Professional Documents

Culture Documents

Light/Extra Light Pipe To Australian Standards: Specification Galvanizing

Uploaded by

Mohamed amine El mtalakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Light/Extra Light Pipe To Australian Standards: Specification Galvanizing

Uploaded by

Mohamed amine El mtalakCopyright:

Available Formats

8 8

liGHT/eXTra liGHT PiPe TO aUsTraliaN sTaNDarDs

sPeCiFiCaTiON GalVaNiZiNG

Grade C350 pipe is a lightweight, Grade C350 pipe is manufactured and tested Grade C350 pipe is manufactured and tested to

high strength pipe for general to meet the requirement of the following meet the requirement of AS 4792 Galvanized

mechanical and structural specifications: Coatings.

applications.

• AS 1163 Structural Steel Hollow Sections Min. Ave Coating Mass 300g/m2

C350 is manufactured by cold- (Grade C350, C350L0). The coating adherence of the galvanizing is

forming and high frequency

• AS/NZ 4792 Hot dip galvanized (zinc) coatings satisfactory for the pipe to be bent to a radius 6

electric resistance welding.

on ferrous hollow sections by a continuous or a times the diameter of the pipe.

C350 is available in black, ILG and specialised process.

galvanized finishes.

Also available with one or both meCHaNiCal PrOPerTies WelDiNG

ends swaged as follows: Minimum Yield Strength 350MPa The following consumables are recommended by

AS 1554.1 when welding C350 sections.

Minimum Tensile Strength 450MPa

Minimum Elongation in 5.65 √So 20% Manual metal-arc (MMAW) E41XX, E48XX

NB Xl l

Gas metal-arc (MIG) (GMAW) W50X

20 a X sUPPlY CONDiTiONs

25 a a Surface Finish Black/ILG/Galvanized

32 a a Straightness Refer to

Thickness Tolerance Australian

40 a a Standards

Dimension Tolerance

50 a X

Standard Length 6.5m

Length Tolerance +50mm/-0mm

mass and Bundling Data - Calculated in accordance with as 1163

Dimensions Bundling mass

Bundle Nominal mass mass per Bundle

Designation Nominal lengths metres

Dimenions

do t size DN Per Bundle Per Bundle kg/m m/tonne tonnes

mm

(mm) (mm) (mm) WxH 6.5m m Black Galv. Black Galv. Black Galv.

26.9 x 2.0 CHS 20 XL 350 306 127 825.5 1.23 1.29 814 767 1.010 1.070

2.3 CHS 20 LT 350 306 127 825.5 1.40 1.46 717 680 1.150 1.200

33.7 x 2.0 CHS 25 XL 372 327 91 591.5 1.56 1.64 640 602 0.920 0.970

2.6 CHS 25 LT 372 327 91 591.5 1.99 2.07 501 497 1.180 1.230

42.4 x 2.0 CHS 32 XL 383 337 61 396.5 1.99 2.10 502 473 0.790 0.830

2.6 CHS 32 LT 383 337 61 396.5 2.55 2.65 392 374 1.010 1.050

48.3 x 2.3 CHS 40 XL 436 384 61 396.5 2.61 2.73 383 364 1.030 1.080

2.9 CHS 40 LT 436 384 61 396.5 3.25 3.36 308 295 1.290 1.330

60.3 x 2.3 CHS 50 XL 422 374 37 240.5 3.29 3.44 304 288 0.790 0.830

2.9 CHS 50 LT 422 374 37 240.5 4.11 4.25 244 234 0.990 1.020

76.1 x 2.3 CHS 65 XL 533 472 37 240.5 4.19 4.33 239 231 1.007 1.040

3.2 CHS 65 LT 533 472 37 240.5 5.75 5.94 174 167 1.380 1.430

88.9 x 2.6 CHS 80 XL 445 397 19 123.5 5.53 5.75 181 174 0.683 0.710

3.2 CHS 80 LT 445 397 19 123.5 6.76 6.98 148 143 0.840 0.860

101.6 x 2.6 CHS 90 XL 508 454 19 123.5 6.35 6.60 158 152 0.784 0.815

3.2 CHS 90 LT 508 454 19 123.5 7.70 8.04 129 124 0.960 0.990

114.3 x 3.2 CHS 100 XL 572 510 19 123.5 8.77 9.05 114 110 1.083 1.118

3.6 CHS 100 LT 572 510 19 123.5 9.83 10.11 102 98.6 1.214 1.249

139.7 x 3.0 CHS 125 XL 698 382 13 84.5 10.11 10.50 98.9 95.2 0.855 0.887

3.5 CHS 125 LT 698 382 13 84.5 11.76 12.10 85.1 82.4 0.993 1.022

165.1 x 3.5 CHS

150 LT 660 451 10 65 13.95 14.40 71.7 69.4 0.907 0.936

150 LT

NOTes:

LT = Light, XL = Extra Light

The term “tube” is synonymous with the term “pipe”.

