems: © Westone Services 2013 Eng2068 7Document1 pageApproval of Piping Systems: © Westone Services 2013 Eng2068 7Mohamed amine El mtalakNo ratings yet

- Creative Commons Attribution 4.0 (CC BY 4.0) LicenseDocument1 pageCreative Commons Attribution 4.0 (CC BY 4.0) LicenseMohamed amine El mtalakNo ratings yet