MRC Data Chart reproduced with the permission of MRC Global Australia.

144 ENG2068 © WestOne Services 2013

You might also like

- Selectrode: 317L Flux Coated TigDocument3 pagesSelectrode: 317L Flux Coated TigUta GilangNo ratings yet

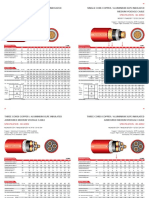

- TDS_Al_XLPE_SWA_PVC-_NA2XRYDocument3 pagesTDS_Al_XLPE_SWA_PVC-_NA2XRYvsumedhaNo ratings yet

- SWA Cable - BS6724 PDFDocument6 pagesSWA Cable - BS6724 PDFQC ĐNNo ratings yet

- Control and Signal CableDocument3 pagesControl and Signal CableLuis Carlos ValdezNo ratings yet

- CRGO Strips India, CRGO Transformer Laminations, CRGO Core IndiaDocument4 pagesCRGO Strips India, CRGO Transformer Laminations, CRGO Core IndiarajfabNo ratings yet

- (1C X 95mm) N2XSYDocument3 pages(1C X 95mm) N2XSYRahmawan fiberhomeNo ratings yet

- B 910 - B 910M - 02 Qjkxmc9cotewts1sruqDocument5 pagesB 910 - B 910M - 02 Qjkxmc9cotewts1sruqJuan Sebastián Londoño MartínezNo ratings yet

- S&T - Design 2013 - 2 PDFDocument40 pagesS&T - Design 2013 - 2 PDFSalmanNo ratings yet

- Hobart MAXAL 4943 WireDocument2 pagesHobart MAXAL 4943 WirebrunizzaNo ratings yet

- Core 1 1 KV Aluminium Copper PVC Insulated Armoured Power CaDocument2 pagesCore 1 1 KV Aluminium Copper PVC Insulated Armoured Power Carnd.ptcwiNo ratings yet

- Selectrode: High Deposition 316L Stainless Steel International ClassificationsDocument2 pagesSelectrode: High Deposition 316L Stainless Steel International ClassificationsMohamed AdelNo ratings yet

- MV Cable Current Carrying Capacity NA2XSEYBY SucacoDocument1 pageMV Cable Current Carrying Capacity NA2XSEYBY SucacoharisNo ratings yet

- Weight ListDocument1 pageWeight ListKishor KadamNo ratings yet

- Cu/XLPE cable specifications for 3.6/6 kV, 6/10 kV and 8.7/15 kV voltagesDocument3 pagesCu/XLPE cable specifications for 3.6/6 kV, 6/10 kV and 8.7/15 kV voltagesRahmawan fiberhomeNo ratings yet

- 11kv LSZH CableDocument3 pages11kv LSZH CableMadushan Eranga KumaraNo ratings yet

- (3.6/6 KV 18/30 KV) Cu/XLPE/CTS/SWA/PVC (N2XSEYRY) : SNI IEC 60502-2 / IEC 60502-2Document3 pages(3.6/6 KV 18/30 KV) Cu/XLPE/CTS/SWA/PVC (N2XSEYRY) : SNI IEC 60502-2 / IEC 60502-2ErwinNo ratings yet

- Tubing PDFDocument20 pagesTubing PDFTheEdgeNo ratings yet

- N2XSRYDocument1 pageN2XSRYYulian Dea ZollaNo ratings yet

- N2XSRYDocument1 pageN2XSRYKrisnandha RahardianNo ratings yet

- Prestressed Concrete Analysis and Design Fundamentals 2nd Ed CAP 2 PDFDocument54 pagesPrestressed Concrete Analysis and Design Fundamentals 2nd Ed CAP 2 PDFCarlos Alberto Pacheco SierraNo ratings yet

- NA2XSEFGbY PDFDocument5 pagesNA2XSEFGbY PDFRizki IrawanNo ratings yet

- Data Sheet Southwire 3c#500kcmilDocument2 pagesData Sheet Southwire 3c#500kcmilNestor-leoNo ratings yet

- Pipes and TubesDocument16 pagesPipes and TubesDaniel Sandoval FernándezNo ratings yet

- 20190114115131cu XLPE CTS SFA PVC (N2XSEYFGbY)Document3 pages20190114115131cu XLPE CTS SFA PVC (N2XSEYFGbY)Yayan ApriyantoNo ratings yet

- TR-XLPE Power CableDocument2 pagesTR-XLPE Power CableRodni EmslieNo ratings yet

- SPEC83013 600 Volt UndergroundDocument3 pagesSPEC83013 600 Volt Undergroundakib javedNo ratings yet

- Prysmian - BS5467 PDFDocument5 pagesPrysmian - BS5467 PDFReginald D. De GuzmanNo ratings yet

- Subm Motor Accessories Catalog enDocument13 pagesSubm Motor Accessories Catalog enmijael104No ratings yet

- EPR Insulated AC Medium-Voltage Submarine CableDocument3 pagesEPR Insulated AC Medium-Voltage Submarine CableGcNo ratings yet

- NYFGbY cable specificationsDocument4 pagesNYFGbY cable specificationsSaung KuringNo ratings yet

- Firetuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionDocument25 pagesFiretuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionBhagoo HatheyNo ratings yet

- Firetuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionDocument2 pagesFiretuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionAngga SenjayaNo ratings yet

- Flexible Flatform Cables: For Cranes, Hoists and Process MachinesDocument4 pagesFlexible Flatform Cables: For Cranes, Hoists and Process MachinesCristhian TaipeNo ratings yet

- LIMCOM SPLICE 1 - Bracing3 OKDocument3 pagesLIMCOM SPLICE 1 - Bracing3 OKmascalzoneNo ratings yet

- Fencing Tech SpecDocument8 pagesFencing Tech SpecMaina MathengeNo ratings yet

- Ts-Po16392-2cx10mm, 3CX6MM, 3CX10MM, 4CX6MM, 4CX16MMDocument2 pagesTs-Po16392-2cx10mm, 3CX6MM, 3CX10MM, 4CX6MM, 4CX16MMmohd darusNo ratings yet

- Calculo Cables Coke2Document3 pagesCalculo Cables Coke2Jose Antonio Salazar HidalgoNo ratings yet

- Wirelines and Well-Service StrandsDocument5 pagesWirelines and Well-Service StrandsJimmyNo ratings yet

- N2XSERY 33xx(25-300) mm2 3.6/6 kV and 6/10 kV Cable SpecificationDocument5 pagesN2XSERY 33xx(25-300) mm2 3.6/6 kV and 6/10 kV Cable SpecificationArthurNo ratings yet

- Standard Power Cables: Low Voltage (600/1000 V)Document11 pagesStandard Power Cables: Low Voltage (600/1000 V)Bhagoo HatheyNo ratings yet

- Standard Power Cables for Low Voltage ApplicationsDocument5 pagesStandard Power Cables for Low Voltage ApplicationsVijay Sagar PydaNo ratings yet

- BS5467 Cable - XLPE Armoured SWA Low Voltage Power CableDocument5 pagesBS5467 Cable - XLPE Armoured SWA Low Voltage Power CableCharles ArsenNo ratings yet

- TDG 19 CLT DiaphragmsDocument6 pagesTDG 19 CLT DiaphragmsCarsonBakerNo ratings yet

- Standard Power Cables for Low Voltage ApplicationsDocument5 pagesStandard Power Cables for Low Voltage Applicationsmo shNo ratings yet

- RhinoDocument2 pagesRhinoValeria Rendon NoyolaNo ratings yet

- N2XB (AL) Y 1 X (16-800) MM 0.6/1 KV Fire Resistant CablesDocument4 pagesN2XB (AL) Y 1 X (16-800) MM 0.6/1 KV Fire Resistant CablesKomang Capung SugiartaNo ratings yet

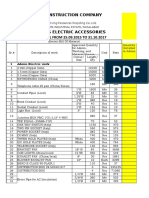

- Electric Bill - 1 31.10.2017 - CheckingDocument6 pagesElectric Bill - 1 31.10.2017 - CheckingSyed Adnan AqibNo ratings yet

- HT Cables - Leading China Cable ManufacturerDocument18 pagesHT Cables - Leading China Cable ManufacturerSIMON S. FLORES G.100% (1)

- Design of Corbels, Brackets and NibsDocument3 pagesDesign of Corbels, Brackets and NibsBrij AkabariNo ratings yet

- Busbar Manual CCA (Copper Clad Aluminium)Document5 pagesBusbar Manual CCA (Copper Clad Aluminium)Affid bin Abi ThalibNo ratings yet

- Medium Voltage Copper/Aluminum XLPE Cables SpecsDocument2 pagesMedium Voltage Copper/Aluminum XLPE Cables SpecsHafidz BandungNo ratings yet

- IEC 60502 Single Core Copper/Aluminium XLPE Insulated MV CablesDocument2 pagesIEC 60502 Single Core Copper/Aluminium XLPE Insulated MV CablesAndrewNo ratings yet

- Anubhav Gupta PPT THDC-ILDocument27 pagesAnubhav Gupta PPT THDC-ILAsdf LkjhNo ratings yet

- CRGO Strips India, CRGO Transformer Laminations, CRGO Core IndiaDocument4 pagesCRGO Strips India, CRGO Transformer Laminations, CRGO Core IndiaKarthikeyan VkNo ratings yet

- ddsr40 MsDocument2 pagesddsr40 MsVali PopescuNo ratings yet

- N2XSEYBY - Cu XLPE CTS DSTA PVCDocument3 pagesN2XSEYBY - Cu XLPE CTS DSTA PVCabhi boyzNo ratings yet

- 1 KM of 33 KV LineDocument3 pages1 KM of 33 KV LineAkram ElhadiNo ratings yet

- NYSYDocument5 pagesNYSYRinda_RaynaNo ratings yet

- Calculate Pressure Thrust and Weld Stress for Bracket DesignDocument19 pagesCalculate Pressure Thrust and Weld Stress for Bracket DesignMichael WaltersNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Socket-Welding Flanges: Fig 2.25: A Slip-On FlangeDocument1 pageSocket-Welding Flanges: Fig 2.25: A Slip-On FlangeMohamed amine El mtalakNo ratings yet

- Approval of Piping Systems: © Westone Services 2013 Eng2068 7Document1 pageApproval of Piping Systems: © Westone Services 2013 Eng2068 7Mohamed amine El mtalakNo ratings yet

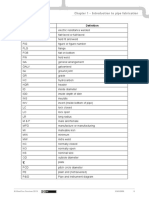

- Abbreviation: © Westone Services 2013 Eng2068 9Document1 pageAbbreviation: © Westone Services 2013 Eng2068 9Mohamed amine El mtalakNo ratings yet

- Pressure - Stress Conversion Chart: 100 Lbf/In2 689 Kpa 100kpa 14.50 Lbf/In2Document1 pagePressure - Stress Conversion Chart: 100 Lbf/In2 689 Kpa 100kpa 14.50 Lbf/In2Mohamed amine El mtalakNo ratings yet

- Chapter 1 - Introduction To Pipe Fabrication 5: 3 © Westone Services 2013Document1 pageChapter 1 - Introduction To Pipe Fabrication 5: 3 © Westone Services 2013Mohamed amine El mtalakNo ratings yet

- Reducing Elbows: Return BendsDocument1 pageReducing Elbows: Return BendsMohamed amine El mtalakNo ratings yet

- ENG2068 Course Guide 2013Document1 pageENG2068 Course Guide 2013Mohamed amine El mtalakNo ratings yet

- Piping Schedule: Fig 4.5: Double-Line Orthographic View With DimensionsDocument1 pagePiping Schedule: Fig 4.5: Double-Line Orthographic View With DimensionsMohamed amine El mtalakNo ratings yet

- Chapter 1 - Introduction To Pipe FabricationDocument1 pageChapter 1 - Introduction To Pipe FabricationMohamed amine El mtalakNo ratings yet

- Abbreviation: © Westone Services 2013 Eng2068 9Document1 pageAbbreviation: © Westone Services 2013 Eng2068 9Mohamed amine El mtalakNo ratings yet

- Approval of Piping Systems: © Westone Services 2013 Eng2068 7Document1 pageApproval of Piping Systems: © Westone Services 2013 Eng2068 7Mohamed amine El mtalakNo ratings yet

- Digital Circuit Projects: An Overview of Digital Circuits Through Implementing Integrated Circuits - Second EditionDocument121 pagesDigital Circuit Projects: An Overview of Digital Circuits Through Implementing Integrated Circuits - Second Editionmihai_agape93No ratings yet

- Creative Commons Attribution 4.0 (CC BY 4.0) LicenseDocument1 pageCreative Commons Attribution 4.0 (CC BY 4.0) LicenseMohamed amine El mtalakNo ratings yet

- 3 Major Types of Welding Machines & Their FeaturesDocument2 pages3 Major Types of Welding Machines & Their FeaturesPratibha MauryaNo ratings yet

- IRONMAN240Document48 pagesIRONMAN240migNo ratings yet

- Repair Manual Genesis 260 350 GSM-GBDocument76 pagesRepair Manual Genesis 260 350 GSM-GBrumburac13No ratings yet

- Welding Inspector: Weld SymbolsDocument53 pagesWelding Inspector: Weld SymbolsJawed AkhterNo ratings yet

- 4.3 ESAB Product Catalogue 2013Document301 pages4.3 ESAB Product Catalogue 2013SAIL ISP Blast FurnaceNo ratings yet

- Fundamental Welding Maintenance Tech - Final1Document79 pagesFundamental Welding Maintenance Tech - Final1Morg ActusNo ratings yet

- Promanu II WeldingDocument68 pagesPromanu II WeldingRyan FilbertNo ratings yet

- Repairs of Hurricane Damaged Platforms in The Bay of CampecheDocument10 pagesRepairs of Hurricane Damaged Platforms in The Bay of CampecheEduardo Jose Sanchez LoboNo ratings yet

- 2021 Key Changes Section IX FinalDocument67 pages2021 Key Changes Section IX FinalHuddarNo ratings yet

- Understanding Key Welding Business Issues and Turning Them Into OpportunitiesDocument7 pagesUnderstanding Key Welding Business Issues and Turning Them Into OpportunitiessanjibkrjanaNo ratings yet

- Closed Book API RP 577 Practice QuestionsDocument10 pagesClosed Book API RP 577 Practice Questionsmuhammadazhar100% (2)

- TECHNOLOGY5 AnswerDocument8 pagesTECHNOLOGY5 AnswerNashaat DhyaaNo ratings yet

- Wps 15Document5 pagesWps 15Avishek GuptaNo ratings yet

- WPS for SMAW Welding of A36 and 304L SteelDocument6 pagesWPS for SMAW Welding of A36 and 304L SteelNector MoyanoNo ratings yet

- FCAW DocumentDocument19 pagesFCAW DocumentKentDemeterioNo ratings yet

- BS en Iso 11970 2016Document28 pagesBS en Iso 11970 2016umur kaçamaklı100% (2)

- Online FDP Brochure - 18-22 May 2020 - Welding SimulatorDocument2 pagesOnline FDP Brochure - 18-22 May 2020 - Welding SimulatorSudhakar NakkaNo ratings yet

- Spiral Welded PipeDocument161 pagesSpiral Welded PipeHerman Sandy50% (2)

- Fundamentals of Welding Joints & ProcessesDocument79 pagesFundamentals of Welding Joints & ProcessesdselvakuuNo ratings yet

- Dime - PQDDocument101 pagesDime - PQDPrasenjit DuttaNo ratings yet

- Distortion in Welding Report for Telcon Excavator PartsDocument38 pagesDistortion in Welding Report for Telcon Excavator Partsgetravi1886100% (1)

- Mig 4004i PulseDocument4 pagesMig 4004i PulseOkan KöksalNo ratings yet

- Lincoln, TECHALLOY® 606 (c14107)Document2 pagesLincoln, TECHALLOY® 606 (c14107)RodrigoNo ratings yet

- What Are Wormholes and How Can They Be PreventedDocument13 pagesWhat Are Wormholes and How Can They Be PreventedElvin MenlibaiNo ratings yet

- Arc Welding Techniques ExplainedDocument4 pagesArc Welding Techniques ExplainedFaris Kadesh50% (2)

- Name: Ogunkanmbi Samuel Olanrewaju Programme: Chemical Engineering LEVEL: 200 MATRIC. NO.: 13CF015155 Course: Gec 218Document5 pagesName: Ogunkanmbi Samuel Olanrewaju Programme: Chemical Engineering LEVEL: 200 MATRIC. NO.: 13CF015155 Course: Gec 218RizzleNo ratings yet

- Welding ConsumablesDocument128 pagesWelding ConsumablesAsad Bin Ala Qatari100% (1)

- GMAWDocument53 pagesGMAWJithuJohn100% (1)

- Welding ManualDocument32 pagesWelding ManualHammondMachineNo ratings yet

- Aisi T 192 Steel Plate Engineering Vol 1 Vol 2Document132 pagesAisi T 192 Steel Plate Engineering Vol 1 Vol 2Ali MkawarNo ratings yet